The Ultimate Guide to Foundation Bottle Materials

Your foundation bottle isn’t just holding product—it’s holding your brand’s reputation, one pump at a time. From frosted glass that whispers “luxury” to PET plastic that takes a drop like a champ, the material you choose says more about your business than you think.

Ever had bottles leak in transit? Or worse—crack before they even hit the shelves? Yeah, we’ve heard horror stories too. Choosing wrong costs more than cash—it chips away at customer trust.

Some folks pick by price tag alone. That’s like buying shoes without checking the size chart. This guide cuts through the noise and shows exactly what works when durability, cost, and design need to play nice together.

Quick Answers in the World of Foundation Bottle Choices

➔ Material Matchmaking: PET, glass, HDPE, LDPE, and acrylic each offer distinct pros—PET for clarity and cost-efficiency; glass for luxury feel and UV protection.

➔ Durability Factors: Wall thickness, cap integrity, and impact resistance are critical to preventing leaks or breakage in transit.

➔ Glass vs. Plastic Showdown: Glass wins on elegance and hygiene; plastic takes the lead in affordability and portability.

➔ Hygiene Priorities: Amber or frosted glass with sterile pumps or droppers keeps foundations safe from light damage and microbial intrusion.

➔ Budget-Friendly Bottling: For startups or sample lines, go with bulk PET or flip-top HDPE containers to maximize value without sacrificing function.

Types Of Foundation Bottle Materials

Looking to match your cosmetic formula with the right container? Let’s break down the best bottle types out there.

Clear PET Plastic Bottles (15ml–100ml) with Screw Caps

• Great visibility means you can always see how much you’ve got left.

• Lightweight design makes them easy to toss in your bag without weighing it down.

• The screw cap seals tight, so no surprise spills.

→ These bottles are made from plastic, specifically PET, which is known for being both tough and crystal clear.

→ You’ll find them in everything from drugstore brands to pro kits because they’re affordable and versatile.

Not just practical—they’re also recyclable, making them a solid pick if you’re trying to keep things green without sacrificing quality.

Amber or Clear Glass Bottles for 50ml Foundations

There’s something about glass that just feels luxe in your hand—and it’s not just about looks. These bottles do more than sit pretty on your vanity; they protect formulas from UV damage, especially when tinted amber. That’s key if your product contains light-sensitive ingredients like vitamin C or botanical extracts.

According to Euromonitor’s Q1 Beauty Packaging Review (2024), consumer preference has shifted toward premium packaging that “feels substantial,” especially in the skincare-foundation crossover category.

Pair these bottles with droppers or pumps, and you’ve got function meeting elegance—no compromise necessary.

Acrylic Foundation Bottles Featuring Frosted Finishes

These sleek containers blend style with serious durability:

▪️ Appearance: Matte frosted finish adds instant shelf appeal.

▪️ Durability: Built tough—resists scratches better than most plastics.

▪️ Compatibility: Works well with both oil-based and water-based formulations.

Grouped by use case:

- For luxury brands aiming at aesthetic perfection, acrylic hits the mark.

- For makeup artists who need sturdy gear on-the-go, it’s resilient enough.

- For indie startups looking to stand out visually—this material nails it.

The body is crafted from high-grade plastic acrylic that mimics glass but won’t shatter under pressure.

HDPE Flip-Top Containers for 30ml and 200ml

Split into two main groups based on usage:

🟢 Everyday Use:

• The flip-top makes one-handed application super easy.

• Great grip even when hands are slippery—thanks to slightly textured surface.

• Withstands drops like a champ due to its flexible but strong build.

🟡 Bulk & Refill Options:

• Larger sizes like the 200ml are ideal for salon backbars or refill stations.

• Wide mouth opening makes pouring less messy.

• Can be reused multiple times without degrading performance.

Made from HDPE plastic, these containers strike a balance between toughness and convenience—perfect when you’re juggling multiple shades or textures daily.

Flexible LDPE Dropper Bottles Ideal for Travel

● Soft-squeeze design lets you control every drop without wasting product.

● Leak-resistant tips mean fewer messes in your carry-on bag.

LDPE is another type of plastic, but way more flexible than PET or HDPE—it feels soft in hand yet holds its shape well enough not to collapse mid-use.

You’ll often spot these as sample-size options at trade shows, but don’t underestimate their value—they’re perfect companions when you’re switching bags often or testing new blends on-the-go.

Topfeel includes LDPE travel droppers across several collections—a smart move considering how many users now want mini versions of their go-to base products.

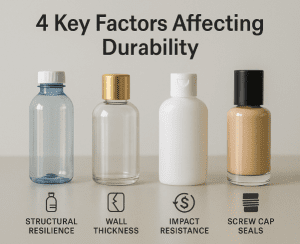

4 Key Factors Affecting Durability

A bottle’s toughness isn’t just about what it’s made of—it’s how it’s built, sealed, and used over time. Let’s break down what really keeps them kicking.

Structural Resilience of PET Plastic

- High tensile strength keeps the bottle’s body from collapsing under pressure or weight during stacking or shipping.

- Clarity remains intact even after repeated use, making it ideal when appearance matters.

- Lightweight nature makes it easy to carry without compromising durability—perfect for folks on the go.

- Recyclable and resistant to water absorption, which helps in maintaining product integrity longer.

PET blends smart design with solid backbone; its resilience is more than skin deep thanks to clever material selection and smart manufacturing processes that prioritize load-bearing capability and long-term performance.

Wall Thickness in Glass and Acrylic Bottles

- Thicker walls distribute stress more evenly across the surface area, reducing fracture risk from sudden drops.

- Acrylic tends to flex slightly before breaking—unlike glass—making it a safer bet in travel kits or handbags.

- Glass offers superior chemical resistance but needs careful design considerations to avoid shattering under thermal shock or impact stress.

While both materials hold up well visually, only properly engineered wall thickness ensures they don’t crack at the first sign of trouble—a real must if you’re tossing your container into a busy tote bag every day.

Impact Resistance of HDPE Containers

• Built like tanks, HDPE bottles can take hits without denting or cracking—great if you’re clumsy or your shelf is high up.

• The polymer chains inside this plastic are tightly packed, giving it flexibility that absorbs shock better than stiff alternatives like brittle glass.

HDPE also shrugs off temperature swings and resists UV degradation—a combo that makes it perfect when environmental conditions vary wildly between storage spaces like bathrooms and cars.

Screw Cap Seals: Preventing Leakage Over Time

Short threads? Loose fit? That cap’s gonna leak eventually—and no one wants foundation all over their makeup pouch.

But here’s what makes a screw cap last:

- Precision threading ensures a tight lock every time—it clicks right into place with minimal effort.

- Silicone liners create a soft barrier against moisture loss while keeping air out.

- Durable plastics resist wear from repeated opening/closing cycles common in daily routines.

The secret sauce lies in balancing good engineering with real-world usage patterns; tight seals prevent contamination while extending shelf life—even if you forget to screw the lid back on once in a while.

Usage Patterns That Influence Durability

Quick bursts of info:

• Daily use wears down seals faster than occasional use—especially if caps aren’t tightened properly each time.

• Travel frequency increases exposure to bumps, temperature shifts, and pressure changes—all enemies of fragile packaging types like thin-walled glass bottles.

• Leaving bottles open exposes contents to air and contaminants—bad news for both product longevity and packaging integrity over time.

How you treat your bottle matters as much as how it’s built—repeated abuse will wear even sturdy containers down unless they’ve been designed with tough-love users in mind.

Protective Coatings & Surface Treatments

Grouped by function:

🛡️ Protection Enhancers:

- UV coatings reduce sunlight damage that can weaken plastics over time or fade tinted containers used for liquid makeup bases.

- Scratch-resistant films keep acrylic finishes smooth despite being tossed around inside drawers full of keys and lipsticks.

💧 Moisture Barriers:

- Hydrophobic coatings help repel water droplets that might otherwise seep into closures through microcracks or loose seams during humid weather conditions.

🧪 Chemical Shields:

- Some coatings resist alcohol-based formulas often found in skincare-infused foundations—which can degrade unprotected surfaces quickly without proper protective coatings applied during manufacturing stages.

These extras might seem minor but they make all the difference when your bottle lives a rough-and-tumble life on bathroom counters or inside gym bags packed tight with other gear.

Design Considerations That Enhance Longevity

Durability doesn’t just come from thick walls or strong caps—it starts at the drawing board:

• Ergonomic shapes reduce stress points where cracks typically form after repeated drops or knocks against hard surfaces like sinks or tiles.

• Reinforced necks prevent breakage where most people grip their foundation container day after day—that area sees serious action!

• Tapered bottoms improve balance so bottles don’t tip easily when placed on uneven surfaces like car dashboards or cluttered vanities.

Smart designers factor everyday chaos into their blueprints—they know exactly where weak spots show up based on years of observing how people actually handle their products daily.

Load & Stress Distribution Across Bottle Types

Grouped insight by material type:

🧴 Plastic Variants:

– PET distributes vertical loads well but may deform under horizontal compression unless reinforced internally using ribbing techniques common in modern cosmetic packaging designs.

– HDPE flexes rather than cracks under pressure; great at absorbing shocks but less rigid overall compared to acrylics or glass forms used for premium base liquids.

🥃 Glass & Acrylic:

– Heavy bottom bases add stability—but also increase weight which affects portability.

– Stress fractures usually begin at narrow neck zones unless strengthened through flared designs which spread force across wider areas instead of concentrating it at single points vulnerable under strain from frequent handling routines common among makeup enthusiasts worldwide using liquid base dispensers regularly!

Understanding how different materials respond under load helps brands design smarter—and helps users choose wisely depending on whether they’re staying homebound or always out-and-about juggling their beauty kit mid-transit!

Each element—from seals to shape—is part of an interconnected system meant not just to hold liquid makeup securely but survive everything life throws at it along the way… including us dropping them twice before breakfast!

Glass Vs. Plastic Foundation Bottles

Choosing between glass and plastic for your makeup base container? Here’s how each material stacks up when it comes to looks, function, and sustainability.

Glass

-

Premium Feel & Aesthetics

• Has a sleek, high-end vibe that instantly elevates the product’s image.

• Often chosen by prestige brands aiming for a luxury shelf presence.

• Offers weight and cool touch that feels upscale in hand. -

Product Protection

• Blocks UV rays better than most plastics, helping preserve formula integrity.

• Less prone to chemical leaching—ideal for sensitive or active ingredients. -

Environmental Impact

• Highly recyclable without losing quality; can be endlessly repurposed.

• Lower carbon footprint over multiple life cycles compared to some plastics.

| Feature | Glass Bottles | Plastic Bottles | Notes |

|---|---|---|---|

| UV Protection | Excellent | Moderate | Helps maintain formulation |

| Recyclability Rate (%) | ~80–90 | ~30–50 | Varies by region |

| Breakage Risk | High | Low | Impacts travel friendliness |

| Material Weight | Heavy | Light | Affects shipping cost |

- Durability vs Fragility

While beautiful, glass isn’t exactly tough—drop it once, and you’ll see why some steer clear of it for daily use or travel kits.

Topfeel’s luxe line uses thick-walled glass bottles with reinforced bases—marrying elegance with improved drop resistance.

Plastic

• Lightweight makes it way easier to carry around—no wrist strain or shattered surprises if you drop your bag at the gym or on your commute.

• Usually cheaper to produce and ship, which translates into more accessible price points for consumers without sacrificing visual appeal thanks to advanced molding techniques.

• Can be molded into quirky shapes and fun colors that are harder to achieve with heavier materials like glass.

- Durability: You can toss these around without worry—they’re built for real life.

- Cost Comparison: Generally less expensive across production and logistics pipelines.

- Design Flexibility: From squeezable tubes to airless pumps, plastic opens creative doors for packaging designers.

Grouped Considerations:

-

Environmental Trade-Offs

- Most plastics aren’t as easily recycled as glass—but innovations like PCR plastic help reduce waste.

- Single-use plastic still poses challenges unless sourced responsibly or reused creatively.

-

Weight & Portability

- Especially ideal for on-the-go users who don’t want their makeup bag weighing them down.

- Better suited for travel-sized products where TSA compliance matters.

In short bursts:

Plastic doesn’t shatter when dropped—that alone is a win for many users on the move. It’s also cheaper but might not scream “luxury” unless designed thoughtfully using premium finishes or matte coatings.

And while the aesthetic may differ from its glass counterpart, smart brands know how to use material composition cleverly so even everyday items feel elevated—without breaking either bottle or budget.

Both materials have strong suits—it just depends what kind of vibe you’re going for and how you plan on using that trusty little makeup base container day-to-day!

Contamination Fears? Opt For Hygienic Glass Solutions

Glass packaging isn’t just pretty—it’s a smart move when you’re worried about keeping your makeup clean and safe. Let’s unpack why glass is your go-to for staying fresh and worry-free.

Amber Glass Shields Against UV and Microbial Growth

- Blocks out harsh UV rays that can mess with formulas.

- Keeps microbial nasties from thriving inside.

- Helps extend shelf life without synthetic preservatives.

- Works especially well for liquid makeup stored on vanities exposed to sunlight.

Amber-tinted containers are more than just vintage-cool—they’re protective. When you’re dealing with light-sensitive ingredients, like in some hydrating bases or vitamin-rich tints, amber glass acts like sunglasses for your product. It’s also naturally non-porous, which means it won’t soak up bacteria or leach anything funky back in. Add that to its ability to resist microbial growth, and you’ve got yourself a solid hygiene hero.

Borosilicate Bottles with Sterile Dropper Caps

• Durable under temperature changes—no cracking if it gets hot or cold

• Sterile droppers = no finger dipping = less contamination risk

• Perfect for serum-like foundations or custom mixers

• Easy to clean thanks to the inert material of borosilicate

Not all dropper bottles are created equal. The borosilicate kind is tough as nails but sleek enough to look high-end on your shelf. Its resistance to thermal shock makes it ideal if you’re storing products near heat sources like hair tools or windowsills. And let’s be real—dropper caps make you feel like a skincare chemist while keeping things super sanitary.

Frosted Glass Pump Containers for Safe Foundation Use

☑️ Looks luxe on your counter

☑️ Protects against oxidation and air exposure

☑️ Pump keeps fingers out—way more hygienic than jars

☑️ Frosted finish hides fingerprints and smudges

Frosted options aren’t just about aesthetics (though they do scream “I’ve got my life together”). They keep product stable by shielding it from light while still letting you peek at how much is left. The pump mechanism adds another layer of protection, making sure each use is fresh without inviting bacteria in—a major win for those who wear base every day.

When choosing between different types of skin-tone liquids, think beyond tone match—think safety too. A pump bottle made of frosted glass offers both style and serious durability, ensuring your daily routine stays clean without sacrificing looks. Plus, it’s easier to sanitize and doesn’t absorb odors over time like plastic might.

By sticking with smartly designed containers made from quality glass, you’re not just protecting your face—you’re investing in long-term product integrity, less waste, and better overall health outcomes from your beauty stash.

High Costs? Affordable Plastic Foundation Bottles Save Money

Budget-conscious brands aren’t compromising anymore—these plastic foundation bottles balance affordability, durability, and style without draining your wallet.

Bulk PET Bottles for Budget-Friendly 200ml Foundations

• Strong resistance to impact makes PET ideal for shipping in bulk.

• Lightweight material means lower freight costs per unit.

• Glossy finish enhances product appeal without extra coating expenses.

• Recyclable nature aligns with eco-aware consumer trends.

- Brands order PET containers in batches of 10,000+ to reduce per-unit cost significantly.

- Mold customization is optional but often skipped to save on tooling fees.

- Standard neck sizes allow compatibility with existing pumps or caps, cutting accessory costs.

☑️ Bonus: PET’s clarity mimics glass at a fraction of the price—visually premium, financially smart.

Grouped benefits:

- Affordability: Lower production and shipping costs due to light weight and high availability.

- Durability: Tough enough to survive transport without cracking.

- Sustainability: Fully recyclable; aligns with green initiatives.

- Market Fit: Ideal for mid-tier brands needing upscale looks on a budget.

PET bottles are a go-to when you want that sweet spot between quality and cost savings without sacrificing visual appeal or structural reliability in your foundation bottle packaging strategy.

HDPE Flip-Top Solutions for 50ml Sample Containers

Grouped feature breakdown:

✔️ Material Strengths:

- High-density polyethylene resists dents and leaks.

- Excellent chemical resistance preserves formula integrity.

✔️ Cap Functionality:

- Flip-tops are user-friendly and reduce spill risk.

- Secure locking mechanism keeps contents safe during transit.

✔️ Cost Efficiency:

- Low mold cost due to simple cylindrical shapes.

- Compact size means thousands can ship cheaply in one crate.

✔️ Use Case Compatibility:

- Perfect for travel-size foundations or trial kits.

- Often used by indie brands testing new shades or formulas.

Multi-step decision flow:

Step 1 → Choose HDPE if your priority is ruggedness over transparency.

Step 2 → Pick flip-tops when ease-of-use matters more than aesthetics.

Step 3 → Go with this combo if you’re offering testers through mailers or beauty boxes.

These mini containers prove that even sample-sized packaging can deliver big-time on both function and affordability, helping you stretch every dollar while maintaining brand trust through durable delivery options.

LDPE Dispenser Bottles with Screw Caps for 30ml Lotions

Here’s how LDPE stands out among other plastics used in cosmetics packaging:

| Feature | LDPE | Glass | PP (Polypropylene) |

|---|---|---|---|

| Flexibility | Very high | None | Medium |

| Cost per Unit (USD) | $0.08–$0.12 | $0.30–$0.60 | $0.10–$0.15 |

| Ideal Fill Volume Range | 10ml–100ml | >50ml | 20ml–250ml |

| Squeeze Dispensing | Excellent | Poor | Moderate |

Multiple short descriptions:

LDPE bottles are soft yet resilient—perfect when your lotion needs precise squeezing action without splatter messes. The screw cap? Simple but secure, no accidental leaks in makeup bags or purses here.

They’re also cheap to produce at scale, especially when sticking with standard molds shared across SKUs—no fancy tooling required unless you’re going bespoke with textures or embossing patterns on the bottle surface itself.

If you’re filling small runs of creamy foundations or tinted moisturizers, this combo hits the mark on both performance and price point while keeping things low-key sustainable thanks to LDPE’s recyclability rating under resin code #4—a win-win across production and user satisfaction lines when choosing your next foundation bottle format.

FAQs

It’s all about the tactile experience. Frosted glass bottles, cool and weighty, instantly suggest elegance. Amber-tinted options add a vintage charm while protecting sensitive formulas from light. Acrylic can mimic this upscale look too—with less fragility—offering a polished finish that still feels premium.

- Choose PET or LDPE plastic for their flexibility and seal-tight compatibility

- Pair with screw caps or secure pump dispensers to lock contents inside

- Add inner seals or shrink bands for an extra layer of protection

These steps help ensure your product arrives as perfect as it left your hands.

Absolutely—and they don’t have to look cheap either. PET plastic is lightweight and cost-effective, especially when ordered in large quantities. With thoughtful design—think matte finishes or custom labeling—you can create something beautiful without breaking the bank.

Amber isn’t just pretty—it’s practical. It blocks harmful UV rays that could degrade ingredients like vitamin C or botanical oils often found in foundations. For anyone formulating skincare-infused makeup, amber glass becomes more than aesthetic—it’s protective armor disguised as style.