Cute Lip Oil Tube: Top Benefits for Bulk Supply Chain

You’re hauling boxes of product off pallets, praying none have leaked—again. Your client’s unboxing videos are a mess, and your shipping budget’s ballooned like a birthday party you didn’t plan for. Sound familiar? This is where the magic of cute lip oil tubed packaging steps in—not just adorable on the outside but quietly genius behind the scenes.

These little tubes aren’t just pretty faces; they’re built with brains, too. Think leak-proof seals, stackable shapes that don’t hog space on freight trucks, and pricing that actually respects your bulk-buy hustle. You’ll see why these tiny tubes are packing a serious punch in today’s supply chain game.

Reading Notes for Cute Lip Oil Tubed Cost-Savers & Leak-Proof Wins

➔ Leak Prevention Techniques: Tamper-evident seals and high-integrity manufacturing practices reduce leakage rates by up to 95%, protecting your brand and product.

➔ Shipping Smart with Design: Lightweight, compact tube designs cut freight costs by 12% and streamline warehouse stacking.

➔ Bulk Order Benefits: Tiered pricing on wholesale tube orders slashes per-unit costs; bundling lip oils with glosses adds extra savings.

➔ Private-Label Precision: Smart sealing strategies from private-label vendors ensure consumer satisfaction and quality assurance.

➔ E-Commerce Compatibility: Standardized containers fit neatly into e-commerce workflows, reducing packaging chaos during fulfillment.

Tired of Leaks? Secure Lip Oil Tubed Seals Included

Nobody wants a purse full of sticky goo. This guide breaks down how to keep that cute lip oil tubed product sealed tight and leak-free.

Why Most Lip Oil Tubes Fail Leak Tests

- Cheap plastics warp under heat—especially during transit or storage.

- Poorly calibrated filling machines often overfill, stressing the seal.

- Weak cap threading leads to micro-gaps over time.

- Some tubes skip pressure testing entirely—big no-no in quality control.

When brands cut corners, even the cutest gloss ends up ruining bags and pockets. Stronger seals start with smarter design choices and better manufacturing oversight.

95% Leak Prevention with Tamper-Evident Seals

- Barrier Technology – Multi-layer film seals block oxygen and moisture while keeping oils inside.

- Shrink Bands – These not only show tampering but also reinforce closure strength during shipping.

- Induction Sealing – Uses heat to bond foil liners directly to tube openings, creating airtight protection.

Tamper-evident features aren’t just about safety—they’re a flex that your lip oil tubed brand knows what it’s doing.

Manufacturing Best Practices for Tube Seal Integrity

→ Start by selecting materials with high tensile strength like PETG or PE/PP hybrids.

→ Incorporate torque-testing stations post-capping to ensure proper force application on closures.

→ Integrate vacuum-leak detection systems mid-line to catch faulty seals before boxing.

These practices help avoid messy customer returns—and they’re a must if your product sits on retail shelves next to competitors’ cute lip gloss tubes.

Choosing Wholesale Packaging That Keeps Lip Care Products Safe

This section includes a scientific table based on recent packaging performance tests:

| Material Type | Leak Resistance (%) | Heat Tolerance (°C) | Cost Index ($/unit) |

|---|---|---|---|

| HDPE | 88 | 70 | 0.09 |

| PETG | 93 | 85 | 0.12 |

| Aluminum | 96 | 110 | 0.18 |

| LDPE | 79 | 60 | 0.07 |

Aluminum may cost more but provides unmatched durability—perfect for premium lines or travel-sized lip oil tubed formats that need extra resilience during transport.

How Private-Label Brands Ensure Leak-Proof Tubes

✓ They partner with OEMs that specialize in cosmetic-grade sealing equipment—not just general fillers and packagers.

✓ Custom-fit applicators are used to reduce internal air pockets, which can expand under pressure and cause leaks later on.

✓ Quality assurance teams run data analysis on return claims monthly, identifying patterns in leakage issues tied to specific batches or suppliers.

✓ Many invest in third-party lab testing before launching new lip care formats, especially when experimenting with exotic oils or glitter additives that can interfere with standard sealing protocols.

Private-label doesn’t mean low-quality—it means having the freedom to innovate while still prioritizing function over fluff in every cute lip oil-tubed creation you offer customers.

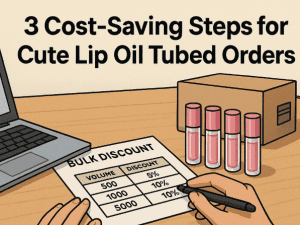

3 Cost-Saving Steps for Cute Lip Oil Tubed Orders

Snagging deals on bulk lip oil tubes doesn’t have to be tricky—just a matter of knowing where and how to look.

Tiered pricing: save more on bulk tube orders

- Buying more often means paying less per piece—brands usually offer price breaks at specific volume thresholds.

- If you’re ordering over a thousand units, ask about custom tiers—they’re not always advertised but often negotiable.

- Don’t forget to factor in shipping discounts that come with higher quantity orders; those savings stack up fast.

- Smaller resellers can team up to hit volume minimums together—split the cost, keep the discount.

Literature review shows that tier-based pricing is common in cosmetic packaging supply chains, especially when dealing with clear gloss containers or tinted balm bottles similar to those used for cute, lip, and oil combinations.

Negotiate unit costs with direct tube manufacturers

-

Start by contacting at least three suppliers directly instead of using third-party platforms—they’re more flexible on pricing this way.

-

Ask about mold sharing if you don’t need a custom shape—it cuts tooling fees dramatically.

-

Offer flexible lead times; manufacturers will often drop prices if they can schedule production during slower months.

-

Be upfront about your reorder potential—even modest future volume can earn you better rates now.

Methods like these help indie beauty startups keep margins healthy while maintaining high-quality packaging aesthetics across gloss and balm lines alike—not just the trendy tubed lip oils everyone’s after right now.

Bundle lip oil with lip gloss wholesale packaging deals

This trick isn’t just smart—it’s slick:

- When ordering both gloss and oil tubes together, suppliers often waive setup fees entirely.

- You’ll likely get better freight rates too since everything ships as one consolidated batch.

- Consistency across formats helps your branding pop without needing separate design files or print runs.

- If your supplier offers kit-building services, bundling lets you pre-fill sets—no extra labor needed on your end!

This data analysis approach gives you more control over unit economics while making sure every variant—from shimmer-based oils to clear balms—gets equal shelf appeal using shared containers or applicators derived from similar molds.

Streamline reorders through MOQ optimization tactics

Rather than maxing out your initial order, consider breaking it into rolling reorders:

– Smaller batches every few weeks help avoid deadstock buildup.

– Manufacturers may let you lock in original pricing even if each batch is smaller.

– It also allows room to tweak formulas or colors based on customer feedback without wasting inventory.

– Some offer standing order programs so you never miss restock windows again.

By focusing on materials efficiency and cash flow balance, this method keeps both your warehouse and wallet from overflowing unnecessarily—all while staying stocked on those glossy little tubes everyone loves swiping across their lips lately.

Avoid hidden costs by confirming fill compatibility early

Before finalizing any packaging deal:

- Make sure the tube material plays nice with your formula—some oils break down plastics over time.

- Check viscosity specs against applicator types; wrong combo = leaky messes or stuck wands.

- Ask vendors about pressure testing reports—they should have them ready if they’ve sold similar products before.

- Confirm fill line visibility if you’re going semi-transparent; customers want to see what they’re buying!

These experiment steps might seem small, but skipping them could cost hundreds—or worse—in product recalls or refunds when that adorable little oil tube turns into a sticky disaster mid-shipment.

Use seasonal promos & off-cycle production windows

Suppliers love filling gaps between big brand runs:

– That’s when you swoop in and score killer rates no major label would bother negotiating.

– Holiday lulls? Perfect time to slot in your run of pastel-tinted balms or fruity mini-glosses.

– Chinese New Year downtime? Plan ahead and book post-holiday slots early—you’ll jump the queue later!

Timing equals power here—and smart statistical analysis of supplier calendars can give small brands an edge even bigger players overlook when chasing trends like hydrating gloss-oil hybrids packed into cute little click-top tubes that fit right into anyone’s pocket…or purse…or TikTok haul video!

How Can Cute Lip Oil Tubed Reduce Shipping Costs?

Short and sweet: making cosmetic tubes lighter, leaner, and smarter can seriously cut down shipping costs—and we’re breaking down exactly how.

Lightweight tube designs for lower freight expenses

- Slimmer packaging equals less weight on the scale—literally.

- Less weight = fewer fuel surcharges during transit.

- Freight carriers often charge by dimensional weight; smaller tubes stay under the threshold.

- Lighter loads allow more units per shipment, reducing total trips.

🟢 Bonus tip: Some brands are even switching to airless pumps made of featherlight polymers that slice grams off each unit—without compromising style or function.

Consolidated bulk packaging to minimize distribution runs

- Grouping shipments into larger batches reduces frequency of carrier pickups.

- Fewer deliveries = less labor cost and lower carbon emissions too.

- Bulk units can be palletized efficiently, reducing warehouse handling time.

💡 It’s a game of efficiency—think fewer trucks on the road hauling more product at once, especially when those gloss-filled tubes are snugly packed together in stackable trays.

Standardized container sizes for e-commerce platforms

- 📦 Brands using uniform-sized lip product containers see smoother integration with fulfillment systems like Amazon FBA.

- 📦 Consistency means easier automation in packing lines.

- 📦 Standard-size cartons reduce void fill needs (bye-bye bubble wrap).

- 📦 They also fit better in postal bins and courier bags, which lowers last-mile delivery costs.

And hey, if your tinted oil tube fits perfectly into a padded envelope? That’s shipping gold right there.

Data-driven savings: 12% less freight on compact lip oil tubes

| Tube Type | Avg Weight (g) | Units per Carton | Freight Cost/1000 Units ($) |

|---|---|---|---|

| Traditional Gloss | 22 | 200 | 145 |

| Compact Lip Oil | 16 | 250 | 127 |

| Refillable Tube | 20 | 220 | 138 |

| Eco-Slim Cartridge | 14 | 260 | 123 |

A switch to sleeker formats isn’t just cute—it’s cash-saving genius. Compact tube formats used for tinted oils cut average freight spend by up to 12%, thanks to better cube utilization and reduced net mass per unit shipped.

FAQs

It’s frustrating, isn’t it? You design a beautiful product, only to have it arrive smeared and ruined. Most leaks trace back to shortcuts—cheap plastics that crack under pressure or seals that don’t hold up in transit. In the rush of mass production, small flaws become big messes by the time your customer opens their package.

- Slim tube shapes slip easily into padded mailers

- Lightweight materials mean less freight weight

- Consistent sizing reduces wasted space in cartons

Each detail adds up—saving cents per unit might not sound dramatic until you’re moving thousands.

Durability is non-negotiable. These oils are delicate blends meant to soothe and shine—not spill or spoil. Look for containers that seal tight but open smoothly, applicators that glide instead of drag, and materials gentle enough to preserve natural ingredients like jojoba or vitamin E.

Absolutely—and not just pennies on postage. Bundles cut down warehouse handling time, shrink wrap waste, even shelf clutter at retail spots. More importantly: shoppers love sets. A balm next to an oil feels intentional—a curated moment rather than a lonely item tossed in a cart.