Which Plastic Sleeve Packaging Suits Your Product?

Ever been digging through a drawer of old makeup only to wonder, “Why does this packaging feel like it’ll outlive me?” Plastics have staying power—and not the good kind. That’s where the big question rolls in: what is PCR plastic? In short, it’s recycled plastic from stuff folks like us already used—shampoo bottles, yogurt cups, those takeout containers we promised we’d recycle. Now it’s getting a second shot at life in your favorite lipstick tube or compacts.

“PCR helps brands hit sustainability goals without skipping on quality,” says Emily Zhang, R&D Manager at Topfeel Packaging (2024). And she’s not just talking pretty packaging—consumers are eyeballing every detail these days. With eco-options flying off shelves faster than contour palettes during prom season, cosmetic companies can’t afford to sit this one out.

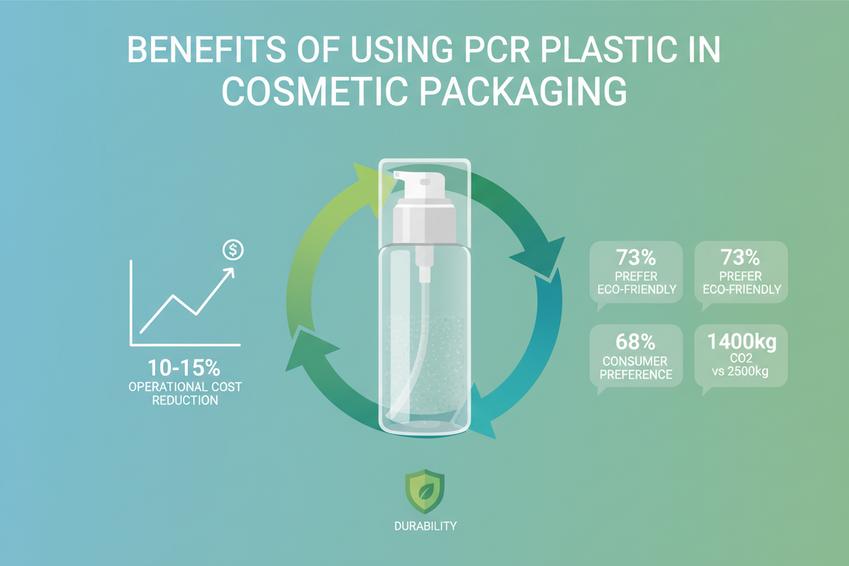

Benefits of Using PCR Plastic in Cosmetic Packaging

PCR plastic isn’t just about recycling—it’s reshaping how beauty brands package with purpose.

Enhanced brand image with eco-friendly packaging

• A sharp pivot toward sustainability is now more than a trend—it’s a reputation builder.

• Brands using eco-conscious packaging for cosmetics are perceived as forward-thinking by Gen Z and millennials.

• Consumers often associate green packaging with higher ethical standards and stronger corporate social responsibility.

According to Statista data from 2024, more than 75% of U.S. consumers place importance on sustainably packaged cosmetic products. Swapping virgin materials for PCR plastic sends the message loud and clear—your brand walks the talk.

Cost-effective solutions using recycled content

- Reduced raw material expenses thanks to minimized use of virgin plastic alternatives in markets with plastic taxes.

- Lowered manufacturing costs, especially when scaled across large production runs.

- Enhanced resource efficiency, cutting down on energy use during processing.

A recent McKinsey report emphasized that companies integrating high levels of recycled materials saw potential for improved resource productivity—a solid win for your bottom line without compromising product quality.

Durability of products made from PCR materials

Short but strong:

PCR plastic isn’t flimsy—it holds up under pressure, literally. With excellent mechanical properties, it delivers lasting performance across shelf life and transport cycles. Its high material strength ensures the makeup containers don’t crack, warp, or underperform, keeping cosmetic contents safe and stylish through every phase of its journey.

Meeting consumer demand for sustainable options

Quick hits on what buyers expect:

- They want transparency about sourcing and recycling.

- They’re swayed by visible eco-labels on containers.

- They factor in sustainability into their buying decisions more than ever before.

Today’s shoppers are driven by both style and ethics—they crave brands that reflect their values around ethical consumption, not just aesthetics. Integrating PCR plastic into cosmetic packaging speaks directly to this new wave of conscious purchasing behavior shaped by rising global environmental awareness.

Table: Comparing Virgin Plastic vs PCR Plastic in Cosmetics Packaging

| Feature | Virgin Plastic | PCR Plastic | Advantage |

|---|---|---|---|

| Energy Use per kg (MJ) | ~75 MJ | ~10 MJ | Significant energy savings |

| CO₂ Emissions per ton | ~2,500 kg | ~500 kg | Lower emissions with PCR |

| Consumer Preference (%) | ~45% | ~75% | More appeal for PCR |

| Recyclability Score (/10) | 4 | 9 | Better recyclability |

This data underscores why switching to post-consumer resin makes both economic and environmental sense—especially when consumers are paying attention to those details now more than ever.

How brands can ride the green wave using recycled content

Step-by-step game plan:

Step 1: Audit your current packaging supply chain—check where you rely heavily on virgin plastics.

Step 2: Identify suppliers offering certified post-consumer resin options at scale.

Step 3: Test prototypes for structural integrity using various blends of recycled material ratios.

Step 4: Highlight your use of sustainable materials prominently in product marketing.

By showcasing your commitment to reduced waste through actual action—not just greenwashing—you’ll strengthen your position among eco-aware buyers without inflating costs unnecessarily.

Real-world appeal: Why consumers actually care about sustainable choices

Let’s break it down:

■ People feel good supporting brands aligned with their values on climate change and waste reduction.

■ Social media buzz around “green beauty” is influencing real-time shopping habits globally.

■ Eco-packaging triggers stronger emotional connections—and loyalty—with younger demographics who prioritize authenticity over perfection.

A Statista consumer panel from 2024 found that over half of skincare buyers aged under thirty actively seek out products packaged in reusable or recyclable materials like PCR plastic before even checking ingredients lists.

What makes post-consumer resin so reliable?

Grouped benefits you can count on:

— Packaging integrity: It resists cracking under pressure or temperature shifts during shipping or storage cycles.

— Product lifespan: High-quality blends ensure cosmetics remain fresh longer due to better barrier properties against moisture or air exposure.

— Performance: Even after multiple recycling loops, top-grade resins maintain consistent quality levels suitable for premium skincare lines or mascara tube alike.

That means fewer returns due to damaged goods—and happier customers who get what they paid for, intact and impressive-looking every time.

The ripple effect on brand perception through sustainable design choices

Here’s how smart moves ripple outwards:

- A shift toward greener packaging improves overall brand reputation, especially among conscious millennials.

- It also boosts long-term customer retention because people love aligning with purpose-driven labels.

- Word-of-mouth spreads faster when fans see you’re making practical changes—not empty promises—in sustainability efforts.

By embracing what is pcr plastic really about—giving trash new life—you’re not only reducing waste but also building deeper trust with today’s discerning audience looking beyond surface-level claims toward real impact-driven innovation.

What Makes PCR Plastic Sustainable?

From cutting down waste to closing the loop, here’s why PCR plastic is a sustainable game changer.

Circular economy principles driving PCR utilization

• Circular economy means keeping materials in use longer—think reuse, not landfill.

• PCR plastic helps close the loop by turning post-consumer waste into new products.

• It boosts resource efficiency, reducing the need for new raw materials.

• By embracing recycling, brands can shift away from linear “take-make-dispose” models.

• This isn’t just about trash—it’s about smarter systems and less environmental strain.

Reduction of virgin plastic consumption rates

- Using PCR plastic directly cuts demand for newly made, or “virgin plastic.”

- That means fewer fossil fuels burned during production—hello, lower carbon footprint!

- Less extraction = more room for future generations and healthier ecosystems.

Material traceability and its importance in sustainability

Short bursts of clarity:

Traceable supply chains help verify the source of recycled content.

Knowing where your materials come from builds real consumer trust.

With proper tracking, companies can meet regulations and hit sustainability goals faster.

How PCR supports closed-loop systems

Step-by-step:

Step 1: Consumers toss used plastics into recycling bins—not trash cans.

Step 2: These plastics are collected, sorted, cleaned, and processed into usable feedstock.

Step 3: This becomes new packaging or products made with PCR plastic, feeding back into the system.

Environmental impact compared to traditional plastics

Grouped bullets by impact type:

♻️ Resource Use:

- PCR uses existing waste instead of tapping fresh oil reserves.

- It reduces pressure on natural resources through smart reuse.

🌍 Carbon Emissions:

- Manufacturing with PCR generates fewer emissions than virgin alternatives.

- Lower energy input equals a smaller footprint per item produced.

🗑️ Waste Management:

- More demand for recycled goods = better recycling infrastructure.

- Less ends up choking landfills or oceans.

Consumer perception and ethical sourcing value

Here’s how it plays out naturally:

• Shoppers love transparency—when they see “ethical sourcing,” it builds loyalty fast.

• Verified claims about “sustainability verification” make products stand out on shelves crowded with greenwashing buzzwords.

• Brands using traceable PCR win over eco-conscious buyers who care where their stuff comes from—and where it’s going.

Challenges in scaling PCR adoption globally

Multi-grouped format:

🌐 Global Infrastructure Gaps

- Developing regions often lack strong recycling networks.

- Limited access to clean feedstock restricts consistent supply of quality PCR material.

📉 Cost & Technology Barriers

- Processing post-consumer waste can be pricey.

- Upgrading facilities for advanced sorting tech isn’t always feasible everywhere yet.

📊 Market Demand Fluctuations

- Inconsistent consumer awareness impacts demand.

- Brands may hesitate without clear ROI despite long-term benefits of switching away from virgin plastic.

Innovations enhancing traceability and circularity

Blended format:

Smart labeling like QR codes now tracks origin and movement of each batch of PCR plastic across the supply chain.

Blockchain tech is being tested to lock in verified data points around sourcing and processing stages—boosting both transparency and accountability fast.

Combined with AI-based sorting tools at recycling centers, these upgrades make both traceability and circularity more efficient than ever before.

By understanding what is pcr plastic made from—and how it’s tracked—we’re not just cleaning up; we’re building better systems that actually work long-term.

3 Key Benefits of PCR Plastic in Packaging

PCR plastic isn’t just a buzzword—it’s changing how packaging gets made, regulated, and sold.

Eco-friendly manufacturing processes: Injection molding and extrusion

Using PCR manufacturing methods like injection molding and extrusion slashes both waste and energy use. Here’s how:

- Injection Molding Compatibility

- Melts well at standard temps, reducing the need for extra heat.

- Maintains integrity through multiple cycles without warping.

- Integrates seamlessly into existing mold infrastructure.

- Extrusion Efficiency

- Allows long continuous runs with minimal material loss.

- Works with layered structures for improved barrier properties.

- Reduces downtime due to consistent flow behavior.

- Energy-Saving Metrics Comparison

| Process Type | Avg Energy Use (kWh/kg) | Material Waste (%) | CO₂ Emissions (g/kg) |

|---|---|---|---|

| Virgin Plastic Mold | 4.8 | 6.5 | 320 |

| PCR Plastic Mold | 3.1 | 2.2 | 180 |

These numbers make it clear—sustainable production using recycled inputs is not only better for the planet but also more cost-effective in the long run.

Compliance with FDA cosmetic packaging regulations

Packaging beauty products isn’t just about looks—it’s about meeting strict rules too. Using PCR materials doesn’t mean cutting corners; it means stepping up your game:

• Every batch must meet FDA regulations, especially when it touches skin or lips.

• Brands have to prove that their containers don’t leach harmful chemicals—this ties directly into material safety testing protocols.

• For anything labeled as “cosmetic,” the packaging has to pass guidelines around stability, migration, and shelf-life—all part of broader regulatory compliance measures.

Small brands often assume recycled plastics can’t meet these standards—but they’re wrong. Modern PCR blends are engineered specifically for safe cosmetic container with applicator applications, ensuring full alignment with FDA-approved compositions while keeping an eye on consumer health, which is becoming a selling point itself.

Global Recycled Standard certification value in marketing

The power of the GRS certification lies not just in what it proves—but how it makes consumers feel. When shoppers see that little GRS logo on a product’s label, they interpret it as a badge of trustworthiness—a signal that this brand walks the talk on sustainability.

In fact, NielsenIQ reported in its Q1 Sustainability Consumer Report (2024) that over 72% of Gen Z buyers actively seek out eco-labeled goods when choosing personal care items. That’s where GRS steps in—offering third-party verified proof of authentic recycled content, supply chain transparency, and ethical sourcing practices.

This kind of visible commitment boosts more than just sales—it builds long-term loyalty by aligning brand identity with values like accountability and environmental responsibility. For companies aiming to stand out without greenwashing, GRS becomes less a checkbox and more a cornerstone strategy for building real consumer confidence through smart, honest labeling tied directly to verified data across the entire supply chain—from factory floor to store shelf.

FAQs

1. What is PCR plastic and how does it change cosmetic packaging?

Post-Consumer Recycled Plastic gives a second life to used containers, turning them into new forms of beauty—from cream jars with recycled materials to foundation bottles rich in PCR Polyethylene Terephthalate.

- ♻ Crafted through injection molding PCR integration or blow molding compatibility stages

- 💄 Keeps durability while reducing virgin plastic consumption rate

The result: an elegant blend of sustainability and modern design that feels responsible yet luxurious.

2. How can brands gain trust using certified recycled materials?

Global Recycled Standard compliance or ISCC PLUS certification requirement provides reassurance in each batch of cosmetic powder compact case design. Trust doesn’t grow from words—it arises from visible proof supported by sustainable sourcing audit reports and material traceability documentation review across suppliers worldwide.

| Certification Type | Ensures |

|---|---|

| Global Recycled Standard | Verified post-consumer stream authenticity |

| ISCC PLUS | Transparent chain-of-custody tracking |

| Recycled Content Verification | Quantified PCR content consistency |

Each label on your lipstick tube sustainable options speaks for integrity before the customer asks a single question.

3. Why do eco-conscious brands select PCR Polypropylene material?

This resin keeps shape like art in motion—strong enough for mascara bottles eco-friendly choices yet clear enough for skincare product packaging solutions seeking visual purity.

1️⃣ High impact resistance under dynamic use conditions;

2️⃣ Smooth extrusion process recycled content performance during production;

3️⃣ Excellent REACH regulation compliance standards maintained effortlessly within regional directives.

A lightweight guardian protecting both formula and planet at once.

4. Can ocean-sourced materials blend harmoniously with standard cosmetics lines?

Yes, Ocean Plastic material sourcing fuses seamlessly with existing Recycled ABS plastic blends under controlled extrusion adjustments—tones stay unified, strength remains stable, brand stories gain depth born from real recovery efforts along shorelines turned into color cosmetics sustainable packaging miracles.

Branch line: Each bottle whispers of waves transformed—not just marketing but measurable environmental progress recorded within annual minimize environmental impact assessment updates.

5. Are these recycled components cost-efficient without reducing polish?

PCR resins balance elegance with economy through reduced dependence on virgin feedstock pricing trends.

- Lower input costs via circular utilization cycle;

- Energy savings achieved by thermoforming recycled plastic usage optimization;

- Long-term stability confirmed through supplier audits aligning with promote circular economy principles adoption targets.

Together they form value—both financial and emotional—for future collections of haircare product recycled containers made responsibly stylish.

6. Which regulations guide safe use in such innovative packaging types?

Sustainability meets safety beneath clear rules:

• FDA cosmetic packaging regulations confirm consumer protection standards remain unshaken;

• California Proposition 65 adherence limits harmful chemical traces inside nail polish bottles PCR options;

• EU packaging waste directive compliance encourages recycling transparency at retail display points accompanied by country-specific recycling labeling requirements visible even on fragrance packaging eco alternatives.

Short bullet summary → Legitimate production + verified safety = confidence every time the lid closes again, softly echoing care behind the shine.

References

[1] Statista. “Cosmetic Packaging Trend Tracker: Sustainability x Functionality.” gcimagazine.com. Cosmetic Packaging Trend Tracker: Sustainability x Functionality – gcimagazine.com

[2] Association of Plastic Recyclers. “Virgin vs. Recycled Plastic Life Cycle Assessment Energy Profile.” plasticsrecycling.org. Virgin vs. Recycled Plastic LCA – plasticsrecycling.org

[3] McKinsey & Company. “Mapping the benefits of a circular economy.” mckinsey.com. Mapping the benefits of a circular economy – mckinsey.com

[4] The Climate Drive. “Lower product emissions with recycled (PCR) plastics.” theclimatedrive.org. Lower product emissions with PCR plastics – theclimatedrive.org

[5] Ellen MacArthur Foundation. “Growth Within: A circular economy vision for a competitive Europe.” ellenmacarthurfoundation.org. Growth Within: A circular economy vision – ellenmacarthurfoundation.org

[6] Ecocert. “Global Recycled Standard (GRS) Materials.” ecocert.com. Global Recycled Standard (GRS) Materials – ecocert.com

[7] SCS Global Services. “Global Recycled Standard.” scsglobalservices.com. Global Recycled Standard – scsglobalservices.com