Raman Polypropylene vs PET: Simple Comparison Guide

Choosing between raman polypropylene vs PET for your cosmetic packaging isn’t just about plastic—it’s about what your brand stands for. Creamy foundations, silky serums, high-impact glosses… the wrong material can mess with product stability or even turn screen printing into a nightmare. It’s like picking the wrong shoes for a marathon—sure, they’re both sneakers, but one leaves you limping.

One senior engineer at Topfeel recently said in an industry roundtable (Shanghai Packaging Week 2024), “You’d be surprised how many brands lose shelf appeal over forgetting oxygen barrier specs.” Yikes. That’s not something you want to explain during a batch recall meeting.

PET might win points on clarity and rigidity—but Raman Polypropylene holds its own when it comes to chemical resistance and cold-weather durability. And if you’re trying to hit sustainability goals while keeping costs sane? Well… now we’re cooking with some serious decision stew.

This guide breaks down the trade-offs without drowning you in jargon soup—just clear pointers on performance, cost, recyclability, and real-world use cases in cosmetics. Buckle up; it’s time to talk plastics that get the job done.

Quick Answers in Clarity: The Essential Rundown on Raman Polypropylene vs PET

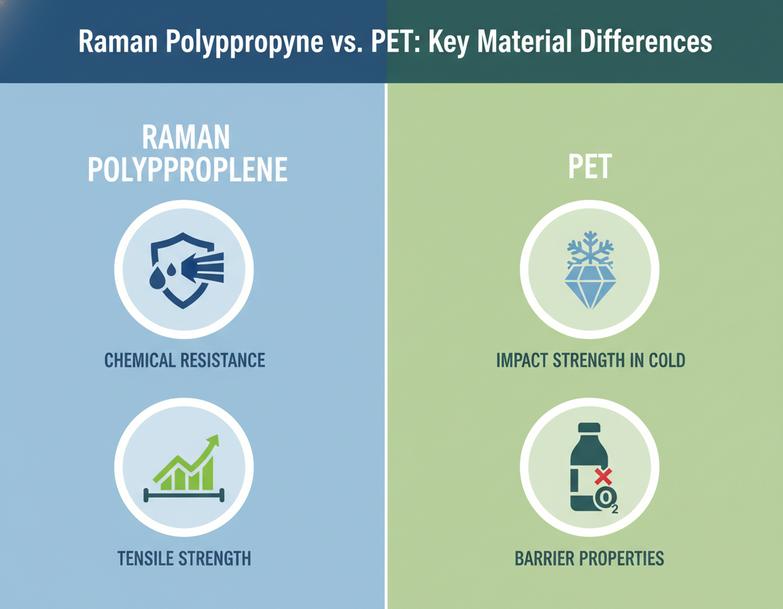

➔ Material Strength: Raman polypropylene offers better chemical resistance and tensile strength, while PET stands out for oxygen barrier performance and low-temperature impact durability.

➔ Cost Factors: Expect lower tooling and processing costs with Raman polypropylene, though PET may incur higher raw material price variability.

➔ Sustainability Snapshot: PET is easier to recycle and can include more recycled content; however, raman polypropylene tends to have a smaller carbon footprint during production.

➔ Cosmetic Compatibility: Use raman polypropylene for creams and thicker products; rely on PET when packaging liquids like foundations or serums.

➔ Manufacturing & Design: Injection molding pairs well with raman polypropylene’s mold simplicity, while blow molding techniques complement PET’s clarity in hollow forms.

Key Differences In Material Properties: Raman Polypropylene Vs Pet

Let’s break down how Raman Polypropylene stacks up against PET across critical performance traits.

Chemical Resistance: Understanding Solvent Interactions

- Raman Polypropylene shrugs off most solvents like it’s nothing—great for chemical storage or cleaning product containers.

- PET, on the flip side, can soften or degrade with prolonged exposure to certain chemicals like acetone or strong acids.

- If you’re bottling harsh stuff, polypropylene is your go-to.

In short: when things get chemically messy, polypropylene keeps its cool way better than PET.

Impact Strength: Performance in Low Temperature Conditions

• Below freezing? That’s where PET flexes hard. It holds its shape and strength even when temps drop below -20°C.

• Meanwhile, Raman Polypropylene gets a little brittle in the cold—it might crack under pressure if mishandled during winter shipping.

So yeah, if your product’s heading into a deep freeze or chilling in cold storage, PET won’t let you down.

Tensile Strength: Comparing Stress Endurance

- Pull it, stretch it—Raman Polypropylene can take more tension before snapping compared to PET.

- Its molecular chain structure gives it more give without breaking apart under steady force.

- PET’s still decent but tends to reach its limit faster under constant load.

For packaging that needs to flex without failing (like straps or caps), polypropylene wins this round hands down.

Barrier Properties: Oxygen Resistance Analysis

→ When it comes to keeping oxygen out and freshness in, PET is the heavyweight champ.

→ Oxygen sneaks through polypropylene much easier over time—bad news for anything perishable inside.

→ So if you’re sealing food, drinks, or anything that hates air? PET delivers longer shelf life and better protection.

Bottom line: for airtight defense against oxidation, PET takes the crown over Raman Polypropylene every time.

The Cost-Effectiveness Of Raman Polypropylene Vs Pet For Packaging

Quick peek into how raman polypropylene vs PET compares when it comes to cost — from raw material pricing to tooling and processing.

Analyzing Raw Material Price Fluctuations

When it comes to price swings, raw materials can make or break your budget. Here’s how things shake out between these two plastics:

- Stability wins with raman polypropylene — it’s less prone to wild market shifts, giving manufacturers fewer headaches.

- PET prices are more volatile, often influenced by oil-based derivative costs.

- Over the last 18 months, PP prices have hovered within a 7% variance range, while PET saw spikes over 15%.

A recent report by ICIS in early 2024 noted that “polypropylene markets showed remarkable resilience against energy price shocks compared to polyethylene terephthalate.” That kind of predictability is gold for long-term planning.

So if you’re chasing consistent margins and hate surprise invoices, raman polypropylene might be the calmer ride.

Tooling Costs: Mold Creation Expenses

Tooling up isn’t cheap—but some materials make it easier on your wallet:

• Mold Complexity

- PET designs often require precision cooling channels and tighter tolerances.

- Raman polypropylene allows for simpler geometries and fewer mold revisions.

• Initial Setup

- Average mold cost for small PET containers can reach $25k–$30k.

- Equivalent PP molds usually stay under $20k due to lower thermal shrinkage constraints.

• Maintenance & Lifespan

- PP molds experience less thermal fatigue; fewer replacements needed over time.

- PET molds degrade faster under high-speed production stress.

In short, if you’re setting up a production line from scratch or switching formats frequently, going with raman polypropylene vs pet could save you thousands upfront—and even more down the road.

Processing Costs: Evaluating Per Unit Production

Let’s walk through what it really costs per unit to get these plastics molded and out the door:

- Start with energy needs:

- PET typically needs higher processing temps (~260°C), meaning more power consumption per cycle.

- Add in cycle times:

- PP cools faster—shorter cycles = more units per hour = lower labor cost per unit.

- Consider waste rates:

- PP is more forgiving during molding; less scrap means better yield ratios.

- Factor in machine wear:

- High-temp processing of PET leads to quicker machine degradation over time.

So while both materials might seem close at first glance on paper, once you tally up power bills, scrap loss, and maintenance downtime—PP quietly pulls ahead on efficiency.

If you’re scaling big or aiming for lean ops, the edge goes clearly to raman polypropylene vs pet when looking at total per-unit output cost.

Environmental Impact: Comparing Raman Polypropylene And Pet

Quick look at how Raman polypropylene vs PET stack up environmentally—recycling, emissions, landfill behavior, and more.

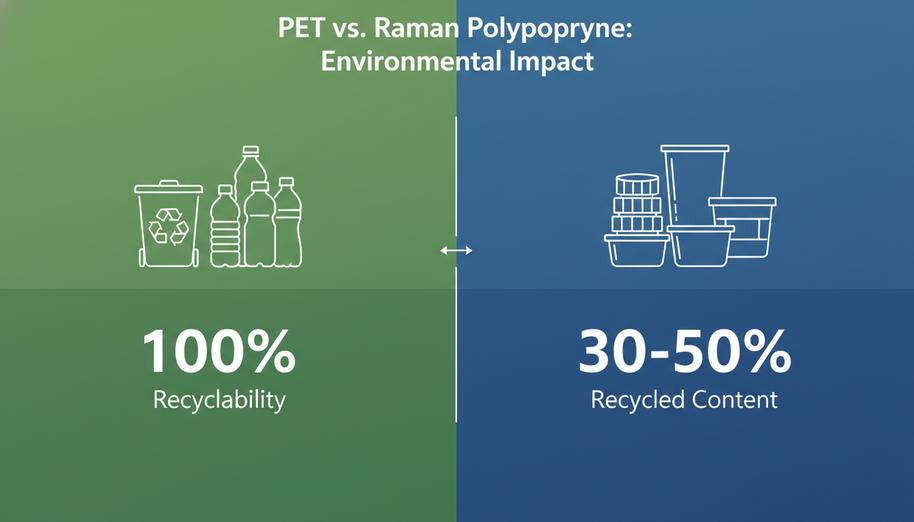

Recyclability: Potential within Current Infrastructure

- PET plastic is commonly accepted in most curbside recycling programs across the globe.

- Raman polypropylene, while recyclable, often faces rejection due to limited sorting tech.

- PET’s clear resin makes it easier for optical sorters to identify and process.

- Polypropylene tends to require manual sorting or advanced near-infrared systems.

- Municipal infrastructure favors PET due to historic investment and established demand for recycled flakes.

- Food-grade rPET is widely reused in bottles; rPP still struggles with food-contact approvals.

Carbon Footprint: Production Impact Assessment

• Making Raman polypropylene requires less energy than producing PET resin. That’s a win for emissions.

• But here’s the twist—transportation plays a role too. Lighter PP containers mean fewer emissions during shipping compared to heavier PET ones.

- Energy consumption during polymerization is lower for PP.

- PET’s higher processing temperatures increase its total carbon load per kg of material produced.

- End-of-life scenarios also matter—if recycled efficiently, both materials significantly reduce their net footprint.

Still, when looking at cradle-to-gate metrics, PP edges out as the cleaner option on paper.

Biodegradability: Performance in Landfill Conditions

Neither of these plastics break down easily:

• Both polypropylene and PET are petroleum-based and persist for decades underground.

• In anaerobic landfill conditions:

- Microbial activity slows dramatically.

- Moisture levels aren’t high enough for degradation processes.

- Light exposure (needed for photodegradation) is absent.

So yeah, tossing either into landfills? Not a great move if you care about long-term waste buildup.

Use of Recycled Content: Percentage Analysis

Let’s compare how much recycled stuff each can handle:

| Material | Max % Recycled Content | Common Applications | Food Grade Approved |

|---|---|---|---|

| PET | Up to 100% | Bottles, clamshells | Yes |

| Raman Polypropylene | Around 30–50% | Caps, tubs | Limited |

- Most beverage bottles today use 25–50% rPET without compromising clarity or strength.

- rPP often shows color variability and structural inconsistencies beyond 40%.

Bottom line? If you’re aiming for circular packaging loops, PET has the edge here too.

Regulatory Compliance: Environmental Regulations Adherence

Both materials generally meet regional environmental standards—but with caveats depending on geography and application type.

In North America and Europe, strict guidelines under agencies like the EPA or ECHA govern post-consumer resin use in food packaging:

While PET has been rigorously tested and certified by many regulatory bodies—including EFSA—for food contact applications using recycled content, Raman polypropylene’s approval pathways remain narrower due to migration concerns from contaminants during reprocessing stages.

That said, both polymers are compliant under RoHS directives when used appropriately—but only if sourced through verified supply chains that ensure traceability from origin through production output.

Usage Cases: When To Use Raman Polypropylene Or Pet

Quick breakdown of how to pick the right plastic—Raman Polypropylene or PET—based on product type, production method, decoration style, and compliance needs.

Cosmetic Product Compatibility: Best Fit for Creams and Foundations

- Raman Polypropylene is a champ with thick creams. It resists chemical reactions better than PET.

- PET, on the other hand, shines with liquid foundations. Its transparency makes shade-matching a breeze.

- Greasy or oil-rich formulas? Stick with polypropylene—it won’t warp or leach.

- For water-based serums or thinner lotions, PET’s barrier properties win out.

You’ll often see raman polypropylene vs pet debated in beauty packaging forums—mostly because their compatibility shifts depending on viscosity and formula pH.

Manufacturing Processes: Selecting Injection Molding vs Blow Molding

- Injection molding works like a charm with Raman Polypropylene, especially when precision detailing matters.

- Blow molding is where PET takes the crown—ideal for bottles and lightweight containers.

- High-volume lines love injection molding; it’s faster when you’re shaping small jars or caps.

💡 Pro tip: If your design needs complex curves or sharp edges, go with injection-molded polypropylene over PET every time.

When comparing raman polypropylene vs pet in manufacturing terms, think about tooling costs and cycle time—they shift drastically depending on your method.

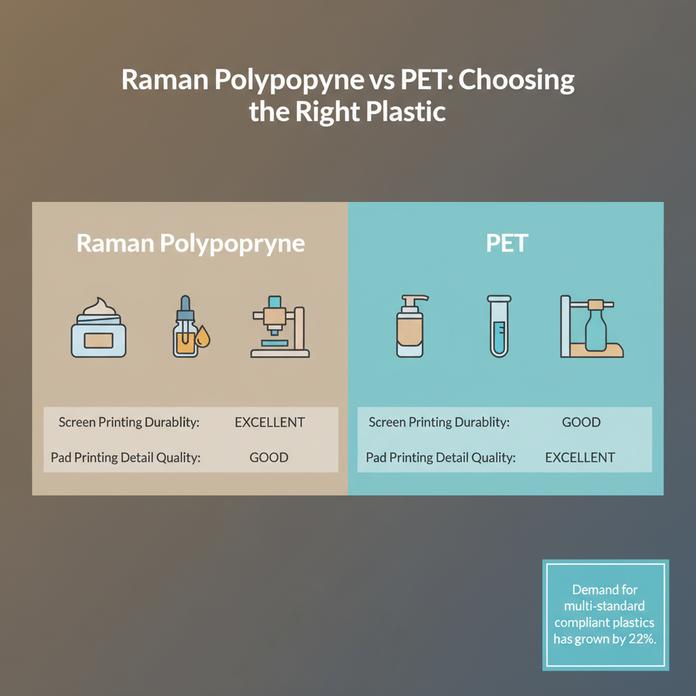

Decoration Techniques: Impact of Screen Printing vs Pad Printing

| Material Type | Screen Printing Durability | Pad Printing Detail Quality | Cost Efficiency |

|---|---|---|---|

| Raman Polypropylene | Moderate | Low | High |

| PET | High | Excellent | Medium |

Screen printing is solid across both materials—but pad printing gives PET that crisp logo finish brands crave.

If you’re deciding between raman polypropylene vs pet for custom branding work, consider how fine your design details are. The smoother surface of PET plays nicer with pad print inks.

Regulatory Compliance: Packaging Standards for Cosmetics

Multiple short insights:

- Both materials meet FDA-grade safety standards—but Raman Polypropylene often clears extra EU certifications faster.

- Brands targeting global markets favor PP due to its wider regulatory acceptance.

- “According to Mintel’s Q1 2024 Packaging Report, demand for multi-standard compliant plastics has grown by 22%, especially among indie skincare brands.”

So if you’re launching internationally and debating raman polypropylene vs pet, go with what clears customs without drama—and that’s usually PP.

Only once per product line does it make sense to switch unless you’re relabeling everything. That’s why Topfeel uses PP as their go-to base material across most powder containers.

Conclusion: Which Material Should You Choose?

Quick wrap-up for folks comparing Raman Polypropylene vs PET—let’s break it down into key traits and what that means for your wallet and the planet.

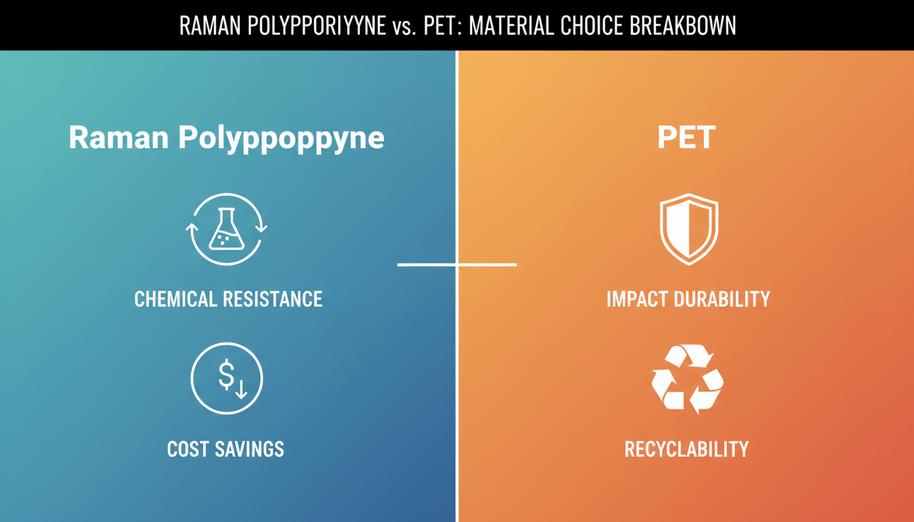

Key Takeaways on Material Properties

When you stack up Raman Polypropylene against PET, the differences are subtle but critical depending on what you’re after:

- ✅ Chemical Resistance & Strength: Raman polypropylene wins here. It resists a wide range of acids and bases, making it ideal for industrial containers or anything exposed to reactive substances.

- 💥 Impact Durability: PET is tougher when dropped or hit—it absorbs shock better, so it’s great for packaging like water bottles or food trays.

- 🔒 Barrier Performance: PET outperforms when it comes to keeping gases and moisture out—important if freshness matters.

- ⚖️ In terms of tensile strength, polypropylene pulls ahead with higher stress tolerance before breaking.

According to a recent 2024 report from Smithers Pira, “While both materials serve overlapping markets, their mechanical profiles make them suitable for distinctly different end-use priorities.”

So yeah, choosing between them? Depends on whether you need chemical toughness or physical resilience.

Final Thoughts on Cost and Sustainability Factors

Let’s talk money moves and eco vibes when picking between these two plastics:

Cost Considerations

- 🏷️ Raman polypropylene is cheaper to produce per kilogram—great if budget’s tight.

- 🔧 Lower energy input in molding processes also reduces long-term manufacturing costs.

- 🛠️ More adaptable in injection molding setups than PET.

Sustainability Snapshot

- ♻️ PET takes the crown in recyclability—widely collected curbside and turned into new products like fiberfill or new bottles.

- 🌍 Raman polypropylene recycling infrastructure is catching up but still lags behind PET globally.

- 📦 If your product needs single-use packaging with low environmental impact post-consumer, PET edges ahead.

In short: if cost-efficiency is king, go with raman polypropylene. But if sustainability goals top your list? Then PET might be your ride-or-die.

References

- PET vs. Polypropylene: The Wrong Choice Can Cost You – Inline Plastics

- Insightful Comparison: PET Bottles vs. PP Bottles in the Cosmetic Industry – Canvard Packaging

- What Is The Difference Between PET And PP Plastic? – Srlon Group

- Packaging – The British Beauty Council

- Recycled Plastics in Food Packaging – FDA

- Blow Molding vs. Injection Molding: Differences and Comparison – Xometry

FAQs

Creams and pigments can be surprisingly aggressive on packaging. Oils seep, colors stain, and over time, some containers warp or crack. Raman polypropylene handles this battle with grace—it resists chemical breakdown from thick creams and oily formulas far better than PET. That means your favorite night cream stays fresh longer, without the jar turning brittle or stained.

PET is more widely accepted by recycling centers globally.

- It’s easier to process into new bottles or fibers—think fleece jackets made from old water bottles.

- Raman polypropylene can still be recycled but often ends up downcycled due to sorting challenges.

So while both are technically recyclable, PET has a smoother path back into circulation.

Raman polypropylene tends to win here:

- Tooling costs are lower since it molds easily into complex shapes.

- Raw materials stay relatively stable in price.

- Processing efficiency reduces waste during production runs.

For brands scaling fast or managing tight margins, that adds up quickly.

PET offers a cleaner canvas for detailed designs—logos look crisp with pad printing and metallic foils shimmer beautifully after hot stamping. But don’t count out raman polypropylene: screen printing sticks well, especially for bold branding elements that need durability through daily use. Each material brings its own cute makeup packaging look and feel.