The Ultimate Guide to Lipstick Tubes: Materials and More

A lipstick might be tiny—but oh, the drama it holds. From the click of the cap to that buttery twist-up moment, lipstick tubes do more than house color—they carry your brand’s soul. And if you’re staring down a hundred decisions about materials, closures, or how to keep costs from spiraling faster than a viral makeup tutorial… welcome. You’re in exactly the right place.

This guide unpacks what seasoned packaging engineers call “the quiet heroes of cosmetic branding.” We’re talking plastics that hustle on production lines, aluminum that screams luxury without saying a word, plus tricks to shave cents off every unit when you’re ordering by the thousands.

Quick Answers in a Twist: Lipstick Tubes from Shell to Shine

→ Material Matchmaking: Plastic is durable and cost-effective, while aluminum elevates luxury branding—choose based on target market and budget.

→ Volume Wisdom: Standard sizes like 15 ml, 30 ml, and 50 ml dominate; align your selection with product weight and consumer expectations.

→ Closure Smarts: Snap fit speeds up production; twist-up adds premium flair—know your priorities between function and feel.

→ Bulk Buying Power: Ordering lipstick tubes in high volume unlocks savings across materials, closures, labeling, and sleeves.

→ Decoration Decisions: Hot stamping lasts longer than screen printing; embossing adds luxury texture for metal shells.

→ Eco-Edge Options: Paperboard cases are biodegradable alternatives for brands leaning into sustainability without sacrificing form.

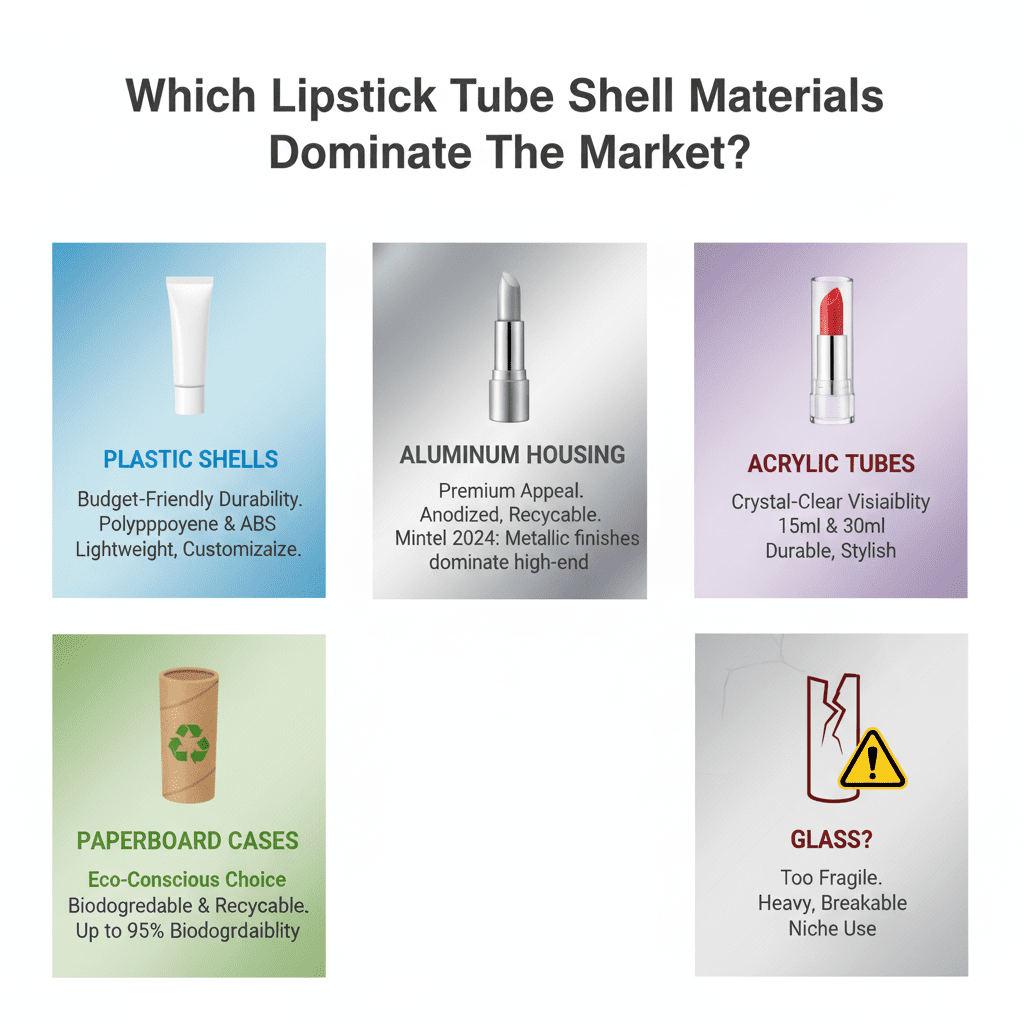

Which Lipstick Tube Shell Materials Dominate The Market?

A quick dive into the materials shaping your favorite lip color’s outer shell—from flashy metals to eco-loving papers, here’s what rules the game.

Plastic Shells: Budget-Friendly Durability

- Polypropylene and ABS plastics are top picks for their low cost and solid build.

- These shells are made using injection molding, which keeps production fast and affordable.

- They’re lightweight, super customizable, and tough enough for everyday use.

💡 Most drugstore brands rely on plastic because it balances price with protection.

But don’t be fooled—cheap doesn’t mean boring. With textures, colors, and finishes galore, plastic shells can still turn heads while keeping your balm or tint safe on the go.

Sleek Aluminum Housing for Premium Appeal

- Anodized aluminum gives off that cool-to-the-touch vibe that screams luxury.

- It’s also lightweight, making it perfect for upscale but portable lipstick packaging.

- Brands love its recyclable nature—it’s green without losing glam points.

Aluminum isn’t just about looks either; it’s tough against dents and scratches, keeping that premium feel intact even after months inside a purse or clutch.

According to Mintel’s Global Packaging Trends Report (2024), “metallic finishes continue to dominate high-end beauty packaging due to their perceived value and durability.”

Crystal-Clear Acrylic Tubes in 15 ml & 30 ml

• Transparent? Check. Durable? Double check. Stylish? Always!

• These acrylic tubes let users see the shade before they swipe—no guessing games here.

• Available mostly in 15 ml or 30 ml, they’re common among glosses and balms where visual appeal matters most.

The combo of clarity with cosmetic-grade toughness makes acrylic a go-to when brands want both form and function—especially when showcasing bold pigments or shimmering finishes through crystal-clear bodies.

Eco-Conscious Paperboard Cases for 5 ml to 50 ml

Paperboard lipstick holders are catching fire among eco-aware shoppers—and not just because they’re cute:

- 🌱 Made from biodegradable fibers

- ♻️ Fully recyclable after use

- 📦 Sizes range from compact 5 ml minis to generous 50 ml formats

- 🖨️ Often printed with soy-based inks for added sustainability cred

These cases scream “I care” without shouting it obnoxiously. They’re also surprisingly sturdy thanks to layered construction techniques that resist crushing better than you’d think.

Here’s how popular paperboard usage stacks up across different volume ranges:

| Volume Range | Common Use Case | Avg Lifespan (Weeks) | Biodegradability (%) |

|---|---|---|---|

| ≤10 ml | Sample-size lip tints | ~4 | ~95 |

| ~15–20 ml | Standard balms | ~6 | ~90 |

| ~30–35 ml | Glossy tubes | ~7 | ~85 |

| ≥50 ml | Multipurpose sticks | ~8 | ~80 |

Is Glass Too Fragile for Lipstick Tubes?

Glass sounds fancy—but here’s the rub:

1️⃣ It’s heavy as heck compared to other options like plastic or aluminum.

2️⃣ One drop? Boom—shattered dreams (and glass).

3️⃣ While undeniably elegant, its practicality is often questioned by manufacturers.

Still, some niche brands flirt with glass due to its luxe weight and glossy finish—but most steer clear because of breakage risk during shipping or daily use.

As Topfeel noted at Cosmoprof Asia last year, “The demand curve always dips when fragility outweighs aesthetic payoff.”

So yeah—glass might look high-end but doesn’t quite pass the durability test when it comes to everyday glam gear like lipstick containers.

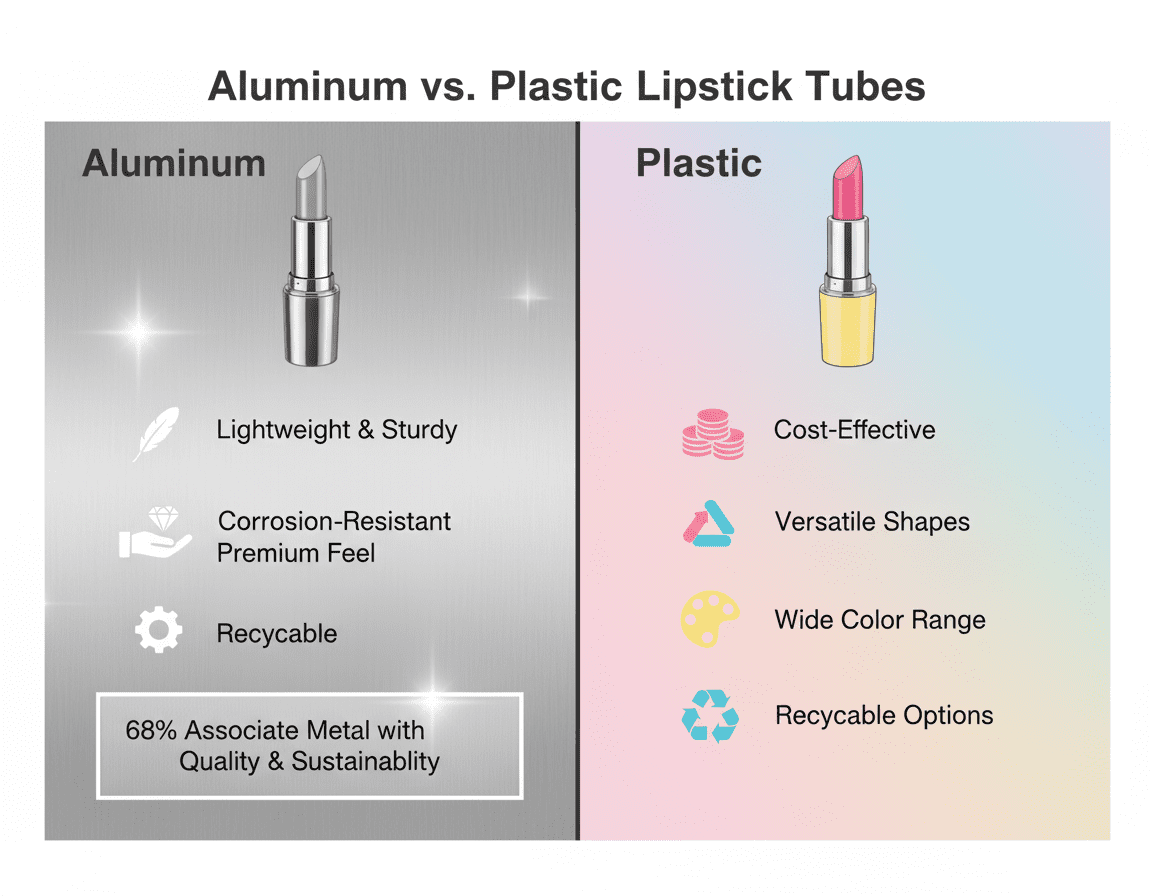

Aluminum Vs. Plastic Lipstick Tubes

Choosing between aluminum and plastic containers can shape how your lip color brand feels in the hand—and in the heart.

Aluminum

Aluminum lipstick cases aren’t just about looks—they’re a whole vibe built on substance.

- Lightweight but sturdy, they bring a sleek touch without weighing down your bag or pocket.

- Their corrosion-resistant nature keeps them looking sharp even after months of use.

- The premium feel makes them a go-to choice when brands want to scream luxury without saying a word.

You’ll also find that these metal tubes are often more durable, making them ideal if you’re tired of cracked caps or flimsy twist mechanisms. They’re not just pretty; they last.

According to Mintel’s Global Packaging Trends Report released in early 2024, over 68% of consumers associate metal packaging with higher quality and sustainability—a stat that continues to nudge upscale cosmetic lines toward embracing more recyclable, elegant formats like aluminum.

Plastic

Plastic lipstick holders are the Swiss Army knives of cosmetics—flexible, affordable, and always ready to adapt.

- They’re super cost-effective, which is perfect when you’re producing at scale or targeting budget-conscious buyers.

- With endless mold possibilities, these tubes can be shaped into anything from sleek cylinders to funky geometric forms—talk about being versatile!

- You’ve got tons of color options, too; whether you want classic black or neon pink, plastic delivers with its wide range of hues and finishes.

Some versions now come with partial bio-based materials or post-consumer resins, offering new-age options that still fall under the umbrella of “recyclable options.” While they may lack the high-end charm of aluminum, their affordability and flexibility make them an easy win across mass-market lines.

And yes—you’ll spot plenty of Topfeel designs using both materials smartly depending on collection goals and price points.

Packaging Costs Too High? Bulk Tube Ordering Solves It

Smart packaging doesn’t have to drain your budget—bulk ordering opens the door to serious savings without skimping on quality.

Volume Discounts for 15 ml, 30 ml, and 50 ml Lipstick Tubes

When you’re scaling up, those pennies add up fast. Here’s how bulk buying trims the fat:

• Buying more means paying less per unit—especially when you’re dealing with volume discounts on 15 ml tubes, 30 ml tubes, or even larger 50 ml tubes.

• Mix-and-match sizing options let you diversify without sacrificing price breaks.

→ If you’re running multiple shades or formulas, sticking to standardized tube sizes can streamline logistics and reduce waste.

A recent report by Global Packaging Trends Review Q2/2024 noted that “unit cost drops by an average of 28% when purchasing beyond the MOQ threshold in cosmetics packaging.”

Topfeel’s scaled pricing model gives brands room to grow while keeping costs lean.

Snap Fit and Screw Cap Closure Deals in High-Volume Runs

Closures aren’t just functional—they’re part of your product’s vibe. In high-volume runs, these details get cheaper:

▪️ Snap fit closure options are ideal for quick-use products—easy open, easy close.

▪️ Prefer something secure? Go with a screw cap closure, especially if your formula is sensitive to air exposure.

▪️ Bulk orders unlock access to wholesale pricing tiers that make even premium closures affordable.

▪️ Combine closures with specific tube volumes for added efficiency in filling lines.

This combo flexibility helps you fine-tune both aesthetic and function while keeping production streamlined across all sizes of lipstick-style containers.

Bulk Hot Stamping & Labeling for Consistent Branding

Consistency is king when it comes to branding. That’s where bulk decoration really shines—literally and figuratively. With large orders, custom touches like bulk hot stamping or precision labeling become cost-effective add-ons rather than luxuries.

Your logo pops every time, whether it’s metallic foil or matte ink laid down perfectly across hundreds—or thousands—of units. These methods not only elevate the look but also ensure repeat customers recognize your product instantly on shelves or social feeds.

By locking in uniform finishes across batches, you avoid mismatched designs that scream amateur hour—and instead build trust through polished presentation from cap to base.

Negotiating Paperboard Sleeve and Palette Bundles

Bulk packaging isn’t just about tubes—it’s about what wraps around them too:

- Bundle deals on outer packaging like custom-fit paperboard sleeves cut down printing costs dramatically.

- Palletizing strategies lower freight charges while protecting inventory during transit.

- You can negotiate multi-tier discounts when combining sleeve production with filler trays or shipping palettes.

- Custom die-cutting services often come free once order minimums are met.

- Using fewer suppliers = fewer headaches + better coordination timelines.

- Strategic bundling makes seasonal product launches faster—and cheaper—to roll out.

Locking this stuff down early keeps last-minute chaos from eating into margins later on—and it looks slicker too once those units hit retail floors or influencer mailers alike.

Unstable Finishes? Metal Tubes Ensure Lasting Shine

Metal packaging isn’t just about looks—it’s about staying power, design integrity, and tactile appeal that doesn’t fade fast.

Metallized Aluminum Tubes with Long-Lasting Shine

- Metallized aluminum gives off a mirror-like gleam that resists fading.

- It holds up under UV exposure better than plastic coatings.

- Polished finishes on these tubes stay intact even after repeated handling.

- Brands aiming for premium shelf presence often favor this material for its light-reflective quality.

- The shine doesn’t just look good—it signals durability to the customer.

Topfeel uses metallization not only to boost visual impact but also to extend the life of the cosmetic’s outer coat—because no one wants dull packaging halfway through use.

Embossing on 30 ml Metal Lipstick Cases for Premium Texture

You pick up a lipstick and your fingers feel it before your eyes do—that’s where embossing wins big.

• Raised logos or patterns on 30 ml metal lipstick cases add an upscale touch without over-designing.

• Texture makes the product easier to grip, especially with slick hands or in humid settings.

• This technique turns standard cosmetic packaging into something you actually want to hold onto longer.

When done right, embossed metal cases don’t just pop visually—they stick in memory too.

Hot Stamping vs. Screen Printing: Which Lasts Longer?

Hot stamping and screen printing both bring flair—but which one really sticks?

- Hot stamping fuses metallic foil into the package surface using heat and pressure.

- Screen printing layers ink directly onto the tube but can wear down faster over time.

- For luxury cosmetics like lip color containers, hot stamping is often preferred because it resists smudging and flaking even after months of use.

According to Mintel’s Q2 Packaging Trends Report from early 2024, “consumers increasingly associate foil-stamped finishes with higher product value.” That speaks volumes about how decoration choices influence perception—and retention—in crowded markets.

Snap Fit Closures Secure Metal Tube Integrity

Keeping things sealed tight isn’t just functional—it’s part of what keeps your brand trustworthy.

Step 1: A precisely engineered snap fit closure clicks into place without threads or twisting.

Step 2: This snap ensures airtight security, keeping contents fresh inside the metal tube body.

Step 3: It also prevents leakage during transit—no messy makeup bags here!

Plus, these closures blend seamlessly with sleek designs while offering mechanical reliability that doesn’t rely on external parts or adhesives.

Topfeel integrates high-tolerance snap fits into their designs so users get a satisfying click every time they close their favorite balm or tint container—simple, secure, stylish.

4 Steps To Customize Your Lipstick Tubes

Get ready to rethink how you design your lipstick tubes—from size to finish, it’s all about making a statement that sticks.

Material & Volume Decisions for Tailoring 5 ml to 50 ml Tubes

• Choose smaller volumes like 5 ml if you’re targeting compact or travel-friendly lines.

• Go bigger—up to 50 ml—for dual-use products or multi-functional balms.

- Match the product type with the right volume bracket. Creamy lipsticks? Think mid-range sizes. Liquid tints? Smaller is smarter.

- Consider brand ethos when picking materials—eco-conscious lines often lean toward biodegradable plastics or refillable shells.

✔️ Don’t forget user habits; some prefer sleek and light, others want something substantial in hand.

A quick tweak in size or shell material can totally change how your audience perceives your product line—it’s that powerful.

Plastic, Aluminum or Acrylic Shells: Style Meets Substance

Plastic, aluminum, and acrylic each bring their own vibe:

– Plastic is lightweight, cost-effective, and versatile with color options galore.

– Aluminum feels premium and cool to the touch; perfect for luxury branding.

– Acrylic offers crystal-clear transparency and a modern edge but costs more.

Mixing these materials across different SKUs can help diversify your lineup without straying from brand identity. Just make sure the outer shell matches both visual goals and durability expectations—nobody wants cracked tubes at the bottom of their purse.

Hot Stamping, Embossing and Metallization Guide

• Use hot stamping for shiny logos that pop under store lights—it’s eye-catching without being over-the-top.

• Want texture? Go for embossing, especially on matte finishes; it adds tactile value customers love touching again and again.

1) If you’re after bold metallic shine, nothing beats full-body metallization, but keep an eye on cost—it ain’t cheap!

2) Combine techniques sparingly; too much flash can feel gimmicky instead of glamorous.

A little flair goes a long way when elevating simple tube packaging into something shelf-worthy—and share-worthy on social feeds too.

Comparing Screw Cap, Snap Fit and Twist Up Closures

Grouped by function:

🌀 Twist-Up:

- Offers seamless application.

- Great for solid lipstick formats.

- Adds a premium touch with minimal effort required by users.

🔗 Snap-Fit:

- Quick-click closure makes it ideal for testers or minis.

- Lightweight, often used in budget-friendly ranges.

- Can wear out faster over time if not engineered precisely.

🔒 Screw Cap:

- Most secure option—no accidental messes in handbags.

- Slightly slower access but works well with liquid formulas or balms.

- Often used in hybrid cosmetic products like tint balms with skincare benefits.

Each closure style has its moment depending on how users interact with the product daily—and that interaction shapes brand loyalty more than you’d think.

Production Line: Speed Assembly With Snap-On Tubes

Quick, clean, and consistent—that’s the name of the game when it comes to high-speed production for personal care packaging.

Optimizing Snap Fit for Aluminum and Plastic Shells

The right snap fit can make or break your assembly line speed. Here’s what matters:

- Material compatibility: Match plastic shells with flexible tolerances; pair rigid designs with malleable inserts.

- Tolerance tuning: Too tight? You’ll slow down automation. Too loose? You risk faulty closures.

- Design geometry: Rounded edges on both aluminum shells and plastics reduce stress points.

- Test early, test often: Prototyping different snap profiles helps avoid expensive mold changes later.

- Thermal behavior: Account for expansion differences between metals and polymers under heat.

“Snap-fit optimization is now directly tied to packaging throughput,” says a June 2024 report by Global Packaging Index. That’s why Topfeel engineers test each shell configuration under rapid-cycle conditions before final approval.

Conveyor Belt Calibration for 15 ml and 30 ml Tube Assembly

Getting your conveyor belt dialed in isn’t just about speed—it’s about precision across sizes:

- Adjust rail width dynamically to cradle both 15 ml tubes and bulkier 30 ml tubes without jamming.

- Sync motor speed with robotic arms to maintain seamless tube transfers during high-volume runs.

- Use dual-position sensors calibrated per size format—this ensures accurate tube stops and prevents slippage mid-line.

- Integrate smart feedback loops that auto-correct alignment shifts caused by temperature or vibration changes.

A well-calibrated conveyor doesn’t just move faster—it moves smarter.

Integrating Screen Printing and Labeling in Fast Production

You want branding that sticks—literally—and keeps up with your output rate:

• Combine inline UV-curable systems with rotary heads for fast-drying, high-resolution screen printing on curved surfaces.

• Align label applicators precisely using optical readers—this guarantees perfect label alignment, even at top speeds.

• Pre-check ink viscosity daily; bad flow ruins adhesion on smooth tubes like gloss-finished plastics or anodized aluminum.

• Automation helps—but don’t skip manual QA checks every few hundred units during long runs to catch misprints early.

By embedding decoration into the assembly rhythm instead of treating it as an afterthought, you boost efficiency without sacrificing style—especially important when working with small-format lip products where space is tight but branding impact matters big time.

FAQs

Plastic remains a go-to choice—affordable, lightweight, and easy to mold into endless shapes. Paperboard is gaining love too, especially from eco-conscious brands looking for biodegradable options without breaking the bank. Acrylic sits comfortably in between: crystal-clear with just enough polish to feel premium but still budget-friendly.

- Hot stamping creates crisp logos that won’t rub off during shipping or shelf life.

- Labeling machines calibrated for mass runs keep placement sharp and uniform.

- For aluminum shells, laser etching adds permanence and a touch of sophistication.

Consistency isn’t just about color—it’s about every tiny detail lining up perfectly when your product hits store shelves.

Snap-fit closures click into place fast—ideal when you’re running high-speed automation lines where seconds matter. Twist-up mechanisms add elegance but require more precise alignment on conveyors. Screw caps offer security but slow things down slightly due to extra rotations per unit.

Choosing the right closure isn’t only technical; it affects how customers experience your brand from the very first twist or pop.

Glass looks stunning—but it’s fragile under pressure (literally). In transit or on crowded displays, it risks cracking unless heavily reinforced, which drives up costs fast. That’s why acrylic or metal often wins out: they mimic luxury while surviving real-world handling with ease.

Beauty should be bold—but also built to last beyond unboxing day.

Screen printing gives you full-color freedom across any material—a great match if you’re working with vibrant logos or playful designs. Hot stamping shines (sometimes literally) when you’re after metallic finishes that scream luxury and don’t fade over time.

Each method tells its own story; it depends whether your brand whispers elegance—or shouts personality through pigment and foil alike.