Why the ISCC Certification Process Matters

You can’t slap a “green” label on a lipstick tube and call it a day. Buyers are getting smarter, regulators are getting stricter, and the ISCC certification process is now the gold standard for proving your packaging isn’t just pretty—but planet-friendly too.

It’s not just about recycled plastics or bio-based polymers—it’s about knowing where every ounce of material came from, how it moved through the supply chain, and if it earned its eco halo. Think of it as giving your packaging a clean bill of environmental health… with receipts.

“Traceability is no longer optional,” says Zoe Lin, Senior Materials Engineer at Topfeel (2024 Q1 Sustainability Report). “Buyers demand proof—and ISCC lets us hand over that proof on paper.”

So if you’re sourcing foundation bottles or mascara tubes by the millions, this isn’t red tape—it’s reputation insurance. Brands with certified packaging don’t just sleep better… they sell better.

Quick Answers: The ISCC Certification Process

→ Understanding ISCC Certification: The ISCC certification validates sustainable sourcing, traceability, and responsible material use in cosmetic packaging like lipstick tubes and compact cases.

→ The Role of Recycled Plastic: Recycled plastics, including PCR materials, help reduce virgin plastic reliance while meeting ISCC mass-balance and traceability standards.

→ How Biodegradable Options Align with ISCC: Bio-based polymers and biodegradable materials support circularity goals when documented within ISCC-certified supply chains.

→ Why Mono-material Design is Key: Mono-material design improves recyclability and simplifies ISCC audits, making it a vital component of certification for packaging items like mascara tubes and foundation jars.

→ Enhancing Supply Chain Transparency: ISCC certification supports material tracking across packaging types, enhancing transparency and accountability from raw material sourcing to finished cosmetic products.

→ Essential Practices for Certification: For materials like aluminum caps and lipstick tubes, proper documentation and sourcing practices are critical for ISCC certification.

→ Step-by-Step Process to Certification: From choosing sustainable packaging materials to implementing refillable systems, each step supports compliance with ISCC’s environmental and traceability standards.

→ Real-World Impact on Brands: Brands that implement ISCC-certified practices see improved sustainability, better product performance, and enhanced brand perception.

The Significance of the ISCC Certification Process

Getting your packaging certified isn’t just a flex—it’s proof you’re playing for the planet, not just profits.

Understanding ISCC Certification: A Pathway to Sustainability

• The ISCC certification process checks if your supply chain is clean and green—from sourcing to production.

• It verifies traceability across every step, ensuring materials like biomass, biofuels, or recycled plastics are responsibly sourced.

• Companies must meet strict standards, undergo third-party auditing, and align with sustainable goals to qualify.

The whole idea? Make sure what ends up in your lipstick tube or eyeshadow pan isn’t wrecking ecosystems halfway across the globe.

The Role of Recycled Plastic in Achieving ISCC Standards

Recycled plastic isn’t just trendy—it’s a gamechanger when it comes to meeting those tight ISCC certification rules:

- Reduces reliance on virgin materials—lower carbon footprint.

- Supports traceable sourcing via mass-balance accounting.

- Helps brands hit sustainability targets without compromising aesthetics.

- Qualifies under the ISCC system if properly documented from source to product.

So yeah, that PCR compact case? It’s not just cute—it’s compliant.

How Biodegradable Options Align with ISCC Certification

Biodegradable doesn’t mean “good enough” unless you’ve got the receipts—aka proper documentation within an ISCC-certified supply chain:

- 🌱 Bio-based polymers need full traceability from crop field to factory floor.

- ♻️ Compostable packaging only counts if it meets biodegradability standards and aligns with circular economy principles.

- 🔁 Without clear tracking, even the greenest materials won’t cut it under ISCC scrutiny.

In short, being eco-friendly is cool—but being certifiably eco-friendly? That’s next level.

Why Mono-material Design is Key to Certification Success

Mono-material packaging makes life easier—for recyclers and auditors alike:

Shorter audit trails → Fewer material types = Less complexity → Easier compliance with ISCC certification process

Products like mascara bottles made from one recyclable polymer simplify everything—from sorting at waste centers to passing sustainability audits with flying colors.

And guess what? Topfeel already nails this approach by designing mono-material formats that look good and check all the right boxes on the sustainability scorecard.

How the ISCC Certification Process Enhances Supply Chain Transparency

This part walks through how the ISCC certification process helps brands stay honest, traceable, and eco-smart across their supply chains.

Transparency Benefits: From Compact Cases to Foundation Jars

• From sleek compact cases to pump-top foundation jars, packaging transparency isn’t just about looks—it’s about what’s inside and where it came from.

• The ISCC system tracks materials from origin to shelf, ensuring each piece of plastic or aluminum is traceable.

• Whether it’s virgin resin or recycled content, every component must meet sustainability and certification requirements before it hits the production line.

→ Different packaging types demand different tracking methods:

- Compacts often use layered materials needing multi-point verification.

- Tubes and bottles require consistent documentation across suppliers.

- Glass jars may include bio-based coatings that need separate ISCC validation.

By tying material sourcing directly to product batches via digital logs, brands can confidently back up their eco claims with real data—not fluff.

The Impact of PCR Materials on Supply Chain Clarity

- Post-consumer recycled (PCR) plastics can’t just show up in your product—they need receipts. Literally.

- Under the ISCC certification process, each shipment of PCR must come with verified sourcing records and clear mass balance documentation.

- This means no funny business—no mixing unverified plastics with certified ones without getting flagged during an audit.

💡 Here’s a quick breakdown:

| Material Type | Traceability Required | Audit Frequency | GHG Reporting Needed |

|---|---|---|---|

| PCR PET | Yes | Quarterly | Yes |

| Bio-based HDPE | Yes | Bi-annually | Yes |

| Virgin PP | Optional | Annually | No |

| Mixed Recyclates | Strict | Monthly | Yes |

By enforcing these rules, ISCC standards make sure sustainability isn’t just a sticker—it’s baked into the whole supply chain.

Enhancing Traceability through Label Application Techniques

- Labels aren’t just for branding—they’re trail markers in your product’s journey.

- With every label application under the ISCC certification process, batch codes link back to raw material sources using smart tracking systems.

- These labels help auditors trace any product right back to its certified origin—kind of like a passport stamp for your jar of moisturizer.

“According to Euromonitor‘s 2024 Packaging Integrity Report, over 68% of consumers trust products more when they include visible sustainability certifications.”

That trust? It starts with clear labeling practices:

• Tamper-proof seals printed with batch IDs

• QR codes that lead straight to chain-of-custody docs

• Smart labels embedded with RFID chips for live scan verification

All this adds up to better compliance checks, smoother audits, and fewer headaches when regulators come knocking—or when customers start asking questions.

By embedding traceability deep into label tech, companies not only meet compliance but also boost their brand’s rep as transparent players in the circular game.

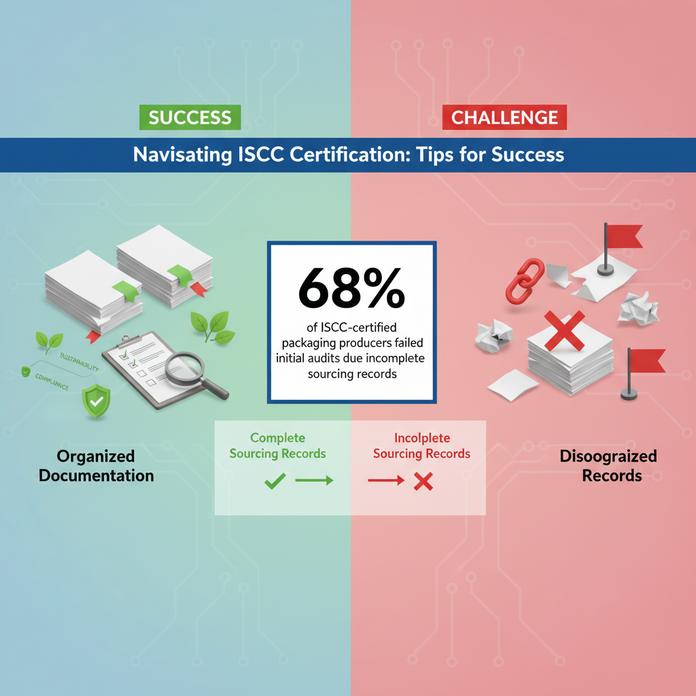

Navigating the ISCC Certification Process: Tips for Success

Getting through the ISCC certification process doesn’t have to feel like rocket science. With the right know-how, it’s more about smart prep than stress.

Essential Practices for Certification: Focus on Aluminum Caps

✔️ Sourcing aluminum caps that meet sustainability compliance standards can be tricky—but not impossible if you lock down these essentials:

- Source from verified suppliers with proper chain-of-custody logs.

- Keep batch-level traceability records—don’t just rely on invoices.

- Audit your internal processes quarterly, not annually.

💡 According to SGS Global Sustainability Report Q2/2024, over “68% of ISCC-certified packaging producers failed initial audits due to incomplete sourcing records.”

For brands like Topfeel that integrate sustainable packaging early on, passing the ISCC certification hurdle becomes less of a gamble and more of a checklist.

Key Documentation for Lipstick Tube Certification

Let’s break down what really matters when certifying lipstick tubes under ISCC standards:

- Material origin certificates — plastic resins must be documented back to renewable sources.

- Processing data — timestamps, machinery logs, and waste percentages are key.

- Supplier declarations — yes, every single one needs a signed sustainability clause.

🧾 Here’s what an ideal documentation log might look like:

| Document Type | Required Format | Frequency | Responsible Party |

|---|---|---|---|

| Origin Certificates | PDF + QR-linked | Per batch | Procurement Team |

| Processing Logs | CSV/Excel | Daily | Factory Supervisor |

| Supplier Declarations | Signed PDF | Quarterly | Vendor Management |

Missing even one? That’s enough for an audit failure under the ISCC certification process, so don’t wing it—organize it.

5 Steps to Understanding the ISCC Certification Process

Getting your packaging ISCC-certified isn’t just smart—it’s essential. Here’s how to nail every part of the ISCC certification process without losing your cool.

Step 1: Choosing Sustainable Cosmetic Product Packaging

- Glass containers are a win—recyclable, elegant, and meet sustainability benchmarks with ease.

- Recycled plastics like rPET hold up under scrutiny and tick the traceability box in the certification process.

- Bio-based polymers? Yep, they’re gaining traction fast for their low carbon footprint and high compatibility with ISCC compliance rules.

- Avoid mixed-material packaging unless you can prove every layer meets the trace chain requirements of ISCC audit procedures.

Step 2: Adopting Metallic Finishes for Visual Appeal

- Vacuum metallization can be used if input metals are sourced from verified origins under strict compliance tracking.

- Electroplating? Only if waste disposal and chemical sourcing align with documented sustainability practices.

- Brushed aluminum accents offer a luxe feel while maintaining material clarity—a plus when undergoing an ISCC audit.

- Remember, documentation is king here—no matter how shiny it looks, it won’t fly without a transparent trail through the entire process step.

Step 3: Implementing Refillable Systems in Packaging

A refill system does more than save plastic—it proves you’re serious about long-term impact.

• Use modular components that simplify disassembly during audits—think pop-out pumps or removable sleeves.

• Design for durability; flimsy refills don’t cut it under real-world usage or during lifecycle assessments tied to the ISCC certification process.

“According to Euromonitor International’s Q1 2024 report, refillable formats in beauty grew by over 28% globally year-on-year, driven by both consumer demand and regulatory pressure.” That momentum isn’t slowing down anytime soon.

• Track each refill cycle using scannable batch codes—this helps verify source materials as required by the ISCC’s chain-of-custody model.

Step 4: Selecting the Right Surface Treatment Techniques

- UV coatings must be free from harmful solvents and sourced from suppliers who meet traceability protocols within the full certification process.

- Matte finishes often use additives—make sure these are documented and approved under relevant sustainability frameworks.

- Water-based varnishes? Excellent choice—they reduce VOC emissions while aligning with most ISCC-compliant production systems.

- Be ready to explain your treatment choices during an audit; transparency is not optional when aiming for full-on ISCC compliance.

Step 5: Utilizing Pantone Matching for Color Consistency

Quick hits on why Pantone matching matters:

• Keeps branding tight across global markets without color drift—a must in consumer cosmetics.

• Ensures all inks used come with traceable origin reports aligned with your overall ISCC materials ledger.

• Allows packaging partners across different regions to stay aligned without risking delays during any phase of the ISCC certification process steps.

Color may seem like fluff—but when your pigment base includes petrochemicals or rare minerals, auditors will want receipts… literally.

Real-World Impact: Brands Benefiting from ISCC Certification

Real brands are making real moves with ISCC certification—and the payoffs are stacking up across sustainability and consumer trust.

Case Study: The Shift to Glass Bottles in Beauty Brands

• Switching from plastic to glass wasn’t just a pretty packaging update—it slashed plastic usage by over half in some SKUs, while boosting environmental stewardship metrics across the board.

• Premium skincare brands saw an uptick in consumer trust, as glass bottles aligned better with eco-conscious messaging and luxury positioning.

• Glass also simplified supply chain traceability, helping meet stricter ISCC compliance standards without reworking entire logistics models.

→ The result? A cleaner shelf presence, stronger brand reputation, and a smoother ride through the ISCC certification process—all thanks to one material switch.

Success Story: Reducing Plastic Content in Mascara Bottles

- A major cosmetics house redesigned its mascara line with lighter caps and PCR-based wands—cutting virgin plastic by nearly a third.

- That move didn’t just lower environmental impact; it helped them hit key milestones within their sustainable sourcing strategy tied to ISCC goals.

- With no compromise on product performance or feel, they gained a competitive edge that was both visible and measurable—especially among Gen Z buyers who prioritize transparency and sustainability.

This approach significantly streamlined their journey through the ISCC certification process, aligning packaging innovation with broader supply chain goals.

How Hot Stamping Techniques Enhanced Brand Perception

Grouped benefits of hot stamping:

- ❖ Upgraded visual appeal without adding non-recyclable coatings.

- ❖ Maintained full visibility into sourcing chains, supporting supply chain transparency.

- ❖ Boosted perceived value at point-of-sale—especially when paired with minimalist design.

- ❖ Supported luxury-tier branding while staying within ISCC traceability requirements.

- ❖ Avoided additional emissions or energy-intensive processes compared to foil laminates.

By integrating hot stamping into sustainable packaging flows, brands improved both their look and their standing under the evolving rules of the ISCC certification process—a double win that resonated with eco-savvy consumers seeking authenticity and class.

Bonus Insight: Unexpected Gains from Sustainable Packaging Overhauls

One brand’s overhaul led not only to reduced waste but also unexpected gains:

Short-term wins:

Reduced packaging weight = lower shipping costs = better margins.

Easier recyclability = more favorable retailer shelf placement policies.

Cleaner materials = fewer regulatory headaches overseas.

Long-term gains:

Increased loyalty among sustainability-minded consumers.

Improved internal alignment on ESG KPIs linked directly to the ISCC certification process.

Stronger pitch power during investor meetings thanks to verifiable progress on environmental stewardship goals.

This kind of ripple effect shows how smart design choices can snowball into serious business advantages—all while keeping you locked into your market advantage under global sustainability frameworks like ISCC.

ISCC Certification: A Sustainable Choice

Explore why brands are choosing ISCC-certified solutions to meet eco-goals and consumer trends with confidence.

Why Compostable Packaging is a Must for Brands

Compostable packaging isn’t just about looking good—it’s about doing good, too. Here’s why it matters more than ever:

- ✅ Aligns with ISCC principles, supporting circular material flows.

- 🌱 Reduces landfill waste by breaking down naturally when managed correctly.

- 📦 Helps brands meet sustainability goals without compromising shelf appeal.

A recent NielsenIQ study from Q1 2024 found that over 73% of Gen Z consumers are more likely to purchase from brands using compostable or biodegradable packaging. This trend shows no signs of slowing, especially as regulations tighten across the EU and North America.

Brands adopting certified compostables through the ISCC certification process gain not only regulatory compliance but also consumer trust—two things money can’t buy easily.

The Movement Towards Custom Colors: Meeting Consumer Demand

Custom hues and pearl finishes used to raise eyebrows in the sustainability world—but not anymore. Thanks to traceable pigment systems under the ISCC certification process, color now meets conscience.

Here’s how it works:

- Pigments are sourced from suppliers adhering to traceability standards under ISCC protocols.

- These pigments follow a strict mass balance system, ensuring renewable input tracking.

- Final products undergo an auditing process, verifying every stage aligns with certified sustainability practices.

| Color Option | Traceability Level | Renewable Material Use (%) | GHG Reduction Potential |

|---|---|---|---|

| Ocean Blue | Full | 65 | High |

| Pearl White | Partial | 48 | Medium |

| Sand Beige | Full | 70 | High |

| Sunset Rose | Full | 60 | High |

With Topfeel’s latest product line incorporating these certified pigments, brands can finally match their aesthetic vision with real environmental action—all while staying within the guardrails of GHG reduction targets and ethical sourcing mandates.

Choosing beauty doesn’t have to mean sacrificing values anymore—and that’s something consumers are noticing fast.

FAQs

1. How does the iscc certification process help large-scale cosmetic packaging buyers build credible supply chains?

A subtle chain of responsibility runs through every certified Compact Case and Lipstick Tube:

- Ensures that Recycled Plastic or PCR Materials come from approved, traceable sources.

- Keeps data transparent across suppliers of Foundation Jars and Mascara Bottles.

- Makes sustainability visible—something consumers can trust at the shelf edge.

2. Which materials work best when applying for the iscc certification process?

Clean documentation meets practical creativity here:

| Material Type | Packaging Match | Traceability Benefit |

|---|---|---|

| Recycled Plastic | Lipstick Tubes / Concealer Tubes | Verified origin reduces virgin resin use |

| Glass Bottles | Foundation Jars / Perfume Lines | Clear audit trail through recycling loops |

| Aluminum Caps | Compact Cases / Eyeshadow Cases | Supports lightweight, circular design |

| Bio-based Polymers (Biodegradable Options) | Blush Compacts / Skincare Pots | Shifts sourcing toward renewables |

Each choice bends form and function toward long-term credibility within the certified network.

3. Why do mono-material designs make certification smoother?

Mono-material thinking gives structure to ambition—every Mascara Bottle or Eyeliner Pen crafted from one material simplifies reporting and testing steps:

① Easier sorting after use; ② Shorter auditing trails; ③ Faster mass-balance approval during review cycles.

In short: simple mono-material composition creates a louder sustainable voice in manufacturing halls.

4. How can refillable systems strengthen compliance during packaging audits?

Refillable Systems turn consumption into continuity: used once, then reborn within refill pods for Eyeshadow Cases or Blush Compacts—each cycle shortening resource footprints while maintaining brand presence on dressing tables. The auditors see visible impact:

- Reduced plastic content per life cycle;

- Extended trace record without re-registration delays;

- End users sense a premium experience that happens to be responsible too.

5. What decoration methods stay compliant under iscc-certified production runs?

Aesthetic precision still follows documented truth:

★ Hot Stamping & Screen Printing: add elegant marks using pigments with known origins – suitable even under strict batch tracking rules.

★ Metallization & Embossing Techniques: give shine without losing recyclability value.

★ Label Application: keeps identification consistent along logistic routes.

Even Pantone Matching or Pearl Effects remain acceptable once each colorant fits inside recorded mass-balance data streams covering Glossy Lamination, Soft Touch coatings, or Matte Finish layers—all shining responsibly beneath the logic of accountability.

References