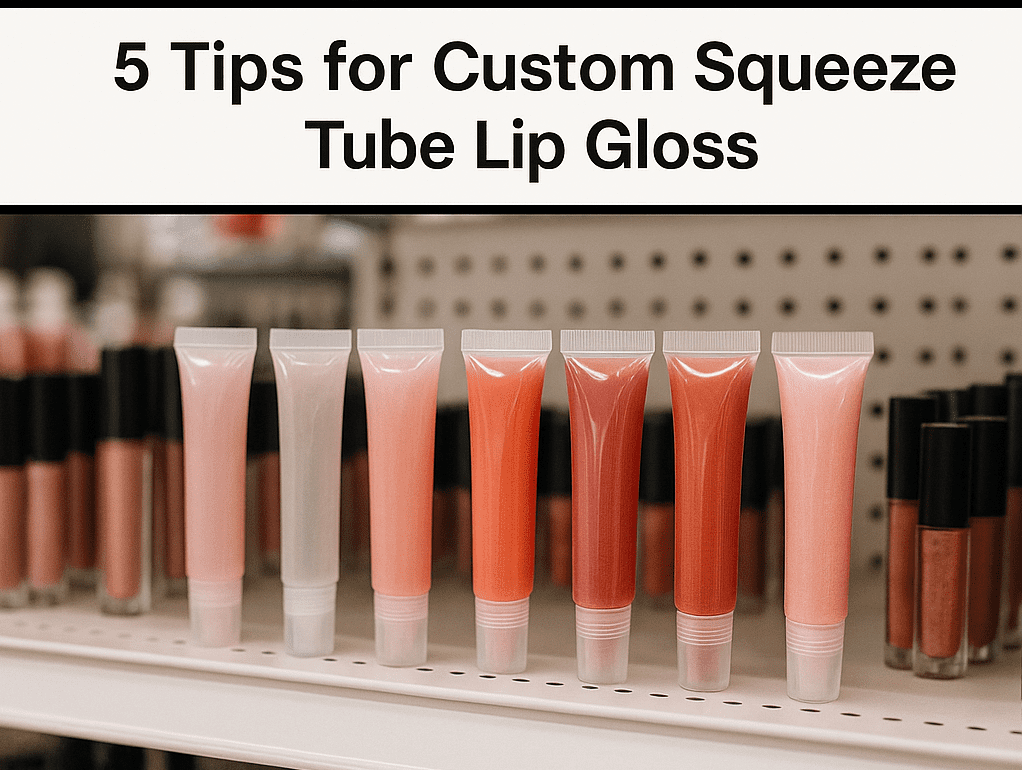

5 Tips for Custom Squeeze Tube Lip Gloss

Finding the perfect squeeze tube lip gloss for large-scale production can feel a bit like speed dating — too many options, not enough straight answers. You’re juggling branding, usability, fill rates, and cost per unit, all while trying not to blow the budget or sacrifice looks. If you’re buying by the thousands, every detail counts.

“Packaging is the handshake of your product,” says Michelle Lee, former editor-in-chief of Allure. And she’s not wrong — especially when that packaging ends up on retail shelves or in influencer unboxings.

This guide lays out five no-nonsense tips to help you choose the right tube, nail the sizing, weigh refillable vs. disposable options, and source smart. Let’s save you time, money, and a few late-night headaches.

How to Select the Right Squeeze Gloss Tube?

Choosing the right squeeze gloss tube is the first big step toward launching a successful custom lip product.

When selecting squeeze gloss tubes in bulk, B2B buyers must weigh a combo of tube material, applicator type, tube size, and even formula compatibility. It’s not just about aesthetics — it’s about how the product performs in the hands of your customers.

Here’s what matters:

- Tube Material: Consider LDPE or PET for durability and flexibility.

- Tube Size: 8ml is sleek, while 10ml suits value-driven markets.

- Applicator Type: Angled tips = precise; flat tips = casual glide.

- Filling Method: Top-fill tubes are common for large-scale automation.

- Tube Color: Transparent tubes highlight the gloss; opaque suits premium.

According to Amira L., Packaging Director at Cosmetex Global,

“The perfect tube isn’t about looks — it’s about cost efficiency, user ease, and protecting your formula from degradation.”

Ultimately, the best squeeze tube matches your gloss formula and aligns with brand positioning — whether you’re going for glam, clean beauty, or mass market-ready. So, don’t just pick what looks good. Pick what works smart.

Where to Procure Affordable Lip Gloss Tubes?

Sourcing affordable squeeze lip gloss tubes at scale requires more than clicking “Add to Cart.” Here’s how smart brands find the sweet spot between price, quality, and reliability.

Direct Sourcing from Tube Manufacturers

Direct procurement from tube suppliers often delivers the best control over quality, cost, and timelines. Working straight with manufacturers ensures optimized component sourcing, reduced margins, and stronger supply chain management.

✔️ Benefits include:

- Volume orders with custom specs

- Built-in quality control protocols

- Closer alignment with production capacity

“Strong manufacturer relationships give you leverage others dream of,” says Jenna Lopez, Supply Chain Director at CosmoForm Labs.

Evaluating Bulk Pricing from Wholesalers

Wholesale pricing isn’t just about who’s cheapest — it’s about cost-per-unit trends, supplier negotiation success, and logistics advantages.

Check this quick breakdown before committing:

| Supplier Tier | MOQ (Units) | Avg. Cost per Tube ($) |

|---|---|---|

| Tier 1 | 10,000 | 0.48 |

| Tier 2 | 10,000 | 0.38 |

| Tier 3 | 20,000+ | 0.29 |

Key tip: Bulk discounts often kick in hard at 10K+. Always request custom quotes and ask about tiered pricing to stretch your procurement budget.

Private Label vs. OEM Procurement Channels

<1> Private label branding allows you to slap your logo on pre-made formulas — great for quick go-to-market strategies.

<2> OEM manufacturing, though, gives you full control over product customization and packaging design.

While private label is faster, OEM is ideal for building long-term brand equity and owning your formula.

⚖️ Which suits you?

- Private Label = speed + simplicity

- OEM = originality + deeper manufacturing partnerships

Choose based on how much brand development control you want, and how your procurement channels align with your supply chain model.

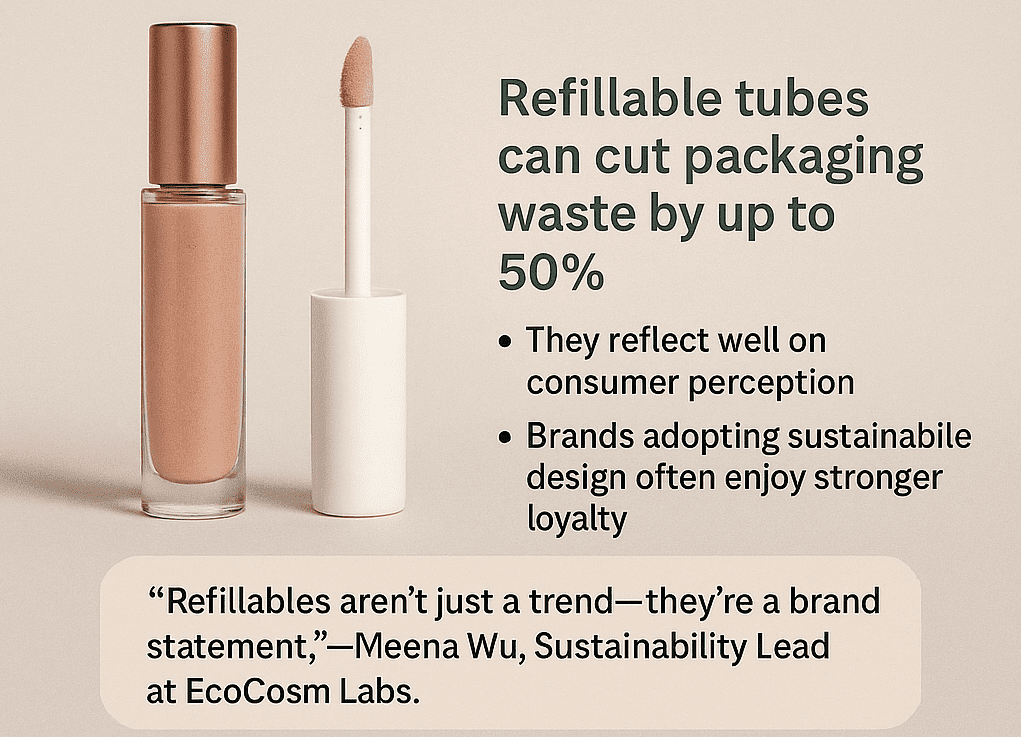

Refillable vs. Single-Use Gloss Containers

Understanding the shift from single-use to refillable lip gloss containers can unlock major opportunities in sustainability-driven B2B markets.

Sustainability Appeal in Refillable Gloss Tubes

Refillable packaging isn’t just trendy — it’s a strategic move. Eco-conscious consumers increasingly favor sustainable design and reduced environmental impact. Brands using refillable lip gloss tubes can enhance consumer perception and align with modern product lifecycle expectations. That’s a big win for brand image, especially among Gen Z buyers.

“Today’s shoppers vote with their wallets — and they’re voting green.” — Mira Tanaka, Packaging Sustainability Analyst

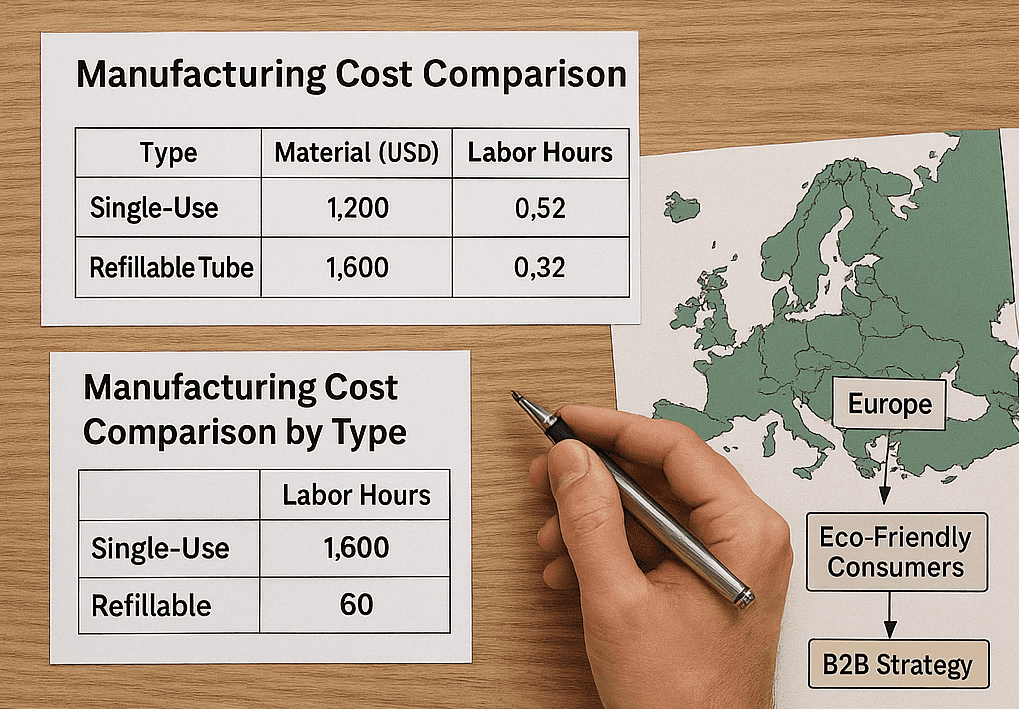

Manufacturing Costs Comparison by Type

When comparing refillable vs. single-use, production expenses vary based on:

| Packaging Type | Material Cost (USD) | Avg. Production Time (mins) |

|---|---|---|

| Refillable Tube | 0.42 | 3.5 |

| Single-Use Tube | 0.26 | 2.1 |

The higher material costs of refillables may be offset by improved labor efficiency and long-term economies of scale in bulk production.

User Experience with Refillable Packaging

Alright, here’s the deal — if your gloss is in a clunky refillable that’s hard to open or messy to use, you’ll lose customers fast. But nail the design? Boom — consumer satisfaction and brand loyalty skyrocket. Usability and convenience must come first, especially when targeting high-end buyers or beauty pros.

Compliance and Sanitary Considerations

Refillables must meet strict regulatory compliance to ensure product safety and hygiene standards. Brands must implement proper sanitation protocols and follow industry guidelines to avoid recalls. Quality control measures and testing processes must be scaled accordingly for refill systems, particularly in international markets.

Targeting Eco-Conscious Retail Segments

Selling to eco-friendly consumers requires smart market segmentation and precise retail strategy. Position your gloss as a green product, and pair that with sustainable marketing visuals — think recyclable packaging, minimalistic design, and clean branding. Tailor messaging for specific consumer demographics and align with major brand positioning goals.

Flat vs. Angled Tips for Squeeze Lip Gloss

Tip design may seem small, but it directly impacts user satisfaction, product usability, and overall gloss performance. Let’s break down how shape affects function.

Consumer Application Preferences by Tip Style

From sponge-tipped applicators to brush-style nozzles, consumer preferences are surprisingly varied. Some users love the angled tip for its clean, targeted swipe—less mess, more control. Others? Total flat-tip fans. It gives them a smoother glide and often feels more luxurious.

And if you’re wondering how cleaning applicators and material compatibility tie in? Think of those DIYers refilling tubes with their fav gloss—they care how easily tips clean and hold up. User preference can make or break repeat purchases, especially in bulk private-label lines.

Impact of Tip Shape on Formula Dispersion

- Formula Application – The way gloss flows through an angled tip versus a flat one alters the dispersion uniformity. Flat tips often spread thinner layers, making them perfect for high-shine finishes.

- Nozzle Design & Coverage – Angled tips can give directional spray patterns (even in non-liquid glosses), focusing product at the center of the lips for bold pigment payoff.

- Cleaning Efficacy – Brands using thicker or glitter-infused formulas need to evaluate how tip shape affects clogging and how it holds up to cleaning solutions.

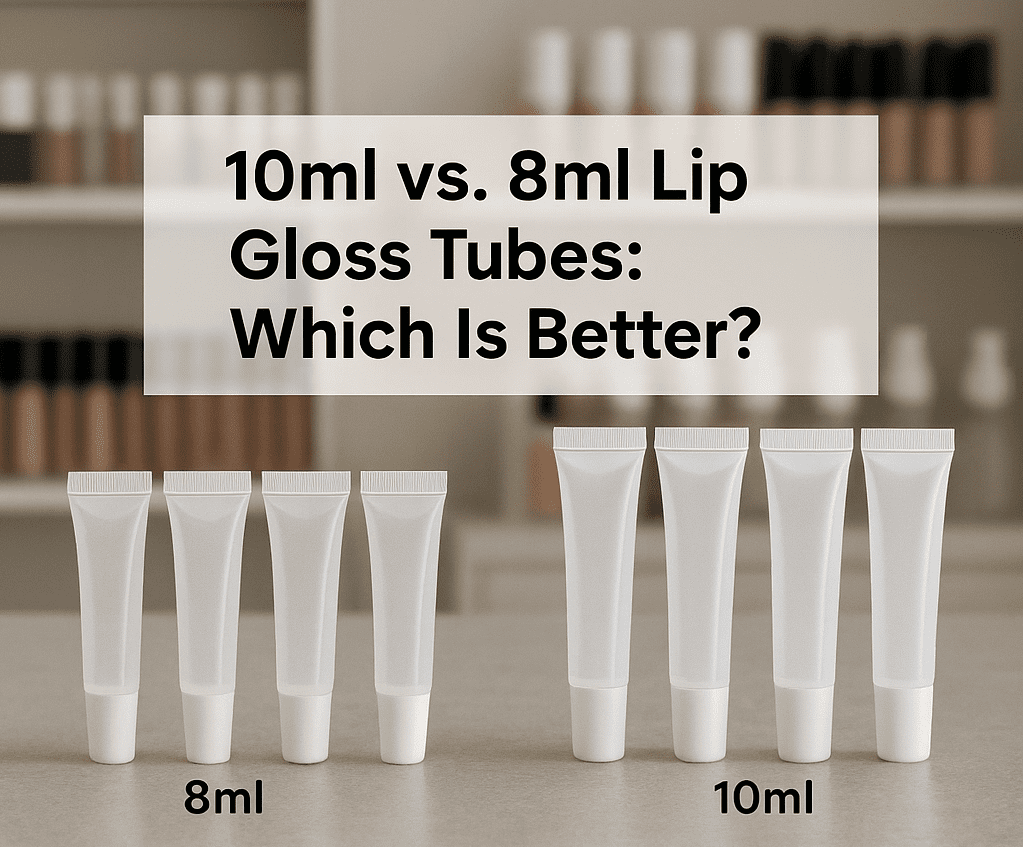

10ml vs. 8ml Lip Gloss Tubes: Which Is Better?

Choosing between 10ml and 8ml squeeze lip gloss tubes might seem minor, but it significantly impacts production, shipping, stability, and brand perception in bulk cosmetic packaging.

Unit Cost per ml in Mass Production

Understanding cost per milliliter is key in bulk manufacturing.

- A 10ml tube may lower unit cost due to economies of scale.

- Raw materials, supply chain efficiency, and manufacturing overhead all impact margins.

- Larger production volumes improve unit economics, but overfilling can waste product and increase cost.

Here’s a simple breakdown:

| Tube Size | Avg. Cost (per ml) | Overhead Savings |

|---|---|---|

| 8ml | $0.048 | Moderate |

| 10ml | $0.041 | Higher |

Shelf Visibility and Branding Considerations

Larger tubes often win the shelf game. With enhanced brand recognition and visual merchandising potential, a 10ml gloss can scream value.

- Packaging design is more flexible with larger tubes—think bolder colors or cleaner layouts.

- In high-traffic retail spots, brand identity must pop. 10ml makes that easier.

- But for minimalist, travel-friendly branding? 8ml could be your sleek winner.

“Retail real estate is visual—make your packaging work as hard as your formula,” says Jordan Claire, cosmetic retail strategist.

Formula Stability in Different Tube Sizes

When it comes to chemical formulation and product degradation, size can actually matter.

- 10ml tubes may reduce air exposure per ml, improving shelf life.

- But packaging integrity in smaller tubes is often tighter, lowering contamination risk.

- Always conduct stability testing and quality control to match material compatibility.

In short: Test before you commit. Bigger isn’t always better for formula life.

Packaging Size and Shipping Efficiency

Let’s talk logistics: • 10ml tubes increase freight costs slightly due to package dimensions, but consolidate well in bulk. • 8ml tubes are lighter, more flexible for transportation optimization, and reduce warehousing strain. • Efficiency depends on your shipping volume and whether you’re air or freight-heavy.

👉 Brands shipping internationally in tight budgets often favor 8ml tubes for better supply chain economics.

Conclusion

Choosing custom squeeze lip gloss tubes isn’t just a detail—it’s the deal. The wrong size or nozzle can throw off your margins faster than a leaky cap ruins a handbag. You’re not just picking a tube; you’re shaping your brand’s first impression.

A buyer once told me, “We lost retail shelf space because our gloss tubes looked like hotel freebies.” Harsh—but true. Design, cost, and function all have to vibe, or it backfires.

Are squeeze lip gloss tubes available in eco-friendly materials?

Yes, several responsible material options exist:

- Sugarcane-based bioplastics

- Post-consumer recycled (PCR) tubes

- Refillable formats with replaceable tips

- Biodegradable or compostable resins

These help align your product with green-conscious buyers.

Can a logo be printed directly onto the tube?

Definitely. Logo customization is standard across most packaging manufacturers. Options include screen printing, hot stamping for metallic finishes, and full-color digital print. Some even offer tactile coatings to enhance shelf appeal.

What tube sizes are most suitable for lip gloss?

Popular sizing choices include:

- 8ml – Great for compact, purse-ready formats

- 10ml – Industry standard for most gloss products

- 12ml or larger – Often used for treatment gloss or hybrid balms

Packaging engineers typically recommend balancing visual impact with formula density.

How long does a custom gloss tube order take to produce?

Lead times vary by project complexity. A basic, unbranded tube may be ready in 2–3 weeks. For custom shapes, printed designs, or unique applicators, timelines range from 4 to 8 weeks, plus transit time depending on location.

What should be tested before committing to a large production run?

A few key elements to evaluate:

- Gloss viscosity under squeeze pressure

- Cap seal and leakage protection

- Material compatibility with gloss ingredients

- Resistance to heat, freezing, or sunlight

Most suppliers offer trial runs or sample kits to assist in this phase.

Is an angled tip better than a flat one for gloss application?

Many brands lean toward angled tips when ease of application is a priority. This shape fits comfortably against the lips and distributes gloss more evenly, especially in formulas with higher shine or shimmer content.

Can tubes be customized beyond just color and logo?

Absolutely. High-end packaging suppliers can deliver:

- Matte or soft-touch coatings

- Gradient or holographic finishes

- Embossed or debossed branding

- Custom-shaped nozzles or caps

These touches often distinguish boutique gloss lines from commodity offerings.

Which certifications are important when sourcing gloss tubes in bulk?

To ensure compliance and reliability:

- ISO 22716 helps verify cosmetic-grade GMP standards

- FDA approval or equivalent for material safety

- SGS or Intertek reports add third-party credibility

- EcoCert or FSC for brands emphasizing sustainability

It’s smart to request supporting documents during your vendor selection process.