2025 Guide: 3 Tips for Makeup Packaging Wholesale

Sourcing makeup packaging wholesale can feel like herding cats—orders run late, prices swing like crazy, and you’re stuck choosing between boring stock jars or dropping five grand on a custom mold. If you’re trying to grow your brand, those roadblocks aren’t just annoying—they’re deal-breakers.

We’ve talked to Topfeel’s OEM engineers, and one thing’s clear: “Most delays come down to poor planning and low MOQ misalignment. But that’s fixable.”

2025 is shaping up fast—sustainability’s not a nice-to-have anymore, and buyers want packaging that looks premium without the high-ticket stress. Bulk orders, smart budgeting, and private label tweaks can be game-changers if you play your cards right.

This guide breaks down three real-deal tips to help you skip the chaos and get packaging that fits your brand, budget, and timeline.

Tip 1: Packaging Delays? Leverage Bulk Ordering Solutions

Hate last-minute packaging chaos? Let’s talk real fixes—not fluffy advice. This tip is all about preventing those annoying delivery delays through smarter supply chain planning.

To validate common practices: safety stock is a widely used buffer in retail and eCommerce (see explanation), and split/partial shipments can prevent bottlenecks and speed up launches (why split shipments help). These tactics align with what we recommend below.

1. Consolidated Purchase Planning

- Look at Sales Forecasts. Start with last year’s SKU demand. A realistic sales forecast isn’t just guesswork—it’s your supply chain GPS.

- Predict Demand, Not Just Hope for It. Use demand prediction tools (like Netstock or SAP) to avoid under or over-ordering.

- Cross-Compare Product Timelines. Bundle items with overlapping production timelines. That way, you can hit MOQ requirements across SKUs with one order.

Helpful internal resources while you plan: explore Packaging for Cosmetics and our Sustainable Cosmetic Packaging insights.

2. Tiered Production Scheduling

This method’s all about breaking big orders into manageable chunks—and shipping smarter, not harder.

Step 1: Segment the Fulfillment Stages Divide your total order quantity into at least 3 fulfillment stages: pilot batch, core launch batch, and refill/restock.

Step 2: Align With Logistics Planning Work backward from your retail or eCommerce launch date. Set delivery checkpoints to match your marketing calendar.

Step 3: Use Tiered Delivery Windows Request your packaging supplier to deliver in waves—30%, 40%, then 30%. Helps keep production flowing without waiting on the full bulk load. This mirrors common partial shipment practices used to reduce time-to-market (see overview).

| Batch Type | Quantity (%) | Delivery Timeline | Use Case |

|---|---|---|---|

| Pilot Batch | 30% | T – 6 weeks | Sampling + Previews |

| Core Launch Run | 40% | T – 4 weeks | Primary Launch |

| Refill Inventory | 30% | T – 1 week | Stock Top-up & Reserve |

3. Local Buffer Stock Strategy

- Think of It as Packaging Insurance. A small safety stock of essential items—like tubes or droppers—near your production site can save your skin during customs hiccups or supplier delays (safety stock basics).

- Start with the Top 2 SKUs. Don’t overcomplicate it. Just pick your bestsellers and stock 5–10% extra inventory for them.

- Rotate Often, Waste Less. Set a 90-day shelf life for buffer stock. Every 3 months, rotate with fresh inventory to avoid holding onto aging materials.

4. Supplier Capacity Commitments

Let’s be honest—without a strong supplier relationship, your spot in the queue is fragile. Here’s how to lock it in.

➤ Partnership Contracts: Negotiate long-term deals that guarantee production slots, especially during peak season. Suppliers respect volume stability.

➤ Volume Forecast Sharing: Show them your forecasted order quantity by quarter. Transparency gets rewarded with priority.

➤ Manufacturing Contracts With Penalty Clauses: Add service-level agreements (SLAs) that define delivery windows and penalties for delays. A little legal nudge goes a long way.

➤ Strategic Alliances: Become more than just a customer. Offer joint development projects or co-marketing—this kind of collaboration can make you irreplaceable.

5. Practical Wrap-Up: Real Bulk Ordering, Not Guesswork

You can’t fix delays by yelling at your supplier. Here’s what does move the needle:

- Predict demand smartly—don’t wing it.

- Break up deliveries into scheduled bursts.

- Hold just enough safety stock nearby.

- Lock in capacity with contracts.

And don’t forget—MOQ optimization isn’t a problem; it’s a tool. It forces you to think long-term, avoid panic orders, and finally stop running out of lipstick tubes the day before launch. If you’re scaling lip color, see our lipstick tube guide or browse lip makeup packaging.

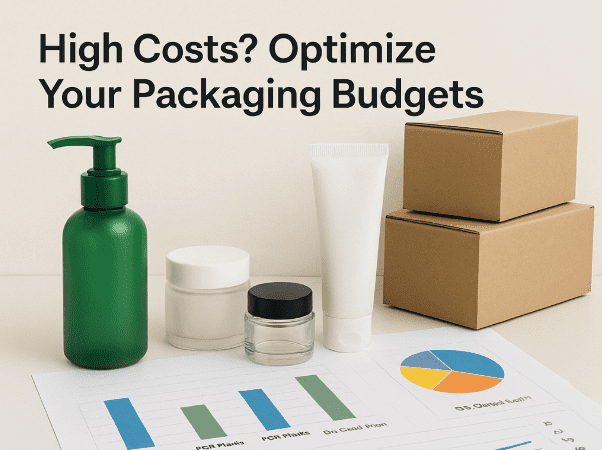

Tip 2: High Costs? Optimize Your Packaging Budgets

When margins are tight, every cent on packaging matters. Let’s unpack some smart ways to cut costs without cutting corners.

Plastic or PCR Cost Analysis

Material Cost Breakdown Plastic (especially virgin plastic) has long ruled the cosmetics world—but prices fluctuate fast. PCR (post-consumer recycled) plastic often carries a cost premium due to sorting/cleaning and feedstock constraints (market context; industry analysis). That premium is expected to narrow as capacity scales (forecast trend).

Sustainability vs. Cost Trade-Off In the EU, new Packaging and Packaging Waste Regulation (PPWR) measures and eco-modulated EPR fees incentivize recyclable designs and recycled content, which can raise the cost of non-sustainable packaging and reward better recyclability (EU overview; EPR fee modulation). Designing for recyclability (e.g., mono-material structures) can also simplify end-of-life processing (why mono-material helps; recyclability guide).

Cost Trends by Plastic Type (2024 Table)

| Material | Avg. Cost per Unit (USD) | Sustainability Score | MOQ Impact |

|---|---|---|---|

| Virgin Plastic | $0.08 | Low | Low |

| PCR Plastic | $0.11 | High | Medium |

| Bio-Based Resin | $0.15 | Very High | High |

Practical Cost Optimization Tips

- Blend PCR with virgin plastic to lower unit cost and retain eco-labeling

- Stick to mono-materials to reduce sorting/recycling costs at disposal

- Opt for matte over metallized finishes to save on coating expenses

Planning a lip launch? Compare formats using our blog deep dives: lip gloss tubes, empty lip gloss tubes, or go straight to products like transparent lip stain packaging supplier.

Paperboard Pallet Freight Savings

Step 1: Swap to Lightweight Paperboard Pallets Paperboard pallets can weigh 56–72% less than wood—meaning more product, less dead weight (weight comparison). Independent comparisons also show typical wood pallets at 30–70 lb vs. paper at ~13–16 lb (material comparison).

Step 2: Cut Down Freight Charges Less weight = lower air and sea freight costs. For international shipping, every kilo shaved off your pallets directly cuts your landed cost (landed cost primer).

Step 3: Boost Load Efficiency Because paperboard pallets are thinner, you can often stack higher. That means fewer pallets, less floor space, and fewer logistics headaches.

Step 4: Green Your Shipping Footprint Paperboard pallets are recyclable, helping you reinforce sustainability messaging with wholesale partners or eco-focused retailers.

Bulk Order MOQ Leverage

Bulk Orders Aren’t Just for Giants Even smaller brands can negotiate favorable MOQs. Suppliers often relax rules when you consolidate orders quarterly—or commit to set volumes.

MOQ = Price Power Doubling MOQ often unlocks tiered pricing. Many suppliers publish price breaks by quantity (1k / 5k / 10k). Typical ranges for cosmetics can be 1,000–3,000+ for simpler, stock-based projects (example ranges; industry context), while fully custom runs (special materials/finishes) may start at 5,000–20,000 (custom MOQs).

Negotiate Like a Pro

- Be upfront about growth plans

- Ask for tiered pricing (1k / 5k / 10k units)

- Offer visibility into your launch calendar to give suppliers production confidence

Don’t Go It Alone Join hands with fellow brands to meet MOQs together. Just make sure product categories don’t overlap—no one wants competitor twins on shelf.

Total Cost of Ownership (TCO) Breakdown

Upfront Price ≠ Final Cost

- That $0.90 jar might cost $1.40 after accounting for freight, duties, inspection, and delays

- Always ask suppliers for a landed cost estimate to see the full picture (what “landed cost” includes; another guide)

Hidden Costs to Watch

- Damage during shipping (especially with glass or airless packaging)

- Label misalignment errors requiring rework

- Storage costs from over-ordering due to unclear lead times

Your TCO Playbook

- Compare at least 2 “all-in” quotes per SKU

- Track post-launch defects for each supplier batch

- Include customs clearance time in your cost estimation model

Tip 3: Limited Customization? Explore Private Label Options

Many small brands feel boxed in by basic stock packaging—but you don’t need thousands of units to make your products pop. Private label strategies offer flexible customization without blowing your budget.

Want fast, stylish options? Check our mascara tubes, empty makeup palette, and lip gloss tubes wholesale collections.

Semi-Custom Molding Options

Want branded cosmetic containers without the heavy mold investment? Semi-custom is your golden middle ground.

- Use stock packaging like glass jars or plastic bottles as a base.

- Add private label enhancements: custom colors, embossing, or branded lids.

- MOQ is often as low as 1,000 units with 2–3 weeks lead time.

- Avoids the $3,000–$8,000 cost of full custom molds.

Think of it like personalizing a classic car—you’re using a proven frame, but with your signature paint job. It’s perfect for seasonal lines or influencer collabs where speed matters just as much as branding.

Shared Mold Libraries

Shared mold pools = factory-owned standard tooling that multiple brands can use. A cost-savvy way to get unique packaging fast.

🟡 Cost Efficiency No mold fees. Factories already have pre-built tooling—just choose, brand, and go.

🔵 Manufacturing Speed Skip the 6-week mold development. Production starts almost immediately.

🟢 Moderate Uniqueness You’re not the only one using the mold, but smart finishes (like frosting or printing) make it distinct.

“Over 65% of our startup clients opt for shared mold programs,” says Rita Zhang, Production Manager at Topfeel. “It’s a shortcut to scale, without sacrificing design flair.”

These programs are ideal for brands entering wholesale markets or testing new SKUs.

Cost-Effective Decoration Techniques

Branding doesn’t always need custom shapes—sometimes, printing does the magic. Here’s how to keep it classy and cost-effective:

- Screen Printing – Best for logos or text on caps and bottles.

- Hot Stamping – Adds metallic foil accents to lip gloss tubes or compacts.

- Label Wrapping – Full-surface branding, ideal for tubes. No tooling required and quick turnaround.

- Pad Printing – Excellent for small curved surfaces like droppers or compact lids.

Each method brings out personality without new tooling, making it perfect for short-run production or limited edition drops.

Premium Finishing with Low MOQ

Want your packaging to scream “premium” even without full customization? Try these surface treatments that suppliers offer with low minimums:

- Frosting: Gives a soft matte touch on glass or PET bottles. Sleek, minimal, and high-end.

- Metallization: Creates shiny gold or chrome effects, especially popular for caps and tube ends.

- Soft-Touch Coating: A velvety feel that enhances grip and visual appeal.

- Gradient Coating: Smooth transitions between colors, trendy for lip gloss or mascara lines.

Most of these are available starting at 1,000–3,000 units, meaning even boutique brands can match the aesthetic of major players.

See inspiration: pretty makeup packaging or product-ready items like clear cosmetic tube lip oil PETG and flat square lip gloss tube.

Where to Find Reliable Packaging Suppliers?

1. Use Verified B2B Platforms

- Alibaba & Global Sources: Start here. Use their Verified Supplier and Verified Manufacturer badges to dodge sketchy traders (Alibaba’s program uses third-party on-site checks by SGS, Intertek, TÜV, etc. — see program explainer).

- Check Reviews & Transactions: Don’t just glance—read between the lines. A supplier with 100+ completed orders is usually a safe bet.

- Chat Before You Pay: Get a feel for how responsive and transparent they are. Ghosting = red flag.

- MOQs & Custom Options: Confirm whether the supplier can handle makeup packaging wholesale volumes with customization flexibility.

Looking for specifics? Our blog covers custom cosmetic packaging and category primers like mascara tube or lip gloss tube.

2. Attend Trade Shows & Virtual Expos

🛫 Why Attend Trade fairs like Cosmoprof Bologna and Beautyworld Middle East offer real-time exposure to packaging innovations—far beyond what online catalogs show (2025 exhibitor directory and packaging zones are already live).

👥 Who’s There You’ll meet suppliers, designers, logistics pros, and even OEM coordinators. Face-to-face chats build trust quicker than emails.

📦 What You Get Physical samples on the spot, updated catalogs, and better price negotiation by showing you’re serious. (For context on 2025 Bologna dates/scale, see this event overview.)

3. Evaluate Through Supplier Audits

3 Key Actions to Ensure Quality:

- Request a factory audit report (e.g., ISO 9001 quality systems or ISO 22716 cosmetics GMP) to confirm standards (ISO 9001 overview; ISO 22716 scope).

- Ask for a compliance checklist (covering labor, environment, and product testing).

- Verify recent QC pass rates for specific product types (e.g., tubes, jars).

| Supplier Name | ISO Certified | QC Pass Rate | Audit Date |

|---|---|---|---|

| TopfeelPack | ✅ ISO 9001 | 98% | May 2025 |

| BeautyBox Co. | ❌ | 83% | Jan 2024 |

| GlamTube Inc. | ✅ ISO 22716 | 95% | Mar 2025 |

Use this type of data to filter serious manufacturers from flashy one-timers.

4. Partner with Local Sourcing Agents

They speak the language (literally) Your sourcing agent in Yiwu or Guangzhou understands both Mandarin and market terms. They cut through the noise.

They know which factories are all talk Sourcing agents can physically visit suppliers, check actual facilities (not showroom façades), and send you unfiltered photos/videos.

They reduce freight headaches By coordinating pickup, labeling, and inspection, they simplify packaging logistics from the ground up.

Quick FAQ Enhancements (with validation)

- What’s the difference between airless and standard pumps? Airless pumps use a piston and no dip tube, limiting air ingress and helping sensitive formulas, while standard pumps draw product via a dip tube and allow air in as you dispense (how airless works; comparison). Browse our airless-friendly lip gloss tubes and mascara tubes.

- What’s a normal MOQ? For stock-based packaging, 1,000–3,000 per SKU is common; more customized projects often start higher (e.g., 5,000–20,000+) (ranges explained; custom context). If you’re testing, explore our wholesale lip gloss tubes options.

Conclusion

Sourcing for makeup packaging wholesale doesn’t have to feel like running a marathon with no finish line. You’ve got delays, tight budgets, and customization headaches—but those don’t have to be dealbreakers. The good news? With the right prep and partners, all of that is fixable without burning out or blowing your margins.

Before you jump into your next big order, keep these in your back pocket:

- Lock in suppliers early to skip last-minute scrambles

- Don’t just chase the lowest price—check the full costs

- Split MOQs or pool orders when your volume’s tight

- Customize smart: semi-custom beats fully custom for speed and cost

- Vet your vendors—ask for proof, not promises

If you need fast-moving SKUs, start here: lip gloss tubes, empty palette, mascara tube, or our broader face makeup packaging range.

References

- European Commission — Packaging waste & PPWR (policy overview) — https://environment.ec.europa.eu/topics/waste-and-recycling/packaging-waste_en (Environment)

- K&L Gates — New EU Packaging and Packaging Waste Regulation (EPR fee modulation) — https://www.khlaw.com/insights/new-eu-packaging-and-packaging-waste-regulation-highlights-and-challenges-ahead (Keller and Heckman)

- S&P Global Commodity Insights — PCR vs. virgin competitiveness & pricing — https://www.spglobal.com/commodity-insights/ (S&P Global)

- Precision Business Insights — PCR plastic packaging: cost drivers & constraints — https://www.precisionbusinessinsights.com/ (Precision Business Insights)

- Mordor Intelligence — PCR premium trend outlook — https://www.mordorintelligence.com/industry-reports/pcr-packaging-market (Mordor Intelligence)

- Berlin Packaging — Why mono-material packaging simplifies recycling — https://www.berlinpackaging.com/insights/sustainability/mono-material-packaging-simplifies-the-recycling-process (Berlin Packaging)

- UPM Raflatac — Packaging Recyclability Guide — https://www.upmraflatac.com/siteassets/documents/sustainability/upmr-packaging-recyclability-guide.pdf (upmraflatac.com)

- Raymond West — Paper pallets are 56–72% lighter than wood — https://www.raymondwest.com/learn/blog/2020/dec/paper-pallets (Raymond West)

- GCB — Corrugated paper vs wooden pallets (weights) — https://gcb.com.my/corrugated-paper-pallets-vs-wooden-pallets-comparing-materials/ (GCB)

- Freightos — Landed cost explained — https://www.freightos.com/freight-resources/understanding-landed-cost-and-profitability/ (Freightos)

- Drip Capital — Landed cost components — https://www.dripcapital.com/en-us/resources/blog/landed-cost (dripcapital.com)

- Shopify — Safety stock vs. reorder point — https://www.shopify.com/retail/safety-stock-vs-reorder-point (Shopify)

- Narvar — Why split shipments help customers — https://corp.narvar.com/blog/why-are-split-shipments-becoming-so-common (corp.narvar.com)

- Alibaba — Verified Supplier program — https://seller.alibaba.com/eu/en/verified-supplier (Alibaba.com Seller Central)

- Alibaba — Verified Suppliers overview (SGS/Intertek/TÜV on-site) — https://fuwu.alibaba.com/page/verifiedsuppliers.htm (fuwu.alibaba.com)

- Global Sources — What is a Verified Supplier — https://www.globalsources.com/knowledge/what-is-a-verified-supplier-on-globalsources-com/ (Global Sources)

- Cosmoprof Worldwide Bologna — official site — https://www.cosmoprof.com/en/ (COSMOPROF)

- Beautyworld Middle East — official site — https://beautyworld-middle-east.ae.messefrankfurt.com/dubai/en.html (beautyworld-middle-east.ae.messefrankfurt.com)

- Wonnda — Cosmoprof Bologna 2025 overview (dates/scale) — https://wonnda.com/magazine/cosmoprof-bologna/ (Wonnda)

- ISO — ISO 22716 (Cosmetics GMP) abstract — https://www.iso.org/standard/36437.html (ISO)

- ISO — ISO 9001 (QMS) overview — https://www.iso.org/standard/62085.html (ISO)

- Richmond Group — Airless pump vs lotion pump explanation — https://www.richmondgroup.com/news-insights/insights/what-is-the-difference-between-a-lotion-pump-and-an-airless-pump (Richmond)

- Lisson — Airless vs. standard pump tubes — https://www.lissonpackaging.com/airless-pump-tubes-vs-standard-pump-tubes-what-s-the-difference.html (Lisson Packaging)

- Fortune International (Cosmetic Manufacturing) — MOQ ranges — https://fortuneinternational.co.in/blog/understanding-minimum-order-quantities-in-cosmetic-manufacturing/ (Fortune International)

- Blackbird Skincare — Low MOQ context — https://web.blackbirdskincare.com/pros-and-cons-of-low-moq-skincare/ (Blackbird Skincare)

- Gideapac — Cosmetic packaging MOQ ranges for custom — https://gideapac.com/everything-you-need-to-know-about-minimum-order-quantity-in-the-cosmetic-packaging-industry/ (Gidea PAC)

FAQs

Skip complex packaging. Go for simpler shapes, shared molds, and larger volumes when possible.

Ask suppliers for volume price breaks. Stick to one material per product when you can—mixing glass with metal or bamboo adds cost quickly.

Start with verified B2B platforms like Alibaba Gold, Made-in-China, or TradeWheel. Look for:

- Verified manufacturers with real photos

- Supplier audit reports (like ISO or SMETA)

- References from real clients

If possible, hire a local agent to check the factory before paying big deposits.

The main difference? How they push product out—and how much air gets in.

- Airless pumps: Push from the bottom up, no air inside. Ideal for serums and sensitive formulas.

- Standard pumps: Use a dip tube. Good for lotions, but air can enter the container.

If shelf life or formula stability matters, go airless.

Yes, you don’t always need custom tooling. Many manufacturers offer standard packaging that can still look unique.

With screen printing, hot stamping, or label wraps, your product can stand out without spending thousands on new molds. These options keep the process fast and more affordable.

MOQ stands for minimum order quantity—the smallest amount a supplier will accept. It changes based on packaging type.

- Bottles or tubes: around 1,000 to 3,000 units

- Custom prints or finishes: may start at 5,000+

- Glass or specialty items: usually need more

If you’re testing a product line, some suppliers offer lower MOQs on stock items.

Delays usually hit during last-minute orders or unclear specs. You can avoid most of them by working smarter:

- Place orders before busy seasons like Q4

- Lock in factory slots in advance

- Use partial shipments so your launch isn’t stalled

- Keep extras of caps or jars in stock, just in case

Quick tip: Pre-approve all artwork and labels early to skip unnecessary back-and-forth.