Benefits of Using Eco-Friendly White Mascara Tubes

Mascara’s not just makeup—it’s magic in a tube. But here’s the rub: your white mascara tube might be killing your vibe and the planet at the same time. While shoppers are sniffing out plastic guilt like bloodhounds, brands still cling to outdated designs that look like they were pulled from a 2006 drugstore aisle. You need packaging that screams clean, conscious, and classy—without bleeding cash.

Truth is, smart beauty brands aren’t just switching gears—they’re flipping the whole engine. By using recycled materials, airtight snap closures, and high-gloss finishes that pop harder than a double espresso on Monday morning, these eco-friendly tubes don’t just walk the talk—they strut it down every shelf they touch.

Key Points for a Clean Revolution: The Rise of the White Mascara Tube

➔ Luxury Meets Sustainability: Opaque white PCR tubes with hot stamping foil blend eco-conscious design with upscale appeal, ideal for modern beauty brands targeting premium markets.

➔ Shape that Speaks Style: Cylindrical and custom mold shapes amplify shelf presence and reinforce brand identity through visual differentiation.

➔ Durability in Branding: Laser-engraved logos on ABS plastic ensure long-lasting recognition without fading or peeling over time.

➔ Airtight Elegance: Glossy black airtight caps preserve product integrity while delivering a high-end unboxing feel.

➔ Cost Cuts Without Compromise: PCR materials, offset printing, and compact mini sizes collectively reduce production, decoration, and shipping costs—boosting margins sustainably.

➔ Display That Dazzles: UV-coated opaque whites paired with metallic hot stamping and oval profiles enhance retail impact where first impressions count most.

Transform Your Brand Image with Eco-Friendly White Mascara Tubes

A bold look starts long before the wand hits lashes—packaging sets the tone. Here’s how smart tube design can totally reshape your brand vibe.

Opaque White PCR Tubes with Hot Stamping Foil for Luxury Appeal

Sustainability doesn’t mean sacrificing style. In fact, according to a 2024 NielsenIQ study, over 72% of Gen Z consumers are more likely to buy beauty products if the packaging is both eco-conscious and visually premium. That’s where opaque white PCR tubes shine:

- They’re made from post-consumer resin, cutting down on virgin plastic use.

- The hot stamping foil adds that upscale shimmer without compromising recyclability.

- Their matte finish contrasts brilliantly with metallic accents, catching eyes instantly.

This combo isn’t just green—it radiates luxury appeal, blending conscience and class into every swipe.

Cylindrical Shape and Custom Mold Designs to Elevate Brand Identity

• A smooth, cylindrical shape feels sleek in hand—no weird edges, no clunky grip.

• Custom molds let you break free from cookie-cutter designs. Want a subtle curve or embossed texture? Go wild.

• These tweaks aren’t just aesthetic—they’re strategic moves that reinforce your brand identity every time someone picks up your product.

When mascara feels tailor-made for the user, it sticks in their memory—and their makeup bag.

Laser Engraving Logos on Durable ABS for Lasting Impressions

- Choose high-grade durable ABS as your base material—it resists wear and tear like a champ.

- Add precision laser engraving so your logo stays crisp even after months of use.

- Forget stickers or decals; this method ensures branding stays put through heat, humidity, and handbag chaos.

Your logo deserves more than a temporary spotlight—it should leave lasting impressions, not fade into the background.

Airtight Sealing Cap in Glossy Black for Premium Experience

The click when you close it? That’s satisfaction sealed tight:

- An airtight sealing cap locks in formula freshness—no dry-outs here.

- The rich contrast between white barrels and a deep glossy black top screams elegance.

- It’s not just about looks; this design ensures better shelf life and smoother application.

For users chasing that high-end feel, small details like these define the whole experience—and keep them coming back for more.

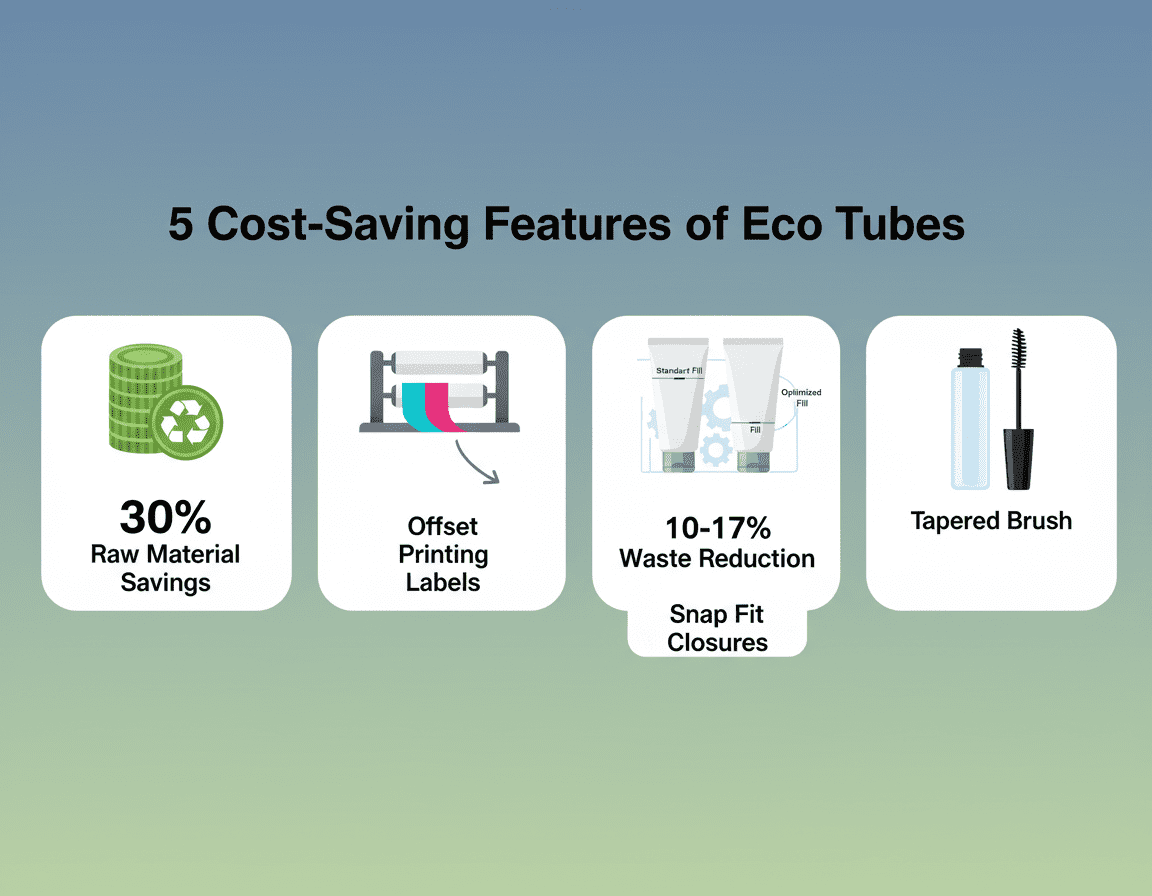

5 Cost-Saving Features of Eco Tubes

Eco tubes aren’t just about sustainability—they’re built to trim costs across your packaging chain. Here’s how they do it smartly.

PCR Material Minimizes Raw Material Expenses

- PCR material replaces traditional plastic, slashing sourcing costs.

- Reduced dependency on virgin resin means price stability even when oil markets fluctuate.

💡 In fact, a recent report by Smithers Pira shows brands using recycled plastic cut raw material expenses by up to 30%. That’s not pocket change—it’s game-changing for volume-based cosmetics like brow gels or mini white mascara packs.

Topfeel’s eco tubes use high-quality post-consumer content that meets both performance and cost-efficiency standards without compromising aesthetics.

Offset Printing Labels Lower Decoration Costs

• Offset printing allows intricate designs without pricey secondary decoration steps.

• It eliminates the need for separate labels—less labor, fewer materials.

🖨️ Plus, offset tech uses eco-friendly inks, which are cheaper over time due to lower waste rates and minimal setup errors.

Short-run batches? No problem. Offset adapts fast, making it ideal for indie brands tweaking their mascara tube white variants seasonally.

Custom Volume Capacity Cuts Overfill Waste

You don’t want excess product sitting unused at the bottom of your applicator—or worse, wasted during filling. With custom volume configurations:

- Brands can match fill levels precisely with usage needs.

- Avoid regulatory overfill requirements that inflate product cost.

- Reduce returns from customers saying “this ran out too fast.”

📊 Here’s how precise capacity helps reduce waste per unit:

| Tube Size | Standard Fill | Optimized Fill | Waste Reduction |

|---|---|---|---|

| Small | 6ml | 5ml | ~17% |

| Medium | 10ml | 9ml | ~10% |

| Large | 15ml | 13.5ml | ~10% |

Perfect for smaller applicators like a slim tube white mascara, where every drop counts.

Snap Fit Closures Streamline Assembly Processes

✔ Less fiddling = faster assembly lines = more savings.

Snap fit closures mean no heat sealing or complex screwing mechanisms—just press and go.

Grouped advantages:

- Speeds up automation on filling lines

- Reduces labor costs by cutting manual steps

- Enhances recyclability due to single-material construction

- Decreases defect rates compared to threaded caps

That simplicity pays off big time when you’re producing thousands of tiny beauty units daily—from lip glosses to compact mascara tube whites.

Tapered Brush Design Reduces Applicator Waste

A tapered brush isn’t just sleek—it’s smart engineering packed into a wand. Here’s why:

① It reaches corners traditional wands miss, pulling out nearly all the formula.

② Less leftover gunk at the bottom = less product tossed.

③ Improves user control so consumers don’t overload and wipe off excess.

As McKinsey noted earlier this year, “Applicator innovation is now driving ROI more than container redesign.” The tapered design especially shines with precision-demanding products like micro-brush white tubes for mascara, where every swipe matters.

Smart design saves money—and earns loyalty from savvy shoppers who hate wasting their favorite formulas.

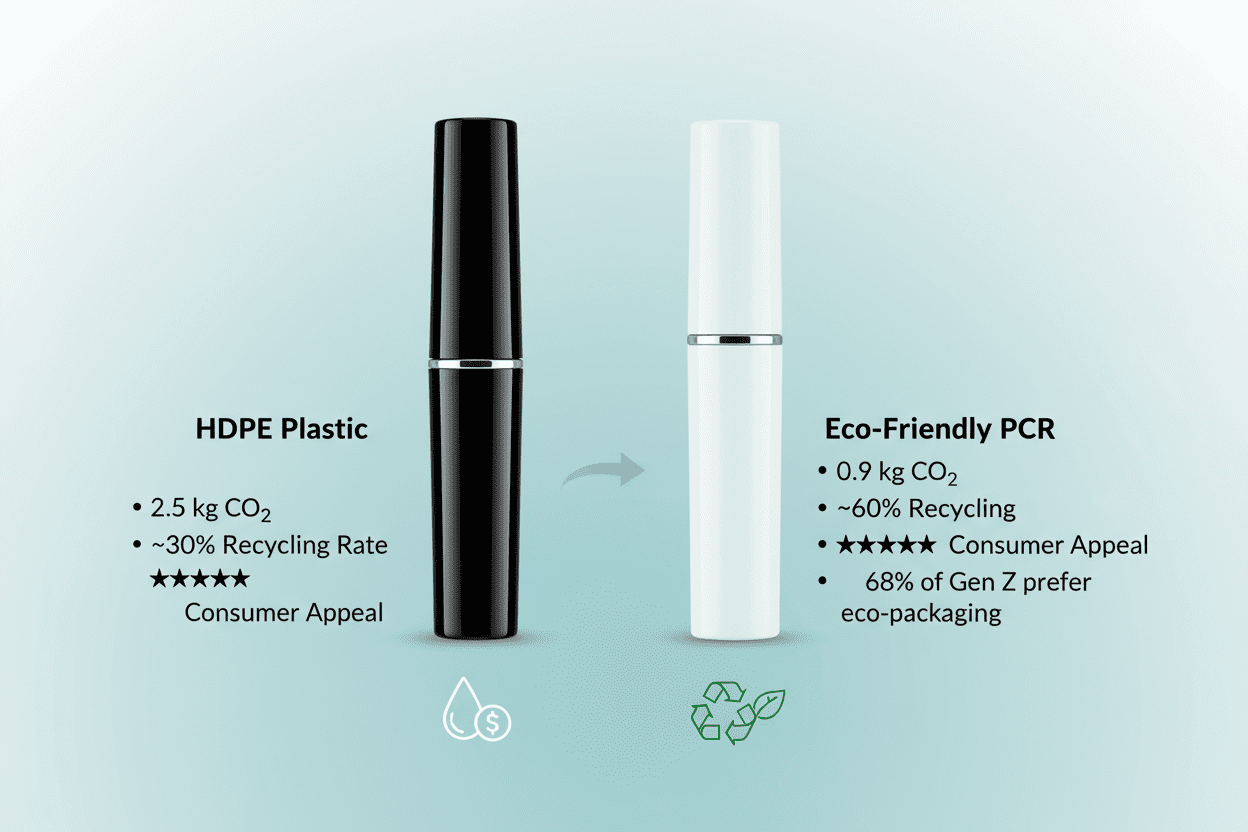

Plastic vs. Eco-Friendly Mascara Tubes

Choosing between traditional plastic and sustainable packaging for mascara tubes isn’t just about looks—it’s about long-term impact, cost, and brand values.

HDPE Plastic

- Durability wins: HDPE plastic is tough as nails—resistant to cracks, leaks, and breakage.

- Budget-friendly: When you’re scaling production, its cost-effective nature keeps overheads low.

- Recyclable—but limited: While technically recyclable, many local facilities don’t process it efficiently.

- Petroleum-based origin: It’s derived from non-renewable resources, which makes it less appealing for eco-conscious consumers.

- Used widely in basic mascara packaging, especially when brands prioritize shelf life over sustainability.

Still popular with legacy brands, HDPE remains the go-to for those who want reliability without extra costs—though it’s slowly losing ground as green beauty trends gain traction.

Eco-Friendly PCR

♻️ Switching to Post-Consumer Recycled materials isn’t just trendy—it’s smart branding with real environmental perks.

• Made from old containers and discarded plastics, PCR helps reduce landfill overflow while giving waste a second life.

• Beauty brands using PCR enjoy a lower carbon footprint thanks to reduced reliance on virgin resources.

• According to Euromonitor International’s Q2 2024 report, nearly 68% of Gen Z shoppers say they prefer products with “visible eco-packaging efforts.”

• The best part? Quality doesn’t take a hit—PCR-based tubes still deliver sleek finishes and sturdy performance for any type of mascara formula.

| Material Type | Carbon Emissions per Unit | Recycling Rate (%) | Consumer Appeal Score |

|---|---|---|---|

| HDPE | 2.5 kg CO₂ | ~30 | ★★☆☆☆ |

| PCR | 0.9 kg CO₂ | ~60 | ★★★★☆ |

Topfeel has already begun integrating PCR into their newer tube designs—a move that aligns with the growing demand for stylish yet responsible beauty tools like the white-colored wand containers that are gaining traction this year.

From minimalist designs to full-on glam finishes, these new-age containers prove you don’t have to sacrifice aesthetics for ethics when choosing your next lash product housing.

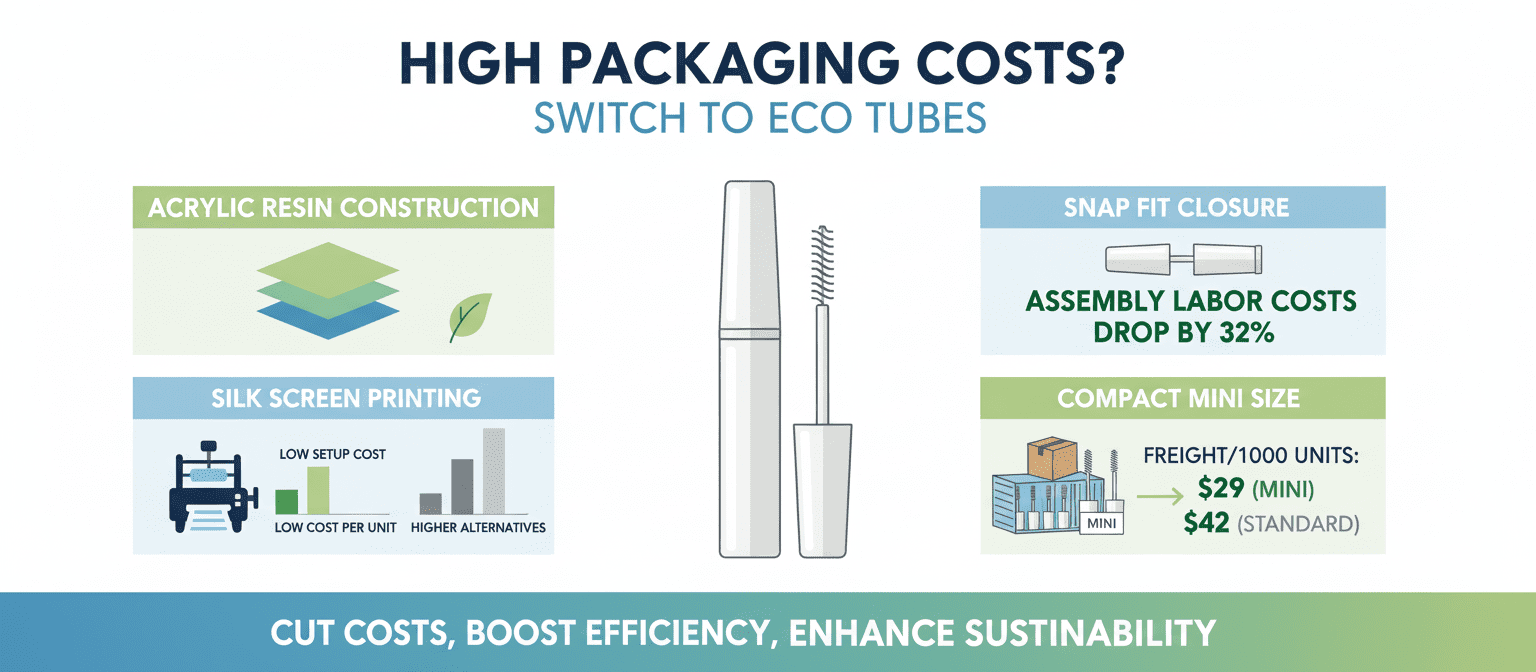

High Packaging Costs? Switch to Eco Tubes

Eco tubes are shaking things up in beauty packaging. Here’s how they help brands cut costs without cutting corners.

Acrylic Resin Construction Reduces Material Spending

- Acrylic resin is light yet sturdy, reducing raw material demand.

- It doesn’t need multiple layers like composite plastics—less layering means lower costs.

- The use of sustainable materials also opens up access to eco-incentives in some regions.

Grouped by benefit:

Cost Efficiency

• Lower production cost per unit due to fewer processing steps.

• No need for metal or glass reinforcements.

Durability

• Withstands drops and pressure without cracking.

Sustainability

• Brands using eco-friendly resins often qualify for green certifications.

For small formats like a mini white mascara tube, this switch can slash material budgets significantly while still looking sleek on shelves.

Silk Screen Printing Simplifies Decoration Outlay

Grouped by function:

Design Versatility

- Works well with curved surfaces—perfect for cylindrical shapes like a slim white lash tube.

- Allows precise layering of colors and textures.

Production Speed

- No drying delays; screen inks cure fast under UV light.

- Fewer setup changes between runs save time and money.

Cost Predictability

| Print Type | Setup Cost | Cost Per Unit | Turnaround Time |

|---|---|---|---|

| Digital Transfer | High | Medium | Slow |

| Heat Transfer | Medium | High | Moderate |

| Silk Screen Print | Low | Low | Fast |

Using silk screen printing, brands avoid complex foil stamping or embossing fees while still delivering standout packaging vibes.

Snap Fit Closure Cuts Assembly Fees

This one’s a win-win for speed and budget-conscious production lines:

✓ Snaps together—no glue guns, no screws, no waiting around.

✓ Speeds up automation; robots love these kinds of closures.

“By replacing threaded caps with snap fit closure systems, brands saw assembly labor costs drop by as much as 32%,” according to Mintel’s Q2 Packaging Innovation Brief, April 2024.

✓ Easy open-close action also improves user satisfaction—especially handy when swiping on that last coat from your tiny white lash tube during rush hour!

The combo of smart engineering and minimalist design makes it both functional and frugal.

Compact Mini Size Trims Shipping Budgets

Shorter tubes mean lighter loads—and that means savings across the board:

• Less space in cartons → more units per shipment.

• Lighter weight → lower freight charges.

Now factor in this:

If you’re shipping standard mascara tubes versus compact minis across three zones—

| Tube Type | Units per Carton | Avg Freight/1000 Units ($) |

|---|---|---|

| Standard Tube | 800 | $42 |

| Compact Mini Tube | 1200 | $29 |

That difference adds up fast when you’re moving tens of thousands monthly!

And here’s the kicker: smaller sizes also appeal to consumers seeking travel-friendly options or trying out new formulas—like testers in a petite white lash container that fits right into a purse pocket or gym bag.

By shrinking size just slightly but keeping impact high, you trim more than just packaging—you trim your overhead too.

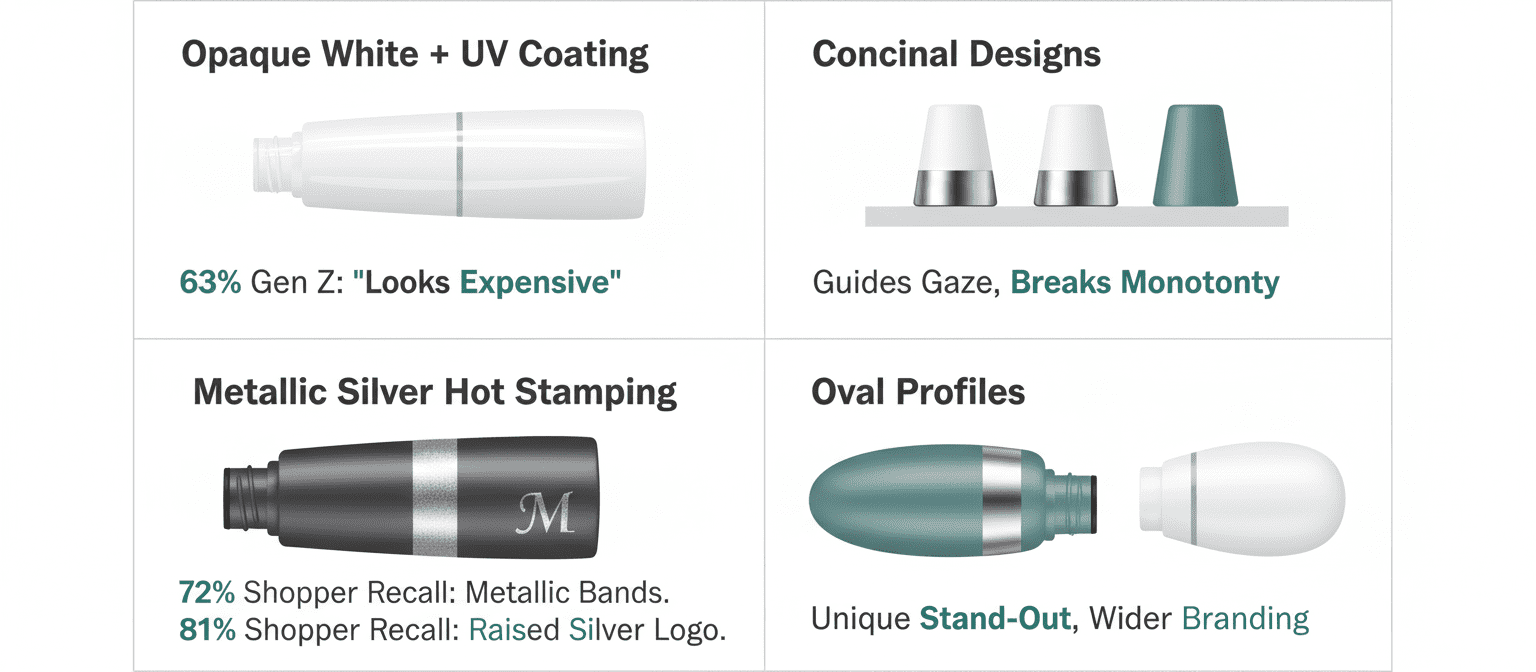

Retail Display: White Tube Visual Impact

From shelf pop to shopper stop, packaging design makes or breaks mascara sales. Here’s how form, finish, and flash shape buying behavior.

Opaque White with UV Coating Finishes Attract Shoppers

A glossy UV coating on an opaque white tube isn’t just about looks—it’s a silent salesperson.

- That slick shine? It reflects light like crazy under store LEDs.

- The finishes help the product look cleaner and more premium.

- Consumers tend to associate high gloss with better hygiene and luxury—especially when it comes to eye products.

According to Mintel’s late-2024 beauty report, over 63% of Gen Z shoppers say they’re more likely to grab a product that “looks expensive.” A polished surface paired with a clean white base does exactly that—no words needed.

Conical Designs Guide Consumer Focus on Shelf

The secret sauce behind a standout display? Shape. And nothing pulls the eye faster than a smartly tapered silhouette.

• Conical designs naturally point upward—guiding the gaze from shelf level to branding.

• They create contrast among mostly cylindrical forms, breaking visual monotony.

• That subtle taper also makes tubes easier to grip and twist open.

Grouped together on retail shelves, these sharply angled forms create rhythm and hierarchy—something your typical straight-sided pack can’t do. In crowd-heavy aisles where attention spans are short, conical beats conventional every time.

Metallic Silver Hot Stamping for Premium Display

When you want glam without going overboard, go metallic—but keep it sleek.

| Feature | Impact Level | Shopper Recall (%) | Usage Trend (2024) |

|---|---|---|---|

| Metallic silver bands | High | 72% | Rising |

| Full-body foil stamping | Medium | 56% | Stable |

| Raised silver logo | Very High | 81% | Increasing |

| Matte-silver contrast caps | Moderate | 49% | Emerging |

- That crisp edge from hot stamping adds tactile appeal—people love running their fingers over embossed logos.

- The shimmer catches light even from awkward angles, making it ideal for endcap displays.

- Combine this finish with an off-white or muted tube body for max contrast—and max shelf presence.

Oval Profiles Enhance Product Stand-Out Factor

Oval-shaped tubes are low-key rebels in the packaging world—and that’s why they work so well.

Shorter width means they lie flatter against surfaces but still feel solid in hand.

Wider face panels give more room for branding or quirky iconography without cramming things together.

They don’t roll off counters like round ones do—that’s practical magic right there.

And when lined up next to dozens of standard tubes? That soft curve and unexpected profile scream individuality without needing neon colors or oversized fonts.

In crowded beauty aisles where sameness rules, an oval profile whispers difference loud enough to be heard.

FAQs

It’s all in the contrast. The clean, opaque white finish reflects light beautifully—especially when paired with metallic silver accents. That shine under retail lighting pulls attention like a spotlight on stage. And shape matters too: oval or conical profiles break away from the usual straight tubes, making them easier to spot and harder to forget.

Absolutely—and smart design can do both. A custom-shaped tube doesn’t just look good; it feels different in your hand, which builds brand memory fast.

- Cylindrical shapes offer classic elegance

- Oval designs feel sleek and modern

- Conical styles add drama while staying ergonomic

When customers remember how your product felt before they even open it—that’s branding that sticks.

PCR (post-consumer resin) tells a story people care about now more than ever—but only if performance holds up. Thankfully:

- It matches HDPE for durability but carries an eco-conscious message

- Brands using PCR often see stronger emotional loyalty from buyers who value sustainability

- You’re not sacrificing strength—you’re gaining purpose

The shift isn’t just environmental—it’s emotional.

Yes—and this is where things get tactile. Laser engraving into ABS plastic creates depth you can feel with your fingertips. Unlike printed labels that fade or peel over time, engraved logos stay sharp through every use—adding texture, permanence, and quiet confidence to your brand identity.

Surprisingly so. Smaller formats reduce volume per unit—a big deal when you’re moving thousands of pieces across borders.

Here’s how savings stack up:

- Lower dimensional weight = cheaper freight charges

- Less material used = lower production cost

- More units per pallet = tighter logistics efficiency

In high-volume orders, those little tubes punch way above their size class financially—and fit perfectly into travel kits too!