MA-79 Private Label Lipstick Stick Packaging Solution

This precision-engineered MA-79 lipstick case includes five PP-based components with a silicone ring to prevent leakage. Great for solid cosmetics and custom branding.

Model Number: MA-79

Capacity: 3.5g – 3.8g

Material: PP, Silicone

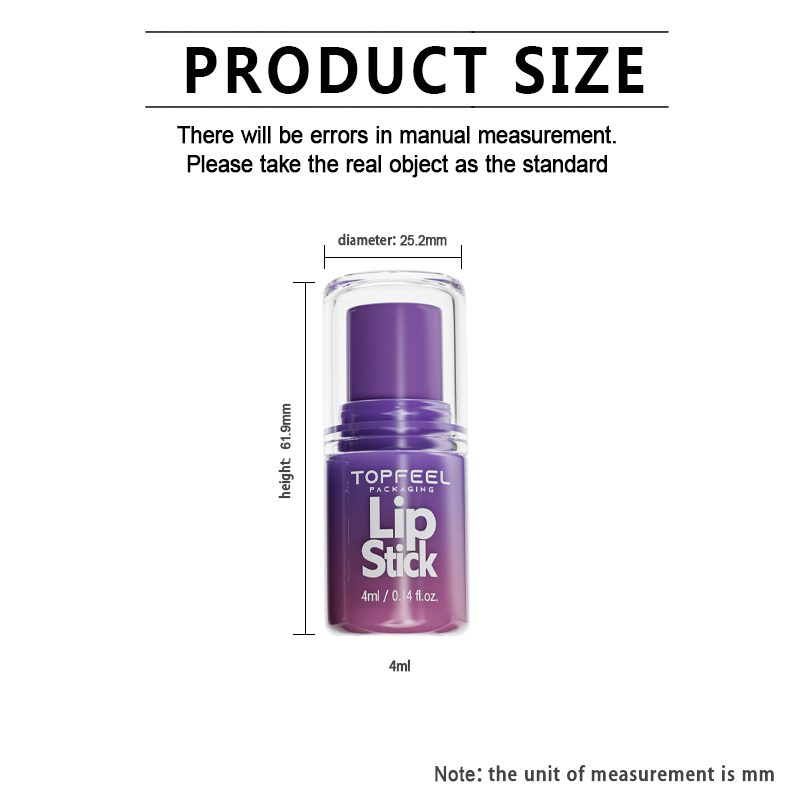

Size: D25mm × H62–76.5mm

MOQ: 12,000 pcs

Application: Lip Balm, Lipstick

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom color and printing

Sample: Available

Features

-

Modular five-part PP and silicone structure ensures airtight sealing and smooth internal product protection.

-

Twist-up mechanism offers controlled application, enhancing consumer satisfaction through intuitive, mess-free use.

-

Supports seamless OEM decoration with smooth surfaces, clean cap integration, and customizable branding zones.

You May Also Like

View Product Details

🔹 Built for Precision Use

-

Modular Five-Part Build

Every component serves a distinct functional purpose:

-

The PP bottle ensures dimensional stability and maintains internal product integrity.

-

A middle band and outer cap provide closure alignment and add physical reinforcement.

-

The inner cap enhances internal sealing while aiding in smooth opening/closing cycles.

-

The silicone sealing ring plays a critical role in leak prevention—especially important for semi-solid or melt-prone lip products.

-

-

PP + Silicone Compatibility

The structural composition uses injection-moldable polypropylene for all major elements. This simplifies mold integration, lowers tooling costs, and ensures easy recyclability at end-of-life. Silicone is selectively used in the sealing ring to improve air-tight performance and extend product shelf life during transit or storage.

“Using mono-material plastics like PP is becoming more important as packaging recyclability is increasingly scrutinized in both EU and North American markets.” –

🔹 Compact Form, Clean Dispense

Simplicity meets functionality in the twist-up mechanism. It’s designed to support a reliable consumer experience, while giving brands flexibility in product delivery format.

Twist-Up Dispensing Control

The intuitive bottom-rotating base allows for steady product elevation without breakage or backflow. This feature is especially relevant for lip balm and lipstick formulas requiring a stable stick form. Its tight pitch design ensures that the product is protected from being overexposed or misaligned—an issue that often leads to returns in cosmetic lines.

🔹 Brand-Ready Finishing Power

MA-79’s surface and structure offer multiple opportunities for premium-grade custom packaging, making it ideal for emerging indie brands, DTC portfolios, and OEM formulations.

-

Seamless Cap Integration

The cap-to-body junction maintains a continuous silhouette. This not only enhances visual harmony on the shelf but also helps standardize packaging lines for collections with unified formats. The smooth cylindrical outline works well in vertical and tray-style retail displays.

-

OEM Support Available

Whether the brand needs a specific twist mechanism calibration, private mold adjustment, or pre-launch mock-ups, Topfeel’s OEM services ensure that packaging aligns with commercial timelines. Prototyping, surface decoration, and logo embossing can be delivered under tight timelines with in-house tooling and QC teams.

“By 2025, over 68% of cosmetic startups are expected to adopt custom packaging molds within the first 24 months of brand launch.” – Euromonitor Packaging Innovation Survey, 2024