Which Plastic Sleeve Packaging Suits Your Product?

Your product’s got the looks, the formula, and a brand story that could charm a cactus—but if your plastic sleeve packaging doesn’t show up dressed for the party, it might as well stay home. In cosmetics, shelf appeal is everything. Clients don’t just buy blush—they fall in love with it at first glance. So when you’re staring down pallet loads of lipstick tube or compacts and wondering how to wrap them like runway models without blowing your budget? That’s where things get real.

Smart buyers know this isn’t about slapping on some clear film and calling it a day. It’s about finding a fit that works hard backstage—durable enough to survive shipping chaos, flexible enough for odd-shaped items—and dazzles under store lights. As Topfeel’s design lead put it at CosmoPack 2024: “Packaging is silent retail theater. If it doesn’t perform, nobody claps.”

Which Styles of Plastic Sleeve Packaging Speak to Your Audience?

The right packaging doesn’t just protect—it persuades. Let’s unpack how plastic sleeve packaging can win over beauty shoppers.

Eye-Catching Designs with Clear Polypropylene

When it comes to grabbing attention, clear polypropylene is like the window display your product deserves. It adds that see-through gloss that lets lipstick shades or mascara tube brushes shine through without distortion.

- Transparent materials make color payoff visible at first glance.

- UV coating and offset printing allow graphics to pop without smudging.

- Consumers gravitate toward clarity—literally. They want to see what they’re buying.

You also get durability without bulk, meaning these clear plastic sleeves won’t crack under pressure in transit or on shelves. Plus, they’re lightweight, which keeps shipping costs friendly while still looking luxe. When paired with smart design, sleeve packaging becomes not just functional but irresistible.

Versatility of Sleeve Wrappers in Cosmetic Displays

Sleeve wrappers are the MVPs of display flexibility—especially when working with oddly shaped or delicate beauty products.

Grouped by use case:

-

For foundation bottles:

- Slim-fit cosmetic packaging sleeves keep things snug and upright.

- Gloss lamination adds shine and water resistance.

-

For powder compact case:

- Die-cut windows allow the mirror finish to peek through.

- Matte finishes reduce fingerprint smudges during handling.

-

For empty palette:

- Bold branding printed on the outer wrap draws attention fast.

- Inner trays remain untouched and protected inside the sleeve.

From square compacts to round jars, these wrappers adapt like a charm—making them ideal for ever-changing product lines across retail shelves. They’re also easy to swap out seasonally without retooling core packaging components.

Benefits of Custom Blister Packs for Brand Visibility

Custom blister packs do more than hold your product—they build trust at eye level. The combo of protection and presentation makes them a go-to for cosmetics that need both shelf appeal and safety from tampering.

| Feature | Benefit | Application Example | Branding Potential |

|---|---|---|---|

| Digital Printing | High-res logos & colors | lip balm tube & eyeliners | Strong visual recall |

| Foil Stamping | Luxurious metallic touches | Limited edition kits | Premium perception |

| Tamper-Evident Design | Builds consumer trust | Skincare tubes | Safety assurance |

| FDA-Compliant Materials | Regulatory peace-of-mind | Lipsticks & lip gloss tube | Health-conscious image |

These packs don’t just protect—they promote. With customizable cavities and printable surfaces, they turn every shelf into a mini billboard for your brand story using smartly designed retail packaging solutions.

The Role of Matte Lamination in Aesthetic Appeal

Matte finishes are subtle but powerful players in premium packaging finish decisions. Their soft-touch feel instantly signals elegance—think velvet instead of vinyl.

Short bursts on why it matters:

• It reduces shine so your branding isn’t lost under harsh store lights.

• It resists fingerprints better than glossy options—great for high-touch displays.

• It pairs well with foil stamping or spot UV for contrast-rich designs that feel upscale.

Ultimately, matte lamination turns ordinary boxes into tactile experiences that whisper “luxury.” If you’re targeting an audience who values aesthetics as much as performance, this layer makes all the difference in shaping their perception of your brand’s quality through thoughtful use of premium packaging techniques tied directly into modern-day luxury cues found in high-end beauty aisles.

How Plastic Sleeve Packaging Reduces Packaging Costs By 15%

Smart brands are slashing overhead by switching to plastic sleeve packaging—here’s how it drives down costs across production, shipping, and sourcing.

Cost-Effectiveness of PET Plastic in Bulk Production

- PET plastic is a goldmine for bulk runs—its consistency makes it ideal for automated filling lines.

- Flexographic printing works like a charm on PET plastic, keeping branding crisp without extra cost.

- Material waste is minimal during thermoforming, saving both time and money.

- Bulk orders reduce per-unit packaging costs by up to 18%.

- Supply chain efficiency improves due to standardized material specs.

- Lower defect rates mean fewer reworks and less downtime.

• Compatible with high-speed machinery

• Offers excellent clarity for product visibility

• Cuts labor costs through automation-friendly form factors

When cosmetic manufacturers scale up, bulk manufacturing using PET plastic becomes a no-brainer. It keeps things clean, fast, and cheap without sacrificing quality. Plus, its durability means fewer damaged units during production runs.

Quick wins: – Less waste equals more savings – Better printability boosts shelf appeal – Streamlined logistics simplify inventory management

Savings from Using PVC Film for Lightweight Shipping

Using PVC film isn’t just about aesthetics—it’s a logistical hack that saves real cash.

- Lightweight construction cuts freight charges instantly.

- Enhanced stackability reduces pallet space needs.

- Products stay snug without extra padding or fillers.

Grouped benefits:

- Freight savings: Lower dimensional weight = cheaper air & ground shipping

- Product protection: Built-in rigidity protects against crushing

- Logistics optimization: More units per shipment = fewer trips

Shipping costs can eat into margins fast—but with lightweight PVC film, brands dodge those heavy fees while still getting durable protection. This kind of smart material choice helps companies ship smarter, not harder.

“In Q1 2024, logistics firms reported an average 12% reduction in parcel weight-related surcharges when clients switched to lightweight flexible films.” — Global Freight Index

Economies of Scale: Recycled Plastic Packaging Benefits

Recycled materials aren’t just eco-trendy—they’re seriously cost-effective at scale.

Grouped advantages:

-

Recycled plastic sources are increasingly stable in price

- Less exposure to virgin resin market volatility

- Supports long-term contract pricing

- Reduces dependency on fossil-derived inputs

-

Drives down packaging spend over time

- Lower raw material costs

- Minimizes landfill fees via reuse programs

- Brands meet sustainability goals affordably

Multi-benefit breakdown:

• Promotes the circular economy, turning waste into value

• Meets REACH compliance standards with fewer headaches

• Enhances brand perception while cutting real costs

As more producers commit to sustainable sourcing, economies of scale kick in hard—especially when using post-consumer resins in their packaging solutions. You’re not only reducing environmental impact but also trimming your bottom line in the process.

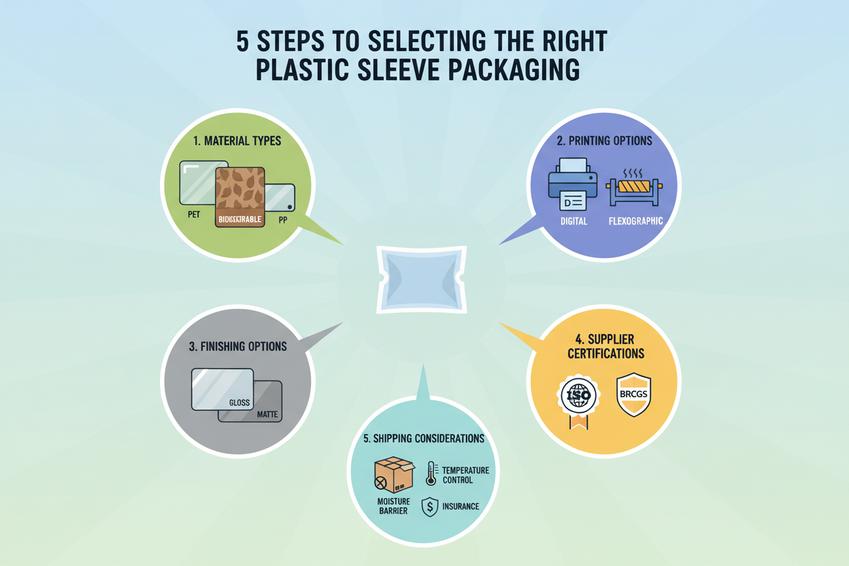

5 Steps To Selecting The Right Plastic Sleeve Packaging

Choosing the best plastic sleeve packaging isn’t just about looks—it’s about protection, branding, and shipping smarts.

Step 1: Analyzing Material Types for Product Protection

When it comes to plastic film, not all materials are created equal—especially if you’re wrapping delicate items like compact mirrors or eyeshadow palettes.

- PET plastic: Crystal-clear and tough, perfect when you need durability with high-end visual appeal.

- Biodegradable polymer: Eco-friendly but less impact-resistant; ideal for brands with a green mission.

- Clear polypropylene (PP): Lightweight and flexible, offering decent protection at a lower cost.

Look closely at factors like material thickness, transparency, and barrier properties before locking in your choice.

Step 2: Evaluating Printing Options: Digital vs. Flexographic

Not sure which printing method fits your cosmetic line? Here’s a quick breakdown of what matters most when customizing your plastic sleeve packaging:

-

Digital printing is great if:

- You’re doing small runs.

- You want quick turnarounds.

- You often change your designs.

-

Flexographic printing works better when:

- You’re producing large volumes.

- You want lower unit costs over time.

- You can invest in custom printing plates upfront.

Both options offer solid print quality, but the right pick depends on your brand’s scale and speed needs.

Step 3: Choosing Finishing Options: Gloss vs. Matte

Think of finishing as the final outfit on your product—it sets the tone instantly.

• A sleek gloss finish makes colors pop and adds shine—great if you’re going bold with visuals.

• A smooth, muted matte finish gives off an upscale vibe—ideal for minimalist or luxury branding.

Mixing finishes with extras like embossing or spot varnish? That’s where real tactile magic happens on your packaging surface.

Step 4: Understanding Supplier Certifications for Quality Assurance

Certifications aren’t just red tape—they’re peace of mind wrapped around every piece of your packaging order.

You’ll want suppliers who hold key credentials like:

- ISO standards, especially ISO 9001, which ensures consistent quality management systems.

- The globally recognized BRCGS standard for food-grade safety—even more crucial if cosmetics contain organic ingredients.

- Documentation supporting traceability, GMP practices, and even optional sustainability credentials such as FSC labeling or carbon-neutral processes.

These certifications help ensure that every batch of custom sleeves meets regulatory demands while keeping production dependable from start to finish.

Step 5: Shipping Considerations: Moisture Barrier and Transit Insurance

Shipping mistakes can wreck even the prettiest packaging job—so think beyond boxes and tape when planning logistics for your cosmetic products wrapped in protective sleeves:

• Add a strong internal moisture barrier, especially during humid seasons or ocean freight routes.

• Use temperature-controlled containers if you’re shipping heat-sensitive formulas like creams or serums inside that sleeve wrap.

• Always include solid transit insurance coverage—because freight mishaps happen more often than anyone likes to admit!

Protecting the integrity of both product and its outer wrap ensures customers get exactly what they expect—flawless goods inside flawless sleeves.

Plastic Sleeve Packaging Vs. Traditional Packaging Methods

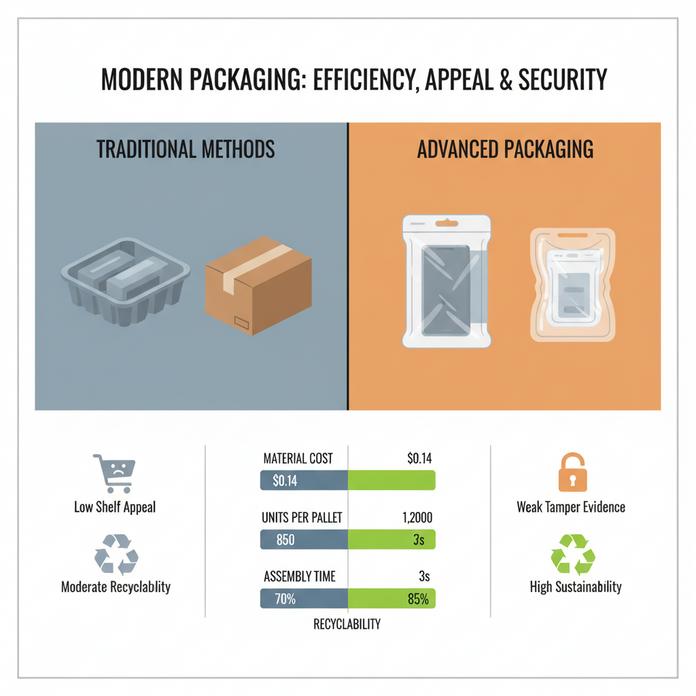

Quick peek into how modern packaging like plastic sleeve packaging stacks up against old-school methods. Material usage, display perks, and theft protection—it’s all here.

Sleeves vs. Thermoformed Trays: A Comparative Overview

Plastic sleeve packaging wins on multiple fronts when you stack it next to thermoformed trays, especially in cosmetics:

- ✅ Lower material costs due to reduced plastic use.

- ✅ Faster manufacturing cycles with simpler assembly lines.

- ✅ Better shelf appeal—sleeves show off the product more clearly.

Now toss in sustainability? Big win. Most sleeves are easier to recycle than bulky trays, making them a smarter pick if you’re chasing greener operations without sacrificing design flexibility or display appeal.

Blister Packs vs. Clamshell Containers in Cosmetic Products

Cosmetics need packaging that’s secure but still snazzy—and that’s where this face-off gets interesting:

- Blister packs offer tighter seals and better tamper evidence, ideal for lipsticks and eyeliners.

- They also amp up your branding game with more printable surface area.

- Plus, they’re lighter and easier to hang on retail racks than clunky clamshell containers.

🔒 Theft resistance? Blisters take the crown there too.

According to Mintel’s 2024 Beauty Packaging Report, “Compact security-focused formats like blister packs are gaining traction among premium cosmetic brands due to their blend of visibility and anti-theft functionality.”

So yeah, if you’re going sleek and secure—blisters beat clamshells hands down.

Packaging Efficiency: Sleeve Wrappers vs. Standard Boxed Options

When it comes to squeezing out every inch of efficiency, sleeve wrappers leave old-school boxes in the dust.

Grouped benefits include:

- 📦 Material usage: Less cardboard waste means lower costs per unit.

- 🚚 Logistics: Higher shipping density cuts freight bills dramatically.

- ⚙️ Automation compatibility: Sleeves adapt easily to high-speed lines.

| Feature | Sleeve Wrappers | Standard Boxes | Winner |

|---|---|---|---|

| Units per Pallet | 1,200 | 850 | Sleeves |

| Assembly Time (seconds) | 3 | 7 | Sleeves |

| Recyclability (%) | 85 | 70 | Sleeves |

This format not only boosts production speed but also works well with vacuum-form inserts, giving you top-tier product protection without bulking up your footprint.

In short? If you’re aiming for leaner logistics and slicker shelf presence—ditch the box; go sleeve instead.

FAQs

What makes clear polypropylene a strong choice for retail cosmetics?

It’s like giving lipstick tubes, mascara wands, and foundation bottlestheir own stage—crystal-clear visibility under store lights.

- Pairs beautifully with offset printing or UV coating, ensuring branding leaps from the shelf.

- Light in weight yet resilient enough to keep products pristine during transit.

Why choose PET plastic sleeve wrappers over thermoformed trays in bulk orders?

PET brings a clean finish and predictable flexographic printing results that make each batch shine. Compared to thermoformed trays:

- Uses less material while keeping product fully visible.

- Cuts production costs without dulling presentation impact for eyeshadow palettes & compact mirrors.

Which finishing touches turn packaging into high-end cosmetic art?

Each option changes the mood:

- Gloss lamination: colors burst alive under light; perfect for vivid lipstick lines.

- Matte lamination: soft elegance ideal for powder compacts prone to fingerprints.

- Embossing effects: tactile drama customers remember long after purchase.

Can recycled plastic still meet sustainability targets without hurting budgets?

Yes—its journey tells a story of care and practicality all at once:

| Feature | Impact on Brand | Effect on Costs | Certification Ready |

|---|---|---|---|

| Recycled Content | Appeals to eco-conscious buyers | Lowers raw material spend | REACH compliance |

| Compatible with Digital Printing | Maintains vibrant designs | Streamlines large runs | Sustainable sourcing |

Why is moisture protection critical for international cosmetic shipping?

Just one humid night at sea can warp packaging or blur ink—moisture barriers are silent guardians here.

- Shields liquid makeup packaging from condensation damage.

- Keeps foil stamping crisp even through tropical climates.

- Works alongside temperature control and stacking strength so every delivery arrives showroom-ready.