MA-128 Wholesale Custom 3D Inner Core Lip Gloss Tube

Model Number: MA-128

Capacity: 4.1ml

Material: PETG, POM, LDPE, TPEE

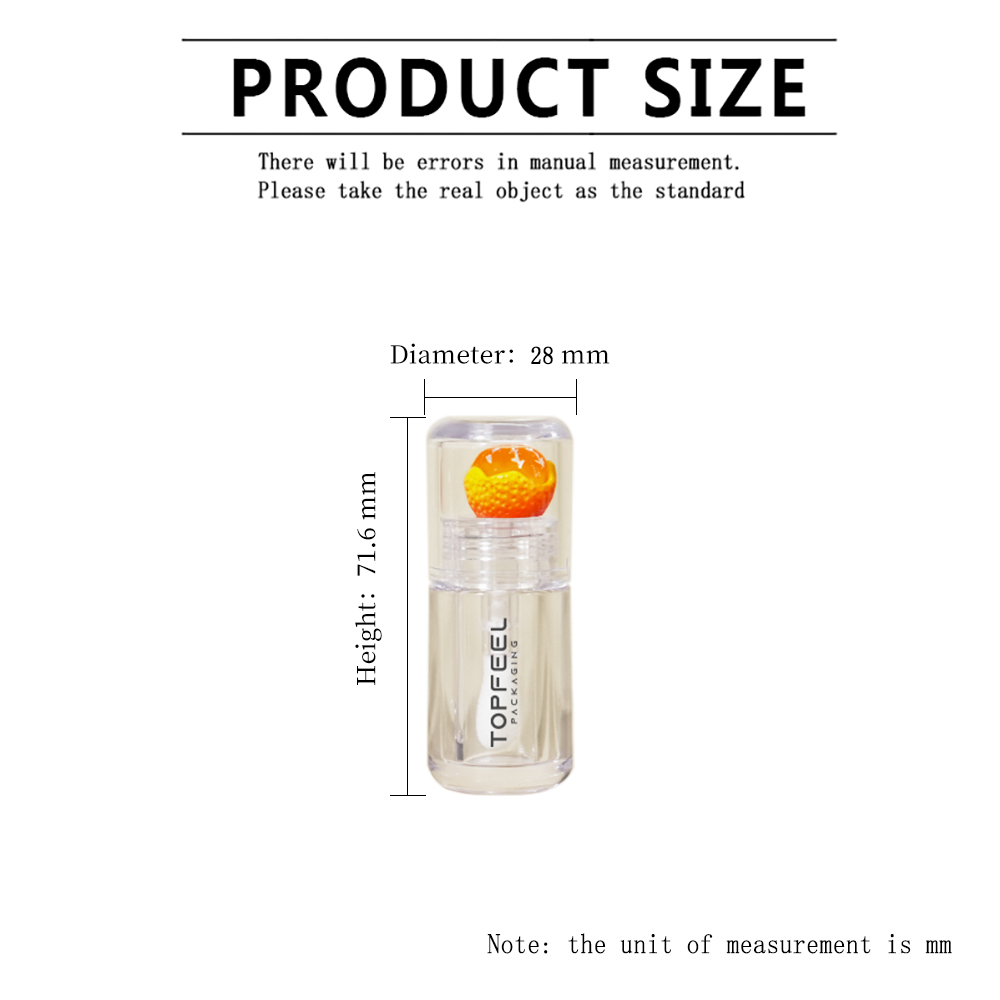

Size: D28mm x H71.6mm

MOQ: 12,000 pcs

Application: Lip Gloss, Lip Oil

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom color and printing

Sample:

Benefits

-

This packaging aligns with dopamine beauty trends by featuring a dual-layer structure that creates a premium, interactive visual effect.

-

Thick-walled construction provides the luxurious clarity and weight of glass while maintaining the superior durability and safety of plastic.

-

Brands can cost-effectively differentiate collections by customizing the inner cap insert geometry while keeping the outer mold standard.

You May Also Like

View Product Details

Captivating 3D Visual Depth

Trendy “Dopamine” Aesthetic Appeal

Consumer demand has shifted toward “joy-inducing” products. According to WGSN’s Big Ideas 2025: Beauty, the “dopamine glam” trend is driving a resurgence in playful, nostalgic, and hyper-visual packaging design. The lip gloss tube answers this call with its vibrant inner core suspended in clear resin, perfectly aligning with the Gen Z desire for photogenic, “shelfie-worthy” items.

-

Social Media Ready: The high-contrast, colorful interior catches the light, making it inherently shareable on platforms like TikTok and Instagram.

-

Emotional Connection:

Glass-Like Heavy Wall PETG

Shatter-Resistant Crystal Clarity

The base is manufactured from heavy-wall PETG (Polyethylene Terephthalate Glycol), a material celebrated for its glass-like optical properties.

-

True Color Representation: The exceptional transparency ensures your formula’s color is displayed with 100% accuracy, vital for tints and glosses.

-

Chemical Resistance: PETG offers superior resistance to aggressive ingredients compared to standard PS or AS plastics, making it compatible with a wider range of clean beauty formulations.

-

Durability:

Modular Inner Core Customization

Replaceable Inner Shape Molds

The architecture of the lip gloss tube allows for the customization of the inner cap insert while keeping the expensive outer molds standard. Developing a new insert mold is significantly faster and cheaper than creating a full custom cap, giving you “custom” packaging at a fraction of the cost.

Flexible Seasonal Collection Updates

Speed to market matters. You can swap the fruit for a 3D heart insert for Valentine’s Day, or switch to a star geometry for the holidays. This flexibility allows you to launch limited-edition drops using the same filling line and outer packaging specs, simplifying your supply chain operations.

This modularity lets you embed your brand DNA directly into the physical structure. Instead of just printing a logo on the surface, you can mold your logo or signature icon inside the cap, creating a permanent, protected brand mark that competitors cannot easily copy.