MA-58 Wholesale Lip Tint Container Leak-Proof

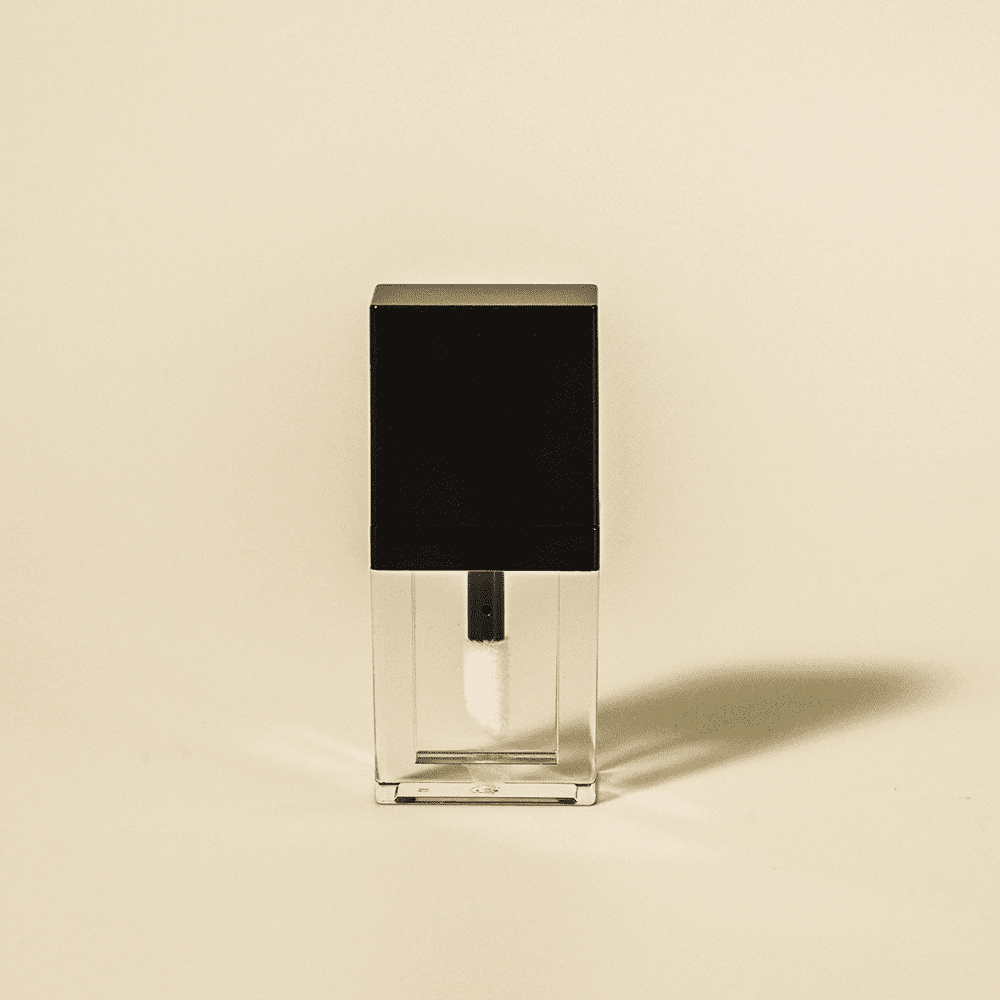

This high-clarity lip gloss tube holds 7.5ml and features a tapered flocked applicator for smooth application. Customizable in color, decoration, and applicator style.

Model Number: MA-58

Capacity: 7.5ml

Material: ABS, PP, PETG

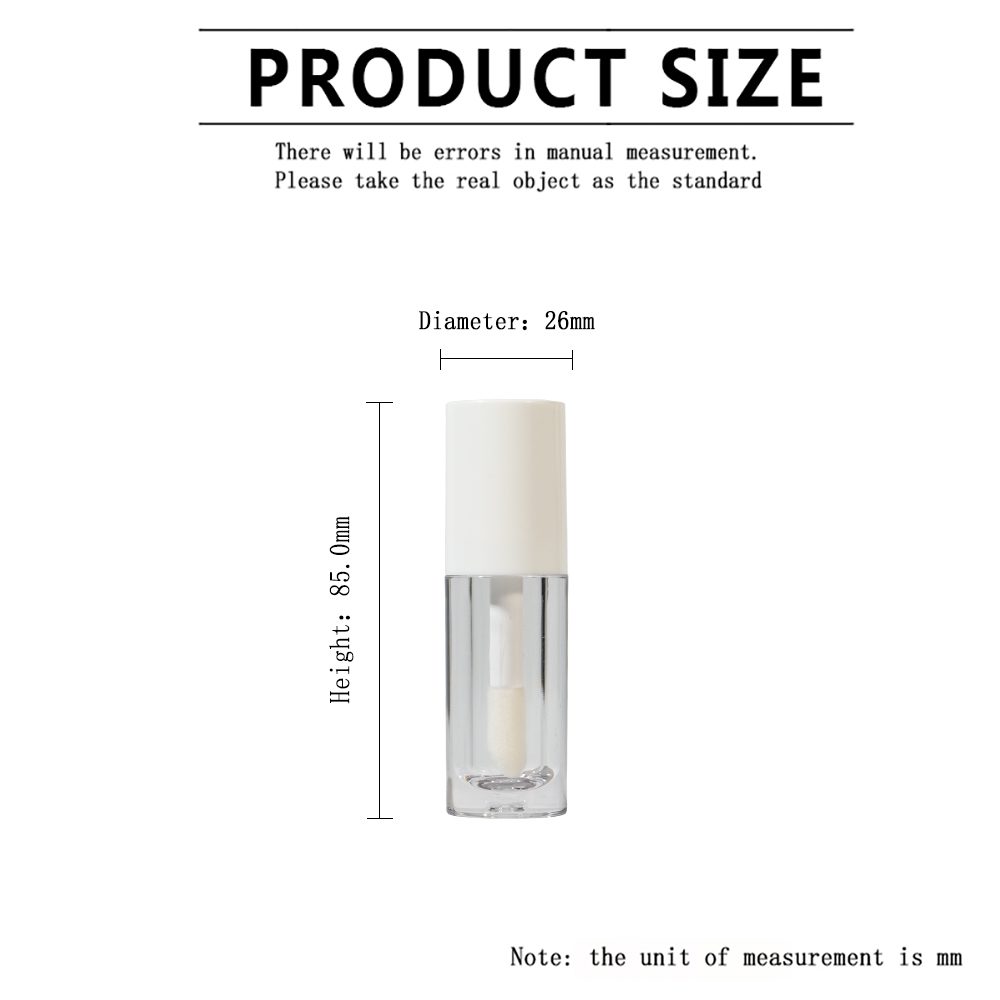

Size: H85mm × D25.4mm

MOQ: 12,000 pcs

Application: Lip Gloss, Lip Tint, Lip Oil

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color and Printing

Sample:

Features and advantages

-

Secure threaded design and soft-tip applicator deliver product stability and smooth, accurate application performance.

-

Clear PETG bottle enhances product visibility, boosting shelf presence and consumer appeal without added decoration.

-

Supports full-color, print, and applicator customization to match brand aesthetics and specific product formulation needs.

You May Also Like

View Product Details

Engineered for Precision Use

-

Functional, Leak-Proof Assembly

The MA-58 utilizes a screw-on ABS lid that aligns with threading on the PETG bottle for a secure, air-tight seal. This reduces the risk of leaks during transport and minimizes evaporation or contamination over time. Its mechanical fit supports high-speed filling lines and precision torque testing standards.

-

The PP brush handle is embedded within the cap for seamless assembly.

-

Internal sealing design conforms to GMPc and ISO 22716 manufacturing protocols.

-

Tolerance-tested to avoid product seepage during environmental changes (temperature, altitude, humidity).

-

-

Soft-Tip Precision Applicator

The applicator tip features a flocked surface and a finely tapered edge, designed to support controlled product pickup and laydown. This level of detail is ideal for liquid or semi-viscous formulas, such as glosses, tints, or lip serums.

-

The PP applicator base is molded for ergonomic grip and consistent resistance during use.

-

-

Visibility That Drives Sales

High-Clarity Bottle Design

PETG’s optical properties provide a clean, undistorted view of the enclosed product, helping brands highlight color, shimmer, or suspension textures naturally—no label window needed.

-

Ideal for visual-driven products and digital photography.

-

Compatible with both matte and gloss coating finishes during secondary decoration.

“Consumer behavior data shows that over 67% of online beauty shoppers are influenced by visible product fill and clarity, particularly for lip color and gloss formats.” —

Tailored to Your Brand

-

Color & Print Personalization

Bottle and cap colors can be adjusted to brand standards through custom UV spray coating, hot stamping, or silkscreen printing.

-

1–4 color print zones available

-

Optional logo placement on cap, sidewall, or base

-

Surface treatments include glossy, matte, or metallic

-

-

Applicator & Volume Options

Applicator shape, flocking density, and brush softness can be modified per product type. Bottle volume and shape remain at 7.5 ml but can be scaled with similar mold families for product line consistency.

-

Support for low-CP and high-CP formulas

-

Interchangeable applicator designs upon request

-

-

FAQs

-

-

Hot stamping, silkscreen printing, and UV coating available

-

Applicator tips and internal brushes are customizable

-

Custom logo placement supported

-

-

-

Lip oils

-

Cuticle serums

-

Eyelash growth liquids

-

Lightweight skincare spot treatments

-

-

Always confirm product compatibility before filling

-

40–50 days

-

May vary based on:

-

Customization complexity

-

Decoration processes required

-

Order volume

-

-

-

-

Leakage testing under thermal and pressure conditions

-

Viscosity compatibility verification

-

Break and abrasion resistance checks

-

Absolutely. Topfeel offers standard or customized MA-58 lip gloss tube samples for quality inspection prior to mass production. Sample terms may depend on customization needs.