6 Key Features to Look for When Buying Lip Balm Tubes

Finding the right lip balm tube isn’t just about tossing something cute in a cart—it’s about smart decisions that affect your entire brand. In 7 Key Features to Look for When Buying Lip Balm Tubes, we’ll walk you through the stuff that really matters: from leak-proof caps to eco-friendly materials that won’t trash your margins—or the planet.

There’s a reason pros say, “Great packaging doesn’t just hold your product—it sells it.” If you’ve ever dealt with tubes that cracked in transit or refused to seal right, you know the pain. One tiny flaw can turn into a batch of customer complaints or wasted product.

This guide cuts through the noise. Quick, clear, and made for folks who buy in bulk and build things that last. Let’s make sure your next order isn’t just big—it’s bulletproof.

What Materials Make the Best Lip Balm Tubes?

Choosing the right tube material is step one for a winning lip balm product. Here’s a breakdown of three top options used across the industry.

🧴 Plastic Tube Types and Their Uses

Plastic tubes remain a go-to for many businesses.

- PVC shades are low-cost and flexible, good for standard balm.

- Acrylic shades offer better clarity and aesthetics.

- Durability? Top-tier. These bad boys resist cracks and handle transit like champs.

- Cleaning methods include gentle wiping or anti-static spray for production-line dust.

Whether you’re looking at plastic lamp shades or lip balm tubes, the same rule applies—choose your plastic based on strength vs. presentation.

♻️ Paperboard Tubes for Eco-conscious Brands

Paperboard tubes scream “sustainable” and are ideal for brands chasing eco goals. They’re made from recycled paper shades and eco-friendly materials, and often attract attention from minimalist and green-conscious customers.

Just handle them right:

- Use a feather duster or vacuum brush for display cleaning

- Avoid exposure to moisture damage or rough storage

Paperboard works best when you want delicate surfaces that show off branding with a natural vibe.

🧑🎨 Aluminum Tubes: Premium Look, Higher Cost

These sleek Aluminum Tubes give you metallic shades with a modern design—think high-end lip balm lines.

- Clean regularly with a microfiber cloth

- Avoid harsh chemicals; use mild polishing agents

- Excellent scratch resistance, but pricier than paper or plastic

According to packaging consultant Erin Bailey:

“Aluminum gives that premium lighting finish and tactile weight consumers associate with luxury.”

If you’re packaging balm that sells on appearance and feel, aluminum is where it’s at.

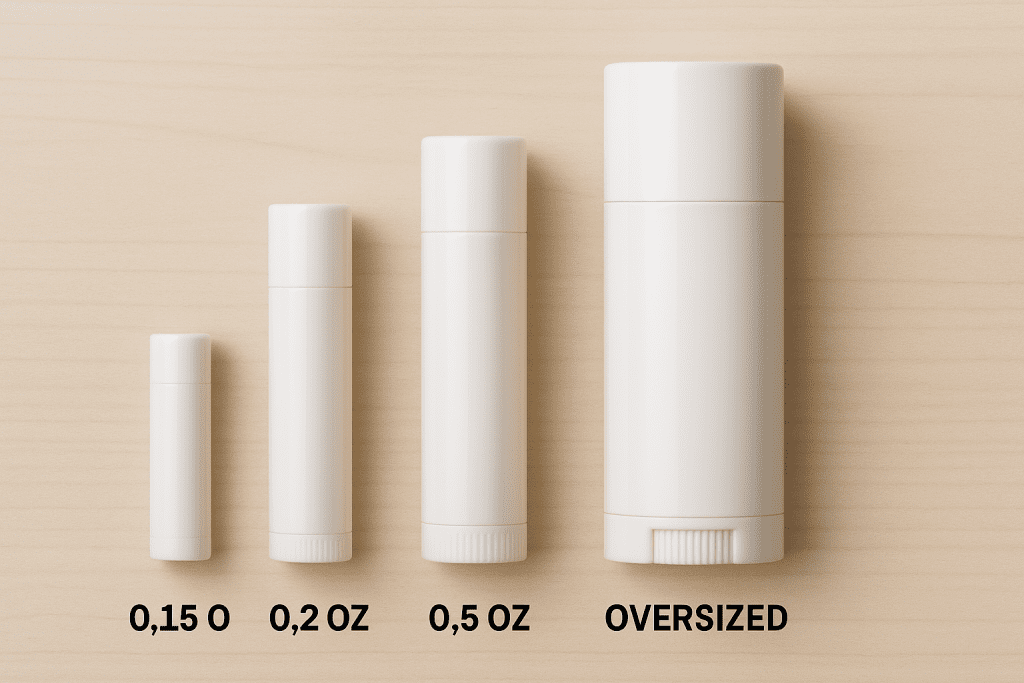

Pick the Proper Tube Size

Choosing the right tube size for lip balm might seem simple—but it’s one of the most strategic packaging decisions for cosmetic brands with large production runs.

Standard Fill Volumes by Market Type

Different market segments demand different tube volumes.

- Consumer goods sold in grocery or convenience stores often use 0.15 oz (4.25g) tubes due to industry-standard compatibility.

- Premium brands or niche skincare lines might use 0.2 oz to stand out.

- Bulk packaging for spas or refillable kits may go up to 0.5 oz.

Each fill volume affects liquid measurement accuracy, packaging cost, and compliance with packaging standards or industry regulations.

Quick Tip: Always match the product’s capacity to its market function.

When to Use Oversized Lip Balm Tubes

Oversized tubes can be a vibe if you know when to use them.

- Niche branding: Big tubes feel premium and communicate richness or “value pack” quality.

- Product marketing: Limited editions or balm sticks with SPF/sunscreen often come larger for better applicator coverage.

- Consumer preference: Some buyers just like a chunky stick—it feels more substantial.

As one packaging consultant put it:

“Bigger tubes aren’t just about more balm—they’re about a louder brand voice.”

In the cosmetic industry, tube size isn’t just function—it’s part of your brand strategy using custom cosmetic packaging.

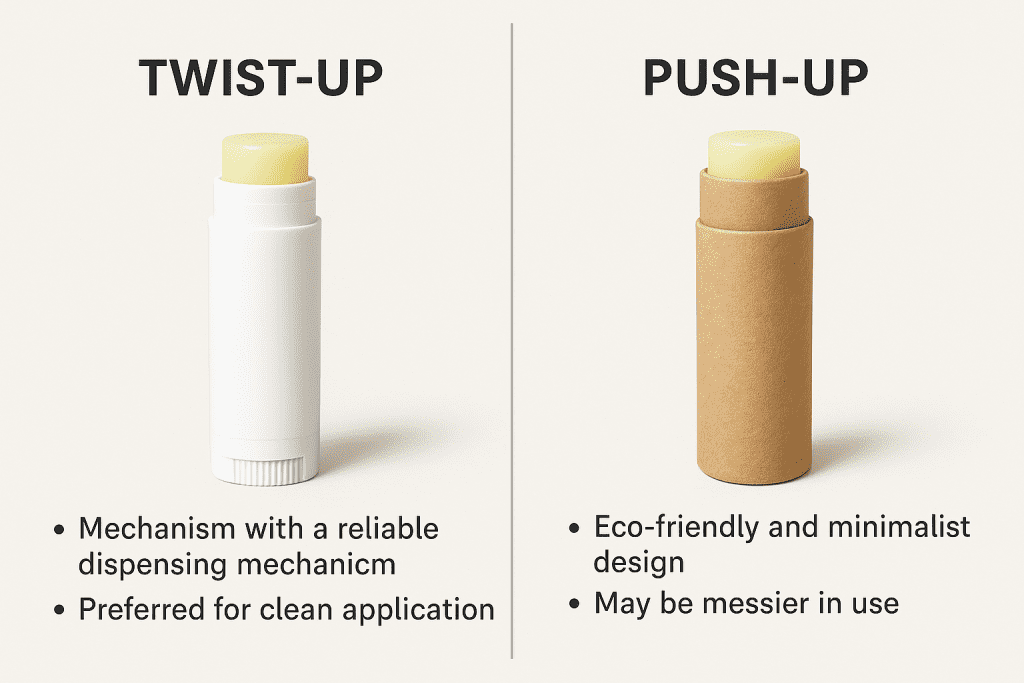

Twist-Up or Push-Up: Which One’s Better?

Choosing between twist-up and push-up lip balm tubes isn’t just about looks—it’s about functionality, brand message, and production fit. Here’s how to decide.

🧱 Mechanism Reliability for Bulk Usage

In large-scale operations, a reliable dispensing mechanism directly affects production efficiency and quality assurance.

- Twist-up tubes often offer better mechanical durability, with a proven track record in bulk processing environments.

- Push-ups, though simpler, may result in slight variance during automated filling, especially at high speed. When you’re talking industrial scale, always favor tested systems with strong operational uptime.

🌍 Consumer Preferences by Region or Demographic

People don’t all like the same thing—and market segmentation proves it.

- In eco-conscious markets like Scandinavia, push-up designs dominate for their perceived natural vibe.

- In urban centers and North America, twist-ups win due to user feedback favoring ease of use and clean application.

- Gen Z? They’re split—they want aesthetics, but also care about cultural influences and brand stance.

“Consumers don’t just buy balm; they buy into identity,” says packaging analyst Lila Herrera of BeautyBox Insights.

🌱 Push-Up Tubes for Eco-Minded Products

Push-up tubes are like the granola of the cosmetic packaging world—minimalist, earth-loving, and quietly effective. They’re ideal when your brand champions biodegradable materials, zero-waste solutions, or natural product formulation. Yes, they might get messy in a pocket. But for brands that care about sustainable cosmetic packaging, it’s worth the sacrifice. You’re telling your customer: we care about more than just shine.

💄 Twist-Ups and Compatibility with Lip Gloss

Twist-up mechanisms are a go-to for lip gloss formulation because they maintain precise control over product dispensing.

- Material science in twist-ups allows smooth handling of both balms and glosses.

- The cosmetic packaging industry favors them for their universal appeal across balm, gloss, and even concealers. Packaging design compatibility = fewer surprises on the production line and higher consumer satisfaction at first twist.

| Formulation Type | Best Fit Mechanism | Packaging Notes |

|---|---|---|

| Waxy Balm | Push-Up | Eco-oriented, simple fill |

| Creamy Lip Gloss | Twist-Up | Precision needed, stable |

| Tinted Moisturizer | Twist-Up | Even application is key |

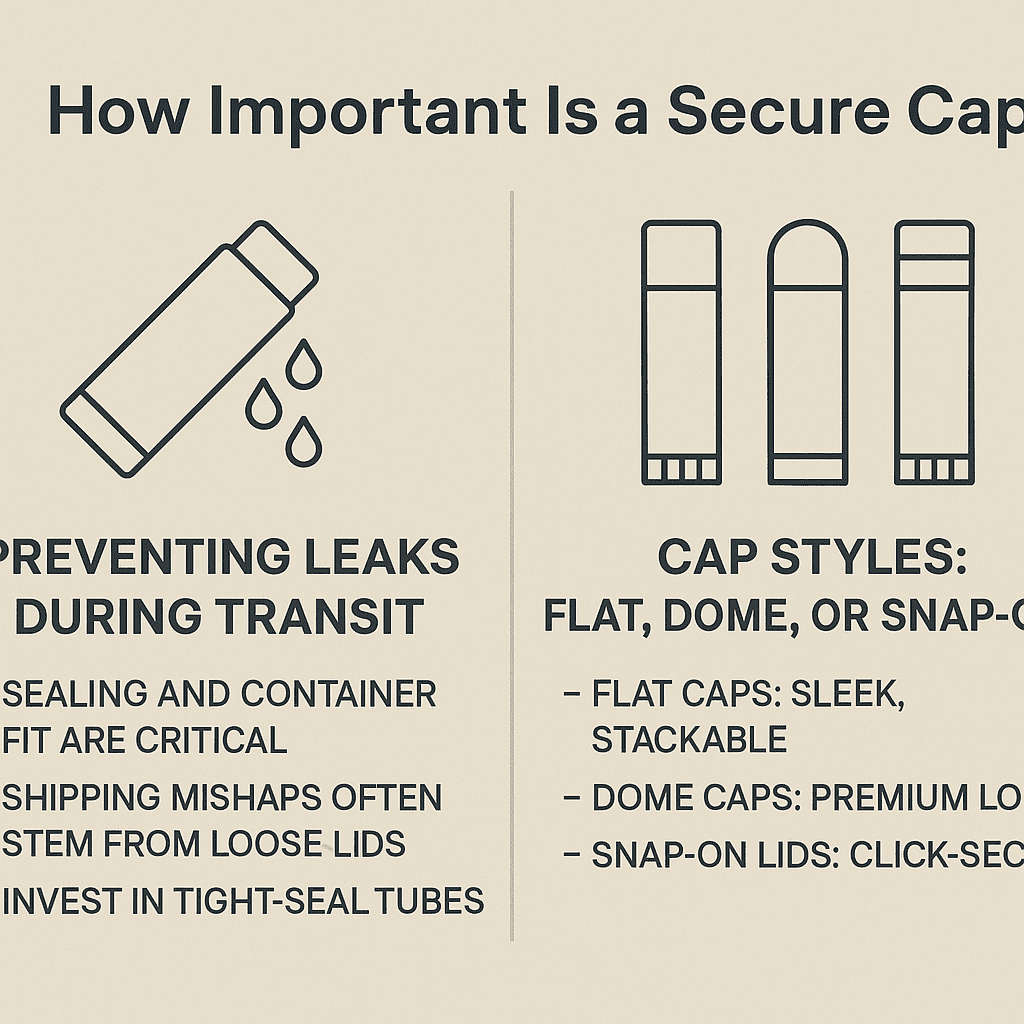

How Important Is a Secure Cap Fit?

A secure cap is not just about looks—it’s your first defense against mess, waste, and customer complaints. Here’s what buyers must know.

Preventing Leaks During Transit

Nobody wants oily balm goo ruining an entire shipment. That’s why sealing and container fit are critical. Choose packaging that’s been drop-tested and pressure-sealed to avoid leakage during transport.

- Shipping mishaps often stem from loose lids or warped tubes.

- Invest in tight-seal tubes compatible with your product’s viscosity.

- Reinforce handling safety with shrink bands or box liners for extra leak insurance.

Pro tip: Look for vendors that provide transit-proof testing data before bulk purchase.

Cap Styles: Flat, Dome, or Snap-On

Caps aren’t just decorative—they affect usability and protection. Let’s break it down:

| Cap Style | User Appeal | Protection Rating |

|---|---|---|

| Flat | Sleek, stackable | Moderate |

| Dome | Premium look | High |

| Snap-On | Click-secure | Very High |

- Flat caps work best for compact packaging and automated label application.

- Dome caps look luxe but may not be travel-friendly.

- Snap-on lids offer better closure integrity during heat changes.

Safety Seals and Tamper-Evidence Considerations

Tamper-evident seals are your security badge—especially in retail. From foil liners to shrink-wrap bands, each plays a role in maintaining packaging integrity.

- Foil safety seals prevent product tampering while preserving freshness.

- Perforated shrink bands offer a visual tamper indicator and boost shelf trust.

- Pre-sealed caps can streamline production and pass basic FDA packaging standards.

“Customers trust what they can see. If your balm looks secure, your brand looks reliable.” — Tasha Nguyen, Packaging QA Director, BeWell Naturals

Choose safety seals that fit your tube style and machine process. Don’t sacrifice protection for looks.

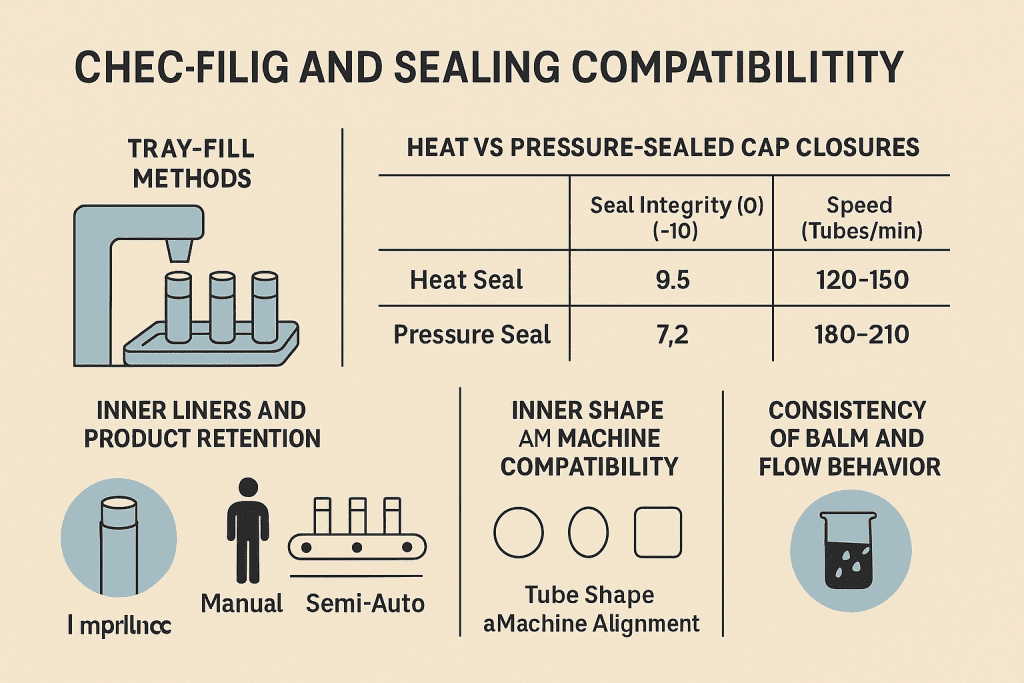

Check Filling and Sealing Compatibility

Choosing lip balm tubes means thinking beyond looks—your filling method and closure style must fit your production setup like a glove.

✅ Tray-Fill Methods for Standard Tubes

Tray filling is still the go-to method for small-to-mid batch lip balm runs. Standard tubes are placed in product trays and filled using heated liquid balm poured from overhead or nozzle-fitted filling machines. It’s fast, scalable, and reliable—especially when automated. Pro tip: use rigid trays to avoid tube tilt during the process.

🔥 Heat vs Pressure-Sealed Cap Closures

Heat sealing uses thermal bonding to secure caps, ideal for high-viscosity balm and long shelf life. Pressure sealing, on the other hand, is quicker but might not deliver the same airtight seal.

| Sealing Type | Seal Integrity (0–10) | Speed (Tubes/min) |

|---|---|---|

| Heat Seal | 9.5 | 120–150 |

| Pressure Seal | 7.2 | 180–210 |

⚙️ Manual vs Automatic Line Compatibility

- Manual Operation: Great for startups—cheaper, more control, but slow.

- Semi-Automated Lines: A hybrid solution for growing operations.

- Fully Automated Systems: Best for high-volume runs; boosts production efficiency and consistency. Whatever the line, always match tube specs with machine compatibility to avoid misalignments and wasted balm.

🧴 Inner Liners and Product Retention

Inner liners aren’t just a luxury—they’re crucial for maintaining balm integrity and reducing leaks. You’ll find materials like foil or plastic laminate that act as barriers against heat, oxygen, or oil migration. Liners help retain product over time, especially for oil-heavy or soft formulas. Skipping liners? Prepare for mess and customer complaints.

🧠 Tube Shape and Machine Alignment

Tube design directly impacts machine alignment during production. Oval, square, or uniquely contoured tubes may require custom jigs or adjusted machine calibration. If your line isn’t ready to handle non-standard dimensions, expect jams or bad fills. Always confirm shape specs before bulk purchasing new packaging types.

🧊 Consistency of Balm and Flow Behavior

Let’s get real—thick, waxy balm isn’t flowing anywhere fast. Your balm’s viscosity and flow behavior (aka how goopy or liquid it is when heated) affect the fill rate, precision, and machine settings. High-viscosity blends may require elevated temps and slower fill speeds. Don’t ignore rheology—it’s the science behind smooth production.

“People forget balm viscosity until it clogs a nozzle or floods a tray,” says Monica Liu, packaging engineer at CosmiPack Systems.

Labeling Space, Branding Impact

A lip balm tube isn’t just packaging—it’s a portable billboard. When done right, it shouts your brand louder than any shelf-talker.

Though this cluster doesn’t include subtopics, its depth is significant. Buyers with high-volume needs must consider how tube size, label area, and custom printing impact logo visibility, product information, and shelf appeal.

Small tubes limit marketing space, so your brand messaging must be sharp and minimal. Round tubes challenge layout alignment, making packaging design and tube aesthetics critical to achieving brand consistency.

As one packaging consultant puts it:

“If your logo fades into the twist cap, your customer’s attention fades with it.”

Choose wisely—or your label might do more hiding than selling.

Conclusion

Picking lip balm tubes isn’t just a box to check—it’s like choosing the tires for your car. Get it wrong, and the ride’s bumpy. Get it right, and everything runs smoother—from filling lines to customer smiles.

A smart tube choice can cut waste, prevent leaks, and make your brand stand out like Beyoncé at a backyard BBQ. As packaging expert Lisa M. often says, “Form follows function—but great design follows both.”

So don’t wing it. Go with options that match your scale, your values, and your vibe. Your future self (and your production team) will thank you.

FAQs

firm formulations

The tube itself won’t expire in the traditional sense, but:

-

Plastic tubes may discolor or become brittle after long UV exposure.

-

Paperboard tubes can soften if stored in humid conditions.

-

Shelf life is typically 2–3 years when stored cool and dry.

Biodegradable paperboard is the top pick, especially FSC-certified tubes. But recycled plastic (PCR) or sugarcane-based bioplastic are gaining ground too. Just be sure your balm’s consistency matches the material’s limits.

-

Consistent fill height

-

Leak resistance during heat fill

-

Clean seal compatibility

-

It depends on your use case. Here’s a breakdown:

-

Snap-on caps – easy, fast, economical

-

Screw-on caps – more secure, premium feel

-

Dome-top caps – great for gift sets or luxe brands

-

Tamper-evident caps – recommended for retail compliance