Easy Tips for Buying Squeeze Tubes for Lip Gloss

You’ve nailed your formula, whipped up the perfect gloss blend—and now you’re stuck hunting down the right squeeze tubes lip gloss won’t leak from, crack under pressure, or scream “cheap” at first glance. Sound familiar? You’re not alone. Packaging can make or break a brand’s vibe faster than a clumpy mascara wand.

Truth is, most buyers think picking out tubes is just a checkbox task… until caps don’t fit snugly, applicators feel weird in-hand, or half your shipment shows up looking like it took a tumble off Mount Everest.

“According to Allied Market Research, the global cosmetic packaging market will hit $39 billion by 2030”—so yeah, presentation isn’t just pretty; it’s power.

If you want customers to reach again for your product instead of tossing it after one use—you’ll need more than cute colors and glittery labels. Let’s break this thing down into bite-sized tips that actually matter when buying in bulk.

Quick Answers for Flawless Squeeze Tubes Lip Gloss Packaging

➔ Material Matchmaking: Choose LDPE for flexibility, HDPE for strength, or eco-friendly bio-plastic to align with sustainable branding goals.

➔ Cap Compatibility Counts: Screw-on caps seal tight, flip-tops offer convenience, and roller balls provide smooth application—pick based on user experience.

➔ Finish & Feel First Impressions: Matte is modern, glossy adds shine, and soft touch boosts grip while enhancing luxury appeal.

➔ Seal the Deal with Multi-Layer Tech: Multi-layer tubes protect against leaks and contamination—especially important in bulk storage or shipping.

➔ Size Affects Seal Integrity: Smaller capacities like 5ml often seal better; larger options (up to 30ml) need reinforced seams to prevent product loss.

➔ Visual Identity Matters: Opt between pearlized shimmer or opaque white tubes to reflect your brand tone; custom colors can elevate shelf presence.

➔ Print Precision Wins Loyalty: Use silk screen or hot stamping for sharp logos and labels that last through daily use without fading or peeling.

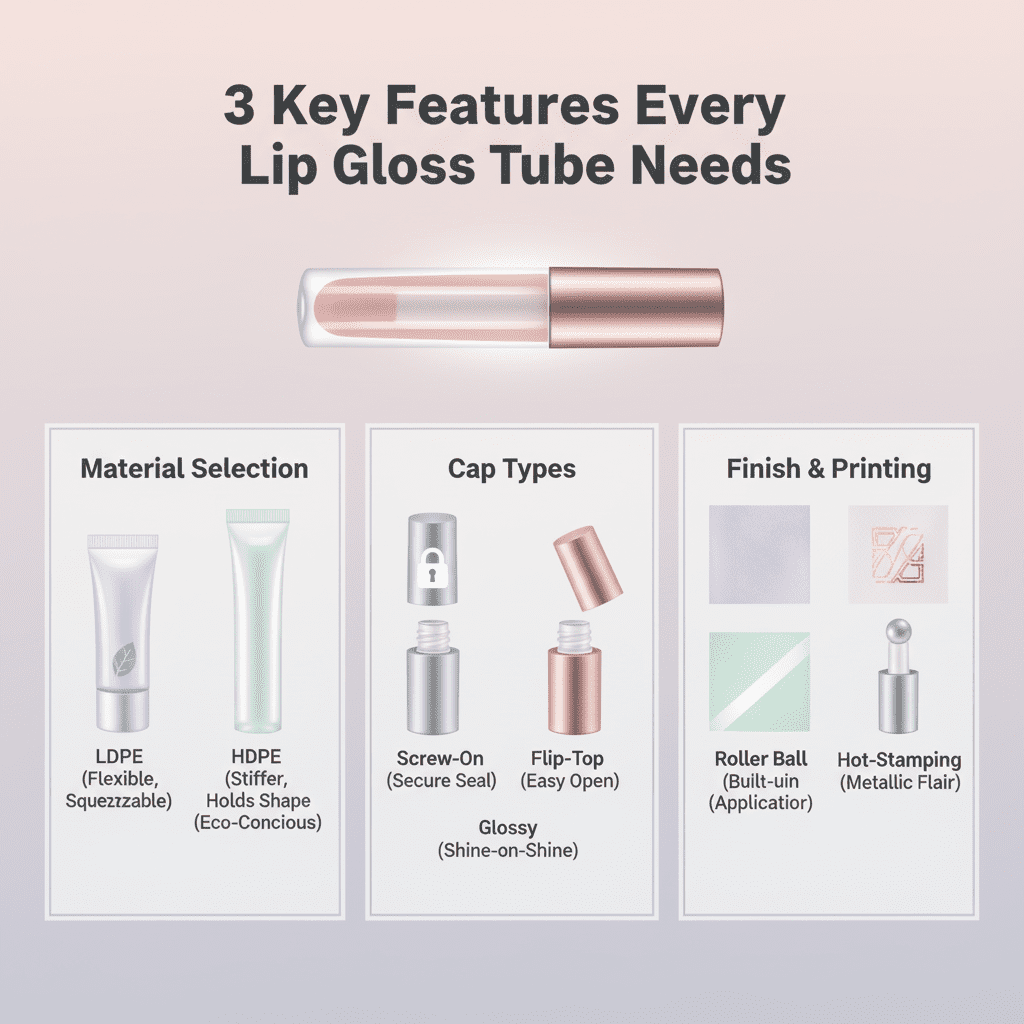

3 Key Features Every Lip Gloss Tube Needs

What makes a lip gloss tube truly stand out? It’s all in the details—materials, caps, and finishes that bring both function and flair.

Material Selection Matters: LDPE, HDPE and Bio-Plastic Tubes

Choosing the right material means balancing feel, function, and eco-consciousness. Here’s how they stack up:

• LDPE (Low-Density Polyethylene) is super flexible—ideal when you want easy squeezability without cracking. Great for soft squeeze tubes that make application smooth.

• HDPE (High-Density Polyethylene) brings more stiffness. It holds its shape better but still lets you press out just enough product without overdoing it.

• Bio-plastic options are rising stars in the beauty world. Made from renewable sources like corn starch or sugarcane, these materials appeal to eco-minded shoppers who want their gloss guilt-free.

Each type has its place depending on your brand vibe and how much pressure users should apply during use. Lightweight plastic choices like LDPE feel soft in hand, while HDPE gives off a sturdier impression—perfect if you’re aiming for premium packaging with a firm grip.

Cap Types Explained—Screw-On, Flip-Top and Roller Ball

Caps aren’t just closures—they’re part of the user experience. These three types each bring something different to the table:

-

Screw-On Caps

-

Secure seal? Check.

-

Travel-friendly? Absolutely.

-

They work best if your formula is thick or prone to leakage.

-

Flip-Top Caps

-

Easy open-and-close action with one hand.

-

Great for quick touch-ups on-the-go.

-

Often paired with mid-softness tubes that balance squeeze control with convenience.

-

Roller Ball Caps

-

Built-in applicator? Yes please.

-

Especially handy when you want ultra-smooth application directly onto lips.

-

Usually found on thinner formulas that glide effortlessly across skin.

The type of closure can totally shift how your audience interacts with your product—and even how often they reach for it throughout the day. Whether you’re designing sleek minimalist packaging or playful designs aimed at Gen Z, matching cap types to both function and aesthetic is key in lip gloss tube design.

Finish & Printing Choices for Matte, Glossy and Hot-Stamping

Design matters just as much as durability when it comes to decorating your lip gloss packaging:

• A matte finish gives off soft sophistication—it doesn’t scream luxury but whispers it instead. Great choice if you’re going after minimalist vibes or muted tones.

• Go glossy if you want shine-on-shine action; this surface treatment reflects light beautifully and pairs well with metallic inks or bold colors printed directly onto the lip gloss tubes.

• Add some flair through hot-stamping, which presses metallic foils into the surface—making logos pop with texture and shimmer that won’t fade easily over time.

Each decoration style works best with specific printing techniques depending on whether you’re using LDPE or HDPE materials since surface tension affects ink adhesion differently across plastics. So before hitting print, think about how finish plays into both visual impact and long-term durability under daily handling conditions.

Leaking Lip Gloss? Secure Squeeze Tubes Seals

Keeping lip gloss from oozing out of its container isn’t just about looking clean—it’s about brand trust and product longevity. Let’s break down how to keep your gloss where it belongs.

Sealing Performance of Multi-Layer Plastic Tubes

-

Multi-layer builds offer:

-

Better sealing performance

-

Increased resistance to punctures

-

Added protection from air exposure

-

Why layers matter:

- The outer layer gives shape.

- The middle barrier stops oxygen seepage.

- The inner lining holds the formula tight.

- ✦ Brands using single-layer tubes often see more leaks during shipping.

Long-lasting gloss starts with the right tube material. Using multi-layer designs helps prevent leaks, especially when tossed in a purse or pocket all day. These tubes hold their shape better and resist pressure changes, making them ideal for even the most active users.

Multiple materials blended into each tube wall—like EVOH or PE—enhance both durability and seal integrity, keeping your squeeze-style packaging looking sleek and mess-free.

5ml to 30ml: How Tube Capacity Influences Seal Integrity

-

Small-sized tubes (like 5ml) tend to hold tighter seals because:

-

Less internal pressure buildup

-

Lower surface tension on seal points

-

Reduced risk of deformation during transport

-

Larger formats (20ml–30ml) often require:

-

Heat-sealed ends

-

Reinforced caps or tamper rings

-

Thicker walls for added compression resistance

From mini testers to full-size products, tube size plays a huge role in leak control. A compact gloss might never see trouble, but once you hit the larger volumes, that extra room inside can stress weak seals—especially under heat or altitude shifts.

To maintain product stability, it’s smart to match your sealing method with your capacity choice. If you’re scaling up production, don’t forget that bigger doesn’t just mean more product—it means more risk if the seal fails.

Bulk Packaging Options to Safeguard Against Leaks

Grouped packaging solutions fall into three main buckets:

Protective Materials

- Bubble sleeves between units reduce friction damage.

- Custom-fit trays prevent rolling and crushing.

- Shrink-wrapped bundles minimize shifting during transit.

Shipping Configurations

- Vertical placement keeps caps upright.

- Layered inserts add shock absorption.

- Moisture-resistant cartons help in humid climates.

Storage-Friendly Designs

- Stackable bins for warehouse efficiency.

- Clear labeling for quick batch identification.

- Tamper-evident tape ensures integrity upon arrival.

Bulk handling isn’t just about moving more units—it’s about preventing costly messes along the way. With proper packaging materials and smart design choices, brands like Topfeel have cut leakage complaints by over half while scaling distribution globally.

Whether you’re sending out five hundred or fifty thousand tubes of lip gloss, investing in secure bulk options is one of the smartest moves you can make for damage control and customer satisfaction alike.

Cracking Tube Caps? Opt for Durable Gloss Tubes

When lip gloss packaging cracks or leaks, it’s more than just messy—it’s frustrating. Here’s how better design and smarter materials can prevent that hassle.

Comparing Nozzle Tip and Brush Applicator Caps

Choosing between a nozzle tip and a brush applicator isn’t just about aesthetics—it’s about how your gloss flows, feels, and finishes.

- A nozzle tip gives you pinpoint control—ideal for high-pigment formulas or targeted touch-ups.

- A built-in brush applicator, on the other hand, glides smoothly across lips, making it great for soft textures or sheer finishes.

- If you’re working with thick gel-based glosses, the brush might struggle; thinner balms benefit from it.

- Material matters too: flexible plastics in caps reduce stress fractures over time.

- Don’t forget cap threading—sloppy threads can cause leakage no matter which type you choose.

The right cap isn’t just a lid—it’s part of the user experience. Match your formula’s texture to the cap design to avoid those annoying mid-use splatters.

Strength of Eco-Friendly Bio-Plastic and Multi-Layer Tubes

Durability doesn’t have to come at the planet’s expense. Modern eco-friendly materials are stepping up big time.

Short-term breakdown? Not anymore. Today’s bio-resins hold their own against traditional plastics in strength tests. In fact, according to Mintel’s 2024 Global Packaging Report, over 62% of consumers now trust plant-based tubes as much as petroleum-based ones when it comes to durability.

Multi-layer designs add another layer (literally) of protection:

– The inner layer resists product erosion from oils or acids.

– The middle core adds toughness without bulk.

– The outer shell supports printing while resisting external pressure.

Together, these layers keep your gloss safe from cracking—even when tossed into a crowded purse or squeezed too hard during application.

Soft Touch Finish for Enhanced Grip

A good grip means fewer drops—and less frustration when you’re applying gloss on-the-go. That’s where a quality soft touch finish comes in strong.

• Adds tactile resistance so tubes don’t slip out mid-swipe

• Offers a velvety texture that feels luxe without being sticky

• Reduces condensation build-up on humid days

Beyond feel-good vibes, this finish can also extend tube life by protecting against minor abrasions during daily use. For squeeze-type packaging especially, grip-enhancing coatings help users apply consistent pressure without distortion—key for precise application with compact formats like travel-sized gloss tubes.

When paired with sturdy materials like multi-layer laminate or bio-plastics, this ergonomic coating turns everyday packaging into something way more functional—and way less crack-prone.

How to Verify Squeeze Tubes Lip Gloss Quality?

Wanna make sure your gloss tubes don’t flop? Let’s walk through how to check if they’re solid, slick, and ready for the spotlight.

Inspecting Material Integrity—LDPE, Aluminum Laminate and Multi-Layer Tubes

When checking the guts of your squeeze tubes, you’ve gotta look at what they’re made of—because not all materials are created equal.

- LDPE: Super flexible and bounce-back friendly. Ideal for easy-squeeze action.

- Aluminum Laminate: Blocks out air and light like a champ. Keeps gloss fresher longer.

- Multi-Layer Tubes:

• Inner layer = product protection.

• Middle layer = strength & durability.

• Outer layer = visual appeal.

If you’re dealing with lip gloss tubes, these layers seriously matter. A quick squeeze test can reveal if the wall thickness is up to par or just flimsy filler. Topfeel always opts for multi-layer when durability meets design.

Verifying Capacity Accuracy for 5ml, 10ml and 20ml Tubes

Not all tube sizes are what they claim—don’t get shortchanged on volume.

• Fill each size with water using a calibrated syringe or pipette.

• Record actual fill volumes against stated capacity:

| Tube Size | Claimed Volume | Measured Volume | Deviation (%) |

|---|---|---|---|

| Small | 5ml | 4.8ml | -4% |

| Medium | 10ml | 9.7ml | -3% |

| Large | 20ml | 19.9ml | -0.5% |

Even minor deviations can mess with your product cost per unit or violate labeling laws—so yeah, measure twice, fill once.

Assessing Color & Finish: Pearlized Shimmer vs Opaque White

Gloss tubes aren’t just containers—they’re part of the whole vibe.

Short takes on finish types:

• Pearlized Shimmer – Reflective, luxe feel; perfect for premium lines or holiday drops. Think soft glow under retail lighting.

• Opaque White – Clean-cut, minimalist aesthetic; lets label design shine without distraction.

• Custom blends? Totally doable—but always request a sample batch to see how it plays with your formula’s hue.

The choice between shimmer and matte isn’t just cosmetic—it subtly signals brand identity before anyone even opens the cap.

Reviewing Printing & Warehousing Options—from Silk Screen to CIF

So you’ve nailed the look and feel—but what about branding and storage? Here’s where things get real strategic.

Grouped options:

🖨️ Printing Choices

- Silk Screen: Crisp lines, great for logos or fine text.

- Offset printing: Best for gradient-heavy graphics.

- Hot stamping: Adds metallic flair—gold foil accents anyone?

📦 Warehousing Terms

- FOB vs CIF shipping? CIF includes insurance + freight right to port—less hassle if you’re importing globally.

- Ask about shelf life guarantees under warehouse conditions—especially if storing filled tubes long-term.

According to QY Research’s May 2024 packaging report, brands that optimize both decoration method and logistics terms reduce total packaging costs by up to 18%. That’s not pocket change—it’s scale-up money waiting to happen.

FAQs

The feel of the tube in your hand matters just as much as how well it protects what’s inside. Soft and pliable LDPE plastic gives a satisfying squeeze, while HDPE offers a firmer grip that holds its shape better over time. If you’re leaning toward sustainability, bio-plastics made from renewable sources are becoming more popular with eco-conscious brands. For formulas that need extra protection—think oils or shimmer-heavy glosses—a multi-layer barrier tube helps keep everything fresh and leak-free.

A leaky package can ruin not just product but trust. To avoid this:

- Go with multi-layer tubes—they’re tougher under pressure.

- Choose caps that seal tightly, like screw-on applicator tips.

- Ask suppliers about drop tests or request pre-shipment samples to check durability.Bulk orders often come with custom palletization too, which adds another layer of defense during transit.

Absolutely—and it’s where branding really comes alive. A matte finish creates an understated elegance; glossy surfaces catch light on retail shelves; soft-touch coatings make each use feel luxurious in hand. Want something bolder? Pearlized shimmer effects or metallic sheens turn ordinary packaging into eye candy.

Cap choice isn’t just functional—it shapes how people experience your gloss:

- Screw-on caps: Great for smaller formats (like 10ml), easy to toss in a bag without worry.

- Flip-tops: Quick access when you’re on the go—ideal for mid-size tubes around 20ml.

- Brush or roller ball applicators: Perfect for smooth application on larger capacities (up to 30ml) where precision meets indulgence.

Each pairing changes how users interact with your brand every time they apply it—so choose thoughtfully!