How Does Color Changing Plastic for Cosmetic Packaging Work?

You ever find yourself tapping a lipstick tube just to see if it’s real? Now imagine it changing color under your fingertips—like magic, but make it science. That’s the thrill of color changing packaging, and trust us, beauty shoppers are eating it up. In a world where everything screams for attention, these shapeshifting containers whisper “touch me” in technicolor.

We’re not talking gimmicks here—we’re talking quiet genius built into PETG, acrylics, even aluminum that morphs with heat or sunlight. It’s more than eye candy; it’s functional flair that tells when your product’s fresh or exposed too long to UV rays. And yeah, buyers notice—because this isn’t just packaging anymore; it’s part of the show.

What Is Color Changing Packaging in Cosmetic Applications?

Peek behind the curtain of smart materials and see how color-shifting tech is changing the game in beauty packaging.

Color changing plastics explained for cosmetic bottles, jars, and applicators

- Thermochromic additives react to heat, shifting hues when touched or exposed to warmth—perfect for user interaction.

- Photochromic dyes respond to sunlight or UV exposure, giving clear containers a surprise pop outdoors.

- Hydrochromic coatings change appearance when wet, ideal for bath and skincare lines that want to stand out.

→ These pigments are blended into polymers like Acrylic, PETG, or even coated onto Glass and Aluminum surfaces. The result? Bottles and jars that shift color depending on their environment—like magic but make it science.

Smart packaging isn’t just about looks. It enhances shelf appeal while signaling product freshness or tampering. That’s why brands are increasingly turning to this type of interactive design as part of their cosmetic bottle innovation strategy.

From lipstick tubes to foundation bottles: where color change adds value

According to Mintel’s 2024 Global Beauty & Personal Care Trends report, “Interactive packaging that responds to touch or light is becoming an expectation among Gen Z consumers.”

• Lipstick tubes with heat-sensitive shells give instant feedback when held—thanks to embedded thermochromic pigments. • Foundation bottles use UV-reactive materials that subtly shift under natural light—a nod to outdoor selfies and real-world conditions. • Mascara wands now feature tips with slight color-changing plastic sections that fade over time, indicating when it’s time for a new one.

This isn’t just cool tech—it drives emotional engagement. A tube that changes shade feels more personal. It’s not static; it reacts like it has a personality. And brands? They love the added layer of brand differentiation, not to mention the boost in perceived value at retail level.

Topfeel has tapped into this trend by integrating smart pigments across multiple SKUs—making them one of the first manufacturers offering full-line reversible packaging solutions across lip, eye, and skin categories.

Reversible and irreversible color change in modern cosmetic packaging

Let’s break this down:

🌀 Reversible changes — Think reusable compact cases where temperature triggers a temporary hue shift using embedded temperature sensors, then reverts once cooled down again.

⛔ Irreversible changes — These are single-use indicators showing product compromise: • UV-exposed containers permanently darken via photo-triggered chemical bonds • pH-sensitive seals turn red if internal formulas degrade • Heat-stressed items show visible warping via irreversible pigment transitions

These shifts aren’t just fun—they’re functional cues for safety and longevity. Smart indicators help users monitor freshness without needing expiry dates printed everywhere.

In high-end cosmetics especially, these innovations offer both premium feel and peace of mind—blending sleek aesthetics with real-world utility through tailored combinations of reversible effects and tamper-evident designs using advanced color-change chemistry.

How Color Changing Packaging Reacts to Heat, Light, and Touch

Color shifting packaging isn’t just eye candy—it’s a smart fusion of science and sensory play that keeps users engaged at every touchpoint.

Thermochromic pigments activated by heat during product use

- Thermochromic pigments shift from opaque to transparent or between colors when exposed to body warmth—think fingers on a lipstick cap.

- These heat activation effects often rely on leuco dyes, which are encapsulated using microencapsulation techniques for durability.

- Temperature thresholds vary, typically around 31°C–34°C for cosmetic use, ensuring color transition aligns with human skin contact.

When you grip an eyeliner pen and it changes hue? That’s not magic—it’s smart material engineering reacting to your body heat.

Photochromic dyes and UV-sensitive inks under light exposure

• Outdoor-ready packaging uses photochromic dyes that react instantly under sunlight. • These color transformations are triggered by ultraviolet radiation, activating the reversible bonds in spiro-compounds. • Great for summer-themed branding or limited-edition UV-reactive compacts and bottles.

Under indoor lighting, the packaging stays neutral—but step outside, and boom! A burst of unexpected color adds flair without electronics or batteries.

Touch-responsive effects on PETG and acrylic cosmetic components

PETG bottles and acrylic jars are going tactile with visual flair:

- Surface-treated with touch-responsive materials, these packages respond with a visible color shift when pressed or rubbed.

- No need for sensors—just your finger creates subtle but satisfying feedback.

- Commonly used on pumps, click pens, or flip-top caps where interaction is frequent.

This isn’t just about looks—it’s about creating memorable haptic moments that connect users emotionally with the product.

Material behavior across injection molding and blow molding processes

Here’s how different molding methods affect pigment performance:

| Process Type | Pigment Dispersion Quality | Color Uniformity | Durability Rating |

|---|---|---|---|

| Injection Molding | High | Excellent | Very High |

| Blow Molding | Moderate | Good | Medium |

| Co-injection | Variable | Depends on layer thickness | High |

| Extrusion Blow | Low | Uneven | Low |

Mold flow direction affects how well pigments like thermochromics settle within the polymer matrix. For example, in high-speed injection molding, you get better dispersion of sensitive additives compared to slower-flowing blow processes.

By choosing the right process—and tweaking those tricky parameters like melt flow index—you can lock down consistency across every batch of your color changing packaging line.

Benefits of Color Changing Packaging for Cosmetic Brands

Color shifting packaging isn’t just eye candy—it’s a marketing magnet. Here’s how it helps cosmetic brands like Topfeel stand out, engage, and sell smarter.

Enhancing shelf impact for mascara containers and compact cases

- Bold hues that shift under light immediately grab attention on crowded shelves.

- Reflective finishes and dynamic gradients make sure your mascara containers don’t just sit—they shine.

- Compact cases pop visually when paired with motion-reactive colors.

🟣 A sudden hue change draws the eye faster than static packaging—especially in impulse-buy zones.

Retailers report up to 27% higher pick-up rates for products using dynamic packaging design, especially when contrasted against flat-color competitors. It’s not about being loud; it’s about being seen.

Interactive user experience through smart packaging color shifts

- A quick tilt of the wrist reveals new shades—making users pause, smile, and share.

- These playful shifts create an emotional hook, enhancing brand recall.

- Add tactile coatings for a double-sensory hit: visual + touch = win.

💡 When smart tech meets good looks, you get more than pretty packaging—you get engagement. The combo of smart packaging, responsive materials, and color transitions makes every use feel fresh.

Supporting premium decoration with hot stamping and UV coating

A luxury look isn’t just about gold foil anymore. Pairing hot stamping, subtle UV coating, and color-shifting inks creates depth that screams premium without saying a word.

• Glossy UV overlays enhance vibrancy during movement • Metallic foils highlight key branding elements • Layered finishes elevate perceived value instantly

This kind of finish doesn’t just catch light—it holds attention. For prestige lines or limited editions, this is where style meets storytelling.

Brand differentiation using metallization and screen printing effects

Group A – Visual Identity • Use dual-layered ink systems to embed personality into every surface • Combine metallic sheens with translucent effects for signature looks

Group B – Competitive Edge • Screen printed gradients over metallized bases = unforgettable first impressions • Iridescent bands act as visual fingerprints unique to your brand

Group C – Material Synergy • Works beautifully on glass-like plastics or high-gloss acrylics • Adapts across tubes, jars, or droppers without losing punch

This is how brands carve out their niche in saturated aisles—through layered visuals that speak louder than logos ever could.

Sustainable storytelling with eco-friendly cardboard and aluminum designs

♻️ Eco-conscious doesn’t have to mean boring brown boxes anymore. With modern print tech:

- Color-shifting inks work seamlessly on recycled board

- Aluminum surfaces reflect sustainability while amplifying shimmer

- Biodegradable coatings maintain gloss without harming the planet

| Material Type | Recyclable (%) | Supports Color Shift | Premium Look |

|---|---|---|---|

| FSC Cardboard | 100% | Yes | Moderate |

| Brushed Aluminum | 90% | Yes | High |

| RPET Blends | 60% | Partial | Medium |

| PLA Bioplastics | 70% | Yes | Variable |

Today’s shoppers want both beauty and responsibility—and this kind of packaging lets brands deliver both in one swipe.

By integrating segmented strategies across shelf appeal, user interaction, luxury aesthetics, brand identity cues, and sustainability messaging—all powered by versatile color changing packaging—brands like Topfeel are setting standards instead of chasing trends.

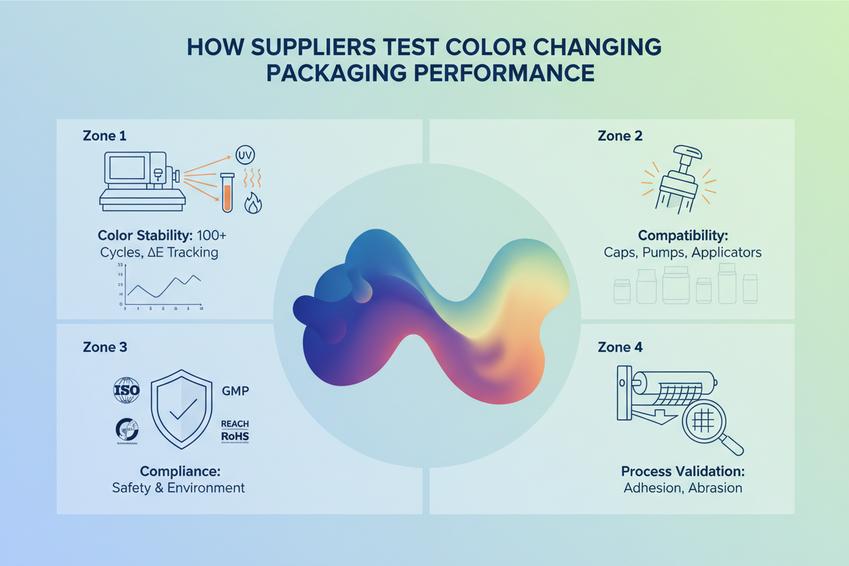

How Suppliers Test Color Changing Packaging Performance

Suppliers go through a gritty gauntlet to make sure your color changing packaging doesn’t flake, fade, or fail under pressure. Here’s how they keep things tight.

Color stability testing during repeated reversible color change cycles

- Color stability tests are done by exposing the material to UV light and heat over hundreds of repeated cycles.

- Materials are checked for visible wear, fading, or inconsistent reversible color change reactions.

- Durability is measured using spectrophotometers that track ΔE (color difference) values.

- Materials are subjected to accelerated aging chambers simulating months of sunlight in days.

- Thermochromic and photochromic coatings face repeated heating/cooling to mimic real-world use.

- Each cycle is logged—any deviation in performance flags a potential failure point.

☆ Spectral analysis also reveals if there’s any slow creep toward permanent discoloration.

A single misstep in the lifecycle test could mean disaster on store shelves. That’s why this isn’t just about looking good once—it’s about holding up after 100+ uses. The goal? Keep that wow-factor alive every time the consumer opens the product.

Compatibility checks with caps, pumps, and applicators

Short tests won’t cut it here—suppliers test everything from twist caps to droppers for smooth interaction with color changing packaging materials.

– Snap-fit caps can stress thin-walled packaging; engineers measure torque resistance and stress points – Pumps need airtight seals without reacting chemically with thermochromic layers – Applicator tips must retain full function even as surface colors shift

Grouped Testing Areas: • Mechanical Fit: How well do closures align without warping the package? • Chemical Interaction: Does pump lubricant degrade the coating? • Functional Integrity: Will repeated compression affect visual consistency?

If any component messes with the material’s mojo, it’s back to redesign. No one wants a pump that sticks—or worse—discolors your whole bottle after two weeks on a bathroom shelf.

Compliance testing under ISO 9001, GMP, and REACH requirements

| Standard | Focus Area | Required Tests | Frequency |

|---|---|---|---|

| ISO 9001 | Quality Management Systems | Documentation audits | Annual |

| GMP | Production Hygiene & Safety | Cleanroom validation | Biannual |

| REACH | Substance Safety | Chemical composition review | Per batch lot |

| RoHS | Heavy Metal Restriction | Lead/cadmium screening | Quarterly |

This isn’t just red tape—these certifications ensure your cosmetic packaging is safe for skin contact and environmentally sound. Every batch gets sampled for chemical safety under REACH, while production lines follow strict GMP cleanliness protocols.

And yes, even decorative elements like metallic overlays get tested under RoHS to prevent hazardous leaching from non-compliant inks or foils.

Process validation across silk screening, pad printing, and vacuum metallizing

Let’s break it down:

• In silk screening, ink thickness is calibrated so it doesn’t smother thermochromic layers underneath • During pad printing, silicone pads must apply consistent pressure without distorting designs • For vacuum metallizing, temperature control ensures reflective coatings don’t disrupt color transitions

Each process undergoes:

- Adhesion strength testing

- Abrasion resistance trials

- Visual uniformity inspections at multiple angles

Why all this fuss? Because if you don’t validate these processes right off the bat, you risk peeling logos or uneven finishes that ruin both aesthetics and function. And when you’re dealing with reactive pigments in premium beauty formats like jars or tubes—that’s a no-go zone.

Even brands like Topfeel run these validations across multiple SKUs before launch—it’s just good form when working with advanced materials like those used in high-end color shifting products.

FAQs about Color Changing Packaging

1. What materials bring the best visual effect in cosmetic color changing packaging?

Different textures create unique transitions—

- Acrylic: crisp clarity paired with thermochromic pigments that respond to touch.

- PETG: flexes light beautifully when mixed with photochromic dyes.

- Glass: hosts UV-sensitive inks for elegant irreversible shifts on display jars and perfume bottles.

- Aluminum & Eco-friendly cardboard: blend durability and sustainability, providing a canvas for vivid sensory play through thin-film coatings or labels.

2. How does reversible vs irreversible color change enhance product communication?

Each reaction tells a distinct story: reversible tones softly fade back after hand warmth leaves a lipstick tube; irreversible shades mark freshness or tamper evidence on compact cases and foundation bottles—messages consumers can see, not just read.

3. Can caps, pumps, and applicators retain smooth performance during activation?

Harmony between motion and pigment control is key:

• Supplier testing checks how caps twist under heat-driven transitions.

• Pumps are matched by design thickness so color travels evenly across surfaces.

• Applicators linked to eyeliner pens hold precise contrast without clogging or patching—proving beauty tools can shift hues yet stay reliable.

4. Which processes help keep tone consistency during large-batch production?

Balanced flow defines quality results across varied shapes:

- Injection molding keeps pigments dispersed evenly inside mascara containers;

- Blow molding builds lightweight jars with stable shine;

- Vacuum metallizing + Silk screening/Pad printing secure decorative alignment even over sensitive thermochromic films while allowing later branding steps like labeling or UV coating.

5. How do certifications connect safety with eco-style appeal in packaging supply chains?

Color changing lines now pair compliance with conscience—audited under ISO 9001, backed by cleanroom standards of GMP, assured through regional regulations from REACH compliance, traceable via material limits under RoHS certification, and reinforced by stories of sustainable sourcing. The outcome feels personal: safe contact layers around a jar or mascara tube that also carry visible proof of Care meeting Creativity.

References

Global Beauty & Personal Care Predictions: 2026 & Beyond – mintel.com

Thermochromic Leuco Dyes – thermographics.com

How Color-Changing Products Work – qualitylogoproducts.com

Photochromic Dyes – tcichemicals.com

Cosmetic Products Regulation – echa.europa.eu

FDA Guidance for Industry: Cosmetic Good Manufacturing Practices – fda.gov