Escolha do tubo de batom: O melhor guia para 2025

No jogo de beleza de hoje, o tubo de batom é mais do que uma concha bonita — é o fator silencioso que fecha (ou desfaz) negócios para a sua marca. Para quem compra em grandes quantidades, escolher o tubo certo é como escolher o terno certo para um tapete vermelho — ele precisa ter um caimento perfeito, ser confortável e chamar a atenção. Mas com tantos materiais, tamanhos e estilos disponíveis, tomar a decisão errada pode significar dinheiro jogado fora e um produto que simplesmente não funciona.

Pense nisso como um namoro—plástico é o confiável, metal é o luxo que impressiona, e papel? Essa é sua parceira ecológica fazendo todos os títulos certos. “Embalagem é o aperto de mão da marca,” diz a especialista do setor Lisa Graham, “e você não tem uma segunda chance de fazer uma boa primeira impressão.”

Por que a escolha do batom é importante em 2025

Em 2025, as opções de batom em tubo serão mais do que meras opções cosméticas: serão movimentos comerciais estratégicos.

De identidade da marca para Embalagens de cosméticos sustentáveis, o tubo de batom tornou-se uma parte essencial do manual de desenvolvimento de produtos. Espera-se agora que os compradores em massa considerem não apenas a aparência, mas também a funcionalidade, os padrões regulatórios e preferências do consumidor.

✔ Um tubo de metal elegante pode transmitir luxo, mas não oferece design ecológico.

✔ Uma solução em papel pode verificar a caixa verde, mas levanta questões sobre integridade do produto e durabilidade.

✔ Plástico? Acessível e personalizável - mas e quanto inovação material e preparação para o futuro contra mudanças tendências de mercado?

Tubos de batom de plástico vs. metal vs. papel

Entender as principais diferenças nos materiais dos tubos de batom ajuda a otimizar decisões de aquisição em larga escala e a se alinhar às metas de marca, sustentabilidade e logística.

Diferenças de durabilidade nos materiais do tubo do batom

Os tubos de batom passam por muita coisa: calor, pressão, bolsas.

- Longevidade do plástico vantagens para o uso diário: ele lida com o desgaste como um campeão.

- Robustez do metal oferece uma sensação sólida e inquebrável, ideal para lançamentos de luxo.

- Tubos de papel? Ótimo para vibrações ecológicas, mas não espere resiliência do pergaminho sob forte atrito ou água. A resistência da seda pode ser poética, mas em testes reais, o plástico ganha em durabilidade, a menos que você precise fragilidade do vidro efeito para estética.

Qual material de tubo é adequado para marcas de luxo?

Se você está perseguindo isso design de ponta, materiais premium não são negociáveis.

- Plásticos com aparência de cristal traga glamour sem o custo de real vidro.

- Tubos de latão e metal gritam glamour old-school com seu peso e acabamento.

- Revestimentos de toque aveludado sobre imitação de plástico estética de luxo sem altas taxas de frete. Como diz um consultor de embalagens:

Considerações sobre peso, envio e armazenamento

A logística não mente. Ao fazer pedidos em grandes quantidades, até mesmo os gramas importam. Aqui vai uma referência rápida:

| Tipo de tubo | Peso médio da sombra (g) | Volume de armazenamento (cm³) |

|---|---|---|

| Plástico | 12.2 | 8.4 |

| Metal | 19.7 | 9.1 |

| Papel | 10.1 | 7.6 |

- Mais peso = mais alto custos de frete.

- Risco de quebra para materiais frágeis como vidro acrescenta despesas de seguro.

- Pense no futuro: volume de armazenamento afeta a eficiência dos paletes e o empilhamento do armazém.

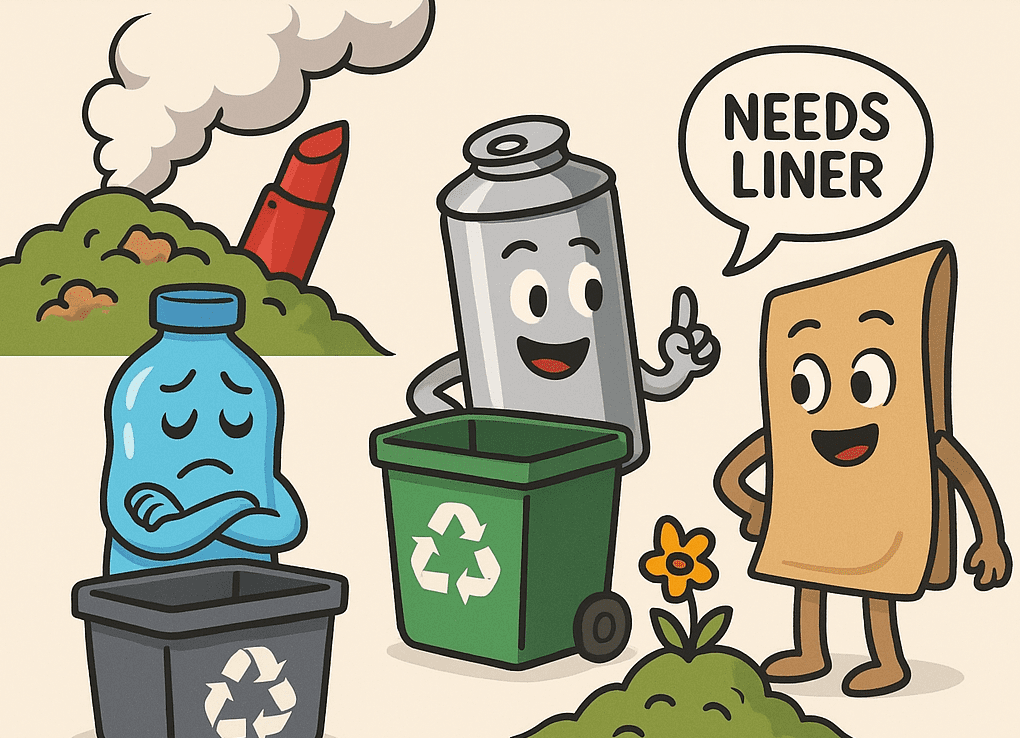

Impacto do material na reciclabilidade e descarte

Vamos ser realistas—aterros sanitários estão cheios, e seu Embalagens para Cosméticos a escolha importa.

- Plástico oferece durabilidade, mas camadas misturadas prejudicam reciclabilidade do material.

- Tubos de metal são frequentemente totalmente recicláveis—especialmente alumínio.

- Opções biodegradáveis como papel brilha com ecologicamente correto apelo, mas precisa de revestimentos para evitar infiltração de cera.

A sustentabilidade não é apenas uma questão de imagem; é uma questão de inteligência avaliação do ciclo de vidaPara marcas que estão crescendo rapidamente, essa é uma mensagem com a qual os clientes se importam — e que as regulamentações em breve exigirão.

O que torna os tubos de batom de papel ecológicos?

Descubra como os tubos de papel para batom estão mudando o cenário das marcas de beleza focadas em sustentabilidade.

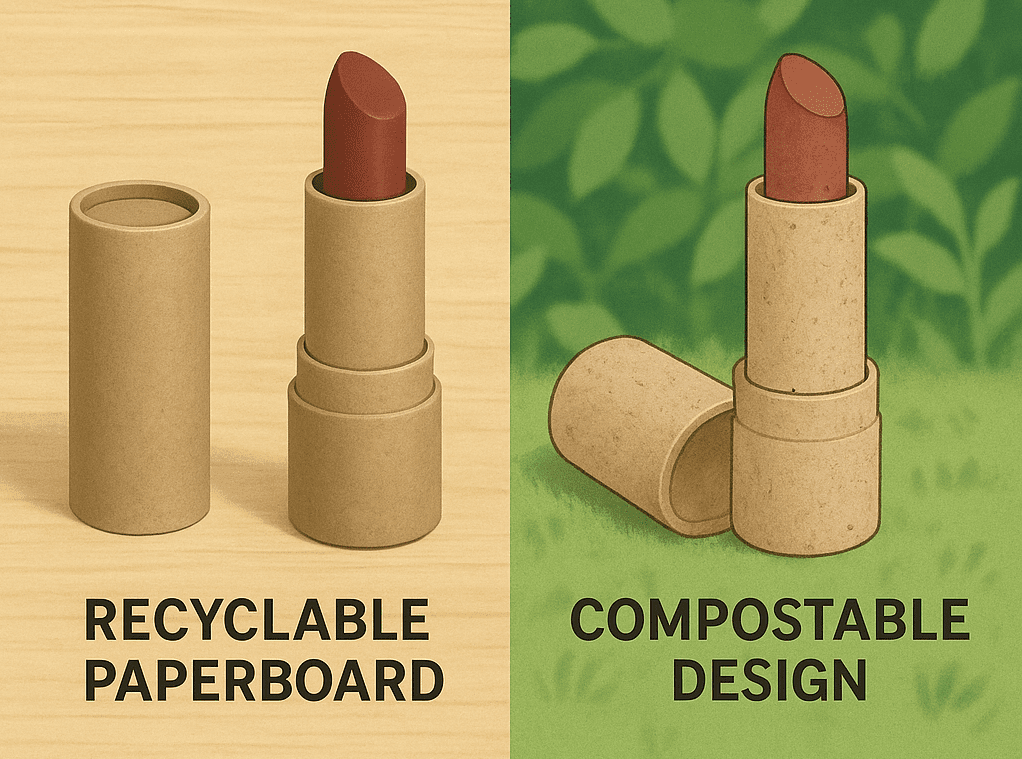

Papelão reciclável vs. designs compostáveis

Nem todos os tubos ecológicos são iguais. Papelão reciclável é ótimo para uso circular—basta jogá-lo na lixeira azul. Mas designs compostáveis? Eles se biodegradam como cascas de banana, sem culpa de aterro sanitário!

- Papelão é projetado por meio da ciência dos materiais para resistir à umidade e ao mesmo tempo permanecer reciclável.

- Embalagens compostáveis, geralmente feito de polpa vegetal, se decompõe em 90 a 180 dias em composteiras industriais.

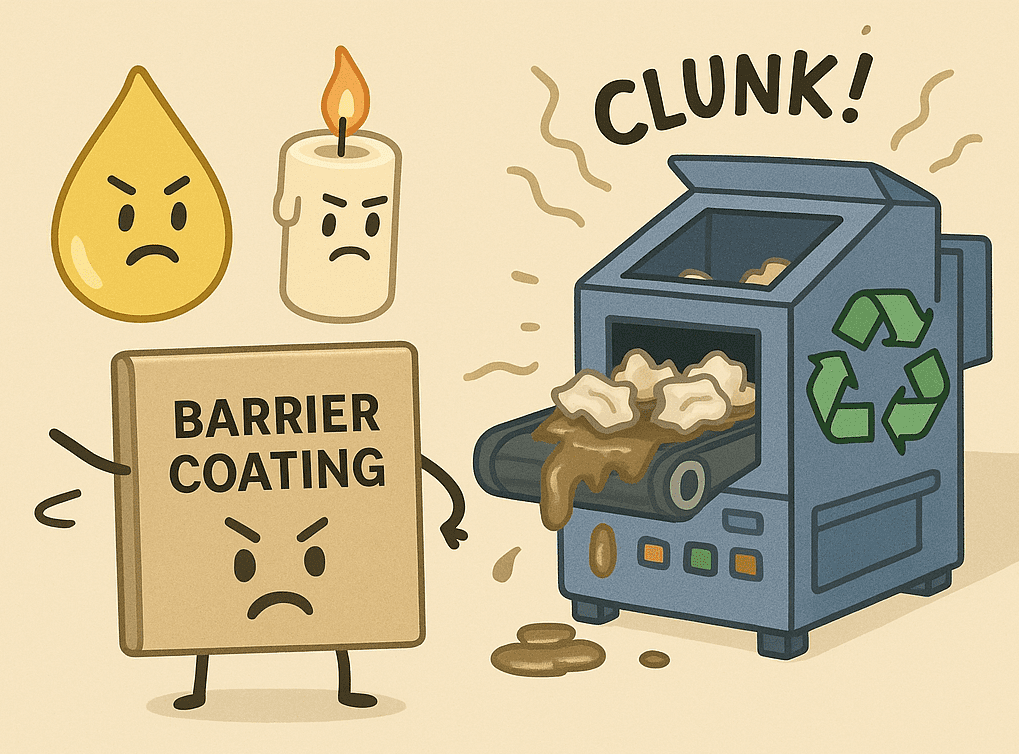

Desafios com revestimentos de barreira de óleo e cera

- Blues da camada de barreira: Revestimentos de óleo e cera podem bloquear a gordura, mas prejudicam a reciclabilidade.

- Situação complicada: Os revestimentos de cera degradam-se de forma irregular, tornando remoção de manchas e tratamento de superfície uma dor de cabeça.

- Por que se importar? Porque quando esse revestimento resiste à degradação, ele obstrui as máquinas de triagem em usinas de reciclagem.

“Precisamos de tratamentos de superfície mais inteligentes que protejam sem poluir”, diz Leah Chan, Diretora de Materiais Sustentáveis do EcoPack Research Lab.

Em suma, revestimentos de barreira são uma bênção para vazamentos, mas uma maldição para as metas de sustentabilidade. Equilíbrio é tudo.

Tubos de batom de metal para uma sensação premium

Tubos de batom de metal esbanjam qualidade premium. Este conjunto explica como eles elevam as linhas de produtos para compradores focados em luxo.

Marca Premium com Acabamentos em Alumínio

O alumínio é o VIP de materiais para tubos de batom. De tons champanhe anodizados a pretos metálicos escovados, ele irradia aquela vibração sofisticada que os clientes adoram.

- Embalagem de luxo = maior valor percebido.

- Acabamentos escovados parecem caros — e são!

- O alumínio melhora o seu acabamento identidade da marca imediatamente.

“Os consumidores associam acabamentos metálicos à confiança e qualidade” - Jules Rivera, Analista de Tendências de Embalagens

Resistência a riscos e apelo de longo prazo

Os tubos de metal são feitos para durar. Seus durabilidade não se trata apenas de força, mas de permanecer fabuloso.

- Revestimentos protetores mantêm a estética renovada.

- Materiais resistentes ao desgaste garantem longevidade em armazenamento ou transporte.

- Sua embalagem parece tão boa no 90º dia quanto no primeiro.

Dica profissional: opte por variantes com revestimento em pó se a resiliência em longas distâncias for essencial.

Opções personalizadas de revestimento e estampagem

Quer se destacar? Galvanoplastia personalizada e tratamento de superfície adicionam aquele impulso extra.

- Ir sob medida com dourado, ouro rosa ou metálicos degradê.

- Grave seu logotipo ou grave uma textura - visual singularidade promove a fidelidade à marca.

- Adicione gravuras decorativas para uma experiência tátil e inesquecível.

Galvanoplastia não é apenas chamativo — ele comunica atenção aos detalhes.

Pesando o custo dos tubos de metal

Claro, o metal é elegante, mas qual o dano para sua carteira?

Fechos Magnéticos e Mecânica de Alta Qualidade

Os compradores de luxo esperam mais do que a aparência - eles querem funcionalidade.

- Precisão engenharia garante torções perfeitas.

- Fechos magnéticos sinta-se suave, silenciosa e segura, como uma porta de carro de luxo.

- Os compradores adoram o som de “clique” - ele sinaliza sofisticação e segurança do produto.

Tubes magnetizados não são apenas inovadores—são viciantes de usar. Para elevar sua linha de produtos, considere um tubo de batom personalizado com esses recursos.

Tubos de batom de plástico: acessíveis e prontos para serem personalizados

Os tubos de batom de plástico oferecem flexibilidade incomparável em preço, velocidade de produção e acabamento — perfeitos para marcas de grande porte que buscam crescer sem sacrificar a qualidade.

Benefícios da moldagem por injeção e produção em volume

Benefícios da moldagem por injeção e produção em volume

Moldagem por injeção é o padrão para produção em massa—é como um truque de mágica de uma fábrica.

- Consistência do material e controle de qualidade rigoroso significa menos unidades defeituosas.

- Além disso, uma vez definido o design das ferramentas, você estará produzindo milhares de dólares em pouco tempo.

- Grande bônus? Principal redução de custos com escala.

“A moldagem por injeção permite resultados precisos e repetíveis em grandes volumes, tornando-a ideal para embalagens de cosméticos”, diz Sandra Leong, engenheiro sênior na PackForm Labs.

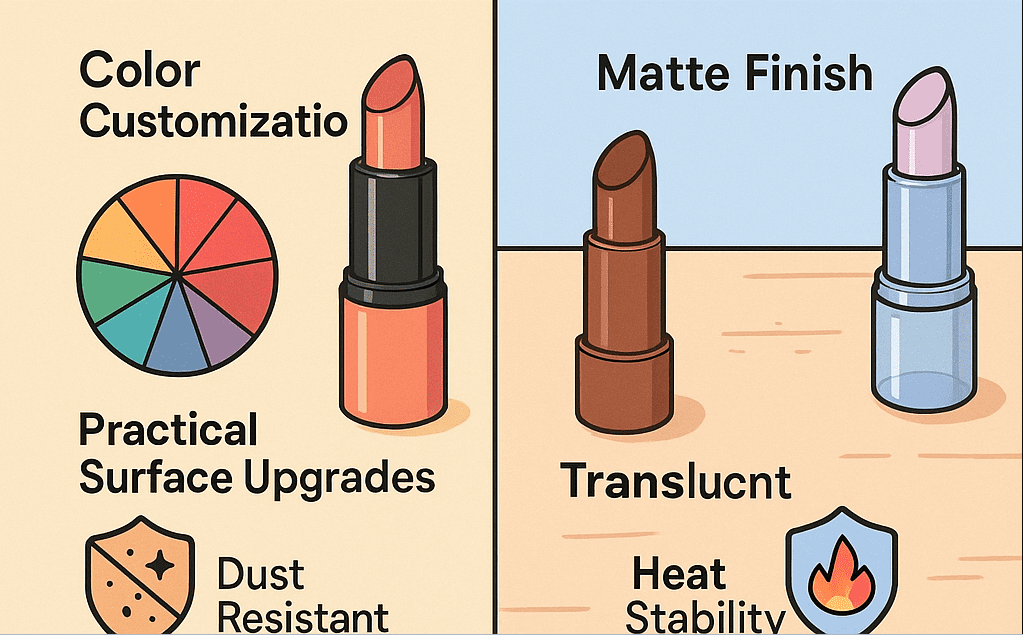

Opções de personalização de cores e acabamento de superfície

- Combinação de cores e identidade da marca As marcas podem alcançar a perfeição combinação de cores em todas as linhas de produtos, criando uma consistência que os clientes lembram.

- Versatilidade Textural De revestimentos foscos suaves a revestimentos UV de alto brilho, você pode criar qualquer ambiente.

- Atualizações práticas de superfície A acabamento resistente à poeira ou material translúcido? Totalmente factível.

| Tipo de superfície | Nível de brilho | Proteção UV |

|---|---|---|

| Acabamento brilhante | 85%+ | Opcional |

| Acabamento fosco | 10–30% | Sim |

| ABS translúcido | 60–75% | Limitado |

Tolerância ao calor e compatibilidade de fórmulas

Algumas fórmulas de batom esquentam — literalmente. Então, é melhor que o seu tubo suporte o calor.

- Estabilidade térmica em polímeros previne degradação do material quando os batons são despejados em altas temperaturas.

- A compatibilidade com os ingredientes garante que não lixiviação química ou empenamento.

- Os plásticos de hoje incluem Estabilidade UV e retardantes de chama para melhorado segurança dos materiais.

Dica profissional: Sempre verifique duas vezes formulação de polímero com seu fabricante ao trabalhar com blends exóticos ou de alto óleo para lábios. Você não quer um desastre com o tubo nas mãos. Certifique-se de escolher um recipiente de batom que passe nesses testes de estabilidade.

Como o tamanho e o formato afetam a embalagem do batom

O tamanho e o formato do tubo de um batom não são apenas uma questão de aparência — eles influenciam diretamente a ergonomia, a marca e a usabilidade.

-

Os designs compactos aumentam a portabilidade

Tubos menores são mais fáceis de guardar em bolsas ou bolsos, o que os torna os favoritos dos consumidores. A portabilidade é um verdadeiro motivador de compra em mercados urbanos de ritmo acelerado.

-

Formas curvas aumentam o apelo das prateleiras Contornos únicos chamam a atenção, seja um cilindro hexagonal ou uma tampa abobadada. Formato criativo = lembrança instantânea da marca.

-

Diâmetros padrão garantem compatibilidade Os moldes para batom geralmente seguem tamanhos de copo universais (12,1 mm, 12,7 mm). Isso garante que as máquinas de envase não emperrem e que a integridade do produto seja mantida.

-

A forma afeta a precisão da aplicação Topos inclinados ou aplicadores giratórios direcionam o batom exatamente onde ele é necessário, o que é essencial para quem busca bordas bem definidas.

-

Citação da indústria “A silhueta de um tubo é tão importante quanto sua fórmula — faz parte do ritual do cliente.” – Lana Cruz, Diretora Criativa da BelleMatte Packaging.

-

A ergonomia melhora a satisfação do usuário Empunhaduras confortáveis reduzem quedas acidentais e escorregamentos durante o uso. Pense: tampas de clique que encaixam firmemente e usabilidade com uma mão. Para mercados de nicho, tubos de protetor labial frequentemente utilizam esses princípios ergonômicos.

Conclusão

Escolher tubos de batom em escala não é apenas sobre aparência—é como escolher os sapatos certos para uma longa jornada. Vá pelo barato, e sentirá isso mais tarde. Vá pelo premium, e envie uma mensagem antes mesmo do produto chegar aos lábios. Para garantir que sua marca se destaque, invista em embalagens cosméticas personalizadas que reflita sua qualidade.

Como diz a especialista em embalagens Jane Smith: "O tubo é o aperto de mão antes da venda". Essa é a sua primeira impressão — não a estrague.

Então, se você está se preparando para os lançamentos de 2025, pense com inteligência: plástico para velocidade, metal para prestígio, papel para propósito. O tubo conversas—certifique-se de que diz a coisa certa.

Perguntas frequentes

A maioria das marcas opta pelo clássico copo interno de 12,1 mm — é o tamanho ideal por um motivo. Acomoda cerca de 4 a 5 gramas de produto e cabe facilmente na bolsa ou no bolso. Mesmo assim, é uma boa ideia verificar o diâmetro ao escolher um molde.

Elas duram mais do que as pessoas imaginam. O segredo é escolher a estrutura certa:

- Papelão grosso com deslizamento suave

- Revestimento interno para resistência à cera e ao óleo

- Base push-up que não emperra

- Tampas compostáveis com fecho seguro

Perfeito para marcas que buscam aquela vibração eco-minimalista.

Ruins? Com certeza. Uma boa embalagem funciona como um sistema de segurança para a fórmula que está dentro. Procure por:

- Sistemas de travamento herméticos

- Materiais que não derretem nem deformam durante o transporte

- Revestimentos para evitar vazamento de óleo

Tranquilidade com um boné e uma torção.

É um playground de design:

- Veludo fosco

- Brilho brilhante

- Toque suave texturizado

- Destaques UV para logotipo pop

Cada acabamento muda a sensação que o produto causa — literal e emocionalmente.

Os recarregáveis estão ganhando força, especialmente entre compradores de alto padrão e consumidores conscientes. O custo inicial é mais alto, mas compensa em termos de fidelidade do cliente e mensagens de reutilização.

Aqui vai um guia rápido:

- Plástico: cerca de 10 a 35 centavos

- Papel: 25 a 50 centavos

- Metal: 60 centavos para $1,50+

Os preços variam dependendo do design, acabamento e volume. Peça sempre orçamentos diferenciados — é aí que os negócios acontecem.

A maioria dos bons fornecedores não hesitará em enviar algumas amostras. Espere:

- 1 a 3 amostras por estilo

- Amostras de cores e texturas

- Frete grátis ou de baixo custo

Não há nada melhor do que segurá-lo em mãos antes de assinar o grande pedido.