Easy Ways to Choose the Right Lipstick Tube Container

You’ve probably never lost sleep over a lipstick tube container—until you’re knee-deep in sourcing thousands of them and realize half the samples crack, leak, or look like they belong in a dollar store bin. Packaging isn’t just packaging; it’s your silent salesperson. And when you’re buying in bulk? One bad batch can torch your margins and your brand’s street cred.

Think of it like choosing the right pair of shoes for a marathon—you want style, sure, but if they rub blisters by mile two? Game over. The same goes here: durability, cost-per-unit sanity, and that on-brand finish (hello Pantone match!) all have to fall into place without making you pull your hair out.

Key Points in Crafting the Perfect Lipstick Tube Container

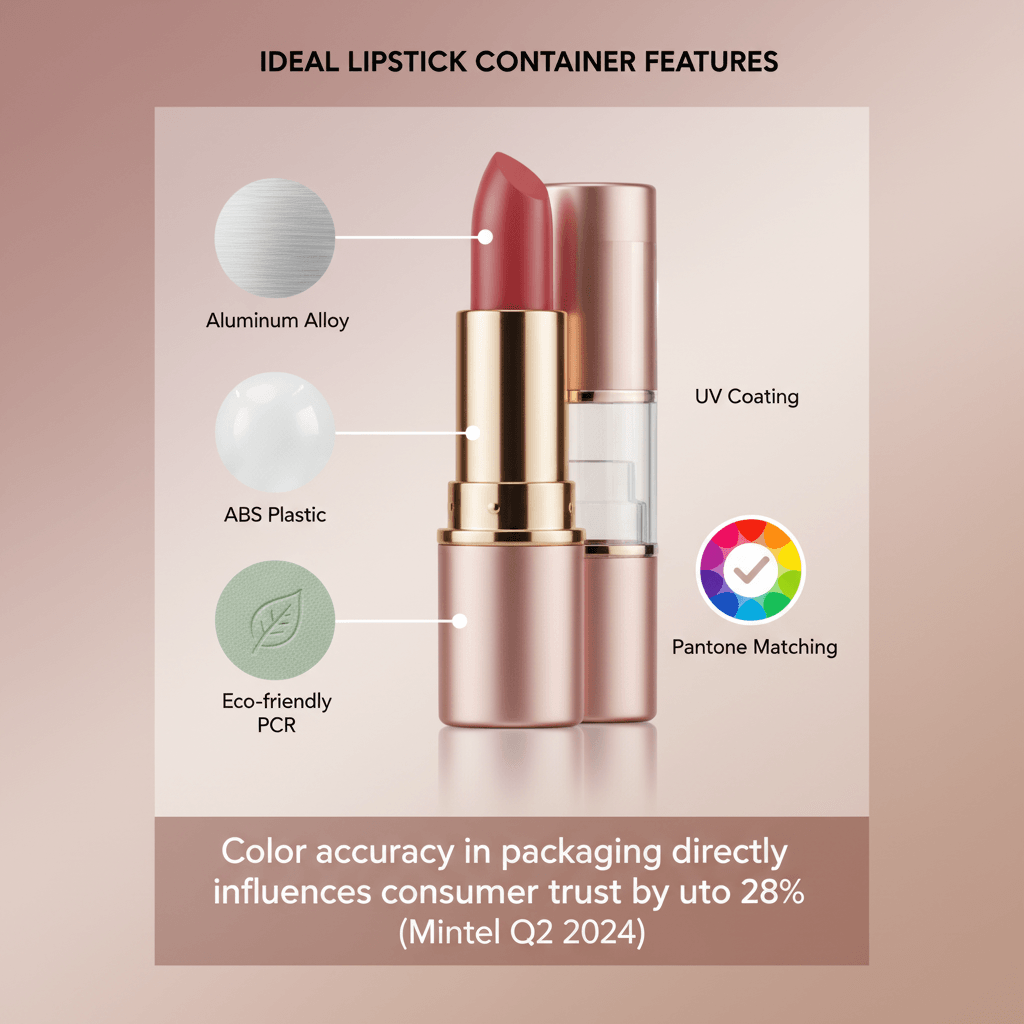

➔ Material Matters Most: Choose from aluminum alloy for strength, ABS plastic for flexibility, or eco-friendly PCR to stay sustainable without breaking the bank.

➔ Surface Finishes That Sell: UV coating not only adds protection but also boosts visual appeal—especially when paired with Pantone-matched colors for brand consistency.

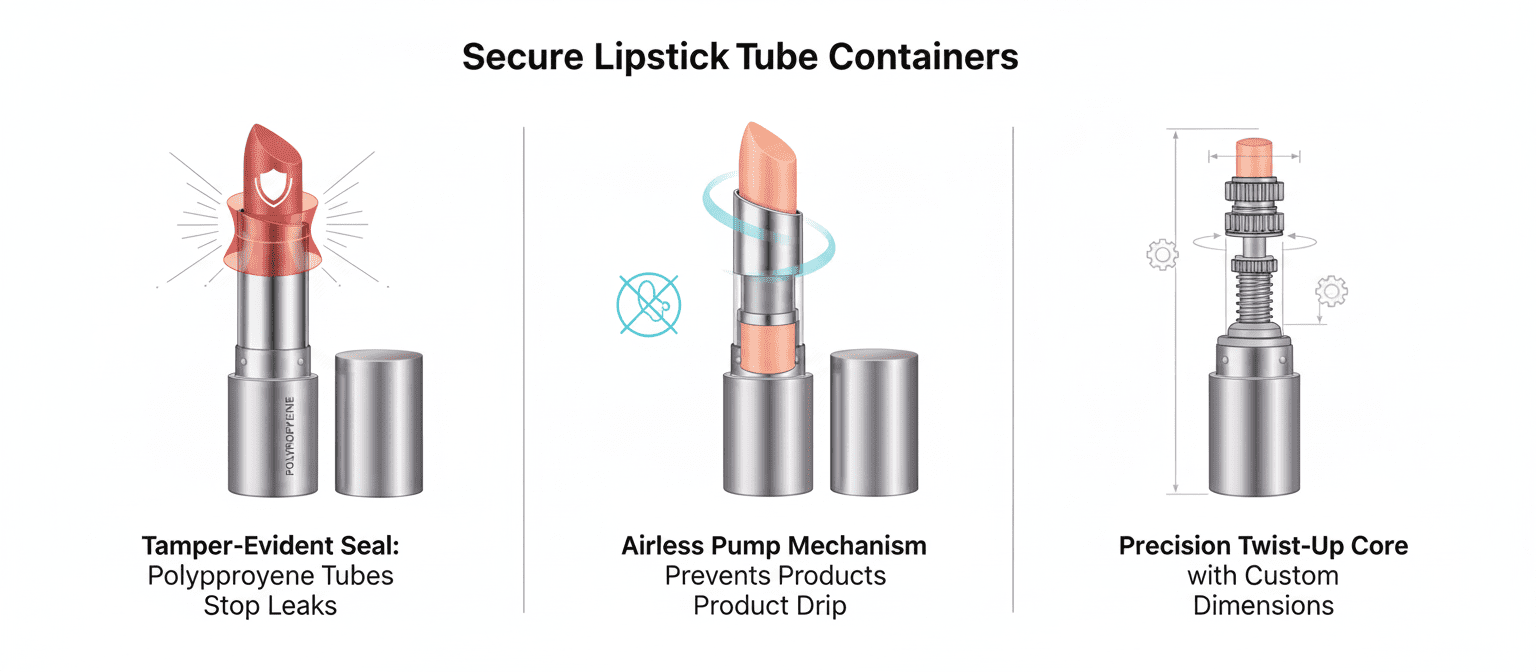

➔ Leak-Proof Engineering: Polypropylene tubes with tamper-evident seals and airless pump mechanisms prevent leaks and product waste during shipping and use.

➔ Function Meets Form: Twist-up cores with custom dimensions make dispensing seamless while slim round designs reduce cost and material usage in bulk orders.

➔ Smart Cost-Saving Styles: Metallic spray finishes and label applications provide high-end looks on a budget—ideal for scaling up production affordably.

Key Features of Ideal Lipstick Containers

The best lipstick holders aren’t just pretty—they’re built smart, tough, and tailored for today’s eco-aware world.

Durable Materials: Aluminum Alloy, ABS Plastic & Eco-friendly PCR

- Aluminum alloy brings a premium feel while resisting dents and scratches like a champ.

- ABS plastic, that sturdy yet flexible stuff, helps keep the tube lightweight without feeling cheap.

- Eco-friendly PCR, made from post-consumer resin, is perfect for brands wanting greener vibes without sacrificing performance.

These three materials together create a killer combo of strength, sustainability, and style—no compromises needed on your next favorite lip color’s home.

UV Coating with Pantone Matching Enhances Appeal

• A good UV coating doesn’t just shine—it shields. It protects the outer shell from fading or cracking under sunlight or rough handling.

• Pair that with Pantone color matching and you’ve got packaging that nails brand consistency every single time—right down to the exact shade of coral pink or midnight plum.

• According to Mintel’s Global Beauty Packaging Report Q2 2024: “Color accuracy in packaging directly influences consumer trust by up to 28%.” That’s no small deal when you’re standing out on crowded shelves.

So whether it’s deep matte black or glossy neon red, this combo keeps your lipstick looking luxe and lasting longer than trends do.

Worried About Leakage? Secure Lipstick Tube Containers Here

Keep your formulas protected and mess-free with smart design upgrades that blend functionality and flair.

Tamper-Evident Seal: Polypropylene Tubes Stop Leaks

- Polypropylene is a beast when it comes to keeping stuff locked in—its tight barrier holds up against oils, creams, and balms.

- Leak-proofing isn’t just about material; tamper-evident bands make sure no one sneaks a peek or twist before it’s yours.

- Want peace of mind in your purse? These tubes won’t betray you mid-commute.

You’ll also notice how these containers handle pressure changes like champs, especially during shipping. That’s the magic of a high-grade polymer seal, not just slapped on but engineered for real-world chaos. From travel bags to retail shelves, this kind of packaging keeps things neat without sacrificing style.

Airless Pump Mechanism Prevents Product Drip

• Airless pump chambers reduce oxygen exposure by over 90%, helping color formulas stay fresh longer

• No more dreaded “lipstick melt”—the internal piston tech prevents backflow and accidental oozing

• Smooth dispensing action means fewer clogs and cleaner application every single time

Grouped Benefits:

- Preservation: Less air = less oxidation, so pigments stay poppin’.

- Hygiene: Keeps fingers off the product—no double-dipping drama.

- Convenience: Consistent output till the very last swipe.

This mechanism isn’t just for skincare anymore—it’s made its way into color cosmetics with serious results. Brands like Topfeel are already integrating these systems into their high-end lip balm formats.

Precision Twist-Up Core with Custom Dimensions

Sometimes it’s all about the little things—like how smoothly your lipstick glides up without breaking off halfway through. That’s where the twist-up core steps in.

| Feature | Standard Size (mm) | Custom Option 1 | Custom Option 2 |

|---|---|---|---|

| Core Diameter | 12 | 10 | 14 |

| Rotation Angle per Turn | 30° | 25° | 35° |

| Max Fill Volume | 4g | 3g | 5g |

| Wall Thickness | 0.8 | 1.0 | 0.6 |

Each tweak—from diameter to rotation angle—affects how product dispenses and feels in hand. Some brands opt for slimmer cores to match sleek designs, others go bulkier for grip and control. Either way, custom builds let you match vibe with function perfectly.

That small twist? It makes a big difference.

Concerned with Costs? Affordable Tube Container Options

Looking to save without skimping on looks or quality? These budget-friendly packaging choices keep your beauty line sharp and sustainable.

Eco-friendly PCR Containers: Budget-Friendly & Durable

• Made from PCR plastic, these tubes reuse post-consumer materials—lowering both environmental impact and production costs.

• They’re tough enough to survive drops and daily use, making them a solid bet for long-term shelf life.

• With consistent sizing, these containers simplify logistics and reduce waste during filling processes.

Metallic Spray and Label Application Lower Costs

- Skip full-sleeve printing—metallic spray finishes give a luxe feel without the price tag of custom molds.

- Labels offer flexible branding options; they’re quick to apply and easy to change for seasonal lines or rebrands.

- Combining both techniques means you can cut tooling expenses while still turning heads on retail shelves.

Slim Round Designs with Twist-Up Systems Save Bulk Orders

Shorter barrels, slimmer walls, smarter savings:

— Slim profiles use less raw material, trimming down unit cost per lipstick tube body.

— The twist-up system is efficient—not only for users but also for assembly lines that benefit from standardized parts.

— These designs stack tighter in shipping cartons, lowering freight fees over large-volume orders.

Smart Design Choices That Slash Your Packaging Spend

Grouped together, these features make a major dent in your budget:

• Slim cylindrical formats – Less resin needed = lower cost per container.

• Integrated twist-up mechanics – Reduces need for additional components.

• Universal cap compatibility – Streamlines supply chain by using one lid across multiple SKUs.

• Minimalist exterior styling – Easier to decorate with digital print or foil stamping instead of full wraps.

• Modular mold systems – Cuts down lead times when scaling up production runs quickly.

Quick Wins: How Small Changes Lead to Big Savings

Tiny tweaks can mean big bucks saved:

– Switching from glossy lacquer to matte finishes cuts curing time—and energy use—in half.

– Using recycled caps instead of virgin plastic can reduce material costs by up to 20%.

– Designing shorter necks on the inner cup saves grams of plastic that add up fast at scale.

From Sketchpad to Shipment: A Cost-Savvy Development Path

Here’s how smart brands trim costs at every stage:

Step 1: Choose a base mold already available in stock libraries—no tooling fee required.

Step 2: Opt for standard screw mechanisms instead of magnets—they’re cheaper and more recyclable too.

Step 3: Finalize artwork early so label printing doesn’t delay timelines—or rack up rush charges later down the line.

Why Bulk Ordering Makes Sense Now More Than Ever

Ordering thousands might sound wild—but here’s why it pays off:

• Per-unit pricing drops dramatically once you hit factory MOQ thresholds.

• Shipping larger batches reduces per-piece freight cost by consolidating pallets.

• Most suppliers throw in free extras like insert trays or shrink wrap when volumes are high enough.

• You lock in pricing before raw material rates spike again—which they tend to do quarterly.

Mixing Functionality with Affordability Like a Pro

Some combinations just work better together:

– Use PCR blends + minimalist shapes = eco-friendly appeal without high costs.

– Pair label application + soft-touch coatings = upscale look minus expensive custom tooling.

– Go with universal inserts + bulk ordering = simplified logistics across multiple product lines like balm sticks or sample-sized lip colors.

By blending these tactics smartly, even indie brands can compete with major players—without breaking the bank on their next run of sleek little color-packed tubes.

FAQs

You want your product to arrive looking flawless. That means using materials that can handle pressure, drops, and time on the shelf:

- Aluminum alloy: Keeps dents at bay while adding a sleek finish

- ABS plastic: Lightweight but tough—ideal for high-volume orders

- PCR (Post-Consumer Resin): Eco-conscious without sacrificing strength

Each material brings its own personality to the packaging, balancing durability with design.

Absolutely. A UV-coated surface resists scratches like armor while locking in color vibrancy. It’s not just protection—it’s polish. For brands chasing bold Pantone shades or metallic effects, this layer ensures every unit gleams under store lights exactly as intended.

Yes—and you should if your formula demands it. Some lipsticks are creamy; others are dense or balm-like. Custom sizing lets you match internal volume with texture so customers get smooth application from start to finish.

Precision twist-up cores also allow tighter control over how much product is dispensed per turn—no waste, no mess.

Not even close:

- PCR supports luxe finishes: think matte black or brushed gold spray coatings

- Strong enough to survive purse life and travel bags without cracking

- Compatible with labels and embossing for premium branding

Eco doesn’t mean compromise—it means smart choices that still impress on shelves.

Shipping thousands of units across cities—or oceans—calls for serious safeguards:

- Tamper-evident seals made from polypropylene lock everything inside until opened by hand

- Twist-up bases snap securely into place so nothing shifts mid-shipmentTogether they form an invisible shield around your formula until it reaches its final destination intact.

If you’re building a visual identity people remember—you bet it is. Color consistency builds trust fast: one glance at the shade of red on your cap tells shoppers they’re holding something familiar, reliable… yours.

Pantone precision keeps every batch aligned—even across different factories or production runs—so what customers see online matches what lands in their hands.