What is Blow Packaging? Uncover Its Secrets and Applications!

In the beauty biz, packaging isn’t just a shell—it’s your product’s first date outfit. Blow packaging has become the go-to for makeup containers that need to be tough, lightweight, and look like they belong on a Sephora shelf. Think mascara tubes that don’t crack in transit or foundation bottles that feel luxe but won’t weigh down your purse.

Cosmetic brands aren’t just chasing pretty looks anymore—they’re hunting for packaging that balances durability with mass production speed. According to a 2023 report by Smithers, global demand for plastic cosmetic containers produced via blow molding is set to hit $10 billion by 2027. That’s not hype—that’s market muscle talking.

So what makes blow packaging such a backstage hero in makeup manufacturing? Hold onto your lip gloss—we’re about to spill every secret worth knowing.

Key Insights into Blow Packaging

→ What It Is: Blow packaging creates hollow plastic containers through air pressure, providing lightweight yet durable solutions.

→ Materials Used: Common materials include PET, acrylic, and plastic, selected for their compatibility with product requirements.

→ Products Produced: It commonly results in beauty essentials like lipstick tube, mascara bottles, and foundation containers.

→ Process Difference: Unlike injection molding, blow molding focuses on creating hollow parts, making it ideal for specific packaging needs.

→ Efficiency Benefits: High production rates and material efficiency make blow packaging cost-effective and fast.

→ User Experience: Ergonomic designs and convenient features enhance usability while also promoting sustainability.

→ Durability and Safety: Blow packaging provides impact resistance and effective sealing, ensuring product integrity and extended shelf-life.

What Is Blow Packaging? Understanding The Basics

Get the lowdown on how blow packaging works, what it’s made of, and what everyday products rely on it—without the jargon.

Introduction to Blow Packaging: What It Is and How It Works

- Blow molding is like inflating a balloon inside a mold—it uses air pressure to shape soft plastic into hollow forms.

- Think shampoo bottles, water jugs, or even mascara tube—all born from this simple but clever process.

- The core steps? Heat plastic → form a parison → blow it into a mold cavity → cool and eject.

You’ll often hear folks call it “air-sculpting” for plastics, and that’s pretty accurate. By using controlled air pressure inside a closed mold, manufacturers can create uniform, lightweight packaging that doesn’t skimp on durability. The resulting hollow containers are everywhere—from your fridge to your makeup bag.

Key Materials Used in Blow Packaging: Acrylic, PET, and More

• PET (Polyethylene Terephthalate) – Lightweight, transparent, and perfect for beverages or cosmetics • HDPE (High-Density Polyethylene) – Tough stuff; great for household cleaners or milk jugs • PP (Polypropylene) – Flexible yet strong; ideal for flip-top caps or squeeze bottles • Acrylic – Crystal clear with premium feel; often used in high-end cosmetic jars

According to Mintel’s 2024 Global Packaging Report, over 62% of beauty brands now favor recyclable materials like PET, citing consumer demand for sustainable packaging solutions. That’s where blow-packaging shines—it works with versatile resins while keeping things eco-conscious.

Common Components Produced by Blow Packaging: Lipstick Tubes, Mascara Bottles, and More

♢ Lip gloss tube with slim nozzles? Yup—blow-molded. ♢ That sturdy bottle your face wash comes in? Also blow-molded. ♢ Even those little travel-size containers you toss in your gym bag—they’re all part of the same family.

From sleek cosmetic packaging like lipsticks and mascaras to rugged detergent jugs and portable beverage bottles—this method handles them all. It’s fast, scalable, and perfect for brands looking to keep costs low without sacrificing quality.

And if you’re wondering who nails this kind of work? Topfeelpack has built a solid rep around producing top-tier beauty containers using advanced blow-packaging tech—no fluff, just seriously good results.

The Process Of Blow Molding: How Blow Packaging Works

Quick peek into how blow packaging takes shape—literally. From raw plastic to shelf-ready bottles, it’s a wild ride of heat, air, and precision.

Blow Molding vs. Injection Molding: What’s the Difference?

- Blow molding is all about making hollow stuff like bottles and containers.

- Injection molding? That’s for solid parts—think caps or hard plastic tools.

- Both use molds, but the design logic is totally different.

-

In blow molding:

- Plastic is melted and inflated inside a mold.

- It cools down into a hollow form.

- In injection molding:

- Plastic is injected into a mold under pressure.

- It solidifies into complex shapes.

✔️ If you’re making anything that needs to hold liquid—like shampoo or juice—you’re in blow packaging territory.

Compared to injection molding, blow molding handles volume better with lighter materials and faster cycles. That means less material waste and more bang for your buck. And when it comes to creative product design, blow molding gives you more freedom with shapes while keeping things airtight and leak-free.

The Step-by-Step Blow Molding Process: From Concept to Creation

Start with resin pellets → end up with sleek bottles on store shelves? Here’s how:

• Heat up the plastic resin until it becomes gooey. • Form a tube-like shape called a parison or use a preheated preform if it’s injection stretch blow molding. • Clamp that hot piece between two halves of the mold cavity. • Blast some air inside—it expands like a balloon! • Let it chill using the built-in cooling system, then pop it out once it’s solidified.

Each stage has its own timing, especially during cooling—the longer that takes, the longer your overall cycle time gets. So optimizing airflow and mold temperature matters big time in production efficiency.

The whole thing happens fast—sometimes under 10 seconds per unit—which makes it perfect for high-volume runs in industries relying on reliable, repeatable output from their blow packaging lines.

Equipment and Tools in Blow Molding: Essential Machines and Techniques

Grouped by function, here are the heavy hitters behind every smooth operation:

🔧 Forming & Melting:

- Extruder – Melts raw plastic resin

- Barrel heaters – Keep temps consistent

- Screw drive – Moves molten plastic forward

🔩 Shaping & Blowing:

- Blow molds – Custom-shaped steel cavities

- Dies – Shape parison/preform precisely

- Air compressor – Delivers high-pressure air for expansion

❄️ Cooling & Handling:

- Water-cooled channels within molds

- Mold openers/ejectors

- Integrated robotics for pickup/placement

These machines don’t just work—they hustle around the clock to keep your production line humming smoothly. Whether you’re crafting wide-mouth jars or narrow-neck vials, having well-calibrated tools ensures each piece of your final product matches spec without fail.

Topfeelpack uses advanced automation across its equipment lineup for consistent quality across thousands of units per hour—and that’s what keeps clients coming back.

Blow Molding Quality Control: Leak Testing and Dimensional Inspection

Quality checks aren’t just paperwork—they’re battle-tested steps that save brands from reputation nightmares:

1️⃣ Visual Inspection Check surface finish, color consistency, flashing around seams—anything off gets flagged immediately.

2️⃣ Dimensional Gauging Use calipers or laser scanners to compare real-world sizes against CAD specs; tolerances matter when fitting caps or labels later on.

3️⃣ Leak Testing Pressurized air fills each container while sensors look for drops in pressure = leaks detected instantly!

4️⃣ Statistical Process Control (SPC) Track trends over time so issues can be fixed before they snowball into full-blown defects across batches.

According to PMMI’s 2024 Packaging Machinery Report, “Leak detection systems have evolved beyond manual testing; now AI-driven sensors can catch micro-leaks invisible to human inspection.”

When done right, these steps ensure every bottle holds up under stress—and looks good doing it too. Because in the world of blow packaging, even one leaky unit can ruin an entire shipment’s credibility.

Benefits Of Blow Packaging: Why Choose This Method?

Blow packaging hits the sweet spot between performance, cost, and sustainability—here’s why brands are switching fast.

Cost-Effectiveness and Efficiency in Blow Packaging Production

You can’t ignore how blow packaging keeps things lean on the production line:

- High-speed machines crank out units fast, boosting manufacturing speed without compromising quality.

- Material is used with precision—minimal waste means better material utilization, which directly cuts costs.

- Automation plays a huge role here; fewer hands needed equals lower labor expenses and improved operational efficiency.

- Because molds are reusable across different product lines, you’re looking at long-term cost reduction, especially for large-scale runs.

Now throw in the fact that it consumes less energy per unit compared to traditional rigid options. That’s real savings on your power bill—hello lower energy consumption. And when you’re pushing high volumes, the numbers add up fast thanks to optimized production volume strategies.

Topfeelpack has nailed this balance perfectly with its streamlined blow-pack systems that deliver both speed and savings.

How Blow Packaging Improves Product Durability and Protection

When it comes to keeping stuff safe inside its shell, blow packaging doesn’t mess around:

• Reinforced walls provide excellent impact resistance, shielding contents from drops or rough handling during shipping. • Advanced barrier layers help maintain freshness by enhancing barrier properties, particularly for food or sensitive liquids. • Leak-proof seals mean no mess, no fuss—solid win for anyone needing reliable leak prevention.

Grouped benefits also include:

- Longer shelf life thanks to controlled oxygen transmission rates—critical for perishables relying on extended shelf life

- Stronger container shapes that maintain their form under pressure, ensuring solid structural integrity

- Overall boost in customer satisfaction due to reduced returns from damaged goods—a big nod toward better overall product safety

This kind of durability makes blow-molded packaging a go-to choice across industries ranging from personal care to industrial chemicals.

Sustainability Benefits: Using Recycled Materials and Biodegradable Plastics

Making eco-friendly moves? Blow packaging’s got your back:

Step 1: Manufacturers now incorporate high levels of post-consumer resin (PCR), increasing overall recycled content without sacrificing strength.

Step 2: Some models use cutting-edge bio-based resins made from plants—yep, actual plants—which introduces biodegradable options into the mix via modern-day biodegradable polymers.

Step 3: By reducing virgin plastic use, companies cut down on emissions and their total supply chain’s overall carbon footprint, helping meet those strict ESG goals everyone’s chasing these days.

Step 4: These changes support a broader shift toward a smarter system—the good old-fashioned idea of a true circular economy built around long-term reuse and serious attention to minimizing total environmental impact through thoughtful design focused on real-world results like massive-scale waste reduction using truly modern-day solutions like compostable films or refillable formats made from more durable yet still recyclable materials.

So yeah—it’s not just about going green anymore; it’s about doing it smart with real-deal results using next-gen eco-friendly materials in every part of the process.

Blow Packaging’s Role In Product Safety And Protection

Blow packaging isn’t just about looks—it’s the real MVP behind keeping products safe, sealed, and shelf-ready.

Impact-Resistance: How Blow Packaging Safeguards Fragile Products

• Designed to take hits, blow molded containers absorb shocks like champs during transit. • The built-in cushioning effect shields delicate items like glass vials or electronics. • With high durability, these packs resist dents and cracks even under pressure.

- During shipping, fragile goods face rough handling—impact resistance keeps them intact.

- The rigid yet flexible walls act as protective barriers, reducing breakage rates.

- For industries like pharma and cosmetics, this means fewer returns and happier customers.

→ A smart combo of shape memory and material elasticity gives blow packaging its edge in shock absorption.

Quality Control in Blow Packaging: Ensuring Leak-Proof and Safe Packaging

- Every unit undergoes strict leak testing, often using air-pressure techniques to catch flaws early. 2) Automated systems monitor for seal failures and dimension errors through real-time sensors. 3) Any container that fails is flagged instantly—no compromises on safety.

✳️ These checks meet global manufacturing standards, ensuring compliance with FDA or EU directives.

→ At Topfeelpack, rigorous quality assurance protocols are baked into every production run to guarantee zero-defect delivery.

Multiple checkpoints:

- Visual inspection for surface defects

- Pressure tests for internal leaks

- Seal verification for airtight closure Each step ensures full control over product integrity and regulatory alignment.

How Blow Packaging Enhances Product Shelf-Life with Effective Seals

Grouped benefits of effective seals: • Airtight closures = reduced oxygen ingress, so oxidation slows way down • Moisture stays out thanks to advanced barrier layers = better moisture protection • Hermetically sealed bottles prevent exposure = top-tier contamination prevention

Here’s how it breaks down:

| Seal Type | Barrier Strength | Shelf-Life Boost | Suitable For |

|---|---|---|---|

| Induction Seals | High | +12 months | Pharmaceuticals |

| Snap-Fit Closures | Medium | +6 months | Beverages & Juices |

| Heat-Sealed Necks | Very High | +18 months | Cosmetics & Serums |

The result? Better product preservation without preservatives—just smart engineering with tight-fit closures that keep everything fresh inside longer than you’d expect from traditional packaging methods.

By combining strong structural design with clever sealing tech, blow packaging makes sure your products not only survive—they thrive on the shelf.

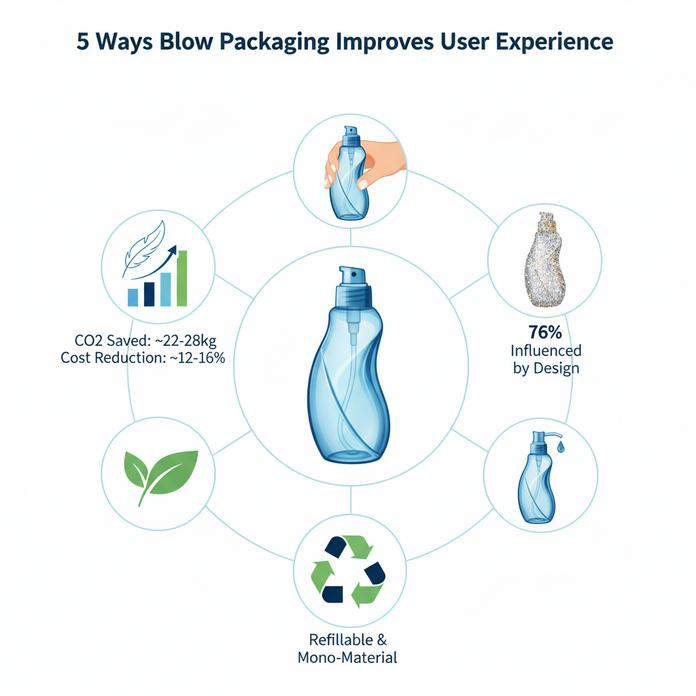

5 Ways Blow Packaging Improves User Experience

Blow packaging isn’t just about looks—it’s crafted to make life easier, lighter, and more sustainable for the everyday user.

Ergonomics of Blow Packaging: Easy-to-Hold and Functional Designs

- Grippy contours that hug your hand

- Lightweight builds that don’t tire your wrist

- No-slip textures for wet or oily conditions

Blow packaging is all about comfort. Brands now obsess over how their containers feel during use—because if it slips or strains, users ditch it. From smooth tapers to thumb rests, these small tweaks boost both usability and product love. A well-designed shape isn’t just pretty; it’s functional.

Custom Decoration Techniques: UV Coating and Silk Screening for Visual Appeal

• UV coating adds gloss and scratch resistance • Silk screening enables vibrant, lasting prints • Foil stamping gives that luxe vibe

Packaging aesthetics aren’t just vanity—they drive shelf appeal and brand recognition. With blow-type packaging, custom finishes like matte or metallic layers elevate the look without compromising recyclability. According to Mintel’s Q2/2024 Packaging Insights, “76% of consumers say attractive design influences their first purchase decision.” That’s not fluff—it’s fact.

Convenience Features: Compact Cases and Foundation Bottles with Precision Dispensers

(1) Compact cases fit perfectly into clutches or gym bags (2) Airless pumps give exact amounts—no waste (3) Lockable caps prevent leaks on-the-go

Modern users want fast access without mess. That’s why smart features like click-to-open lids or one-handed pumps are now common across blow pack formats. These upgrades bring both practicality and polish to daily routines.

User-Focused Design: Refillable Packaging and Mono-Material Solutions

♻ Refill-ready designs cut down plastic use ♻ Mono-material packs simplify recycling streams ♻ Modular parts allow easy disassembly

Eco-consciousness is baked into today’s best blow mold packaging strategies. New refillable options reduce single-use waste while mono-material builds ensure smoother recycling cycles. It’s a win-win—for brands pushing sustainability goals and customers who care deeply about their carbon footprint.

Lightweight Blow Packaging: Reducing Packaging Waste and Transport Costs

Long gone are the days of bulky bottles weighing down shipments—or your tote bag.

Today’s lightweight blow-packaged containers offer:

- Reduced material usage without compromising strength

- Lower CO₂ emissions from logistics thanks to decreased weight

- Easier stacking & storage on shelves

Lightweighting doesn’t mean cutting corners—it means smarter engineering. Brands like Topfeelpack have pioneered ultra-light solutions without sacrificing quality or durability.

Is Blow Packaging Right For Your Product?

Choosing the right packaging can make or break a product. Let’s find out if blow packaging checks your boxes.

Identifying the Best Products for Blow Packaging: Key Considerations

Before diving into production, ask yourself—does your item really vibe with blow packaging? Here’s how to figure that out:

- Product characteristics like fragility, viscosity, and shelf life matter big time. Liquids, gels, and semi-solids are ideal.

- If you need high-volume output fast, the process delivers. The high-speed molding suits brands scaling quickly.

- Got weird shapes? No problem. The technique offers wild levels of design flexibility, even for ergonomic or novelty containers.

- Think about your market too. High-turnover consumer goods such as personal care products or condiments benefit most.

- Don’t forget material compatibility—HDPE and PET are top dogs here due to their durability and recyclability.

- Low unit cost at scale makes it a win for budget-conscious brands.

Now zoom out a bit.

If your product requires strong barrier properties, like pharmaceuticals or carbonated drinks, you’ll want to explore multilayer options within blow forming—or maybe another method altogether.

And when it comes to volume? If you’re planning small batch runs or custom designs every other week, this may not be your best bet. But if you’re pumping out thousands of units daily? Perfect match.

Blow Packaging vs. Other Packaging Methods: Which is Best for Your Needs?

You’ve got choices—so how does blow packaging stack up against other methods like thermoforming or injection molding?

🟢 Injection Molding • Great when you need ultra-detailed parts—but it’s slower and pricier for hollow items. Also less flexible with container shapes.

🟢 Thermoforming • Awesome for flat-surfaced trays and clamshells but limited when it comes to creating enclosed volumes like bottles.

🟢 Rotational Molding • Strong contender for large hollow forms—think water tanks—but way too slow and costly for small consumer goods.

Now let’s talk numbers:

According to McKinsey & Co.’s 2024 Global Packaging Outlook, “Blow-forming technologies offer up to 30% lower production costs compared to rotational molding when scaled beyond 10K units/month.”

So what makes blow forming shine?

- It nails high-volume jobs without sacrificing quality.

- It supports sustainable materials more easily than some alternatives.

- It provides superior performance on lightweight yet durable containers—ideal where shipping weight matters.

FAQs about Blow Packaging

Which cosmetic containers are often crafted with blow packaging?

The technique brings hollow elegance to life—perfect for:

- Lipstick tube that glide smoothly in your hand.

- Mascara tube built to cradle the perfect brush.

- Foundation Bottles in PET or Acrylic, light yet durable.

Every curve is intentional, every contour chosen for comfort and beauty in daily use.

How does blow molding stand apart from injection molding in cosmetics?

Think of two artists working with different tools:

- Blow Molding breathes life into bottles—hollow shells for liquids and creams.

- Injection Molding sculpts solid parts like Compact Case bases, Aluminum caps, or Eyeliner Pen bodies with tight precision lines.

What visual touches can be added for large runs of blow-molded items?

A container’s allure grows through finish and detail:

- Hot Stamping catches the light like jewelry on a dresser top;

- Silk Screening places a logo as steady as a signature;

- UV Coating protects sheen against time;

- Metallization wraps plastic in metallic drama;

- Labeling ties brand identity to touchpoints customers remember by feel.

Which sustainable choices do suppliers offer here?

Eco-conscious production doesn’t mute luxury—it reshapes it:

| Sustainability Feature | Emotional Benefit |

|---|---|

| Recycled Materials | Gives past plastics a second beautiful chapter |

| Biodegradable Plastics | Leaves less behind when beauty fades away |

| Refillable Packaging | Turns habit into ritual instead of waste |

| Mono-material Design | Simplifies recycling without losing design grace |

How is quality kept at its peak before reaching store shelves?

Quality control is an unseen hero weaving trust between maker and buyer through steps such as:

★ Leak Testing avoiding heartbreak over wasted foundation;

★ Drop Testing protecting PET walls from travel mishaps;

★ Dimensional Inspection keeping cap-and-neck fits just right;

★ Color Matching honoring the exact shade that makes packaging part of brand memory;

★ Surface Treatment Inspection ensuring each gloss or matte feels deliberate under fingertips.

References

- Smithers – The Future of Blow Moulded Plastic Packaging to 2027

- Mintel – Global Packaging Trends

- Xometry – Blow Molding vs. Injection Molding: Differences and Comparison

- PMMI – 2024 Transforming Packaging and Processing Operations

- McKinsey & Company – Sustainability in packaging: Across the value chain and in 2025 and beyond

Blow Molding Process Animation This video is relevant because it visually demonstrates the extrusion blow molding process described in the article, showing how the parison is formed, the mold closes, and the bottle is blown and ejected.