What materials are used for monoprinting in makeup packaging ?

When it comes to eye-catching product design, the real secret sauce isn’t just the graphics—it’s what you print on. “What materials are used for monoprinting?” is a question that keeps packaging pros up at night… and for good reason. You could have the Mona Lisa of lipstick logos, but slap it on a surface that flakes or fades? That’s brand sabotage. Pick wrong, and your luxe look turns into aisle 5 clearance-bin tragedy.

Truth is, not all plastics play nice with ink, and some metals have moods. Acrylic’s glossy charm makes colors pop like confetti cannons—while bamboo brings eco brownie points in an Instagram-driven market where 73% of Gen Z buyers rank sustainability as non-negotiable. Choosing the right material isn’t just about aesthetics—it’s strategy in disguise.

What Makes a Material Suitable for Monoprinting?

Choosing the right material can make or break your monoprinting game. Let’s break down what makes each type shine.

Characteristics of Acrylic Plastic Containers in Monoprinting

Acrylic plastics are go-to options when clarity and durability matter most. Here’s why:

- Transparency: Crystal-clear visibility enhances design alignment during monoprinting.

- Smooth surface: Ensures even ink adhesion, which leads to crisp visuals.

- Chemical resistance: Compatible with various ink types, including water-based and UV-curable formulas.

- Durability: Withstands pressure from both manual and machine-based transfers.

- Recyclability: Many acrylics now come in eco-friendly, recyclable forms—great for brands going green.

When asking “what materials are used for monoprinting?”, acrylic checks nearly all the boxes.

Why Glass Bottles with Droppers Enhance Design Flexibility

Glass bottles aren’t just about aesthetics—they’re printing-friendly powerhouses too.

• Controlled application using droppers means less mess, more finesse.

• The non-porous nature of glass supports sharp, detailed designs.

• Smooth cylindrical surfaces optimize direct transfer techniques like gel plate or stencil work.

And because these containers resist heat and moisture, they’re perfect partners when experimenting with different monoprinting techniques on premium packaging.

The Benefits of Aluminum Compact Cases for Large Runs

Aluminum stands out when you’re running high-volume orders. Here’s a quick look at how it stacks up:

| Property | Performance Level | Impact on Monoprinting | Durability Score |

|---|---|---|---|

| Heat Resistance | High | Prevents warping | ★★★★★ |

| Surface Energy | Moderate | Good ink retention | ★★★★☆ |

| Texture Uniformity | Excellent | Consistent print finish | ★★★★★ |

| Recyclability | High | Eco-conscious branding | ★★★★☆ |

If you’re wondering what materials are used for monoprinting that can handle scale without losing quality—aluminum is a solid bet.

What Shapes Optimize Monoprinting Quality?

Shape matters—a lot more than you’d think—for clean monoprints.

Cylindrical shapes like mascara tubes or droppers allow smooth rolling contact with plates or stencils, making them ideal for continuous designs. Flat surfaces—like powder compact lids or palettes—offer stability during pressure application, especially useful in ghost print methods where precision rules.

Oddly contoured items? They may look cool but often lead to patchy prints or smudging unless paired with flexible substrates like silicone or soft paperboard.

So when you’re picking what materials are used for monoprinting, don’t forget to factor in form as much as function—it’s half the battle won!

Topfeelpack continues pushing boundaries by pairing smart shapes with next-gen materials like biodegradable polymers, giving brands both style and sustainability in one slick package.

Eco-Friendly Materials in Monoprinting: A Sustainability Perspective

Choosing the right materials for monoprinting isn’t just about print quality—it’s about caring for the planet too.

Exploring Sustainable Bamboo Packaging as an Eco-Friendly Option

Bamboo isn’t just panda food—it’s a packaging powerhouse. Here’s why:

- Renewable and fast-growing: Bamboo matures within three to five years, making it one of the most renewable resources used in sustainable ink formulations.

- Biodegradable and compostable: It breaks down naturally, leaving no toxic residue behind.

- Durability meets design: Its sturdy nature makes it ideal for luxury cosmetic packaging that doesn’t compromise on style.

When considering what materials are used for monoprinting, bamboo stands out not only for its strength but also its low environmental impact compared to plastics or virgin wood pulp.

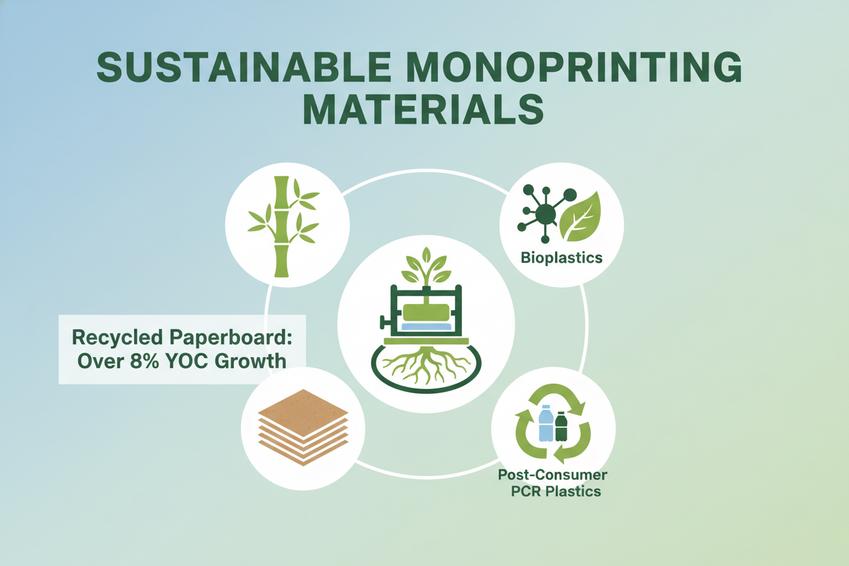

The Impact of Recycled Paperboard Palettes on Environmental Footprint

Recycled paperboard is changing the game—and here’s how:

- Cuts down landfill waste by reusing post-consumer paper.

- Uses less water and energy during manufacturing than virgin pulp.

- Supports circular economy goals through high recyclability rates.

According to Future Market Insights’ April 2024 report, “Eco-packaging made from recycled paperboard has seen a year-over-year growth rate of over 8%, driven by consumer demand for low-waste beauty products”. This makes it a top pick when asking what materials are used for monoprinting sustainably.

Comparing Eco-Friendly Material Options: Bamboo vs. Recycled Paperboard

Let’s size up these two green giants side-by-side:

| Feature | Bamboo | Recycled Paperboard |

|---|---|---|

| Source | Renewable grass | Post-consumer paper waste |

| Durability | High | Moderate |

| Biodegradability | Excellent | Good |

| Cost-efficiency | Medium | High |

Both are solid choices depending on your packaging goals—whether you want premium feel with bamboo, or cost-effective mass production using recycled paperboard. When choosing what materials are used for monoprinting, these two lead the eco-pack parade.

Benefits of Using Bioplastics in Monoprinted Packaging

Bioplastics aren’t science fiction anymore—they’re here and ready to clean up our act:

- Made from renewable sources like corn starch or sugarcane

- Lower carbon footprint than petroleum-based plastics

- Compatible with some forms of compostable materials

Still wondering what materials are used for monoprinting that won’t haunt landfills? Bioplastics offer a transitional solution between traditional plastics and fully biodegradable options.

How Glass and Aluminum Support Circular Monoprinting Models

Glass and aluminum don’t just look classy—they’re champions of reuse:

• Glass can be endlessly recycled without losing clarity or quality.

• Aluminum boasts one of the highest recycling rates worldwide—over 75%.

While not always biodegradable, both fit perfectly into closed-loop systems where durability meets recyclability. These substrates answer part of the question around what materials are used for monoprinting when aiming to reduce long-term waste.

Using FSC-Certified Substrates for Ethical Sourcing in Monoprinting

Short bursts on why FSC-certified options matter:

They guarantee wood comes from responsibly managed forests. – Help brands meet ethical sourcing standards without greenwashing.

Boost trust among eco-conscious consumers looking at every detail—including substrate origin.

So if you’re still asking what materials are used for monoprinting responsibly—FSC-certified papers should be at the top of your list.

Compostable Materials That Break Down Without Harming Ecosystems

Here’s how compostables step up:

Step 1: Made from organic matter like cornstarch or bagasse

Step 2: Designed to decompose in industrial compost facilities within months

Step 3: Leave behind zero microplastics or toxins

They’re not perfect yet—but they’re getting better fast. For brands exploring what materials are used for monoprinting with minimal ecological impact, compostables add serious value.

PCR Plastics vs Virgin Plastics in Cosmetic Monoprinted Products

Grouped comparison shows clear winners:

PCR Plastics

- Derived from recycled plastic waste

- Reduces reliance on fossil fuels

- Often indistinguishable from virgin plastic in appearance

Virgin Plastics

- Derived from petroleum

- Higher environmental toll during production

- Still dominates due to lower initial cost

If you’re balancing performance with purpose while deciding what materials are used for monoprinting, PCR plastics offer a guilt-free compromise without sacrificing shelf appeal.

Role of Water-Based Inks on Sustainable Substrates

Water-based inks aren’t just safer—they’re smarter too:

• Contain fewer harmful solvents compared to oil-based alternatives

• Work seamlessly with porous surfaces like recycled paperboard, boosting adhesion and vibrancy

• Emit lower levels of VOCs, improving air quality during printing

This combo is especially powerful when paired with greener substrates—so if you’re curious about what materials are used for monoprinting that align with clean beauty values, water-based inks should be part of your toolkit.

Advancements in Plant-Derived Pigments & Solvent-Free Ink Tech

It’s wild how far ink tech has come lately—check this out:

New-generation inks use plant-derived pigments, ditch synthetic dyes entirely.

Many are now totally solvent-free, reducing workplace hazards and emissions alike.

Brands can now combine these innovations with low VOC carriers to create truly clean prints on sustainable mediums like bamboo or bioplastic shells.

So next time someone asks you what materials are used for monoprinting that won’t mess with Mother Earth—you’ll know exactly where to point them!

The Role of Ink in Monoprinting Materials for Cosmetics

Choosing the right ink and protective finish is key to making cosmetic packaging pop and stay that way. Here’s how it all works out.

Pantone Matched Colors: Selecting the Right Ink Shades

- Pantone matching guarantees uniformity across global packaging runs. That hot coral lipstick box? It looks the same in Tokyo as it does in LA.

- Brands often lock down specific printing inks using Pantone codes to avoid color drift over time or between batches.

- Consistency matters not just for aesthetics but also for legal claims—think SPF labels or shade numbers.

- “Color accuracy is now a top priority for 72% of beauty packaging managers,” notes a 2024 report from Mintel.

- Matching isn’t just visual—it’s emotional branding. A slightly off-pink can feel like betrayal to loyal customers.

| Pantone Code | Product Example | Material Type | Ink Type |

|---|---|---|---|

| 2035 C | Lip Tint Container with Precision Tip | Plastic materials | UV-curable ink |

| 7625 C | Blush Powder Compact Case Lid | Metal components | Water-based ink |

| 2747 C | Mascara Tube | Acrylic surfaces | Solvent-based ink |

| 7499 C | Foundation Carton | Paperboard | Cosmetic-grade ink |

This kind of color control ensures every monoprinted item feels like part of a larger, intentional collection—because it is.

The Benefits of UV Coating for Ink Protection

• When you’re dealing with heavy-duty handling—from warehouse to vanity bag—coated inks are your best bet.

• UV coating adds serious muscle to your prints, especially on glossy or slick packaging substrates like plastic tubes or glass jars.

• It’s not just about shine. This layer shields against scratches, moisture, and even chemical rub-off from oily hands or makeup residue.

• For brands using high-end finishes like metallic inks, UV coating helps preserve those luxe details without dulling them out over time.

• Think of it as sunscreen for your print work—it blocks fading caused by exposure to sunlight and heat during transit or shelf display.

• Inks on textured surfaces like embossed cartons also benefit; the coating fills micro-gaps that otherwise trap dirt or oils, keeping things clean longer.

So when someone asks, “What materials are used for monoprinting?”—don’t forget the unsung hero: coatings that keep those materials looking flawless day after day.

What to Consider When Selecting Materials for Monoprinting?

Choosing the right materials for monoprinting makeup packaging isn’t just about looks—it’s about performance, feel, and cost. Here’s what actually matters.

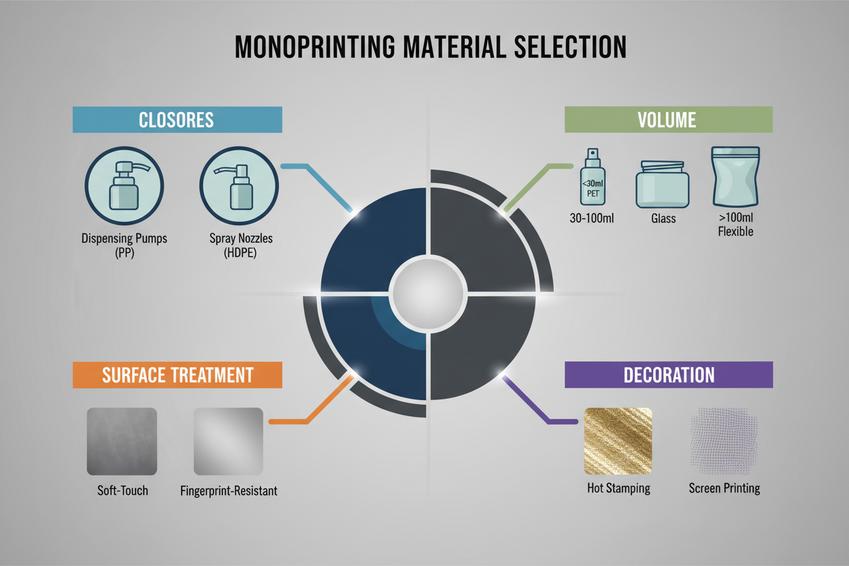

Key Component Types: Choosing Between Dispensing Pumps and Spray Nozzles

When asking “what materials are used for monoprinting?” it’s smart to start at the top—literally—with closures. The type of dispensing component you use affects not only consumer experience but also how well ink adheres during printing.

• Dispensing pumps work great on products needing precise control like serums or lotions. Their surfaces often use plastics like PP, which offer decent adhesion properties for most UV-curable inks. • Spray nozzles, found on mists and toners, usually require more durable finishes due to frequent handling. Here, materials like HDPE or even metal components can be used—but they need special primers for better printability.

Choosing between them? Think function first, then match your substrate and ink accordingly.

Volume Matters: Best Container Sizes for Different Products

Size doesn’t just affect shelf presence—it changes everything from printing technique to material waste. Here’s how volume plays into it:

- Small-volume containers (<30ml): These typically use lightweight PET plastics, ideal for travel-size items but trickier for intricate prints due to limited surface area.

- Mid-range volumes (30ml–100ml): Often made from glass or thicker PP, these offer better durability and broader print zones.

- Large formats (>100ml): Think body creams or toners—these often shift toward flexible packaging using multilayer flexible films, which demand high-performance inks like solvent-based inks that resist cracking during flex.

So if you’re still wondering “what materials are used for monoprinting,” remember—size always shapes that decision.

Importance of Surface Treatment: Soft Touch vs. Fingerprint Resistant

Surface treatments can make or break both visual appeal and practicality—and they’re a big deal when choosing substrates compatible with monoprinting techniques.

Soft-touch coatings give packaging that velvety feel everyone loves, especially on premium lines. They work best on rigid surfaces like coated paperboard or matte-finished plastics, but care must be taken—some soft-touch layers don’t bond well with certain inks unless pre-treated.

On the flip side, fingerprint-resistant coatings are clutch for high-handling items like powder compacts or lipstick tubes. These typically go over glossy finishes on materials such as lacquered metal or polished glass, helping maintain clean visuals over time while still allowing sharp screen prints using durable pigments like metallic pigments.

Each finish needs its own prep game—so pick based on product usage first, then backtrack into compatible treatments.

Decoration Techniques: Hot Stamping Foil vs. Screen Printing

Two flashy ways to decorate—but totally different beasts when it comes to execution:

• Hot stamping foil:

Best suited for crisp logos and metallic accents

Requires heat-resistant substrates like thick-walled glass, anodized aluminum, or treated paperboard – Doesn’t always mix well with textured surfaces

• Screen printing:

Offers incredible detail across curved surfaces

Works beautifully with both rigid and flexible containers made from materials like smooth-finish PET and coated PP

Supports layering effects using specialty finishes such as pearlescent pigments

If you’re evaluating “what materials are used for monoprinting,” your chosen decoration method will dictate which substrates you can realistically work with—and vice versa.

Understanding the Role of Closure Types in User Experience

Closures might seem minor—but they’re often the first thing users interact with. And yeah—they influence how well your design holds up too!

Step-by-step breakdown:

- Identify closure functionality: Is it twist-off? Flip-top? Airless pump?

- Match closure material to product viscosity—for example, thick creams do better with airless systems using sturdy molded PP.

- Evaluate surface compatibility with your chosen ink system—most closures need either a primer coat or specially formulated inks like food-safe water-based options.

- Consider tactile feel—a soft matte finish may elevate luxury perception but could smudge easily without fingerprint resistance.

- Align closure color/material with main container aesthetics so your monoprinted design looks seamless across all components.

So yeah—the next time someone asks “what materials are used for monoprinting,” don’t forget those tiny caps matter way more than you’d think!

FAQs

1. Which materials give the best print clarity and definition?

Smooth surfaces make all the difference—where ink meets precision.

- Acrylic plastic containers: crisp edges and high visibility for branding art.

- Glass bottles with droppers: fine texture perfect for screened custom designs or hot stamping foil highlights.

- Aluminum compact cases: retain consistent coloration under UV coating protective layers through heavy production use.

2. How do shape types influence ink performance in packaging design?

Form whispers to pigment; every contour changes the way color settles.

① Cylindrical shaped bottles keep logos balanced around curves.

② Square compact containers favor symmetrical embossing of text and mirrors inside lids.

③ Round jar designs welcome waterproof sealing layers that lock the artistry longer.

3. Why are Pantone matched colors essential across product lines?

Unified tones become part of brand identity—luxury lives in repetition done right.

✶ Metallic gold finishes, matte black coatings, glossy white surfaces, or custom tinted shades keep each 15ml serum bottle consistent beside its 100ml toner spray companion.

4. What surface treatments bring durability and comfort to monoprinted cosmetics?

Short feel-first branch line structure:

Soft touch coatings wrap a tactile elegance over acrylics; anti-scratch protection keeps square compacts appealing after countless touches; fingerprint resistant finish defends matte panels from everyday smudges while oil resistant treatments guard against formula stains on screw-on jar lids.

| Surface Treatment | Visual Effect | Functional Trait |

|---|---|---|

| Soft Touch Coating | Velvet-like glow on aluminum cases | Comfortable handling |

| Fingerprint Resistant Finish | Clean look even with use | Longevity & neatness |

5. Which eco-friendly materials support both beauty values and environmental care?

The movement toward sustainable refinement grows stronger each year—integrity with aesthetic purpose.

- Sustainable bamboo packaging: natural fiber warmth matching embossed logo detailing on oval palettes.

- Recycled paperboard palettes: lightweight yet sturdy, pairs beautifully with labeling adhesive stickers.

Those options prove monoprinting can feel heartfelt without sacrificing sophistication when spread across 30g cream jars or 200g powder compacts sealed under soft UV glimmer coats that speak responsibility as much as style itself.

References

[1] Consumers care about sustainability—and back it up with their wallets – McKinsey

[2] Paperboard Packaging Market Outlook (2024 to 2034) – Future Market Insights

[3] Mono-Material Packaging in the Beauty Industry – APC Packaging

[4] Benefits of FSC certification – Forest Stewardship Council

[5] Do PCR cosmetic containers affect product stability or quality? – APG Packaging