Silver Tube Mascara: Effective Sealing Methods Explained

Silver tube mascara looks like a million bucks on the shelf—but it sure doesn’t matter if half of it ends up leaking in transit or drying out before your customer even pops the cap. We’re talking about packaging that’s all flash but no function unless you seal that shiny sucker right. And trust me, when you’re ordering by the tens of thousands, one bad batch can tank your margins and your reputation faster than a TikTok trend dies.

For high-volume buyers juggling deadlines and QC nightmares, sealing isn’t just technical—it’s tactical. From finicky anodized aluminum to temperamental PETG blends, what works pretty on paper may fall flat on pallets. If you’ve ever cracked open a box only to find mascara goo where product should be… yeah, this article is built for you.

Key Points in Sealing Silver Tube Mascara Without the Drama

- Aluminium–PETG Compatibility Matters: Skipping compatibility tests between aluminum and PETG can lead to disastrous seal failures—always verify material pairing before scaling production.

- Anodized Surface Adhesion Challenges: Anodized finishes might repel common adhesives. Choose sealants specifically formulated for anodized surfaces to avoid weak bonds or leaks.

- Don’t Skip Epoxy Phenolic Layers: These protective coatings inside tubes guard against internal corrosion and leakage, especially critical during long-distance shipping or warehousing.

- Test Heat Seals on ABS Thoroughly: ABS plastic can be finicky with heat-based sealing methods; always conduct full test runs before committing to mass production lines.

- Hermetic & Induction Sealing Strategies Work Best: For silver tube mascara packaging, hermetic seals suit anodized aluminum, while induction seals pair well with lacquered PETG tubes for leak-free transit confidence.

- Ultrasonic Welding = Eco-Win for PCR Tubes: If you’re using eco-friendly PCR materials or ABS plastics, ultrasonic welding offers both strength and sustainability.

- Tube Size + Cap Combo Impacts Integrity: Streamline your choices—10 ml, 15 ml, or 20 ml sizes paired with screw caps often outperform flip tops in secure bulk handling.

- Tamper-Evident Layers Double as Labeling Aids: High-volume buyers benefit from tamper-evident seals that also support automated labeling systems for speedier fulfillment.

- Barrier Protection Is Non-Negotiable in Bulk Transit: Protective film layers inside the tube ensure product integrity across shipment zones—especially when temps fluctuate mid-haul.

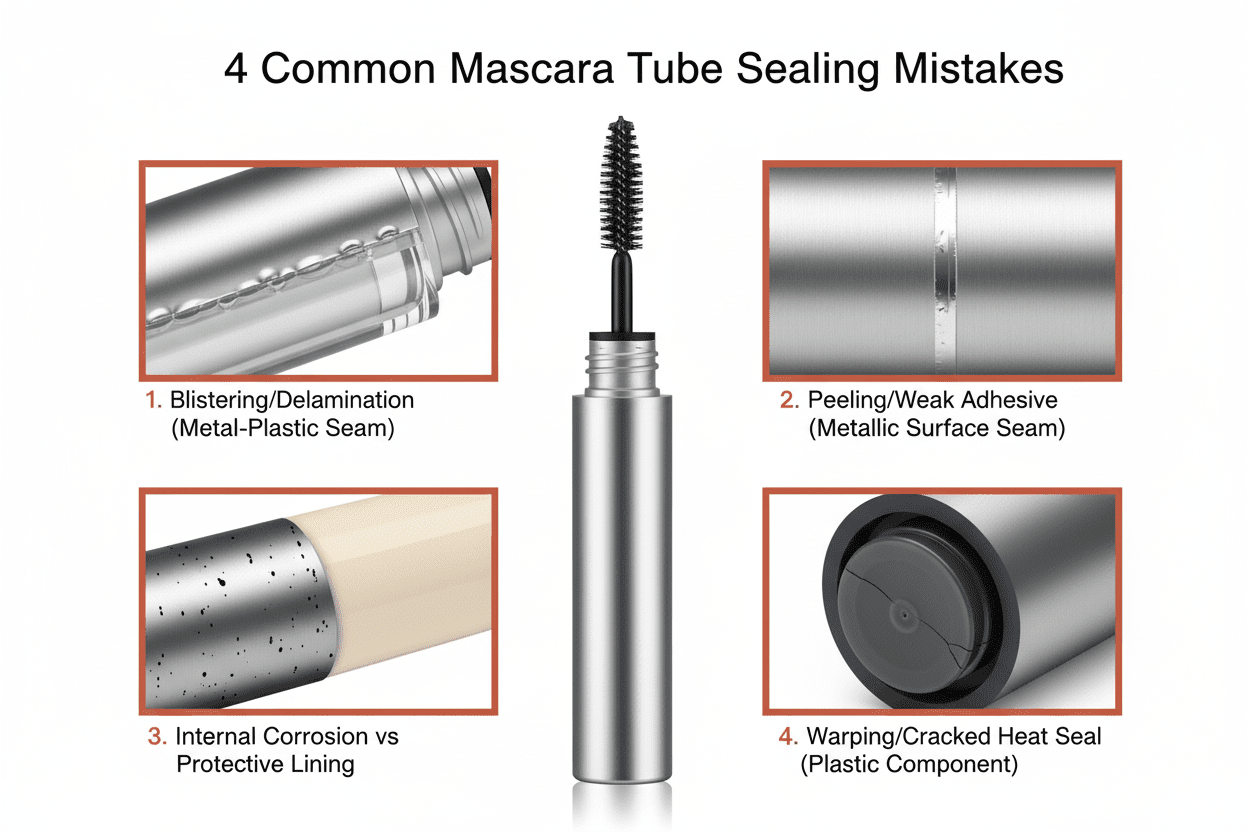

4 Common Mascara Tube Sealing Mistakes

Watch out—these common sealing slip-ups can wreck your mascara packaging before it even hits the shelf.

Overlooking Aluminium–PETG Compatibility Risks

When Aluminium meets PETG, they don’t always play nice. That’s not just a hunch—it’s chemical fact.

• PETG contains glycol-modified polymers that can react with untreated aluminum, weakening seals over time.

• If you’re using a silver tube mascara design with a PETG insert, you better run compatibility tests under heat and pressure conditions.

• Skipping this step? Expect blistering, delamination, and seal failures that’ll haunt your QA reports.

→ Always use barrier coatings or liners when pairing these materials to avoid chemical drama.

Misjudging Anodized Surface Adhesion

An anodized surface might look sleek, but it messes with adhesives more than you’d think.

- Oxidation layer issues: The anodizing process creates an oxide barrier that resists most standard bonding agents.

- Sealant mismatch: Many adhesives simply won’t grip properly to anodized finishes without pre-treatment.

- Mascara tubes at risk: Especially those with brushed metallic finishes often have poor adhesion zones near seams.

- Surface treatment matters: Plasma or corona treatments may help improve adhesion, but testing is key.

- Seal integrity check: Weak bonds here lead to leaks or cap pop-offs—total shelf-life killers for any product involving a shiny silver finish.

Skipping Epoxy Phenolic Protective Layers

Leaving out an epoxy phenolic coating inside your mascara tube? Big mistake—here’s why:

• These protective layers act like armor against corrosion from water-based formulas and preservatives.

• In metal-based packaging like aluminum tubes, lack of lining invites pitting and black specks—gross for consumers.

• A good liner also prevents chemical leaching into the formula, preserving both scent and stability.

A lot of folks assume their base material is tough enough—but without the right coating, even high-grade metals degrade faster than expected.

Relying on Heat Sealing for ABS Without Testing

ABS might seem heat-sealable on paper… until it warps under pressure in real life.

- 🔹 ABS has uneven thermal conductivity; hotspots cause deformation during sealing.

- 🔹 Every heat sealer behaves differently depending on dwell time and temperature control.

- 🔹 Without proper trials, you risk inconsistent seals that crack open days later.

- 🔹 For any component in a plastic-heavy mascara tube—especially if you’re aiming for a glossy silver exterior—test every variable before scaling up production.

ABS can work great—but only if you treat it like the finicky material it actually is.

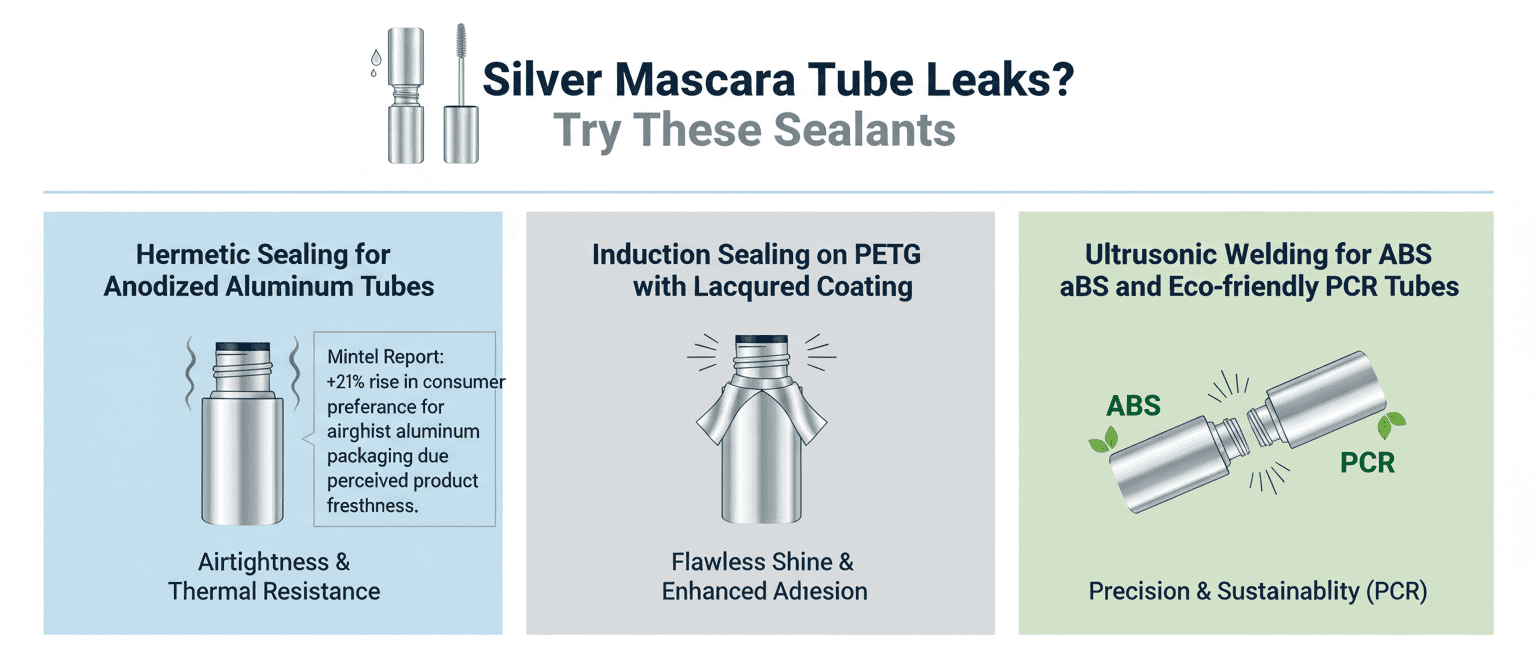

Silver Mascara Tube Leaks? Try These Sealants

Don’t let leaky tubes mess with your vibe—these sealing tricks keep your mascara safe and sound.

Hermetic Sealing for Anodized Aluminium Tubes

Keeping air out is key. For anodized aluminium tubes, hermetic sealing does the heavy lifting when it comes to leak prevention.

- Material Compatibility: The oxide layer on anodized aluminium enhances adhesion with heat-seal liners.

- Seal Integrity: Proper alignment and pressure during the seal process ensure long-lasting airtightness.

- Thermal Resistance: These seals hold up under high temps, making them perfect for hot-fill products.

- Use Case: Perfect for premium silver-finish tubes where aesthetic meets performance.

A report from Mintel’s Q2 Cosmetics Packaging Review notes that “airtight aluminum packaging saw a +21% rise in consumer preference due to perceived product freshness.” That says a lot about why this method works.

Induction Sealing on PETG with Lacquered Coating

PETG might be tough, but when it’s paired with a lacquered coating, you need extra finesse—enter induction sealing.

• A foil membrane is placed over the opening. When exposed to an electromagnetic field, the foil heats up.

• The heat melts the polymer layer underneath, bonding it tightly onto the PETG rim.

• That lacquer? It boosts adhesion while also protecting the design from scratches or abrasion.

This combo not only stops leaks but keeps your tube’s outer shine flawless—ideal for those sleek silver tube mascara designs that demand both form and function. And yep, Topfeel nails this process like pros.

Ultrasonic Welding for ABS and Eco-friendly PCR Tubes

Here’s how brands are stepping up their game using ultrasonic welding on both traditional ABS and sustainable PCR tubes:

| Tube Type | Material Base | Weld Strength Rating | Eco Score (/10) |

|---|---|---|---|

| Standard ABS | ABS | High | 4 |

| PCR Blend | PCR + ABS | Medium–High | 8 |

| Full PCR | Recycled Resin | Medium | 9 |

The trick is in vibration frequency—the weld happens fast without melting or deforming the tube body. This makes ultrasonic welding ideal for eco-conscious lines that still want precision seals without adding adhesives or wasteful liners.

Shorten downtime, reduce material overlap, cut energy use—and still get tight seals? That’s what we call smart sealing tech.

Bulk Packaging: Ensure Mascara Tube Integrity

When you’re moving serious product volume, your packaging can’t slack. Here’s how to keep every silver tube safe, sealed, and stylish—no matter the batch size.

Streamlining Orders with 10 ml, 15 ml, and 20 ml Tubes

- 10 ml tubes are perfect for travel kits or trial runs—lightweight and cost-effective.

- 15 ml tubes strike a balance between compactness and generous fill volume, ideal for mainstream retail.

- 20 ml tubes cater to high-use consumers or pro markets needing longer-lasting supply.

💡 Want better margins? Volume discounts kick in fast when you optimize by tube size. With Topfeel’s ordering system, scaling up doesn’t mean losing control—it means smarter logistics and fewer headaches. Whether it’s a mini run or a full production line of metallic-finish mascara containers, choosing the right fill capacity keeps things lean.

Flip Tops vs. Screw Caps Which Excel in Bulk?

- Flip tops:

- Snap-shut ease

- Quick application access

- Less risk of misplacement during busy salon use

- Screw caps:

- Tighter seal = better shelf life

- Ideal for transit-heavy distribution

- Supports more precision during filling

Choosing between these two depends on your focus—speed or security? For bulk shipments of bulk packaging, screw caps tend to win out due to their superior sealing effectiveness, especially when paired with creams or heavier mascara formulas housed inside sleek silver-tone barrels.

Protective Barrier Layers for Transit Durability

Impact-resistant materials matter more than you think when you’re shipping thousands of units cross-country—or cross-continent.

• Multi-layer films offer heat resistance plus puncture protection.

• Inner foil linings preserve formula integrity under pressure shifts.

• Rigid outer shells deflect crushing forces during stacking.

According to QY Research’s April 2024 report on cosmetic transport trends, “formulation loss from inadequate barrier packaging remains a top concern among global manufacturers.” So if your shiny new silver tube is arriving dented or leaking? That’s not just bad optics—it’s lost revenue and refund requests waiting to happen.

Tamper-Evident Sealing Meets High-Volume Labeling

First impressions count—and so does product safety.

Short-run label jobs can get messy without automation, but high-volume setups thrive with integrated sealing + labeling systems:

• Tamper-evident bands boost consumer trust at point-of-sale.

• Heat-shrink wraps double as both seal and branding surface.

• Adhesive strength matters—a weak label won’t survive warehouse handling.

And don’t forget authentication cues like QR-coded seals that support digital traceability. For brands offering premium lines like reflective chrome mascara tubes with rich pigment payoff, this combo of security features and sharp-looking labels is non-negotiable—especially once those units hit retail shelves en masse.

FAQs

It’s not always the formula—it’s often the packaging. When aluminium meets PETG without a proper barrier, corrosion creeps in. A missing epoxy phenolic layer? That invites disaster. And heat sealing ABS without testing is like trusting a paper bridge in a storm: it might hold for now, but pressure will tear it apart.

Anodized aluminium looks sleek and feels strong—but appearances can deceive if you’re not careful with sealants. Its surface resists bonding unless treated right, so pairing it with hermetic seals becomes essential. Done well, though, this combo offers both elegance and airtight protection.

- Ultrasonic welding stands out—cleaner than adhesives and more precise than thermal methods.

- It creates tight bonds that don’t buckle under stress.

- Especially useful when working with recycled materials prone to warping under heat.

Because your formula deserves better than reacting with its container. This invisible shield blocks corrosive reactions between active ingredients and raw metal surfaces—keeping the product stable longer while preserving texture and color integrity over time.

Flip tops offer speed; they snap shut quickly on assembly lines and feel intuitive in hand—a win at retail counters where ease matters most. Screw caps bring peace of mind during long hauls or warehouse storage; their tighter grip keeps thick mascaras from oozing out mid-transit. The choice depends on what matters more: convenience up front or security down the line.