The Ultimate Guide to Lipstick Tube Container Materials

Your lipstick is flawless, your shade’s a showstopper—and yet, that clunky plastic casing? Total buzzkill. Picking the right lipstick tube container isn’t just about packaging; it’s branding, product protection, and eco-street cred all rolled into one tiny cylinder. In a market where looks matter (a lot), even the click of the cap can make or break how customers feel about your brand.

From sleek aluminum that screams luxury to biodegradable resins for brands with a conscience—the stakes are high and options wild. Skip the guesswork. This guide spills what you need to know before placing that bulk order no one’s allowed to regret later.

Key Points in a Lipstick Tube Container Love Song

➔ Material Variety Matters: From lightweight aluminum to versatile plastics and eco-friendly resins, the material you choose defines both product performance and brand identity.

➔ Finish Is More Than Skin Deep: Matte or glossy surface finishes influence consumer perception—glossy shines on shelves, while matte whispers luxury.

➔ Eco Takes the Stage: Sustainable options like refillable tubes, biodegradable resins, and magnetic closures are turning heads in green beauty markets.

➔ Form Meets Function: Shapes like round or square and features like tamper-evident caps aren’t just aesthetic—they affect usability and safety too.

➔ Decoration Seals the Deal: Hot stamping and silk screening deliver visual appeal without compromising sustainability goals.

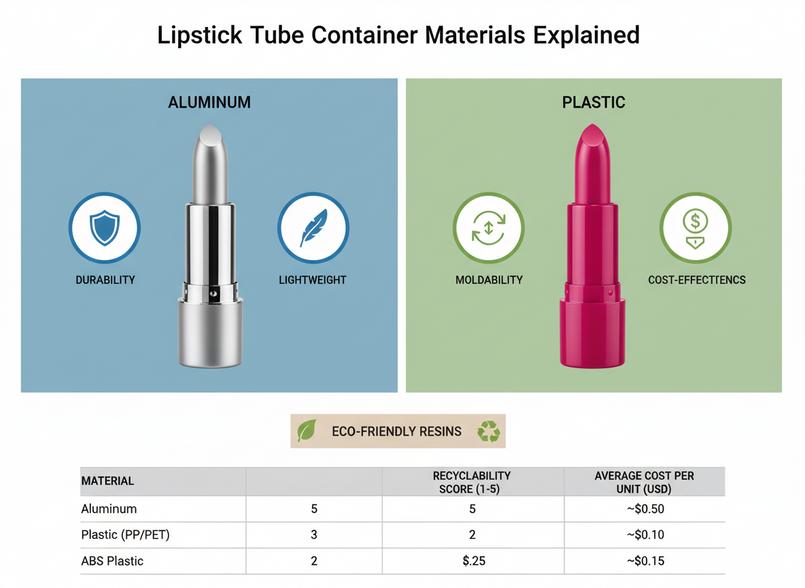

Types Of Lipstick Tube Container Materials Explained

Quick peek into what makes your favorite lipstick tube container tick—different materials bring different vibes, durability, and sustainability.

Aluminum Lipstick Tubes: Durable and Lightweight

- Durability: These tubes are tough. They don’t crack or warp easily, making them ideal if you’re always tossing your makeup bag around.

- Lightweight: Despite being made from metal, they’re surprisingly light. That’s a win when you want portability without bulk.

- Premium feel: The sleek look and cool touch of aluminum scream luxury. It elevates the product’s perceived value instantly.

| Material Type | Weight Class | Recyclability Score | Average Cost per Unit |

|---|---|---|---|

| Aluminum | Light | High | $0.12 |

| Plastic | Ultra-Light | Medium | $0.07 |

| Acrylic | Medium | Low | $0.10 |

| ABS Plastic | Medium | Low-Medium | $0.09 |

These figures show why brands often go for aluminum when looking to balance quality with eco-consciousness in their lipstick packaging.

The Versatility of Plastic Lipstick Containers

Plastic’s like the chameleon of the packaging world—it adapts fast and looks good doing it.

• You can mold it into pretty much any shape—curvy, square, even novelty forms that stand out on shelves.

• It plays well with color too; think transparent gloss or bold matte finishes.

• And let’s be real—it keeps production costs way down, which is a big deal if you’re scaling up.

Whether it’s classic cylindrical designs or quirky geometric ones, plastic opens doors creatively while keeping things wallet-friendly. No wonder it’s still a top pick in the cosmetic packaging scene.

Eco-friendly Resins: A Sustainable Choice for Packaging

Let’s break this down into what makes these newer materials worth considering:

🟢 Biodegradability – These containers won’t sit in landfills forever; many degrade naturally over time.

🌱 Plant-based sources – Most are derived from corn starch or sugarcane, making them more sustainable than petroleum-based plastics.

♻️ Brand image boost – Consumers appreciate when brands make an effort to use environmentally friendly options like bioplastics or compostable resins in their lipstick tube container lineup.

This shift isn’t just trendy—it reflects real concern about waste reduction and greener choices in beauty packaging today.

Acrylic vs. ABS Plastic: Which is Best for Your Brand?

Short bursts of insight help compare these two popular plastics:

• Acrylic stands out with its glass-like clarity—perfect if you want that high-end shine on display shelves. But it can be brittle under pressure.

• On the flip side, ABS plastic is tougher—less glam maybe, but solid where durability matters most like travel kits or rugged use cases.

• If aesthetics matter more than toughness? Go acrylic. If function wins? ABS all day long.

Both offer unique strengths depending on whether your brand leans toward style or substance—or maybe a bit of both in your next standout lipstick design.

How Lipstick Tube Container Material Affects Product Quality

Understanding how the material and design of a lipstick tube container influence both product integrity and user experience is key to standing out in a crowded beauty aisle.

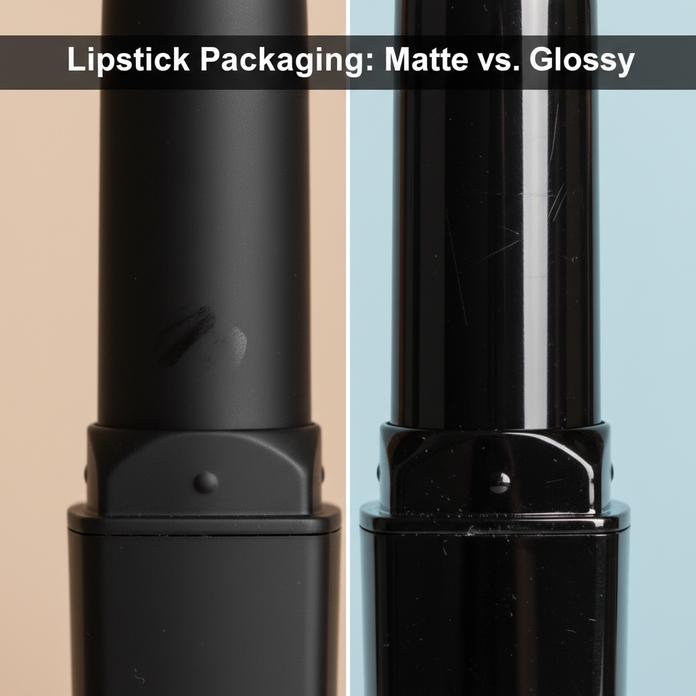

Surface Finish Matters: Matte vs. Glossy Finishes

Choosing between matte and glossy finishes isn’t just about looks—it can shape how your product feels in hand, wears over time, and even stands out on shelves.

• A matte finish gives off that sleek, premium vibe—less glare, more grip, and it hides fingerprints like a pro.

• Meanwhile, the glossy finish screams shine and glamor but tends to show scratches faster than you’d like.

• Brands aiming for luxury often lean toward matte due to its modern aesthetic and tactile appeal.

Now toss in texture—some users love a soft-touch coating that adds durability while others want that slick lacquered effect that reflects light beautifully. The choice affects not just visual appearance, but also how long the packaging holds up under daily use. Ultimately, whether you’re going for subtle elegance or high-shine drama, choosing the right surface coating helps define your brand story from touchpoint one.

The Impact of Material on Lipstick Formula Preservation

The material inside your lipstick tube container isn’t just holding the formula—it’s actively protecting it from breakdowns you don’t see coming.

- Material composition: Plastic blends with low oxygen permeability help slow down oxidation.

- Temperature resistance: Metal tubes may look chic but can heat up fast—risking formula melt or separation.

- Preservation properties: Airtight seals combined with UV-resistant materials extend overall shelf life.

- Degradation prevention: Some containers include inner linings that block chemical interactions between waxes or oils and external elements.

- Types like polypropylene or acrylic are common picks because they balance durability with chemical neutrality.

- Using high-barrier materials ensures color payoff stays consistent—even after months on a shelf.

A good lipstick formulation deserves better than average packaging—and brands like Topfeel know this well by integrating advanced preservation features into every lipstick tube body they produce.

Custom Colors: Enhancing Aesthetic Appeal and Quality

Nailing custom colors for your lipstick tube container is more than branding—it’s about triggering instant recognition while keeping quality top-tier every step of the way.

Step 1: Decide your core palette based on brand tone—minimalist neutrals? Loud primaries? Rich metallics? Each sets an emotional tone before anyone even opens the cap.

Step 2: Work with pigment specialists who understand colorfastness so you don’t end up with fading hues after sun exposure or extended storage times.

Step 3: Match internal components too—like aligning bullet base tones to outer casing for seamless visual unity.

Step 4: Test for color stability across batches; nothing turns customers off faster than inconsistent shades across units labeled “same.”

Step 5: Finalize using coatings that lock in pigment without dulling vibrancy—this keeps your custom tone crisp over time while enhancing perceived quality on-shelf.

When done right, customized color schemes don’t just elevate visual identity—they subtly reinforce trust through consistent quality cues embedded into every swipe-ready detail of your packaging design.

Sustainable Lipstick Tube Container Materials: A Growing Trend

Eco-conscious beauty is booming, and the lipstick tube container is getting a major green makeover. Here’s how materials and features are shaping a cleaner future for cosmetics.

Eco-friendly Resins Leading the Movement

- Bio-based polymers like PLA and PHA are now replacing petroleum plastics.

- Brands are switching to compostable resins, cutting down landfill waste.

- Some manufacturers use recycled plastics blended with natural fibers.

- PLA (Polylactic Acid) – made from corn starch, fully compostable in industrial facilities.

- PHA (Polyhydroxyalkanoates) – biodegradable even in marine environments.

- Recycled PET – keeps plastic out of oceans by repurposing water bottles.

♻️ These resins not only reduce carbon footprints but also appeal to consumers demanding planet-friendly packaging.

A growing number of indie brands now opt for biodegradable materials, seeing them as both ethical and smart business moves.

Short-term perks? Lower emissions during production. Long-term? Less microplastic pollution from discarded lipstick cases.

Hot Stamping and Silk Screening for Eco-conscious Brands

• Uses low-VOC inks that don’t pollute indoor air quality during application.

• Incorporates water-based coatings, reducing chemical runoff into waterways.

• Supports branding with eco-friendly pigments that still pop on shelves.

Hot stamping avoids traditional labels, meaning less material waste overall—plus it works great on both glass and recycled plastic surfaces.

Silk screening allows direct printing using minimal resources, often paired with recyclable materials to keep things clean inside and out.

This combo gives brands the power to stay stylish while keeping their environmental impact low-key but effective.

Magnetic Closure: Combining Sustainability with Functionality

A well-designed magnetic closure isn’t just cool—it’s sustainable when done right:

- Use of recycled magnets helps avoid mining rare earth elements from scratch.

- The durable design means fewer broken tubes tossed prematurely into trash bins.

- It supports reuse by enabling long-term functionality without wear-and-tear failure points.

Many eco-luxe brands combine this with metal-free packaging or bamboo outer shells, further reducing reliance on virgin plastic components while maintaining aesthetic charm.

The result? A satisfying click that locks in your favorite shade—and peace of mind too.

Refillable Tubes: How They Promote Environmental Responsibility

Refillables are gaining serious traction:

• Swappable cores or interchangeable cartridges mean you keep the outer shell forever.

• Many refill systems align with a full-on circular economy, minimizing single-use waste cycles entirely.

Grouped benefits include:

– Reduced cost per unit over time;

– Boosted customer retention via loyalty programs;

– Alignment with global zero-waste initiatives;

– Compatibility with various shades using one case;

Brands adopting these systems often use sturdy aluminum or bamboo bodies paired with internal inserts made from sustainable materials, making it easier than ever to look good without trashing the planet.

The Role of Tamper-evident Features in Sustainable Packaging

Here’s how smart safety meets green design:

1️⃣ Use of plant-based films and paper seals—these act as visible security indicators without relying on synthetic adhesives.

2️⃣ Incorporation of biodegradable seals ensures nothing lingers after disposal.

3️⃣ Labels made from post-consumer fiber or FSC-certified sources add another layer of eco-integrity.

4️⃣ Even closures can be fitted with snap-locks using only minimal material input yet ensuring full consumer trust at point-of-sale.

| Feature Type | Material Source | Biodegradability | Added Safety |

|---|---|---|---|

| Seal tabs | Corn-starch polymer | Yes | High |

| Label adhesives | Natural rubber resin | Partial | Medium |

| Closure mechanisms | Molded cellulose | Yes | High |

| Printed warnings | Soy ink on kraft | Yes | Low |

By integrating these elements into a typical lipstick tube container, brands show they care about both product integrity and environmental responsibility—all wrapped up in one sleek little package.

FAQs

What materials make lipstick tube containers feel luxurious and last longer?

The tactile experience matters. A lipstick container should feel solid in your hand—like it belongs there. That’s why materials like aluminum or thick-walled ABS plastic are often used. They don’t just look good; they protect the product inside from heat, light, and wear.

- Aluminum: Cool to the touch, sleek finish, doesn’t dent easily.

- ABS Plastic: Sturdy with a smooth glide when twisted open.

- Acrylic: Shiny and clear like glass but less fragile.

Each material brings its own personality—and that connection between user and object is what keeps people coming back.

How does packaging material affect how long my lipstick stays fresh?

Lipstick isn’t just color—it’s chemistry. Exposure to air can dull pigments or change scent over time. So the container acts as both guardian and stage:

An airtight seal (especially with aluminum or high-grade plastic) slows down oxidation dramatically. The formula stays creamy, vibrant, exactly how you remember it—even months later.

So yes—the right shell makes all the difference in preserving what’s inside.

Why do brands choose hot stamping instead of labels for decoration?

Hot stamping feels intentional—like someone cared enough to press foil into place rather than slap on a sticker.

- It resists peeling better than adhesive labels.

- Works beautifully on eco-resins without interfering with recyclability.

- Adds elegance without adding waste—a rare win-win in cosmetics packaging.

For sustainable lines especially, this method blends beauty with responsibility effortlessly.

Are refillable lipstick tubes actually practical for everyday use?

Absolutely—and not just because they’re better for the planet. Refillable designs invite customers into an ongoing relationship with their favorite shades:

You keep one beautiful case but switch out refills as needed—less clutter in your drawer and fewer tubes tossed away after each season’s trend fades out.

Bulk buyers love them too:

- Lower cost per use over time

- Encourages repeat purchases through refill programsIt turns makeup into more than consumption—it becomes ritualistic reuse wrapped in style.

Can I customize colors on acrylic or plastic lipstick containers to match my brand vibe?

Yes—and it’s easier than you’d think. Acrylics take pigment well; plastics can be Pantone-matched precisely so every detail aligns—from cap to base ring:

Think rose gold barrels paired with matte black caps…or soft lilac tones that echo spring campaigns across square or oval shapes alike.

Your packaging becomes part of your story—not an afterthought—but something customers recognize before even reading your name.

References

- Aluminium: The Future of Cosmetic Packaging? – people4ocean.com

- PLA vs. PHA: Which Bioplastic Is Best for Sustainable Packaging Needs? – made-with-regen.ca

- Acrylonitrile Butadiene Styrene (ABS) v.s. Acrylic in Manufacturing: An In-depth Comparison – weprofab.com

- The Rise of Refillable Cosmetic Packaging – originltd.com