Talk to Our Product Experts Today!

How to Choose the Best Printing Method for Cosmetic Bottles

2026.02.06When printing on cosmetic bottles goes wrong, budgets bleed—but mastering color and finish turns bulk packaging into brand legend....

Why Mono Material Packaging is the Future of Sustainable Solutions

2026.02.06Eco drama meets efficiency: mono material packaging makes your cosmetic launch greener, smoother, and a Gen Z-approved showstopper....

Why Lipstick Design Packaging Is the Secret to Brand Success in 2026

2026.02.06When lipstick design packaging turns magnetic and eco-chic, it’s not vanity—it’s strategy. See why brands crave smarter, sexier tubes....

Why Recycle Lipstick Tubes? The Benefits for a Sustainable Future

2026.02.06Recycling lipstick tubes just got glamorous—cut waste, wow eco-savvy buyers, and keep margins glossy in bulk cosmetic packaging deals....

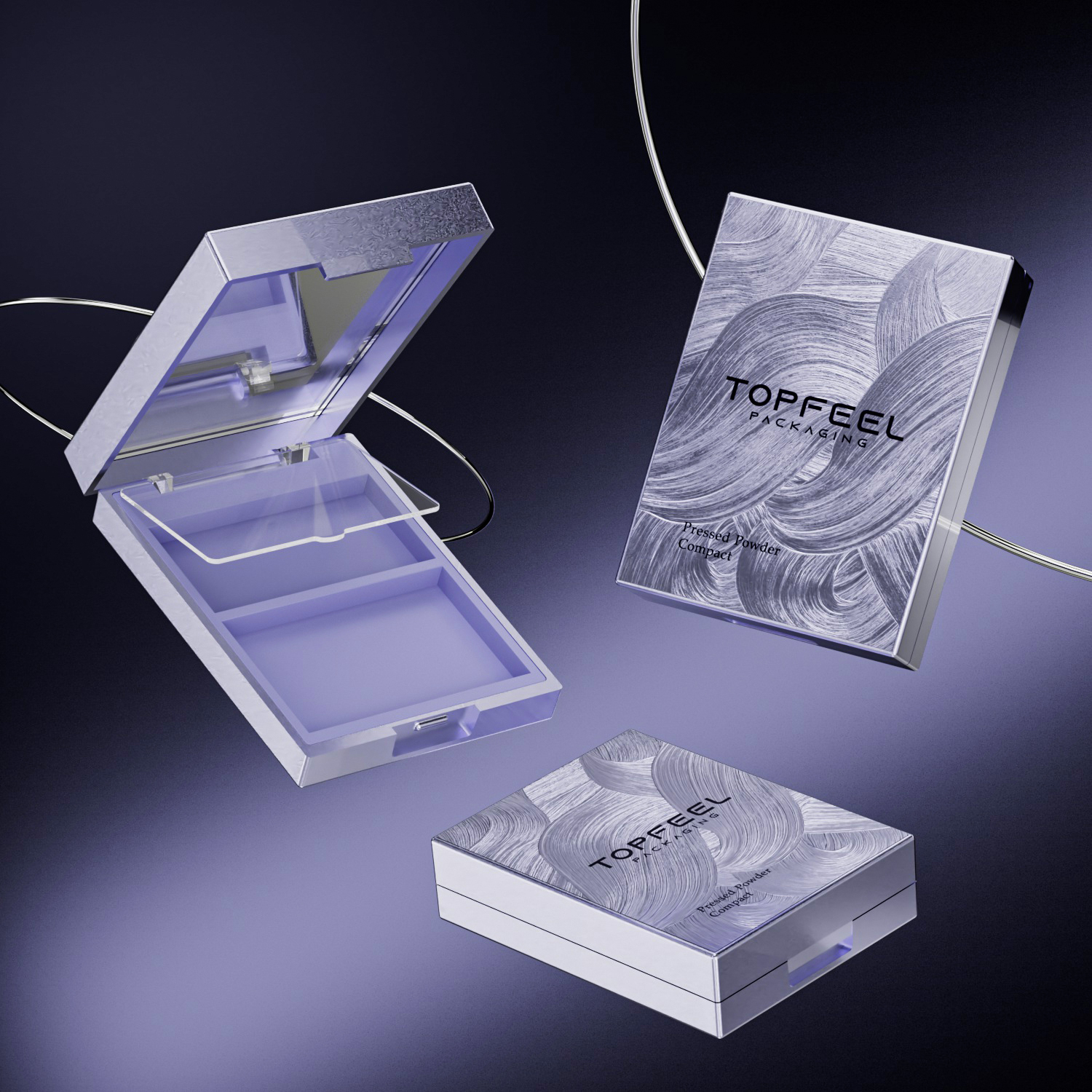

What Makes a Square Makeup Compact Stand Out?

2026.02.06When the square makeup compact turns heads in bulk, every hinge, gloss, and curve turns into high-stakes beauty engineering....

FACE MAKEUP PACKAGING

Premium packaging solutions for blush, powder, and foundation—designed for brands seeking exceptional aesthetics, functional precision, and flexible customization.

-

DB26 30g Mono-Material PP Deodorant Stick Container

-

MC-18 Custom 10g Brow Wax Jar Wholesale Manufacturer

-

MB-73 Wholesale Custom Dual Pan Compact Powder Case Supplier

-

MB-52 Custom Slim Blush Container Private Label Packaging Manufacturer

-

MB-78 Customized Round Setting Powder Container Supply

-

MB-08 Unique Triangle Makeup Case Custom Logo Factory

-

MB-06 Wholesale 58mm Round Pressed Powder Compact with HD Mirror

-

MB-07 Wholesale 15ml PP Twist Up Blush Stick Supplier

-

TU76 Custom Precision Nozzle Tube for Liquid Foundation Wholesale

-

MB-70 Custom 20g Loose Powder Case With Mesh Sifter Wholesale

-

MB-84 Private Label 15ml Refillable Foundation Bottle with Blending Brush

-

MB-83 Custom Heart Shaped Portable Blush Charm Supplier

1. Discover Our Face Makeup Packaging Advantages

Trusted by over 1,000 brands worldwide, with full OEM/ODM support.

-

Global Certifications: ISO 9001, ISO 22716 (GMPc), BSCI, Sedex, SGS

-

Manufacturing Scale: 20,000㎡ factory; 32,000㎡ GMPc workshops

-

Customization Strength: Over 100 private molds/year; 3-day 3D prototyping

-

Surface Decoration: Gradient spray, UV coating, hot stamping, silkscreen, laser

-

Sustainable Options: PCR plastic, refillable mechanisms, biodegradable materials

-

Proven QA Process: Rigorous testing—torque, leakage, thermal, color, aging

Topfeel combines speed, scale, and precision with a deep understanding of cosmetic formulation needs to deliver packaging that performs as well as it looks.

2. Not Sure What You Need? Start Here

Not sure which face packaging format best suits your formula or brand needs? Here’s a fast breakdown:

| Product Type | Best For | Key Traits |

|---|---|---|

| Blush Stick Packaging | Solid, balm, or highlighter formulas | Twist-up design, compact, portable |

| Powder Compact Case | Pressed or baked powders, dual-use items | Snap/magnetic closure, mirror or refillable |

| Foundation Container | Liquid or cream foundations | Pump, dropper, airless bottle options |

Can’t find an exact fit? We can adapt any existing mold—or develop a new one to suit your project’s formula, filling method, and brand story.

- 👉View Empty Blush Stick Options

- 👉Explore Compact Case Designs

- 👉Browse Foundation Packaging

3. Custom Services

Use our flexible OEM/ODM workflow to create your ideal packaging.

Whether you bring your own concept or start from one of our existing mold libraries, we offer full customization at every step:

-

Structure: Choose your container’s size, shape, closure, or refill system.

-

Surface Finish: Gradient spray, UV gloss, soft-touch coating, anodizing, etc.

-

Logo & Decoration: Silkscreen, hot stamping, foil, laser engraving, or digital print.

-

Eco Options: High PCR content plastics, refillable pans, mono-material designs for recycling.

Our in-house R&D, mold-making, and QC teams ensure speed and precision across all stages.

4. Sustainable Packaging Options

Eco-forward designs for beauty brands that care.

We help clients meet growing sustainability demands with real, production-ready packaging solutions:

-

PCR Content: PCR available for select components (material-dependent).

-

Refillable Designs: Compact shells, foundation bottles, and blush sticks designed for easy refill.

-

Material Selection: PLA, glass, aluminum, mono-material plastics for recycling.

-

Reduced Waste: Optimized mold tooling and multi-cavity injection processes.

You can even combine sustainable packaging with premium aesthetics—no compromise needed.

5. Quality Is Engineered into Every Unit

Strict inspection and performance testing at every stage.

Every product family passes through multi-step inspections and tailored functional tests:

-

Leakage, torque, and drop tests (up to 50 °C / –15 °C, 48 h)

-

Dome deviation and viscosity calibration

-

Abrasion resistance and UV weather simulations

-

Packaging and shipping pre-inspection for global delivery readiness

We provide optional test summaries and production reports upon request.

6. Work With Topfeel — From Idea to Delivery

Fast sampling, flexible MOQs, and responsive global support.

-

MOQs: As low as 10,000 pcs for standard items; custom tooling may vary

-

Lead Times: Typically 40–50 days depending on customization complexity

-

Sampling: Stock or custom samples available for verification

-

Shipping: Secure global logistics with full export documentation

Ready to Start? Contact us

Use the form below to submit your RFQ or sample request. You can upload drawings, artwork, or simply tell us your vision—we’ll help you build the perfect solution.

FAQs

A: Yes. We offer full mold development services, with 3-day 3D prototyping and over 100 private molds created annually.

A: We offer UV coating, hot stamping, silkscreen, laser etching, gradient spray, soft-touch, and more.

A: Absolutely. We support PCR materials, refillable designs, and recyclable mono-material structures.

A: Around 40–50 days depending on mold/tooling and decoration complexity. Stock-mold projects are faster.

A: Yes, we provide spec sheets and dielines upon request or sample approval.