MA-66 Clear Lip Gloss Packaging with PETG Wand

Model Number: MA-66

Capacity: 5 ml

Material: PETG, LDPE

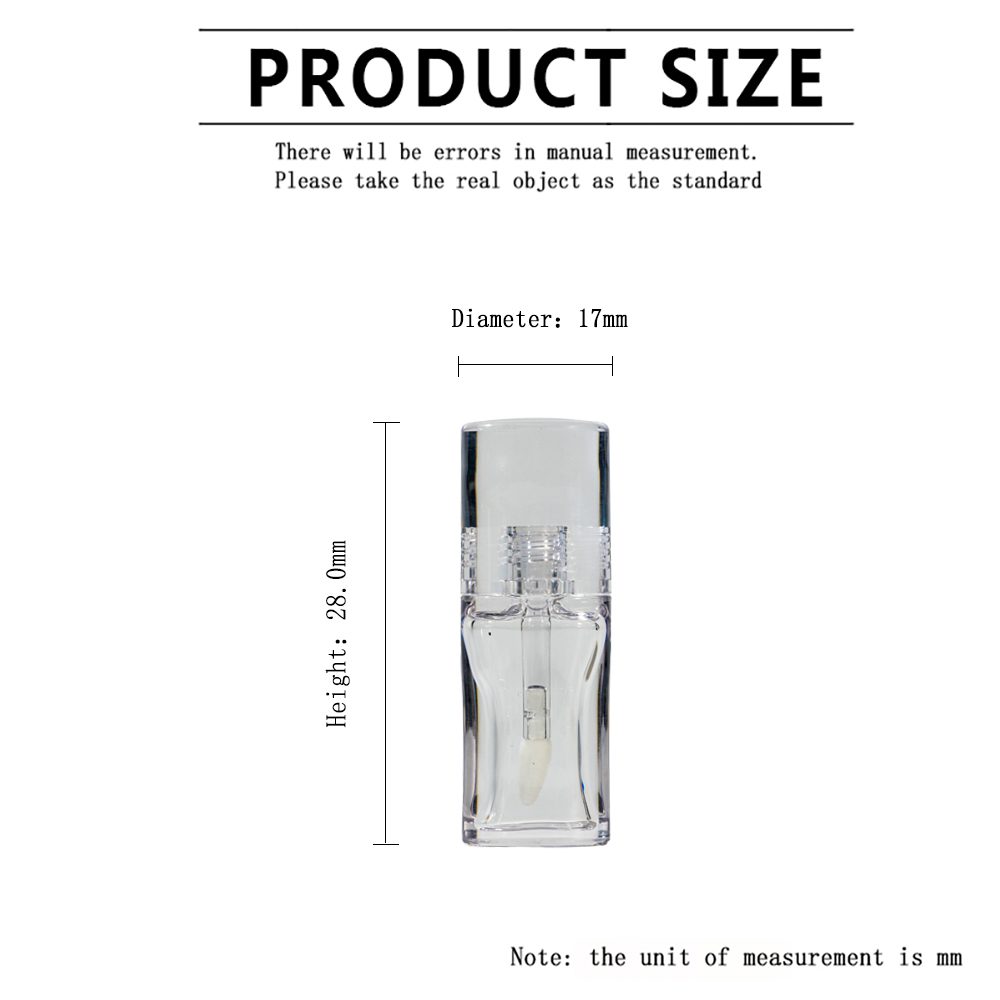

Size: Φ17mm × H28mm

MOQ: 12,000 pcs

Application: Lip Gloss, Concealer, Lip Oil, Serum, Spot Treatment

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color and Printing

Sample: Available

Advantages

-

Features a modular PETG structure with a concave inner wall for enhanced clarity, durability, and premium appearance.

-

Compact 5 ml size tailored for lip gloss, serums, and other targeted liquid cosmetic applications.

-

LDPE stopper ensures controlled dispensing and clean application with minimal product residue.

You May Also Like

View Product Details

Built for Precision & Clarity

● Four-Part Modular Build

This packaging consists of four precisely formed parts:

-

Bottle (PETG): Durable and crystal-clear, offering visibility of the internal formula while maintaining resistance to impact and chemical degradation.

-

Cap (PETG): Screws securely into place with smooth torque and minimal thread resistance, supporting leak-proof sealing.

-

Wand (PETG): Affixed to the cap, the wand is sturdy and shaped for optimal compatibility with sponge tips or other applicator designs.

-

Inner Stopper (LDPE): Flexible and form-fitting, enabling consistent flow control and minimizing product waste.

● Inner Concave Wall Design

This container features a subtle but strategic concave contour inside the bottle. While the primary function remains containment and clarity, the inward-curved surface contributes to the following:

-

Enhanced aesthetic symmetry without altering external dimensions

-

Improved liquid visibility, especially for tinted or iridescent formulations

-

Visual differentiation for shelf display without added decorative components

Smart Fit for Liquid Beauty

● Ideal for Targeted Liquid Use

This format meets the needs of brands producing concentrated formulas or premium cosmetic products that require precise dosing.

-

Lip glosses & lip oils: The stem length is matched to bottle height, ensuring near-total product retrieval.

-

Concealers & correctors: The transparent PETG body makes shade identification straightforward during batch handling.

-

Serums or spot treatments: Leak-resistant stopper and ergonomic wand design ensure consistent dispensing for thin or thick formulas.

According to a 2024 Euromonitor report, liquid-based cosmetics in precision packaging (under 10 ml) grew by 18.7% year-over-year, driven by sampler kits, travel SKUs, and hybrid formulas across skincare and makeup.

Clean Swipe, Every Time

● No-Mess Applicator Flow

Engineered with an inner stopper designed to reduce product overload, this component ensures a consistent amount of formula is dispensed with each use. Its functionality is particularly beneficial in OEM/ODM contexts where formula viscosity can vary.

-

The LDPE material is resilient, providing long-term flexibility and wear resistance during repeated insertions and withdrawals of the applicator.

-

The stopper opening can be customized based on formula viscosity (e.g., low-viscosity serums vs. high-viscosity concealers).

-

Reduces the need for secondary cleaning components during manufacturing and post-filling quality assurance.