MA-65 Dual Sided Lip Tint Container with Precision Tip

Engineered for performance, the MA-65 cosmetic packaging combines PETG, ABS, and POM for structural durability. Its soft applicator supports clean, direct use for under-eye or lip products. Perfect for trend-aligned skincare and cosmetic launches. Fully customizable for brand integration.

Model Number: MA-65

Capacity: 5.5ml

Material:

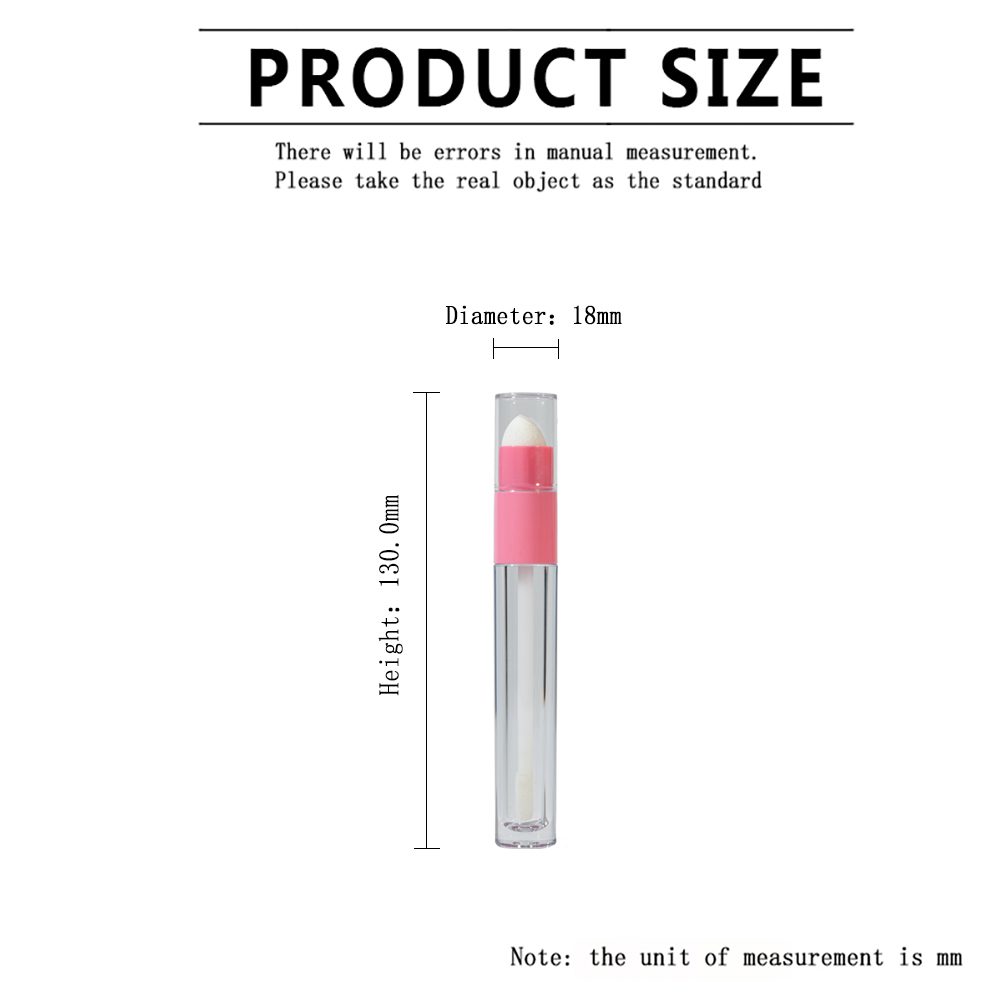

Size: Ø18.5mm x H130mm

MOQ: 12,000 pcs

Application: Lip Gloss, Concealer, Skincare Serum

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color and Printing

Sample: Available

Advantages

-

Multi-material construction supports leak-proof performance and controlled application for serums, glosses, and concealers.

-

Aligns with the trend toward hygienic, targeted beauty application tools in skincare and cosmetics.

-

Clear packaging enhances usage control and user satisfaction by making product levels easily visible.

You May Also Like

View Product Details

Engineered for Precision Use

Soft-Touch Applicator Head

The German-imported polyester applicator head is a standout feature, delivering controlled application across targeted areas.

-

Ideal for smooth glide without excessive absorption or friction

-

Resilient to frequent consumer use and formula variation

Leak-Proof & Durable Build

The MA-65 integrates multiple thermoplastics to prevent leakage and maintain structural performance under varied handling conditions. Each part plays a functional role:

-

PETG bottle and cap — transparent, impact-resistant, and chemically stable for a wide range of skincare and cosmetic liquids.

-

ABS middle section — provides structural support and integrates easily into automated filling and capping lines.

-

POM stem and LDPE inner plug — ensure smooth flow, tight sealing, and excellent compatibility with different viscosities.

Answering the Market Shift

As the global skincare and beauty packaging industry evolves, demand is rising for smart applicator designs and targeted delivery formats.

Demand for Targeted Application

According to Mintel’s 2024 Global Beauty & Personal Care Trends Report, 68% of skincare product developers are prioritizing applicators that minimize direct skin contact.

The MA-65 answers this with a:

-

Direct-to-skin applicator that avoids fingers, reducing contamination risk

-

Fine-tuned flow mechanism that controls dosage and product waste

-

Applicator compatibility with both thin liquids and creamy emulsions

Designed Around Daily Use

Clear Body, Clean Control

This feature allows procurement teams to deliver not just user-friendliness but post-sale efficiency. For consumers, being able to visually monitor remaining content increases perceived value and satisfaction—without needing to open or shake the unit.

-

Reduces unnecessary returns or complaints due to “empty” perception

-

Helps inform re-purchase cycles with more predictable usage feedback

-

Assists in sample-based marketing where transparency boosts trust

Combined with the durable PETG shell, the MA-65 packaging supports both primary use and promotional trials—providing a flexible solution for mass-market or niche launches alike.

FAQs

-

Polyester tip provides smooth, precise gloss application

-

Leak-proof design prevents spillage in transit or use

-

PETG body allows clear visibility of gloss shade and volume

-

Fully compatible with viscous gloss formulations

-

Absolutely. The soft polyester applicator is gentle enough for lip balms or treatments, and the tight sealing structure ensures protection against oxidation and leakage during use or storage.

The MA-65 accommodates a wide range of formulations across skincare and color cosmetics:

-

Water-based or oil-based serums

-

Creamy concealers or correctors

-

Lip glosses with shimmer or tints

-

Lightweight emulsions and liquid highlighters

Yes, while the base PETG material is clear, you can request frosting, matte UV, or partial opacity depending on your branding and product positioning needs.

For lip gloss, the MA-65 offers key functional benefits:

-

Soft applicator tip avoids product buildup

-

Clear tube helps consumers monitor fill levels

-

Tight seal reduces risk of formula drying or leaking

-

Compatible with thick or glossy textures

Topfeel runs rigorous quality checks, including leak testing, torque validation, abrasion resistance, and UV weather simulation to ensure each unit meets international QC standards and shipping resilience.