Benefits of Choosing Aluminum Empty Lipstick Tubes

You know how some things just feel right—like slipping on your favorite jeans or hearing that satisfying click when a pen cap snaps shut? That’s the vibe aluminum brings to an empty lipstick tube. It’s sleek, strong, and doesn’t crack under pressure (unlike, say, plastic in a hot delivery truck). If you’re scaling up or rebranding your beauty line, this little metal marvel isn’t just packaging—it’s a power move.

Plastic might be cheap today but it’s costing brands tomorrow. With refillable designs and lower shipping weight, aluminum is shaving dollars off budgets while ticking every eco-conscious box. According to McKinsey & Company’s 2023 report on sustainable beauty trends, over 60% of consumers now factor recyclability into purchase decisions. Time to give ’em something shiny worth keeping—and refilling.

Key Points to Pocket: The Smart Move Behind Every Empty Lipstick Tube

-

Aluminum Over Plastic: Consumers are leaning into sustainable packaging—aluminum tubes offer a recyclable, durable alternative to plastic that aligns with eco-conscious values.

-

Refillability is Revenue: Refillable designs not only minimize environmental waste but also boost brand loyalty and long-term cost savings.

-

Lightweight Shipping Wins: Aluminum’s featherlight nature cuts down on freight costs, making bulk distribution more efficient and affordable.

-

No More Leaks or Meltdowns: With airtight seals and UV protection, aluminum lipstick tubes keep formulas intact—even in hot delivery trucks.

-

Style Meets Substance: Matte, glossy, or metallic finishes elevate shelf appeal while CNC machining ensures flawless precision during production.

-

Partner Smarter for Quality Control: Working with trusted manufacturers guarantees consistency across batches—no leaky lids or uneven threading surprises.

Why Aluminum Empty Lipstick Tubes Dominate Packaging Trends

Metal packaging has gone glam — and smart. Here’s why aluminum tubes are stealing the spotlight in lipstick packaging.

Eco-Friendly Aluminum vs Recyclable Plastic in Cosmetic Containers

Grouped Bullet Structure with Market Research Quote

- Sustainability Score: Aluminum boasts a recycling rate of over 75%, far outpacing most plastics that hover around 9–20%, depending on type and region.

- Energy Efficiency: Producing recycled aluminum uses up to 95% less energy than creating new aluminum from raw ore — that’s serious eco cred.

- Longevity Matters: Unlike plastic, which degrades with each recycle loop, aluminum retains its quality indefinitely.

According to Euromonitor International’s April 2024 report on sustainable cosmetics packaging, “Aluminum’s closed-loop recyclability positions it as the material of choice for brands seeking carbon-neutral goals.”

Consumers are clocking this shift too — more shoppers now check materials before tossing them into their carts.

Durable and Lightweight Lipstick Tubes Enhance Refillable Cases

Natural Combination Structure with Scientific Table

Aluminum doesn’t just look sleek — it works hard behind the scenes too.

• It’s tough enough to survive purse drops and makeup bag chaos without cracking or warping.

• Featherlight by nature, it’s ideal for portable beauty routines — no one wants their clutch weighing them down.

| Feature | Aluminum Tube | Plastic Tube | Glass Tube |

|---|---|---|---|

| Average Weight | ~12g | ~18g | ~45g |

| Drop Resistance | High | Medium | Low |

| Refill Compatibility | Excellent | Moderate | Poor |

That combo of strength and weight makes these tubes perfect for refillable designs — users get durability without bulk, all while cutting waste.

Eye-Catching Matte, Glossy, and Metallic Finishes for Makeup Packaging

Multi-item Grouped Bullet Structure

Visuals matter big time in beauty aisles — and finishes can make or break a sale:

-

Matte Finishes

• Understated luxury vibe

• Great grip feel; no slip during application -

Glossy Finishes

• Reflect light beautifully under store lights

• Often perceived as more premium -

Metallic Finishes

• Bold shine grabs attention instantly

• Perfect canvas for embossing or laser engraving logos

Each finish tells its own story. Whether you’re going minimalist chic or full-on glamazon, these surface styles let brands align aesthetics with identity — all while staying functional.

Streamlining Production with CNC Machining and Thermoforming Techniques

Long Descriptive Structure

Modern production isn’t just about pumping out units fast—it’s about precision meets speed. That’s where techniques like CNC machining shine: custom molds carved down to microns ensure every lipstick shell fits perfectly with internal components like twist mechanisms or refills. Meanwhile, advanced thermoforming techniques allow shaping at scale without losing detail—ideal when mass-producing thousands of identical shells without sacrificing design integrity.

Together, these processes slash error rates and reduce waste during manufacturing runs—less scrap metal means lower costs over time and cleaner production floors overall.

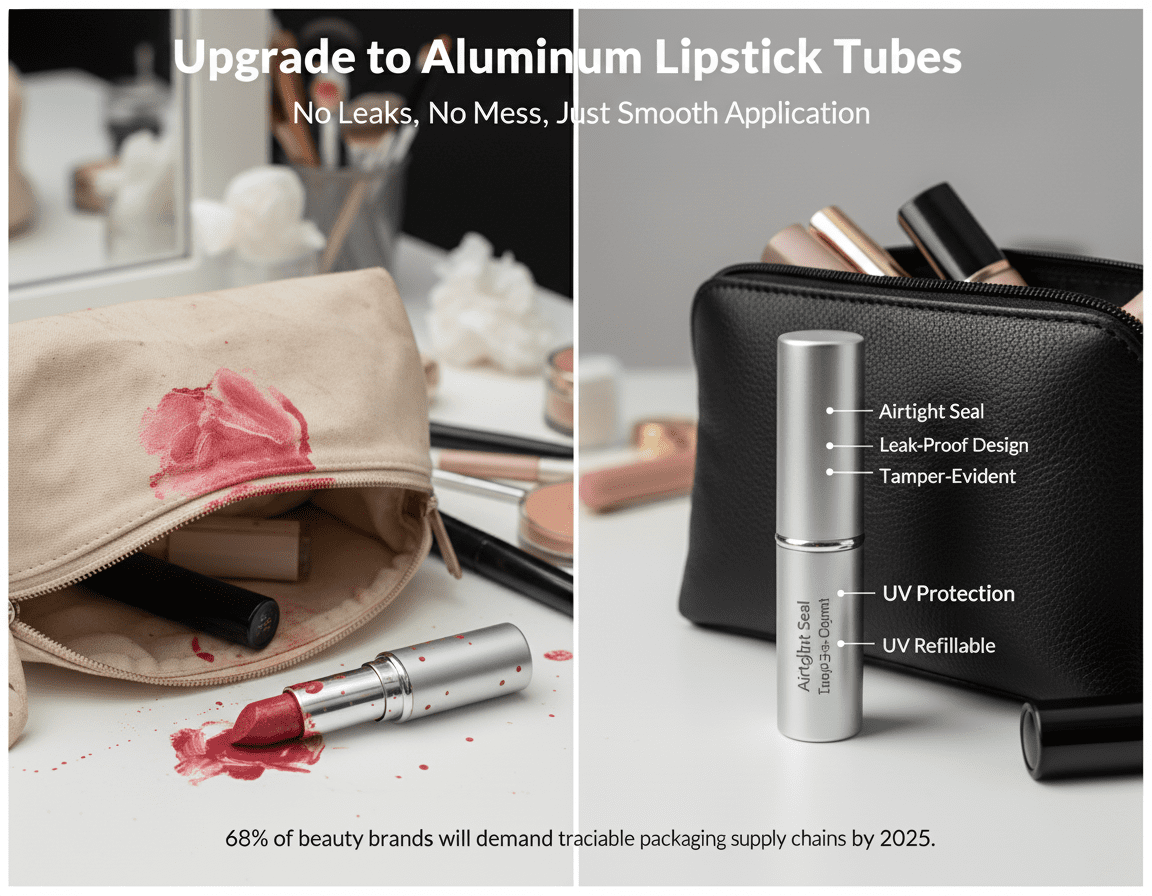

Leaky Tubes? Switch To Aluminum Lipstick Tubes

Say goodbye to messy bags and wasted product—here’s why switching to aluminum lipstick tubes is the smart move.

Airtight Seal and Leak-Proof Design for Mess-Free Lipstick Application

- Aluminum tubes naturally form a tighter barrier than plastic, locking in moisture and keeping formulas fresh.

- A leak-proof design means no more smudges on your makeup pouch or coat pocket.

- That clean snap when you close it? It’s the sound of an airtight seal doing its job.

- Keeps your favorite shade from drying out

- Saves product by reducing exposure to air

- Helps maintain color consistency with every swipe

✓ No leaks

✓ No mess

✓ Just smooth, reliable lipstick application

Unlike traditional packaging that warps over time, these sleek shells hold their shape—and your look—together.

Tamper-Evident Aluminum Tubes Featuring Built-In UV Protection

| Feature | Benefit | Material Used | Shelf-Life Impact |

|---|---|---|---|

| Tamper-evident band | Alerts consumers to product safety | Brushed aluminum | +6 months |

| UV-blocking inner coating | Protects formula from sun damage | Oxide-treated film | +3 months |

| Dual-lock twist cap | Prevents accidental opening | Hardened alloy | Neutral |

A secure tube isn’t just about looks—it’s about trust. The built-in tamper ring cracks on first use, making it clear if someone else has gotten into your stash. Plus, that subtle shimmer on the outside? It’s not just pretty; it’s part of the UV protection system that helps preserve active ingredients longer.

Refillable Designs That Prevent Spills and Reduce Packaging Waste

You pop in a refill, click it shut, and you’re done—no glue sticks or sticky fingers involved.

• Reusable casing cuts down on landfill-bound trash

• Inner cartridges are easy to swap without spills

• Compatible with most standard-size inserts

These refillable designs aren’t just eco-friendly—they’re wallet-friendly too. You get premium packaging once, then refill as needed. And since everything stays sealed inside until you’re ready to apply, there’s zero chance of those dreaded purse explosions.

Partnering with Packaging Manufacturers for Consistent Quality Control

“By 2025, over 68% of beauty brands will demand traceable packaging supply chains,” according to Global Cosmetic Insights’ Q1 2024 report.

That stat alone makes one thing clear: sloppy packaging is no longer an option. Topfeel partners directly with vetted packaging manufacturers, ensuring every batch meets strict visual inspection and pressure-seal testing standards before it ever hits your shelf.

Multiple quality control points:

– Raw material verification

– Automated seal integrity testing

– Manual torque resistance checks

This tight grip on the manufacturing process helps eliminate defects like cracked closures or warped threading—issues that can ruin even high-end formulations.

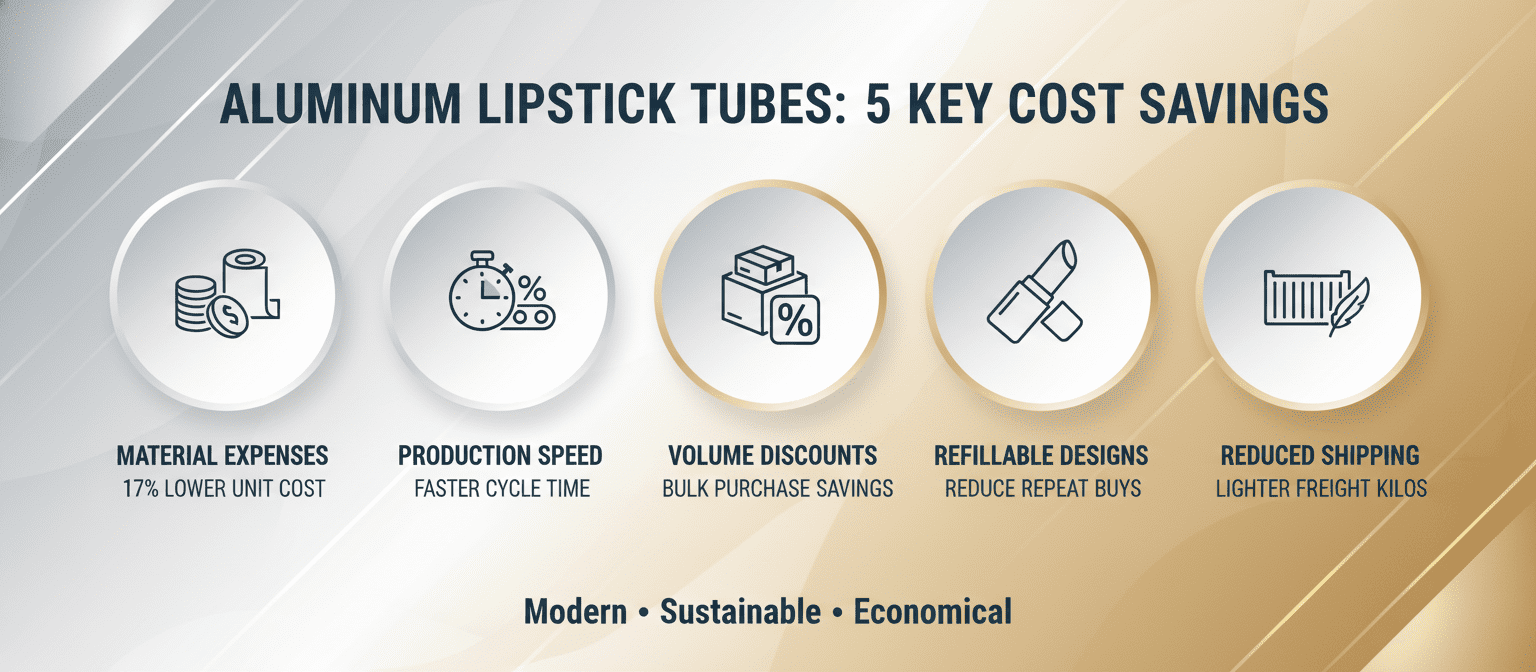

Five Cost-Saving Points For Aluminum Lipstick Tubes

Aluminum lipstick packaging isn’t just sleek—it’s a wallet-friendly game changer for brands scaling fast.

Lower Material Expenses Compared to Plastic and Acrylic Containers

Shifting from plastic or acrylic to aluminum cuts the fluff right out of your material bills.

• Plastic resin prices have been climbing, while aluminum remains relatively stable in global markets.

• Acrylic is flashy but pricey—especially when custom molding is involved.

• With lipstick tubes, going metal means fewer additives, no colorants, and less finishing work.

According to Euromonitor’s Q1 2024 packaging cost analysis, aluminum-based cosmetic containers show a 17% lower average unit cost than their plastic counterparts across Asia-Pacific markets.

In short? Less money on raw stuff, more room for profit margins.

Faster Production with Injection Molding and CNC Machining

Speed kills delays—and that’s where aluminum shines:

- Injection molding handles high-volume parts like caps and sleeves in minutes.

- Precision comes from CNC machining, perfect for those sleek inner tube threads.

- No waiting around for curing or drying—just punch, polish, pack.

- These processes cut manual labor hours significantly, especially at scale.

- Automated lines keep quality consistent while slashing turnaround times.

For brands pushing thousands of units weekly—like Topfeel—the time saved translates directly into lower per-unit production costs and faster market entry.

Volume Discounts through Wholesale Distributors and Contract Manufacturers

Bulk buying isn’t just smart—it’s essential when you’re scaling up your cosmetics line.

→ Order larger batches of aluminum components? You unlock serious price breaks through trusted wholesale distributors.

→ Partnering with experienced contract manufacturers means bundled services: sourcing + assembly + QC = fewer middlemen.

→ Brands can negotiate better rates by committing to recurring orders rather than one-off runs.

This combo gives you a tighter grip on your supply chain while keeping costs predictable—even when you’re introducing new shades or limited-edition styles of your favorite empty lipstick tubes.

Savings from Refillable Designs Minimizing Packaging Waste

Refillable designs aren’t just good vibes—they’re cost-cutting machines:

You buy the outer shell once—crafted from durable aluminum construction—and refill it as needed. That means way less cash spent on full packaging every cycle.

Consumers love the eco-angle; brands love the repeat purchases without repeated packaging expenses. Plus, it reduces overall packaging waste, which can help meet retailer sustainability requirements without extra spend.

Sustainable doesn’t have to mean expensive—it can actually be cheaper in the long run.

Reduced Shipping Costs Thanks to Lightweight Aluminum Construction

Shipping adds up fast—but lighter loads change everything:

• The naturally low weight of lightweight aluminum shaves off grams per unit

• Multiply that by thousands of units per shipment—you’re dropping kilos off freight charges

• Less weight = smaller carbon footprint + reduced fuel surcharges

• Easier handling during logistics lowers breakage risk too

When shipping internationally or across distribution hubs, this efficiency makes all the difference in keeping costs tight without compromising product integrity—even for fully assembled empty lipstick tube variants ready for retail shelves.

FAQs

Plastic feels familiar, but aluminum speaks a different language—one of elegance and responsibility. It’s sleek in the hand, cool to the touch, and carries a quiet strength that plastic can’t match. Beyond aesthetics, it’s endlessly recyclable and far more durable, making it perfect for refillable designs.

Absolutely—and not just on paper.

- Aluminum is lighter than you’d expect, which means lower freight charges across large shipments.

- CNC machining and injection molding streamline production at scale without sacrificing quality.

- Over time, fewer replacements are needed due to its durability.

It’s personal now—people want products that reflect their values. A refillable design says: “I care.” It reduces waste while offering something reusable and beautiful to keep using again and again. That emotional connection builds loyalty faster than any discount ever could.

Yes—they’re built like tiny vaults for your favorite shade: secure closures snap tight; airtight seals lock moisture in; no smudges in your purse or makeup bag when you’re rushing out the door.

There’s room here for personality:

- Matte gives off a soft sophistication.

- Glossy feels bold—almost reflective of confidence itself.

- Metallic catches light like jewelry on skin.Custom textures like frosted or velvety coatings can also be added—it all depends on how you want your brand to feel when someone holds it.

Refillables aren’t just trendy—they’re emotional anchors between product and person. Instead of tossing away packaging after every use, people hold onto something they love—a weighty case that reminds them of who they were when they bought it…and who they’re becoming each time they twist it open again.