Loose Powder Containers: Wholesale Benefits and Discounts

You know what’s wild? In a world where setting powder is basically fairy dust for your face, the humble loose powder container is doing some serious heavy lifting. If you’re running a cosmetics brand—big or boutique—you’ve felt the squeeze: packaging costs creeping up, orders stuck in limbo, and lids that just don’t seal right (cue the glitter bomb in aisle five). Skimp on containers and your product loses its sparkle—literally.

Thing is, buying smart means buying wholesale. Bulk orders bring down cost-per-unit faster than a flash sale at Sephora—and unlock perks like custom logos, tighter seals, and sturdy jars that can brave cross-country shipping without cracking under pressure. Smart brands aren’t just selling makeup; they’re packing ambition into every pot of powder.

Quick Answers for the Loose Powder Container Hustle

-

Bulk Orders Slash Costs: Volume pricing on loose powder containers significantly reduces per-unit costs—especially when ordering by pallet.

-

Material Matters: Plastic jars offer cost savings and impact resistance, while glass adds premium appeal but demands foam-padded shipping cases to prevent breakage.

-

Lid Logic: Snap lids and interlocking closures are ideal for compact storage and safe transport; tamper-evident seals boost consumer trust across cosmetic and food powders alike.

-

Customization Perks: Higher volume orders unlock custom labeling options—boosting your brand’s shelf presence without blowing the budget.

-

Stackability Saves Space: Stackable designs in plastic, aluminum, and glass mean smarter warehouse layouts—and fewer crushed dreams during delivery runs.

-

Safety First for Industrial Needs: Child-resistant closures and reinforced packaging are essential when handling pharmaceutical or industrial powders in bulk vessels.

-

Know Your Powder Type: Pricing varies based on whether you’re filling containers with glittery cosmetics or gritty chemical blends—match container type to product need for best ROI.

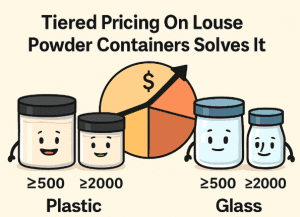

Tiered Pricing On Loose Powder Containers Solves It

Wholesale buying isn’t just smart—it’s strategic when you’re sourcing packaging like powder jars and drums.

How Volume Pricing Reduces Costs on Wholesale Jars

- Volume pricing kicks in once you cross certain quantity thresholds—think hundreds, not dozens.

- That means lower per-unit costs, especially when ordering standard sizes.

- The more units you snag, the deeper the discounts go.

- For businesses scaling up, this can shave thousands off annual packaging expenses.

When you’re dealing with thousands of plastic jar units per month, every penny counts—especially if you’re filling them with bath soaks or setting powders.

Tiered Wholesale Rates for Plastic vs. Glass Containers

Plastic jars and glass vessels don’t play by the same rules when it comes to wholesale rates.

🔹 Glass containers often carry higher base costs but offer premium appeal—great for high-end cosmetic powders.

🔹 In contrast, plastic options are lighter and cheaper to ship, making them ideal when margins matter more than aesthetics.

Pricing by Powder Type: From Cosmetic to Industrial

Different powders need different homes—and that affects how much you’ll pay per container.

“According to Packaging Strategies’ Q3 Market Report,” says Drayton & Co., “container compatibility drives over half of procurement decisions in powdered goods manufacturing.”

• Fine-grain cosmetic blends may demand airtight seals and UV-resistant materials—raising container costs by up to 30%.

• Industrial-grade powders like lime or cement fillers? They’re less picky but require rugged builds—often metal-lined plastic drums or reinforced barrels.

So yeah, what goes inside seriously shapes what you’ll spend outside.

Unlocking Custom Labeling at Higher Discounts

Custom labels aren’t just about looking good—they’re about selling faster on shelves or online carts.

Here’s how volume plays into branding:

1️⃣ Hit higher MOQs on containers and label printing vendors start offering combo deals—like free design tweaks or foil stamping upgrades.

2️⃣ Pairing custom labeling with high-volume orders can drop your total cost-per-package by up to 20%, thanks to bundled production runs.

3️⃣ This is where the magic happens: brands suddenly look boutique without blowing their budget.

When your product line includes everything from blush refills to powdered supplements, unlocking these branding perks through bulk ordering is a no-brainer—even if you’re still bootstrapping it from your garage workshop.

Let’s face it: if your jar looks pro-level out of the box? You’ve already won half the sale before they even unscrew the lid.

3 Steps To Secure Powder Container Bulk Discounts

Nailing down container deals isn’t just about buying in bulk—it’s about knowing what you need, how to talk money, and sealing it smart.

Assessing Container Requirements for Cosmetic and Food Powders

Before you even think about price tags, get your specs straight. Different powders act differently—moisture-sensitive blush powder isn’t going to sit pretty in the same jar as a dense protein mix.

- Powder properties like granularity and moisture absorption determine if your container needs an airtight seal or UV protection.

- Container materials should match functionality—PET plastic might work for dry food blends but not oily cosmetics.

- Regulatory compliance matters—especially for cosmetic powders, where FDA packaging standards come into play.

- Volume counts too; bulkier items may require stackable drums over jars or tins.

Don’t forget: poorly matched containers can cost more long-term through spoilage or recalls. For anyone handling loose product types like finishing dusts or baking blends, choosing the right fit upfront is half the battle when chasing discounts on large orders.

Finalizing Orders with Tamper-Evident Seals and Custom Labeling

Once you’ve got quantity and price nailed down, it’s time to wrap things up tight—literally and figuratively—with security features and branding polish.

⦿ Add tamper-evident seals tailored for your product type; heat-shrink bands work well for food-grade drums while breakaway lids suit fine cosmetic powder batches.

⦿ Consider custom labeling not just for branding but also regulatory compliance (ingredient declarations, batch codes).

Grouped essentials:

- Order fulfillment:

- Confirm lead times

- Cross-check order specs against sample approvals

- Request pre-shipment photos if overseas

- Packaging standards:

- Match label adhesives with drum surface material

- Ensure seals survive transit temperatures

- Shipping requirements:

- Choose palletized freight if over 500 lbs.

- Ask about insurance options during transit

| Feature | Cosmetic Use Case | Food Use Case | Notes |

|---|---|---|---|

| Tamper Seal Type | Breakaway cap | Heat shrink band | Based on consumer expectations |

| Label Adhesive | Low-tack (easy peel) | Permanent adhesive | Varies by drum material |

| Minimum Order Quantity | 250 units | 500 units | Impacts pricing tier |

| Custom Print Lead Time | Up to 10 business days | Up to 7 business days | Plan ahead |

Even small changes at this stage can make or break how your loose powder container line performs once it hits shelves—or customs checks.

Reinforced Packaging To Prevent Breakage

Strong packaging isn’t just a nice-to-have—it’s survival gear for fragile and heavy-duty containers during shipping.

Why Glass Jars Need Foam-Padded Shipping Cases

• Glass breaks. That’s no secret—but when you’re shipping a truckload of glass jars, even a small bump can cause major losses.

• Foam padding absorbs shock on impact, reducing the chance of fractures or chips.

• Wholesale distributors often opt for custom-fit foam inserts that hug each jar tightly inside rigid shipping cases, adding both stability and protection.

• For fragile goods like these, choosing the right type of foam—whether polyethylene, polyurethane, or EVA—can make all the difference.

Snap-Lid Plastic Jars: Impact-Resistant Design

-

The snap-lid isn’t just about convenience—it’s part of what makes these plastic jars so tough under pressure.

-

Their design disperses force across the surface instead of letting it concentrate at stress points.

-

Many models now feature reinforced corners and thicker walls near the lid for added durability during rough handling.

-

These upgrades have made them a go-to option for businesses looking to ship bulk orders without worrying about breakage mid-transit.

Child-Resistant Closures with Protective Outer Packaging

Grouped by function:

Safety Mechanism:

• The twist-and-push mechanism on most child-resistant closures prevents accidental opening by young children.

• These are tested under strict protocols to meet safety standards like ASTM D3475.

Packaging Armor:

• Products are often housed within an additional box or clamshell case that provides outer-layer defense against drops and tampering.

Tamper-Evidence:

• Seals and shrink bands around the cap area add visual confirmation that nothing’s been opened before it hits store shelves.

Combined, this approach ensures contents stay safe from both curious hands and careless handling during transport.

Loose Powder Containers Travel Best With Hybrid Protection

Loose powder? It’s sneaky—leaks through seams, shifts with every bump, clings to everything if spilled. That’s why hybrid protection works best:

- Rigid outer shells prevent crushing under stacked loads during warehouse storage.

- Inner seals keep fine particles locked tight inside.

- Cushioning foam buffers any jolt from sudden stops or careless drops.

- Tamper bands offer peace of mind on store shelves.

- A snug fit between lid and base keeps air out—and product fresh longer.

When you’re dealing with powders inside compact plastic vessels, every layer counts—from seal to shell to carton outside it all.

Combining Materials for Custom Container Protection

Sometimes off-the-shelf won’t cut it—you need tailored solutions based on container type:

• For glass-based options like essential oil bottles or spice jars? Pair foam-lined boxes with corrugated partitions that separate each unit individually.

• If your product comes in thick-walled plastic tubs? Use molded pulp trays fitted into double-wall cartons—they absorb shock without adding excess weight.

• Shipping metal tins filled with loose powder blends? Go full industrial—wrap each tin in kraft paper before stacking them into padded crates lined with fiberboard panels for extra rigidity on long hauls.

Mixing materials lets you adapt protection levels precisely where needed—and avoid overpacking where you don’t need it at all.

Stackable Container Designs For Compact Storage

Smart storage starts with clever design. These stackable options don’t just save space—they change the game for powder packaging and bulk handling.

Interlocking Lids on Plastic Bulk Jars

When it comes to securing your stash, interlocking lids on plastic jars bring both brains and brawn. Here’s how they make life easier:

- Snap-lock grooves prevent tipping when stacked high.

- Wide-mouth tops allow easy scooping without spillage.

- Durable polymers resist cracking under pressure.

- Reusable builds reduce waste and cost over time.

With a tight secure closure, these jars are perfect for everything from protein blends to bath salts. If you’re storing any kind of loose fill—especially finely milled powders—this style keeps contents safe while maximizing shelf real estate. Think wholesale shops, craft rooms, or even commercial kitchens; stack ’em up and forget the clutter.

Nested Aluminum Containers for Vertical Efficiency

If you’re working with limited vertical space but need something sturdy, nested containers made from lightweight aluminum are a slick solution. Their compact form hides serious utility:

• Nest inside each other when empty—ideal for return logistics.

• Rust-resistant surfaces keep powders dry and uncontaminated.

• Smooth interiors prevent clumping or residue build-up.

Grouped into two key types:

— Small-batch tins for artisan spice blends or cosmetic powders.

— Large nested cylinders used in labs or light manufacturing.

Because they’re feather-light yet tough, these containers are often chosen by mobile vendors and boutique brands alike looking to store finely sifted product without fuss.

Stackable Glass Vessels with Induction Sealing

Glass might seem fragile, but don’t let that fool you—it’s a powerhouse when paired with modern sealing tech like induction liners. These stackable vessels combine elegance with airtight performance:

- A silicone-sealed rim hugs the neck snugly before induction sealing kicks in.

- Electromagnetic pulses bond foil closures directly onto the jar mouth.

- The result? Zero air exchange and peak freshness retention.

“According to Mintel Packaging Trends Report, over 60% of consumers trust glass packaging more when it includes tamper-evident features like induction seals.”

Perfect for luxury skincare dusts or gourmet spice mixes, these containers offer both visibility and protection—a rare combo that elevates any shelf presence while keeping your loose fill pristine.

FAQs

Bulk orders bring more than just savings. They simplify operations, reduce per-unit costs, and open doors to perks like custom branding and freight optimization. For businesses scaling up or managing multiple product lines, pallets of stackable containers can turn chaos into smooth logistics.

Absolutely. The nature of your powder often dictates the best material:

- Glass is popular for cosmetics—sleek, clear, and premium-looking.

- Plastic suits food-grade powders due to its lightweight and shatterproof qualities.

- Industrial powders need something tougher—steel or aluminum drums get the job done when durability matters most.

Yes—and it’s worth considering if you’re shipping products that require trust at first glance. Tamper-evident lids or shrink bands not only protect contents but also reassure customers that what they’re opening hasn’t been touched since leaving your hands.

Once you hit a certain quantity threshold, many suppliers offer discounted custom labeling services. That means your logo on every jar or drum—not just packaging tape slapped on boxes. It’s a small detail with big impact when those containers land on retail shelves or client workstations.

Definitely. A glass jar needs padding; an industrial drum wants strapping down tight:

- Foam inserts cushion fragile items like cosmetic jars.

- Snap-lid plastic jars travel well thanks to their shock-resistant build.

- Metal drums ride securely in crates built specifically for weight distribution during long hauls.

Stackability plays a huge role here—but it’s not all about shape:

- Interlocking lids prevent toppling during storage.

- Induction-sealed glass adds stability while keeping contents fresh.And those nested aluminum units? They save space by sliding right into each other like puzzle pieces made for efficiency.