MA-63 Twist Cap Lip Gloss Packaging Manufacturers

Model Number: MA-63

Capacity: 5ml

Material: PETG, ABS, POM, LDPE

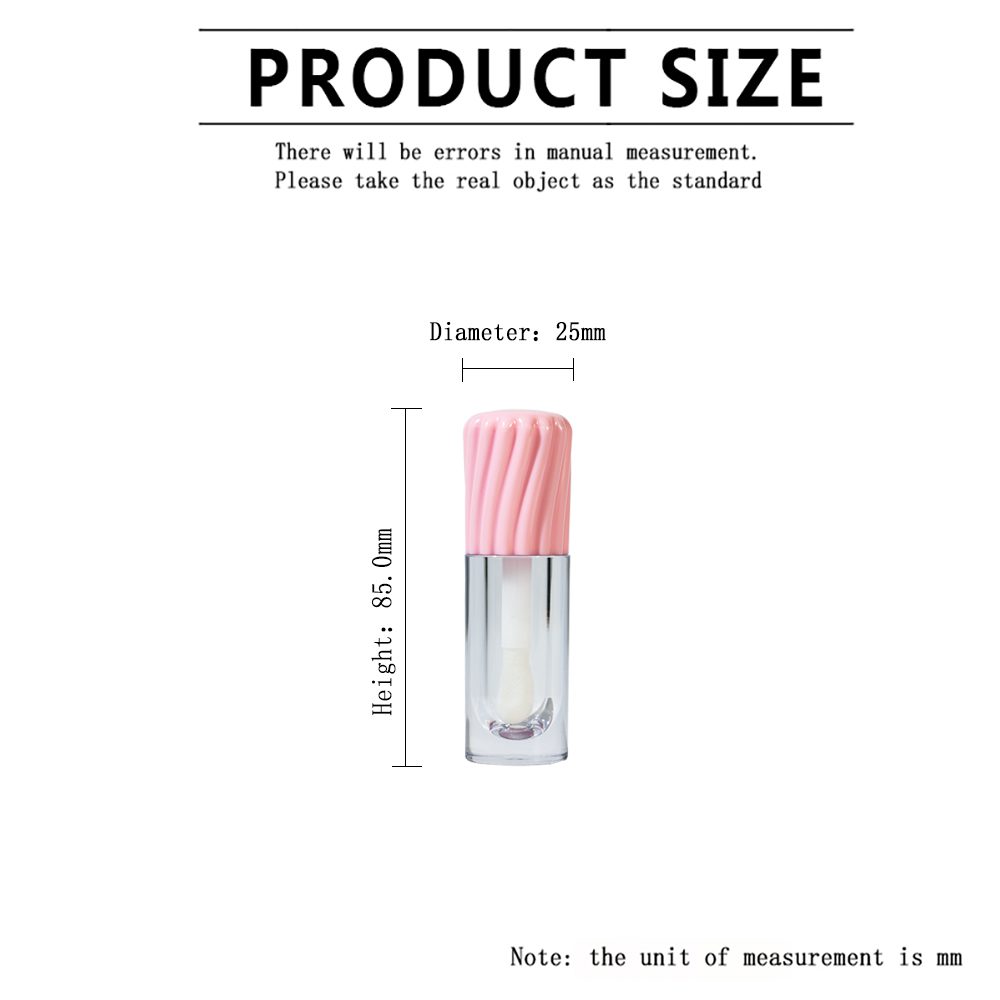

Size: Ø25.5mm x H84.92mm

MOQ: 12,000 pcs

Application: Lip Gloss, Lip Oil, Liquid Lipstick

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color and Printing

Sample:

Highlight of This Product

-

Reliable multi-material construction with enhanced grip design ensures product safety, usability, and long-term durability.

-

Streamlined transparent design offers excellent shelf visibility and full compatibility with decoration customization processes.

-

Soft-tip applicator ensures smooth, precise application of viscous lip formulas, improving overall consumer usage experience.

You May Also Like

View Product Details

Durable & Functional Build

The packaging integrates four precision-selected packaging materials to balance strength, flexibility, and chemical resistance:

-

Container body – PETG plastic: Offers high clarity and toughness, allowing full product visibility while withstanding solvent-based formulations.

-

Twist cap – ABS resin: Known for its impact resistance and molding precision, making it ideal for tight-fit components and threaded closures.

-

Applicator wand stem – POM: A high-stiffness thermoplastic providing reliable insertion support and dimensional accuracy during repetitive use.

-

Wiper insert – LDPE: Ensures optimal product retrieval and application control, while maintaining a tight seal against leakage or evaporation.

Non-Slip Twisted Cap

The cap features a textured spiral surface that improves user grip without requiring external coatings or unnecessary embellishments.

-

The twisted design not only serves a functional purpose but also supports custom packaging solutions such as pattern molding and embossed logo detailing, tailored to brand-specific needs.

-

Material hardness and thread integrity have been verified through torque testing

Modern Look, Market Ready

Transparent Display

The PETG plastic used in the container body is crystal clear, allowing full visibility of the internal formulation’s shade and volume.

-

Simplifying color management and shade identification during fulfillment

-

Allowing consumers to easily view product usage levels

-

Supporting visual consistency across cosmetic packaging lines

Custom-Ready Surface Design

From matte finishes to high-gloss UV coatings, the MA-63 is compatible with various decoration techniques offered by Topfeel. Supported methods include:

-

Silkscreen printing

-

Hot stamping

-

Spray painting

-

Labeling services

These allow for quick brand adaptation without requiring mold changes—ideal for brands managing multiple SKUs or fast-changing seasonal campaigns.

“According to a 2024 report from Packaging Strategies

Thoughtful Application Experience

In color cosmetics, every small detail counts. The MA-63 enhances consumer usability with a carefully engineered applicator wand that minimizes waste and improves end-user satisfaction—while remaining highly producible.

Soft Tip Applicator

The included applicator features a soft-tipped wand, calibrated for even pickup and distribution of lip products:

-

Precision fit with the wiper insert prevents overload and ensures even spread

-

Suitable for low- to mid-viscosity formulations typical of lip gloss and liquid lipstick

-

Designed for ease of replacement or customization depending on formula characteristics

As a custom packaging solutions provider, Topfeel supports alternate wand shapes and applicator materials to meet specific formula demands or consumer segment preferences.

“Consumer product studies by Mintel Global Beauty Reports (2025) show that 65% of buyers rank applicator performance as a primary factor influencing product repurchase—underscoring the importance of upstream packaging design.”

FAQs

The MA-63 integrates four distinct packaging materials for strength, clarity, and compatibility:

-

PETG plastic for the transparent container body

-

ABS resin for the textured twist cap

-

POM for the applicator wand stem

-

LDPE for the inner wiper insert

Topfeel supports multiple decoration techniques for OEM/ODM clients, enabling extensive customization:

-

Silkscreen printing for detailed logos

-

Hot stamping for premium foil effects

-

Spray painting and UV coating for matte/gloss finishes

-

Automated labeling for high-volume consistency

filling and assembly services

-

Soft-tip flocked wands (standard)

-

Slanted-tip applicators

-

Custom-shaped tips for viscous or gel-based cosmetic product types

-

Branded wand tips for

The twist cap adds both ergonomic and branding advantages:

-

Increases grip for better consumer usability

-

Supports anti-slip functionality without additional coatings

-

Readily accepts custom molded textures or logos

-

Matches well with various decoration techniques