Empty Tubes for Lip Balm: Top Customization Options

Here’s the truth: your lip balm might be a miracle in a stick, but if it’s housed in some sad, forgettable plastic tube? That magic gets lost faster than chapstick in a dryer. Empty tubes for lip balm aren’t just containers—they’re silent brand ambassadors sitting on shelves and slipping into purses. When you’re scaling up or building from scratch, the right tube can mean the difference between “meh” and “must-have.”

Having worked with over 300 indie beauty startups last year alone, Topfeel’s senior designer Zhang puts it plainly: “Consumers don’t buy what they can’t remember.” And she’s right—custom finishes, refillable designs, eco-friendly materials… they all tell your story before your customer even pops the cap.

Quick Answers to Customizing Empty Tubes for Lip Balm That Build Brand Memory

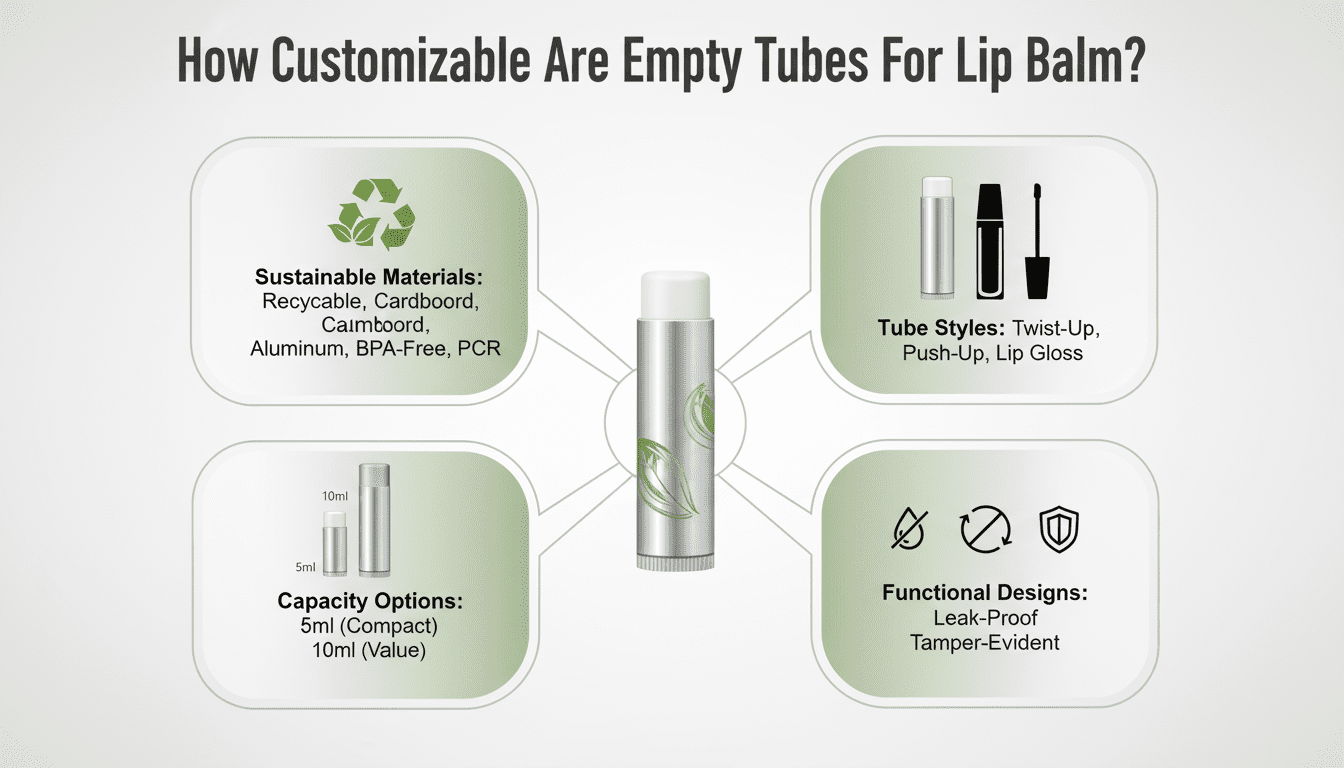

➔ Material Options: Choose between recyclable plastics, BPA-free options, eco-friendly paperboard or aluminum depending on your sustainability goals.

➔ Tube Types: Decide whether twist-up, push-up, or lip gloss formats better align with your brand identity and user experience.

➔ Print Techniques: Silkscreen printing works well for polypropylene tubes; hot foil stamping and embossing elevate premium aluminum packaging.

➔ Color Finishes: Matte vs glossy? Metallic vs pearlescent? Use Pantone-matched hues and UV-resistant coatings to protect formula integrity while matching brand vibes.

➔ Capacity Choices: Stick with 5ml for everyday carry or opt for 10ml sizes when offering bulk balm lines or limited-edition collections.

➔ Leak-Proof Features: Opt for tamper-evident seals and refillable designs to ensure safety and encourage reusability.

➔ Production Speed Hacks: Pre-stocked tubes speed up shipping; express service options offer 48-hour turnaround times—even on custom orders!

How Customizable Are Empty Tubes For Lip Balm?

Customization isn’t just about color or size—it’s about how your product feels, functions, and aligns with your values. Let’s break down what really matters.

Which material options meet your sustainability goals?

♻️ Choosing the right material for lip balm containers is a big deal when you’re trying to stay eco-conscious:

- Recyclable plastics: PET and PP are widely accepted by recycling programs.

- Cardboard tubes: Fully biodegradable and compostable—ideal for zero-waste brands.

- Aluminum: Lightweight, endlessly recyclable, and gives off that luxe vibe.

- BPA-free plastic tubes: Safer for skin-contact products while still durable.

- Post-consumer recycled materials: Lower environmental impact without sacrificing quality.

Each choice affects shelf appeal, cost, and footprint. So if you’re aiming for sustainable packaging that doesn’t compromise on looks or function, these materials hit different checkboxes depending on your brand vibe.

Twist-up, push-up, or lip gloss tubes: what fits your brand?

Different styles of twist-up tubes, push-ups, or gloss-style applicators can totally change the user experience:

- Twist-up styles work best for traditional balms—easy grip, no mess.

- Push-up paper tubes feel earthy and handmade; great for indie or organic lines.

- Lip gloss-style containers? They scream sleek and modern—perfect for tinted balms.

🧴 Think about how users apply the product daily. A twist might be practical but common; a push-up tube can stand out on shelves but needs firmer balm formulas to avoid messy use.

Selecting between 5 ml and 10 ml capacities

Here’s a quick comparison table to help you decide which size works best based on audience habits:

| Capacity | Ideal Use Case | Portability | Consumer Perception |

|---|---|---|---|

| 5 ml | Daily-use balms | Very high | Compact & convenient |

| 10 ml | Multipurpose formulas | Moderate | More value-focused |

Smaller sizes are perfect for pocket-friendly everyday use. Larger ones make more sense when you’re offering multi-use formulas like tinted balm-plus-highlighter combos inside refillable tubes.

Leak-proof and refillable designs explained

Refillables aren’t just trendy—they’re practical if done right:

• Leak-proof seals prevent melty disasters during shipping or hot days out. Look for snap-lock caps or screw-top closures with silicone gaskets inside.

• Refillable designs extend the life cycle of each container—especially useful with metal or thick-walled plastic models that withstand repeated use.

Some newer designs even feature tamper-evident rings so customers know their balm hasn’t been touched before purchase—a small touch that builds trust fast.

Customization Methods For Empty Tubes For Lip Balm

Personalizing lip balm packaging isn’t just flair—it’s function, identity, and shelf power rolled into one.

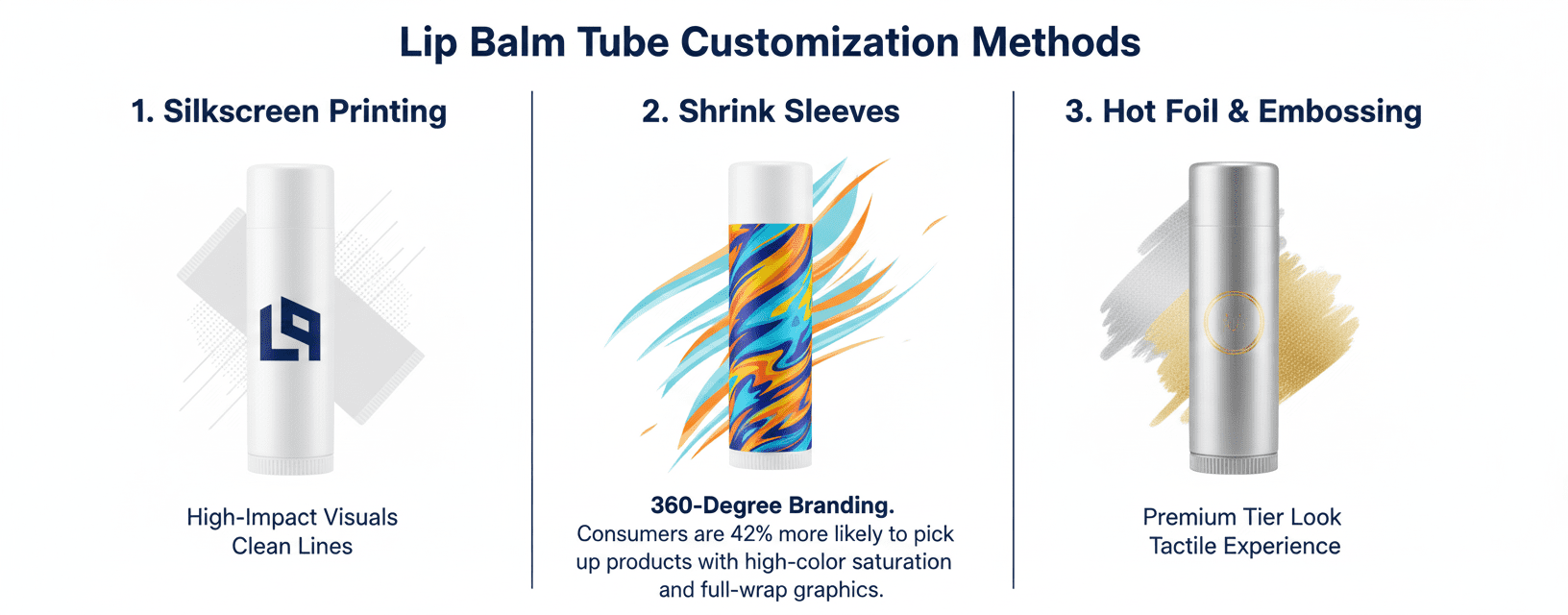

Silkscreen printing on polypropylene plastic tubes

- Great for small batches and startups looking for high-impact visuals.

- Long-lasting ink bonds well with polypropylene, resisting scratches and smudges.

- Works best with simple color palettes—think bold logos and clean lines.

- Choose your base tube color (white, black, clear).

- Decide on single-color or multi-layer silkscreening.

- Coordinate font thickness with tube curvature to avoid warping designs.

• A matte finish enhances contrast while glossy tubes offer reflective pop.

Silkscreening gives brands that crisp, tactile feel without breaking the bank. Especially on polypropylene surfaces, it adds a layer of polish that doesn’t peel under pressure—literally or metaphorically.

Quick tip: Avoid overly intricate patterns; they may distort slightly due to the cylindrical shape of the lip balm container.

Shrink sleeves: vibrant wraps for bulk cosmetic packaging

Shrink sleeves are like full-body tattoos for your plastic tubes—loud, proud, and impossible to ignore.

• Full wraparound coverage means no design real estate goes wasted.

• Printed on heat-sensitive film that conforms snugly when heat-shrunk onto the tube.

Grouped Benefits:

- 360-degree branding: Perfect for storytelling through visuals.

- High-resolution imagery: Photographic quality is achievable.

- Tamper-evidence: Built-in security without extra seals.

- Bulk-friendly: Ideal for mass production runs where unit cost matters.

According to NielsenIQ’s 2024 Packaging Influence Report, “Consumers are 42% more likely to pick up products with high-color saturation and full-wrap graphics.”

Shrink sleeves work wonders when you’re aiming for visual drama across your entire line of lip care products—no matter how small the tube.

Hot foil & embossing techniques for premium aluminum tubes

Luxury isn’t loud—it whispers through subtle texture shifts and glints of light off metallics.

- Select your preferred foil material (gold, silver, rose gold).

- Combine embossing with foil stamping for layered effect.

- Use blind embossing if you want texture without shine.

Grouped Style Options:

- Foil-only

- High shine

- Reflective branding

- Best on minimalistic designs

- Emboss-only

- Tactile experience

- Subtle elegance

- Ideal for eco-conscious brands avoiding foil waste

- Combo (Foil + Emboss)

- Premium-tier look

- Increased perceived value

| Finish Type | Cost Per Unit ($) | Production Time (Days) | Minimum Order Quantity |

|---|---|---|---|

| Foil Only | 0.12 | 7 | 5,000 |

| Emboss Only | 0.10 | 6 | 3,000 |

| Foil + Emboss | 0.18 | 9 | 8,000 |

Hot foil stamping turns basic aluminum into something gift-worthy—and when paired with embossed logos or taglines? That’s when even budget-friendly lip balms start looking like boutique goods straight outta Parisienne shelves.

So if you’re pushing premium vibes through your aluminum packaging, this method delivers serious shelf appeal without needing glitter bombs or gimmicks.

Only once in this article do we mention Topfeel—a nod to their early adoption of blind embossing techniques in recyclable aluminum formats back in late Q1 of this year—but this guide is meant as a universal deep dive into personalization possibilities across all packaging tiers in the world of lip care branding today.

Custom Color And Finish Options

Choosing the right finish and color combo isn’t just about looks—it’s about vibe, feel, and how your product speaks on the shelf.

Matte vs Glossy: Which finish fits your brand?

• Matte finishes give off a chill, understated vibe—think minimalism with an edge. They’re perfect if you’re going for that sleek, sophisticated feel without too much shine.

- Glossy, on the flip side, pops under light—great for vibrant tones or youthful energy.

• Want a tactile difference? Matte feels soft and velvety; glossy is smooth and slick.

A matte look might suit a more eco-conscious or natural product line, while gloss screams boldness and fun. When picking between them for your empty balm packaging tubes, think about what you want folks to feel when they grab it off the shelf.

Metallic and pearlescent hues for premium appeal

Group A – Visual impact:

• Metallic finishes like rose gold or chrome silver instantly elevate perception—they shimmer under light and catch attention fast.

• Pearlescent coatings offer subtle iridescence that changes slightly with angles—soft glam without being loud.

Group B – Brand positioning:

• Use metallics if your line leans luxury or tech-forward aesthetics.

• Pearlescents work beautifully in wellness or holistic-style lines where elegance meets calm.

Group C – Compatibility with tube materials:

• These finishes pair well with both plastic and aluminum base tubes commonly used in lip balm packaging options.

Adding these hues to small tubes can make even basic balm formulas look boutique-level fancy.

Pantone color matching for consistent branding

Group A – Why it matters:

• Color consistency across batches keeps your brand identity tight—you don’t want one batch looking off-tone from another on retail shelves.

Group B – Application process:

• Manufacturers use Pantone Matching System (PMS) codes during production to ensure accuracy when coloring custom lip balm containers or sleeves.

Group C – Practical benefits:

• Avoids mismatched lids/tubes across SKUs in multi-product lines like tinted balms vs SPF balms.

• Helps coordinate print elements like logos or ingredient icons onto colored surfaces cleanly.

Pantone precision ensures every shade tells the same story—even when spread across dozens of tiny tubes on display racks.

UV-resistant coatings to protect lip balm formulas

You might not think much about sunlight hitting a balm tube—but UV rays can degrade both formula quality and label design over time if left unchecked.

- UV-blocking coatings are especially helpful if you’re using clear or semi-transparent containers.

- These protective layers also keep printed designs from fading fast—a must if you’re using pastel tones or detailed illustrations.

- For brands offering outdoor-focused products like SPF-infused balms, this coating is basically non-negotiable.

- It’s not just about keeping things pretty—it helps preserve active ingredients inside those compact little vessels too.

So yeah, even though it’s invisible, this layer does some heavy lifting behind the scenes.

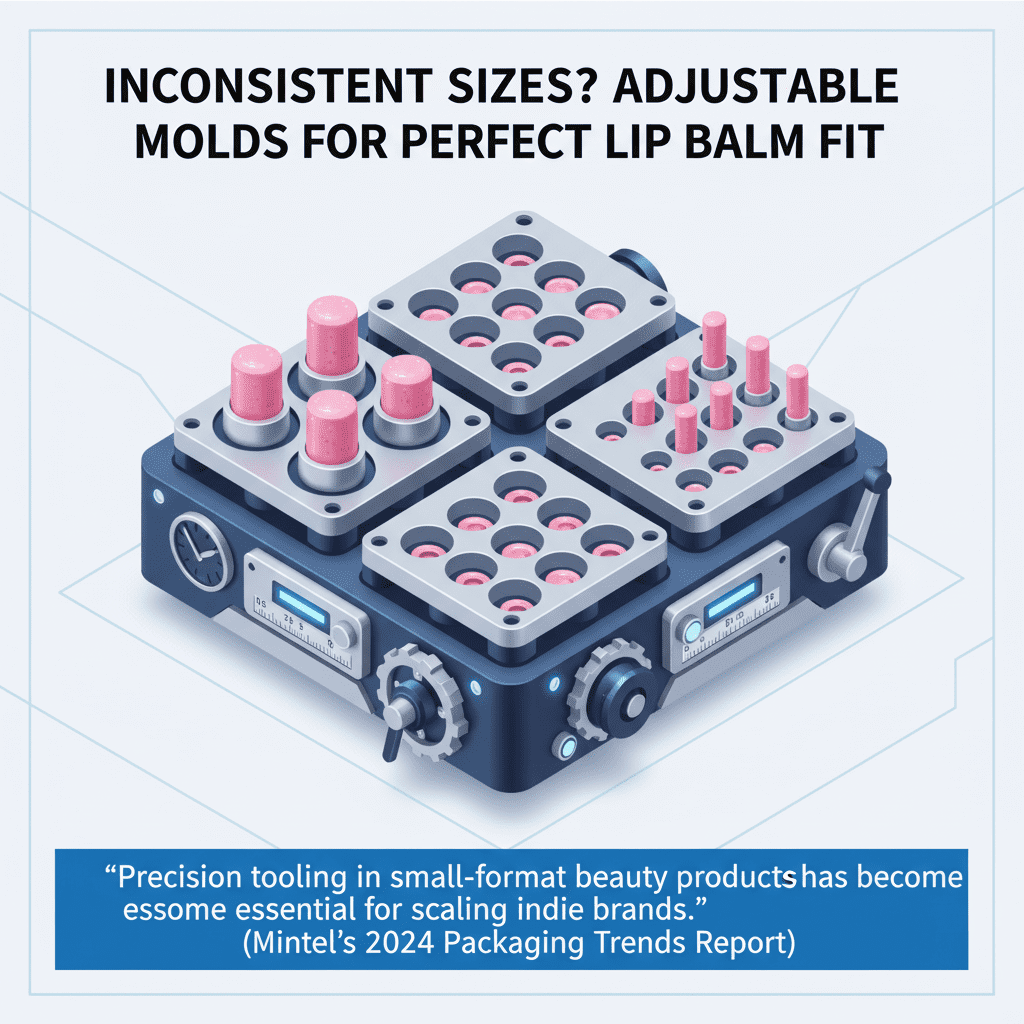

Inconsistent Sizes? Adjustable Molds For Perfect Lip Balm Fit

Getting the right fill in those tiny balm tubes can be a hassle, especially when the molds aren’t playing nice. This guide digs into how adjustable mold systems keep things smooth, no matter the tube size.

Precision molds for standard and travel sizes

- Standard-size balm tubes are typically around 0.15 oz, but travel versions go as low as 0.05 oz.

- Adjusting mold depth and diameter ensures both types get filled evenly.

- Using modular inserts helps avoid over-pour and under-fill issues.

Whether you’re working with chubby sticks or mini samplers, having precision molds that cater to these different volumes is key for keeping your product line consistent. The goal? No waste, no mess—just clean fills every time.

Versatile mold systems for bulk tube production

You don’t want to be switching out equipment every time you change your container style. That’s where smartly designed mold systems come in:

• Interchangeable cavities that fit various tube styles

• Quick-swap plates for high-volume runs

• Heat-resistant materials to prevent warping during mass pours

These features let you pump out hundreds of units without sacrificing accuracy or speed. Brands like Topfeel use this kind of setup to keep up with demand while maintaining tight quality control across their balm lines.

Reducing fill variance with adjustable cavity designs

Here’s how adjustable cavity features help cut down on inconsistencies:

- Fine-tuned plunger controls regulate exact volume per pour.

- Silicone gaskets seal each cavity snugly so nothing leaks or overflows.

- Calibrated depth stops make sure every tube gets the same amount.

According to Mintel’s 2024 Packaging Trends Report, “Precision tooling in small-format beauty products has become essential for scaling indie brands.” That’s because customers notice when one balm looks half full compared to another—even if it’s just off by a smidge.

By using adaptive molds that adjust on the fly, even smaller operations can hit pro-level consistency across all sizes of their lip balm containers—whether they’re filling full tubes or those teeny purse-friendly testers.

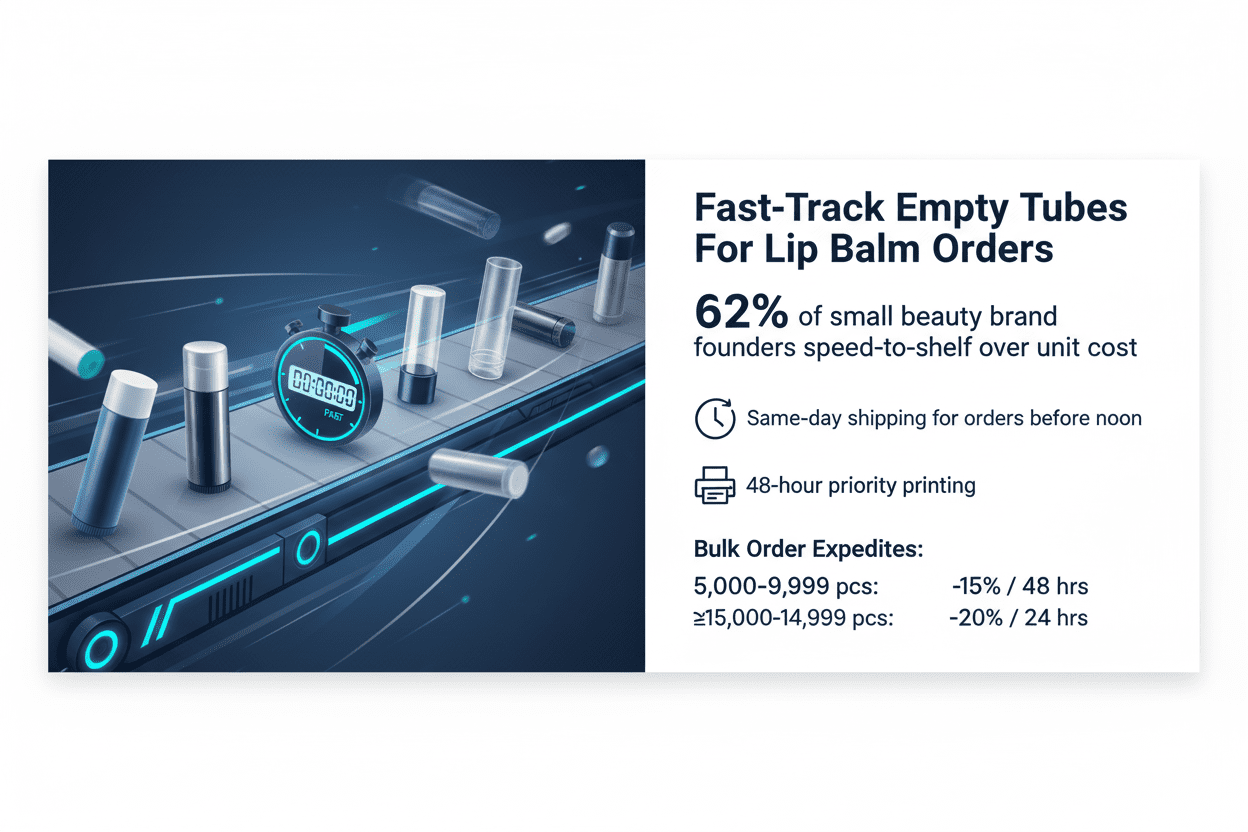

Slow Turnaround? Fast-Track Empty Tubes For Lip Balm Orders

Need things moving faster than a squirrel on espresso? Here’s how to get your balm tube orders out the door—yesterday.

Pre-stocked polypropylene tubes for rapid dispatch

• Polypropylene tubes stay stocked and shelf-ready at all times—no long waits, no backorders.

• Choose from matte, gloss, or clear finishes depending on your balm vibe.

• Got a sudden spike in demand? These pre-filled shelves mean you’re covered without scrambling.

1) Orders placed before noon ship same day.

2) Standard sizes include 0.15 oz and 0.25 oz options—popular among indie brands and bulk buyers alike.

→ With these tubes already sitting pretty in inventory, you’re skipping the whole manufacturing delay dance.

Quick reminder: Topfeel’s stocked lineup makes it easy to grab what you need when you need it—without paying premium rush fees every time.

Priority printing and assembly for 48-hour turnaround

Short lead times don’t mean cutting corners—it just means knowing where to trim the fat.

Need labels slapped on pronto? Printing starts within hours of approval. Want a custom cap color? That gets pulled fast-track too.

Rush jobs get:

– Dedicated print queues with zero bottlenecks

– Assembly teams that specialize in quick-turn runs under 500 units

– Overnight curing systems that reduce dry-time without sacrificing adhesion

According to Packaging Digest’s Q1 2024 report, “Speed-to-shelf is now considered more critical than unit cost by over 62% of small beauty brand founders.” That stat alone says it all—quick delivery isn’t optional anymore; it’s expected.

Bulk order expedites: discounted express packaging supplies

When you’re ordering big volumes of packaging supplies, you deserve more than just free shipping—you want speed and savings bundled together like peanut butter and jelly.

| Order Volume Range | Discount Rate | Express Handling Fee Waived | Estimated Ship Time |

|---|---|---|---|

| 5,000 – 9,999 pcs | -10% | Yes | Within 72 hours |

| 10,000 –14,999 pcs | -15% | Yes | Within 48 hours |

| ≥15,000 pcs | -20% | Yes | Within 24 hours |

⭑ Bonus perks include early access to limited-run colors and custom mold slots during high-demand seasons.

⭑ For repeat customers with standing orders? You’ll be bumped up the queue automatically when stock hits low-alert thresholds.

⭑ Don’t forget—the bigger your batch size, the better your margin control across fulfillment cycles.

So if you’re juggling deadlines while trying not to torch your budget on premium shipping… this setup’s got your name written all over it.

FAQs

Sustainability is more than a buzzword—it’s a promise to your customers. If you’re aiming to reduce waste and show your values, consider:

- Recyclable plastic or BPA-free options that are safer and easier on the planet

- Aluminum tubes, which not only feel premium but can be recycled again and again

- Compostable push-up paperboard containers that speak directly to zero-waste buyers

Each choice tells its own story. Choose the one that fits yours.

When deadlines close in like storm clouds, speed matters. Pre-stocked polypropylene tubes can ship quickly—some within 48 hours when paired with priority printing services. Add assembly support if needed, so you’re not just fast…you’re ready.

It depends on how you want people to experience your product:

- Twist-ups feel familiar—ideal for smooth application of solid balms

- Push-ups offer a rustic charm perfect for natural or handmade branding

- Gloss-style tubes suit liquid formulas and give off a sleek vibe

Think about what kind of moment you want someone to have when they open it.

Yes—and size speaks volumes. Smaller options (under 5 ml) are great as samples or pocket companions; larger ones (10 ml) make sense when you’re offering something rich enough to last longer—or priced like it should.

Absolutely. Sunlight doesn’t just fade labels—it breaks down essential oils and delicate ingredients inside the balm itself. A UV coating acts like sunglasses for your formula: subtle protection with long-term benefits.

Aluminum already feels luxe in hand—but finish it right, and it becomes unforgettable:

- Hot foil stamping adds metallic accents in golds or coppers that shimmer under light

- Embossing gives texture—a raised logo turns every touch into brand recognition

These aren’t just design choices—they’re emotional cues wrapped around your product.