Talk to Our Product Experts Today!

2026 Trends Shaping the Future of Cosmetic Components Packaging Design

2026.01.28From eco-smart glam to TikTok-ready flair, Cosmetic Components Packaging is now the showstopper buyers crave in bulk....

How Does Color Changing Plastic for Cosmetic Packaging Work?

2026.01.28Beauty that flirts back—our color changing packaging turns heads, sparks sales, and makes bulk makeup buys feel downright irresistible....

How to Design Makeup Packaging

2026.01.28From flirt to function, this guide on how to design makeup packaging shows why smart, seductive design sells big in bulk beauty orders....

What is a Custom Eyeshadow Palette Packaging Design?

2026.01.28Turn heads (and sales) with custom eyeshadow palette packaging design that seduces buyers before the first swatch—bulk orders welcome....

Why the ISCC Certification Process Matters

2026.01.28Fake “green” claims won’t cut it—prove your eco game with the ISCC certification process and turn packaging for cosmetics compliance into brand bragging rights....

EYE MAKEUP PACKAGING

Topfeel offers a wide range of customizable eye makeup packaging, engineered for performance, aesthetics, and sealing precision. From mascara tubes to eyeshadow palettes, every component is developed with deep expertise in formula compatibility, applicator systems, and surface decoration.

-

Personalized Massage Tip Eye Serum Tube Partners

-

TU83 Custom Eye Cream Tube with Silicone Massage Tip

-

MC-19 ODM Dual Ended Brow Setting Gel Tube Solution

-

MC-16 12 Pan Pressed Powder Compact OEM Partner

-

MC-15 14g Large Capacity Lash Primer Container Private Label

-

MC-13 Custom 8ml PET Mascara Tube Wholesale Supplier

-

MB-63 Wholesale Highlighter and Blush Palette Packaging Vendor

-

TU80 Wholesale Soft Tube for Lip Care

-

MC-09 Wholesale Mascara Tube with Straight or Curved Applicator

-

MC-07 Custom 9-Pan Eyeshadow Palette for Private Label Brands

-

MC-10 PETG Brow Tint Tube with Precision Brush

-

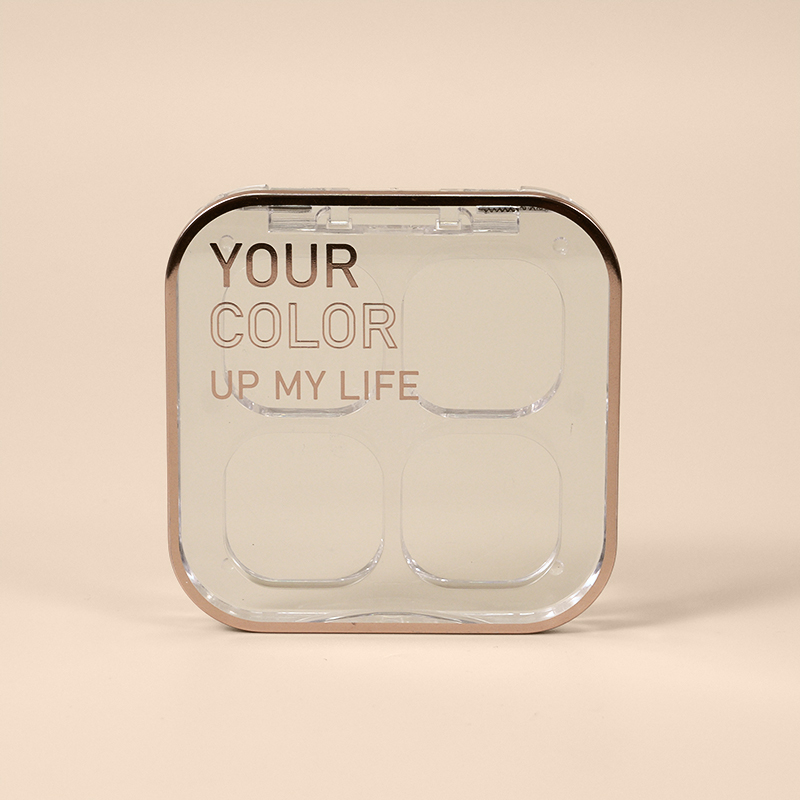

MC-01 Four-color Eyeshadow Powder Compact Cosmetic Packaging Manufacturer

We possess the following advantages:

-

Certifications: ISO 9001, ISO 22716 (GMPc), BSCI, and Sedex-audited factory.

-

Advanced Technology: Over 277 patents in cosmetic packaging design.

-

OEM/ODM Capabilities: Custom tooling, applicator matching, wiper calibration, and unique design finishes.

-

Material Variety: PETG, PCTG, PP, ABS, Acrylic, Glass, Cardboard.

-

Finishes Available: Glossy coating, matte surface, soft touch.

-

Sustainability Options: PCR materials, mono-material, refillable option, and removable components where technically feasible.

-

Reliable QA: Torque, seal integrity, leak simulation, abrasion resistance, and thermal testing.

Quick Selection Tips

Quickly find the product you need based on the following information:

| Formula Type | Recommended Packaging | Key Considerations |

|---|---|---|

| Mascara | Mascara Tube | Choose brush type (fiber/silicone), wiper durometer, neck size, sealing strength |

| Eyeliner (liquid) | Eyeliner Pen or Tube | Flow control, felt/brush tip, alcohol-based compatibility, airtight cap |

| Brow Gel | Mascara or Custom Oval Tube | Applicator type, secure lid, product viscosity, brush retention |

| Lash Serum | Eyelash Tube or Cylindrical Bottle | Clear window optional, flocked tip, light-sensitive protection |

| Eye Primer | Airless Pump or Glass Bottle | Dosing precision, formula stability, frosted glass or opaque finish |

| Pressed Eyeshadow | Eyeshadow Palette (Magnetic or Pan) | Pan size, mirror inclusion, refillable design, magnetic closure |

Eye Makeup Packaging Solutions

Explore our sub-series of packaging solutions:

-

Oval or cylindrical design with wiper customization. Soft touch or frosted glass finishes available.

-

Slimline round case or rectangular box with felt or brush tip; cap engineered for airtight performance.

-

Glass bottle or PETG container with secure lid; ideal for serums or lash oils.

-

Multi-pan eyeshadow palette in square, round, or rectangular shapes. Includes options for a built-in mirror and magnetic closure.

Materials & Design Options

We support a wide range of structural and decorative materials to ensure optimal compatibility with sensitive eye formulas:

-

Material Types: PETG, acrylic case, aluminum tube, glass bottle, plastic compact, cardboard box, paperboard sleeve

-

Shapes: oval tube, round case, square palette, rectangular box, compact design

-

Finishes: frosted glass, smooth finish, matte surface, glossy coating, textured grip

-

Colors: black container, clear window, rose gold, gold accents, silver details, colorful design

All materials undergo migration and leak testing to ensure formulation compatibility and product integrity.

Quality Assurance

We can conduct quality testing tailored to your target market:

-

Leakage tests: High/low temperature and pressure simulation

-

Applicator life testing: Brush and felt tip durability

-

Cap torque and closure seal strength

-

UV and print durability tests for glossy/matte coatings

-

Abrasion test for soft touch and frosted finishes

Get a Quote or Request a Sample

If you’re interested in our products, please note:

-

MOQ starts from 10,000 pcs

-

Lead time: 7–10 days for sample, 25–35 days for production

-

Incoterms: FOB, CIF, DDP (on your request)

-

Structured RFQ form: choose capacity, shape, material, finish, artwork upload, delivery timeline

FAQs

Yes, we support multiple applicator styles (fiber/silicone) and fine-tuned wiper hardness based on your formula’s viscosity.

Yes, we offer magnetic closure palettes and pan-based refills, available in square palette and round case formats.

Yes, we offer solvent-resistant materials like PP and airtight caps designed for long-wear formulas.

Absolutely. You can choose a clear window for visibility or frosted glass or tinted acrylic for light-sensitive formulas.

Yes, we offer palettes with built-in mirror and space for brush or applicator included.

Yes, our mono-material designs help streamline end-of-life recycling, especially in PCR plastic compact builds.

Glossy coating, soft touch, matte surface, textured grip, and hot stamping are available depending on the material.