MA-67 Private Label Lip Color Tube Cosmetic Supply

Built from high-clarity PETG, the MA-67 lip gloss container offers seamless dispensing, ergonomic application, and leak protection. The flat-sided body supports hot stamping and silkscreen customization, making it perfect for brand differentiation and mass production.

Model Number: MA-67

Capacity: 6.5ml

Material: PETG, LDPE

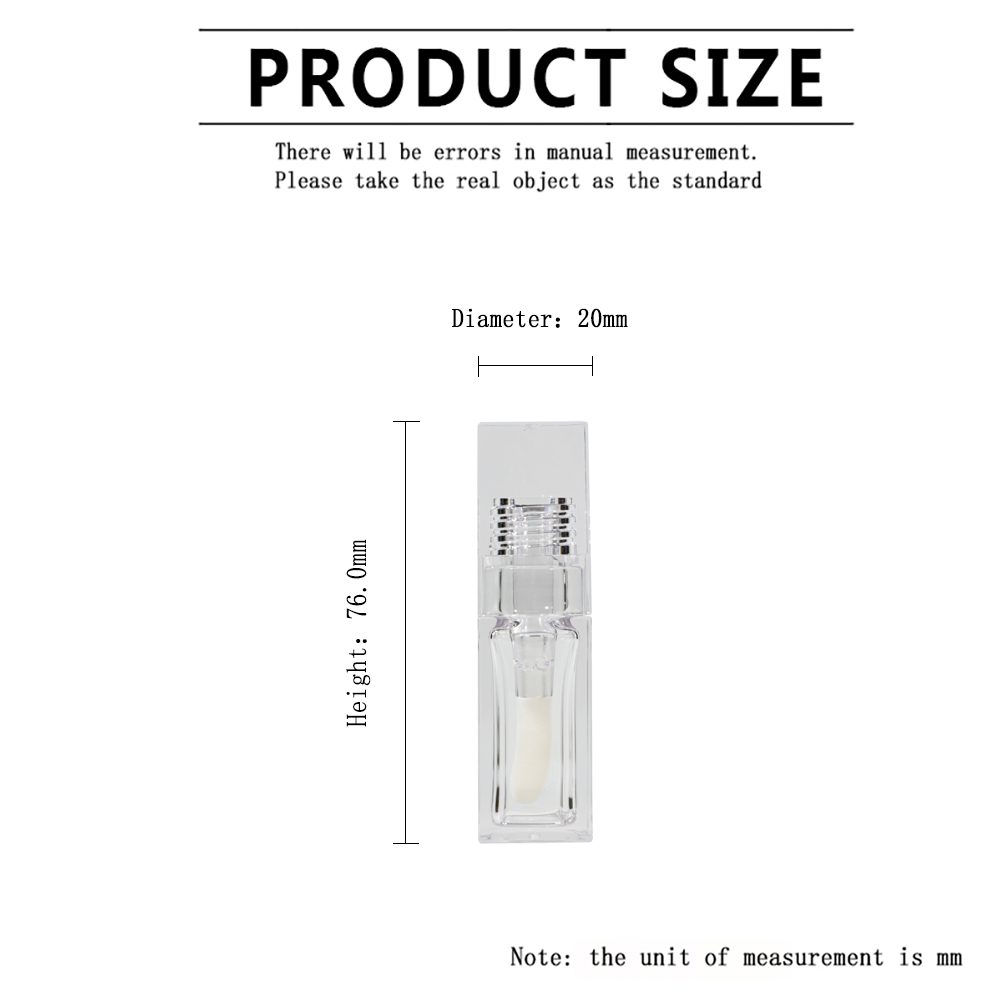

Size:

MOQ: 12,000 pcs

Application: Lip Gloss, Liquid Eyeshadow, Concealer, Serum

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color and Printing

Sample: Available

Features and advantages

-

Durable PETG structure with integrated stopper ensures leak prevention, structural strength, and compatibility with high-speed production lines.

-

Soft-tip applicator offers precision and comfort, enhancing user control for smooth application of liquid cosmetic formulas.

-

Flat-sided design supports decorative branding, with custom mold options available for exclusive private-label differentiation.

You May Also Like

View Product Details

Built for Performance

1. Unified PETG Composition

The MA-67 is constructed using 100% PETG for its bottle, cap, and applicator stem.

-

PETG (Polyethylene Terephthalate Glycol) offers high clarity while maintaining excellent chemical resistance—suitable for most cosmetic liquid formulations.

-

PETG supports UV coating, hot stamping, and silkscreen printing without compromising the material’s durability or visual transparency.

2. Leak-Preventing Inner Stopper

A small but critical feature, the LDPE (Low-Density Polyethylene) inner stopper enhances the precision of liquid dispensing. Its flexible yet secure fit provides multiple benefits:

-

Acts as a flow restrictor, controlling the amount of product retrieved per dip.

-

Reduces product oxidation and potential evaporation through tighter internal sealing.

-

Adds a barrier against accidental leakage during transport or retail handling.

For manufacturers and contract fillers, this feature contributes to lower return rates

Effortless to Apply

• Soft-Tip Applicator Wand

Integrated into the screw-on cap is a precision-engineered PETG stem topped with a soft, consumer-grade applicator. This wand was designed with user behavior in mind:

-

Provides precise product pick-up and distribution without clumping.

-

Eliminates the need for external brushes or spatulas, reducing packaging components.

-

Brand-Ready, Inside and Out

1. Flat-Sided for Decoration

Its square profile isn’t just aesthetic—it’s practical. Flat surfaces on all four sides allow:

-

Consistent alignment during automated printing or labeling processes.

-

Compatibility with multi-panel decoration, giving creative teams freedom to craft distinct visual narratives.

Flat geometry also contributes to efficient shipping and packing with less dead space, reducing secondary packaging needs.

-

Custom Mold Options Available

For brands seeking exclusive shapes or unique consumer interactions, Topfeel offers:

-

Rapid prototyping (3-day 3D model production)

-

Support for exclusive private mold ownership

-

Optimized for automated filling and capping lines,

According to the Euromonitor International 2025 Global Beauty Packaging Outlook, over 72% of mid-tier and premium beauty brands now prioritize customizable packaging formats during product development to improve shelf recognition and reduce market entry barriers.