Effective Ways to Enhance Lip Chap Tubes with Printing

In the wild world of cosmetics, lip chap tubes are like the unsung heroes—always there, rarely flashy, but absolutely essential. And here’s the kicker: your packaging might be speaking louder than your formula ever could. With shelves crammed tighter than a rush-hour subway car, a dull tube just won’t cut it anymore.

Picture this—you’ve got a killer balm that glides smoother than jazz on vinyl, but it’s wrapped in a snooze-fest of plastic. That’s how you lose customers before they even twist the cap. Great design isn’t fluff—it’s shelf appeal that converts to sales.

“89% of consumers say packaging influences their purchase decisions,” notes Topfeel’s senior product designer Megan Zhou. “If your tube doesn’t tell your story instantly, someone else’s will.” Translation? Looks matter—a lot.

We’re talking silk screening sass, hot-stamped elegance, and tactile textures that practically flirt with fingertips. You want branding people remember? Start with where their lips land first.

Reading Notes for Lip Chap Tubes: A Packaging Remix That Pops and Sells

➔ Print Wizardry: From metallic hot-stamping to UV gloss, printing techniques like silk-screening and shrink sleeves transform chap tubes into branding powerhouses.

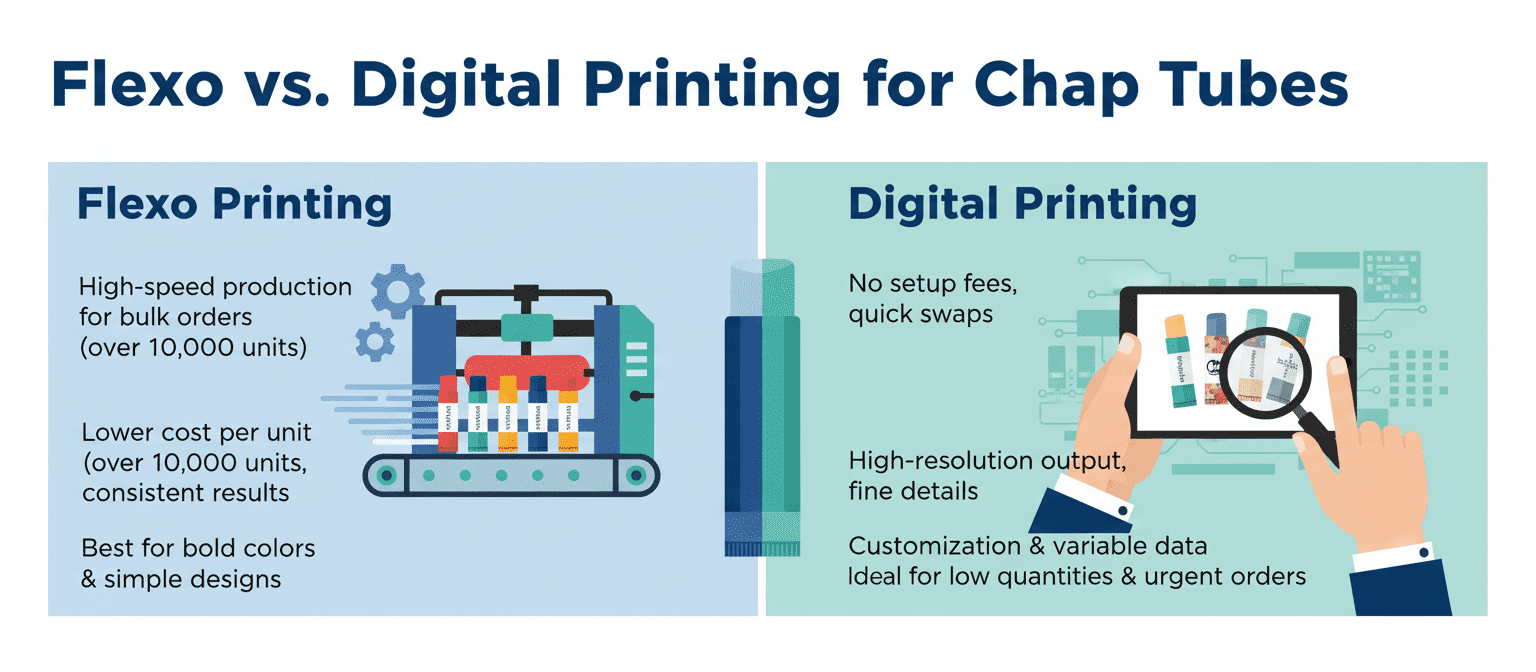

➔ Big Run vs. Small Batch: Flexo printing suits high-volume aluminum tube production, while digital shines in short runs with quick turnarounds and vivid detail.

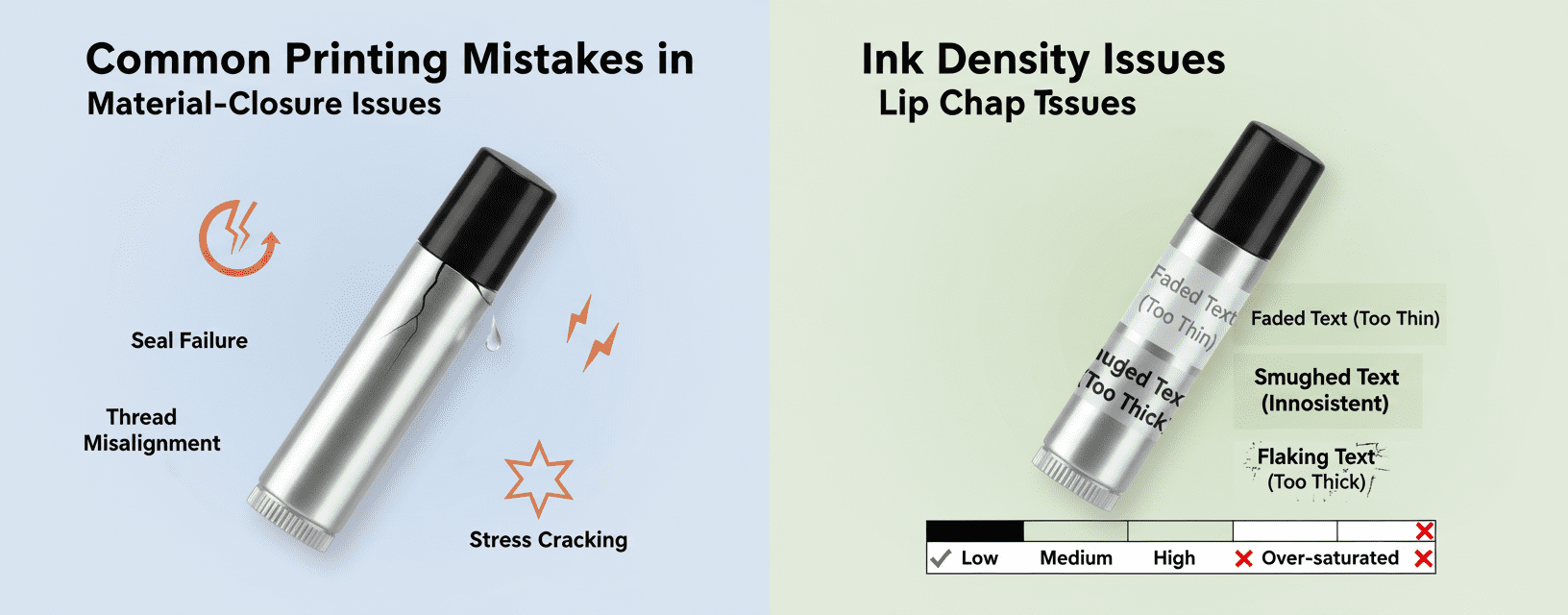

➔ Common Mistakes to Dodge: Don’t mismatch closures with materials—poorly sealed screw caps on plastic can spell disaster. Also, ink density matters big time on acrylic tubes.

➔ Embossing = Extra Touch: Whether it’s grip-enhancing textures or luxe raised logos on aluminum or acrylic, embossing elevates both feel and function.

➔ Bulk Smarts: Large orders? Silk screening for paperboard, flexo for aluminum, and shrink sleeves for plastic offer the most cost-effective branding options at scale.

Wow! 5 Unexpected Printing Tricks to Revitalize Your Lip Chap Tubes

Breathe new life into your lip balm packaging with these off-the-wall printing tricks—some flashy, some subtle, all game-changing.

Hot-Stamping Metallic Accents on Snap-On Plastic 15 ml Tubes

This method adds a real pop of polish to your plastic tubes and grabs attention fast.

• Reflective gold or silver foil creates instant shelf appeal.

• Works best on smooth-surfaced snap-on plastics for clean transfer.

• Ideal for highlighting logos and brand names in lip balm label printing.

You’ll want to keep the design minimal—let that metallic shine do the talking while the rest of your tube stays sleek.

Silk-Screen Vibrancy in Twist-Up Acrylic 10 ml Lip Chap Tubes

Silk-screen printing delivers rich color payoff and sharp detail, especially on twist-up acrylic formats.

- Offers long-lasting ink adhesion on curved surfaces.

- Supports up to five colors without smudging or ghosting.

- Best used when showcasing bold graphics or typography-heavy branding.

For brands leaning into colorful aesthetics, this is a go-to technique for turning heads with every twist of the tube.

Shrink-Sleeve Artwork Wrapped Around Paperboard 5 ml Chap Tubes

Shrink sleeves wrap around like a second skin—and they’re perfect for paperboard tubes that need full-body branding love.

The real kicker? You get uninterrupted design flow from top to bottom, even around curves and seams. That’s huge when you’re working with smaller formats like these compact paperboard options often used for eco-conscious collections or travel-size lines of eco-friendly lip balm tubes.

Plus, shrink sleeves play nice with matte finishes or glossy textures depending on how loud you want your artwork shouting from the shelf.

Metallic Ink Overlays on Aluminum 30 ml Chap Tubes Unleashed

Here’s where things get fancy—metallic inks bring shimmer without needing hot-stamped foil layers.

Grouped Benefits:

• Adds depth and dimension through reflective pigments.

• Pairs beautifully with minimalist black-and-white designs or bold neon contrasts.

Use Case Combo:

– Premium grooming lines wanting upscale vibes;

– Seasonal collections aiming for holiday sparkle;

– Limited editions that need extra oomph beyond standard lip balm packaging design norms.

According to Mintel’s Q2 Beauty Packaging Report from April 2024, over 38% of consumers associate metallic finishes with “luxury” and “trust.” That stat alone makes it worth testing out this overlay method when targeting upscale buyers who crave sophistication in their daily carry items like aluminum-based chap containers.

| Tube Type | Finish Type | Consumer Appeal (%) | Best Use Case |

|---|---|---|---|

| Aluminum | Metallic Ink | 38% | Luxury seasonal drops |

| Plastic | Hot Stamping Foil | 29% | Everyday premium branding |

| Acrylic | UV Gloss + Print | 34% | High-color impact |

| Paperboard | Shrink Sleeve | 31% | Eco-luxe & travel kits |

UV-Printed, High-Gloss Finish on 50 ml Acrylic Chap Tubes

Big format acrylics deserve big visual drama—and UV printing delivers just that with durability baked right in.

Step-by-Step Breakdown:

Step 1: Prep surface with anti-static treatment—acrylic attracts dust like crazy before print time.

Step 2: Apply high-gloss UV-curable ink under low heat exposure for vibrant results without warping the tube body.

Step 3: Seal it off using a clear coat if needed—especially useful if you’re adding tactile elements like raised logos or embossed shapes tied into your branded lip balm identity system.

What makes this trick stand out? It holds up against sweaty palms, makeup bags, and hot car dashboards without fading out after two weeks—a must-have trait when designing long-life promotional items or keeping your product fresh-looking throughout its shelf cycle across retail displays or subscription boxes tied into personalized campaigns featuring custom lip balm tubes at scale.

Flexo vs. Digital Printing for Chap Tubes

Choosing the right print method for your lip balm packaging is a game changer—let’s break down what works best and why.

Flexo Printing

This method is all about speed, volume, and consistency when it comes to decorating those tiny chapstick tubes.

• High-speed production makes it perfect for bulk orders of cosmetic packaging.

• Lower cost per unit once setup is complete—ideal for brands scaling up.

• Durable inks ensure your branding stays crisp on every tube.

Cost Efficiency by Volume

| Production Volume | Setup Cost ($) | Unit Cost ($) | Turnaround Time |

|---|---|---|---|

| Under 10,000 | $800 | $0.25 | 10 days |

| 10,000–50,000 | $900 | $0.18 | 7 days |

| Over 50,000 | $950 | $0.12 | 5 days |

Flexographic printing becomes significantly more affordable as order size increases—a big win for brands pushing thousands of units monthly.

Ink Types Used in Flexo

A few ink types dominate the flexo scene:

- Solvent-based inks: Great adhesion and durability, especially on plastic cosmetic packaging.

- UV-curable inks: Dries instantly under UV light; vibrant finish with minimal smudging.

- Water-based inks: Eco-friendlier but less robust on slick surfaces like lip tube plastics.

Each has pros and cons depending on your material and environmental goals.

Print Quality Considerations

Short answer? It’s solid—but not flawless for fine detail:

• Best suited for bold colors and simple designs.

• Halftones or gradients may appear less sharp compared to digital methods.

If you’re after clean logos or large text on your lip product containers—flexo nails it every time.

When to Choose Flexo Over Digital

Here’s how you know flexographic printing is your move:

① You’re producing over 20k units per SKU regularly.

② Your design doesn’t rely heavily on photographic detail or ultra-fine lines.

③ You want consistent results across huge batches of tubes.

It’s a no-brainer when volume trumps variation.

Digital Printing

Digital’s where flexibility meets flair—perfect if you’re testing markets or launching limited runs of new flavors in your balm lineup.

Benefits at Low Quantities

• No setup fees—print what you need without breaking the bank.

• Quick swaps between designs make seasonal runs a breeze.

For indie makers or test batches, this one’s gold dust.

Graphic Precision & Color Depth

Digital tech shines here:

① High-resolution output captures even micro-details like texture effects or shadows.

② Full-color gradients print smoothly without banding.

③ Perfect registration ensures no misaligned prints—even on curved surfaces like small balm tubes.

Your cherry swirl graphic? It’ll pop just like you imagined it would!

Customization Possibilities

Let’s say you’re running five scents—you can do this:

🟢 Print different labels with unique artwork in one batch run.

🟢 Add variable data like batch codes or QR links per unit—no extra charge!

That level of personalization helps smaller brands stand out fast in crowded shelves.

Comparing Turnaround Times with Flexo

Here’s how they stack up:

- Digital jobs can ship within three days post-proof approval.

- Flexo needs plate-making + setup = longer wait times upfront.

- For urgent orders under tight deadlines? Digital wins hands down every time.

Even better if you’re tweaking designs last minute before launch day!

Limitations to Watch Out For

Short-run magic aside, digital isn’t perfect:

① Per-unit costs stay higher than flexo past ~10k units.

② Limited ink adhesion options compared to specialized flexographic printing formulas.

③ Not ideal for highly glossy finishes unless topcoated post-printing—which adds cost/time.

Still, if agility matters more than economy-of-scale? Worth every penny!

Ideal Use Cases by Brand Size & Strategy

Small batch startup? Go digital from day one—it’ll save headaches down the road while giving you room to experiment freely with each new scent release across your lip-care lineups.

Established brand producing tens of thousands weekly? Stick with flexo—it’ll keep costs predictable as you scale SKUs across global markets like Topfeel does today with their high-volume balm packaging runs.

Common Printing Mistakes in Lip Chap Tubes

Even small printing flaws on lip balm packaging can mess with branding or cause leaks. Let’s break down two big mistakes that often get overlooked.

Ignoring Material–Closure Matches: Screw Cap Plastic Tubes Failures

When the tube material and cap type don’t vibe, things go sideways fast:

- Seal failure – If the plastic is too soft or too rigid, screw caps may not grip properly, leading to leakage.

- Thread misalignment – Incompatible materials can warp under heat during filling, making threads unreliable.

- Shrinkage issues – Some plastics contract after cooling, loosening closures and compromising product safety.

- Stress cracking – Certain plastics react poorly with essential oils or alcohols in balms; add a tight-fitting cap to that mix and you’ve got cracks.

- Transportation damage – Weak closures from mismatched materials don’t hold up during shipping jostles.

These flaws don’t just ruin a batch—they wreck trust in your brand. And when customers see smeared balm or oily smudges from loose tubes, they remember it.

Choosing the Wrong Ink Density for 10 ml Acrylic Lip Chap Tubes

Getting ink density wrong isn’t just about looks—it affects everything from shelf appeal to scanability. Here’s where things go off-track:

- Too thick? You’ll get raised text that flakes off over time.

- Too thin? Expect faded logos and barely-there labels after a few weeks on the shelf.

- Inconsistent application? Smudging galore—especially when tubes are stacked before drying.

Now take a look at how ink density directly impacts performance on acrylic surfaces:

| Ink Density Level | Print Clarity | Dry Time (sec) | Smudge Resistance |

|---|---|---|---|

| Low | Poor | 5 | Low |

| Medium | Good | 8 | Medium |

| High | Excellent | 12 | High |

| Over-saturated | Blurry | 20+ | Very Low |

For acrylic-style balm containers like these, medium density usually hits the sweet spot—clean visuals without bleeding into design lines.

Messing this up doesn’t just mean ugly tubes—it means unreadable ingredients lists and barcodes that won’t scan at checkout. That’s more than bad design—it’s bad business.

And if your brand’s printed label starts to fade before the balm runs out? You’ll be remembered—but not in a good way.

Can Embossing Elevate Your Chap Tube Packaging?

Embossing isn’t just about looks—it’s a tactile experience that can transform how folks interact with your balm packaging.

Enhancing Grip with Embossing on Twist-Up Plastic Chap Tubes

- Improve usability—textured surfaces reduce slipping, even with oily fingers.

- Add subtle branding cues—icons or patterns can reflect your identity.

- Create visual contrast—glossy vs matte finishes pop more with texture.

On twist-up tubes made from soft plastics, this grip boost is not just functional—it gives the product a more premium, thoughtful vibe that users appreciate during daily use. When holding a small balm stick, every bit of friction counts!

Embossing on Aluminum Tubes: A Premium Touch

Embossing aluminum? Now we’re talking upscale vibes with purpose. These tubes already feel luxe—but add raised detailing and suddenly you’ve got something people won’t forget.

• Precision embossing allows for detailed logos or geometric textures

• Reflective metal surfaces enhance embossed shadows and depth perception

According to Mintel’s Q1 2024 report on cosmetic packaging trends, “Consumers increasingly associate tactile design elements like embossing with quality and trustworthiness.” That means a little raised logo could go a long way toward building brand loyalty—and Topfeel knows exactly how to make that happen without blowing up your budget.

Tactile Branding via Embossed Labels on 30 ml Acrylic Tubes

Smooth acrylics are sleek—but they can also feel cold or impersonal if left bare. That’s where embossed labels come alive:

Quick hits:

– They add grip without altering the tube shape.

– They give your logo real-world presence—people literally feel it.

– They break up shiny monotony with matte contrast zones.

So when someone picks up your gloss balm housed in an acrylic tube, it doesn’t just look sharp—it feels intentional, too. That sensory connection matters more than you think.

Combining Texture and Function Across Chap Tube Materials

Let’s break down how different materials respond to embossing techniques, so you can pick what works best for your brand:

Plastic chap containers

• Best for: Grip-focused embossing

• Considerations: Flexibility may limit design complexity

• Cost impact: Low

Aluminum-based balms

• Best for: Luxury appeal and detailed logos

• Considerations: Requires precision tooling

• Cost impact: Moderate to high

Acrylic casings

• Best for: Label-driven branding effects

• Considerations: Works well with adhesives + foil layering

• Cost impact: Medium

Each choice comes down to how much tactile flair you want versus what fits your budget and production flow.

Consumer Perception & Market Trends Around Embossed Packaging

You know what really sells? Stuff that feels good before it even gets opened. Here’s why embossed balm tubes are catching fire lately:

– People crave texture—they’re tired of smooth plastic everything.

– Raised designs help products stand out on cluttered store shelves.

– Eco-conscious buyers love reusable tubes that still look fresh after months of use.

Combine all that with smart design considerations, and you’ve got packaging people remember—and reuse. That’s the kind of consumer bond most brands dream about building through something as simple as touch.

FAQs

Branding isn’t just about a logo—it’s how your product feels in someone’s hand. Different tube types respond best to specific techniques:

- Hot-stamping adds that flashy metallic glint on snap-on 15 ml plastic tubes—perfect for catching light (and attention).

- Silk-screening brings bold, tactile color to twist-up acrylics, usually around 10 ml.

- Shrink sleeves wrap paperboard 5 ml options with full-color art like a second skin.

- UV printing gives larger acrylic formats (like 50 ml) an almost glass-like shine.

Each method has its own personality. The right one depends on what story you want your lip balm to tell before it even touches lips.

It comes down to tension—literally. When rigid screw caps meet soft plastic bodies, they don’t always get along. Under pressure during shipping or temperature changes, the seal can weaken and leak. It’s not poor design; it’s mismatched materials trying too hard to cooperate.

A better match might be flexible closures or switching tube material altogether if durability is key.

Absolutely—and beautifully so. Digital printing skips the long setup dance of traditional presses and goes straight into vivid detail work from day one. For indie brands testing seasonal scents or limited editions, this means fast turnaround without sacrificing quality—or draining budgets.

Small batches still deserve big impact, and digital makes sure every unit counts.

Embossed textures add more than elegance—they invite touch. On twist-up plastics, raised patterns improve grip subtly but noticeably; no more fumbling mid-winter with cold fingers. On aluminum or labeled acrylics, embossing becomes part artistry, part function—a quiet luxury that whispers quality instead of shouting it.

In short: texture tells stories where flat surfaces fall silent.