Dlaczego biodegradowalne opakowania kosmetyków są przyszłością produktów beauty

The beauty aisle ain’t what it used to be. These days, biodegradable packaging cosmetics aren’t just a nice touch—they’re the secret handshake between brands and buyers who actually give a damn. You’ve got customers scanning QR codes in the serum aisle, asking where your tubka szminki goes after its last swipe. If your product’s still rocking plastic like it’s 2003, you might as well slap on a flip phone and call it vintage.

It’s not about slapping leaves on the label—it’s about showing receipts. Big-name retailers are shifting their priorities fast, chasing packaging made of mushroom fiber or seed paper that literally sprouts wildflowers when tossed in soil. This isn’t fluff; it’s function wrapped in eco-chic design—and buyers are sniffing out partners who can deliver both at scale.

3 Key Benefits of Biodegradable Packaging for Cosmetics

Biodegradable packaging in cosmetics isn’t just a trend—it’s reshaping how beauty brands connect with people and the planet.

Enhancing Brand Image: How Sustainable Materials Attract Eco-Conscious Consumers

- Świadomi ekologicznie konsumenci are actively choosing brands that walk the talk on sustainability.

- Używanie zrównoważone materiały like mushroom leather, bamboo pulp, or seaweed film signals real commitment—not just greenwashing.

- Brands integrating biodegradable packaging cosmetics often see a spike in lojalność wobec marki, especially among Gen Z and millennials.

- Ethical production and etyczne pozyskiwanie practices create a ripple effect—consumers talk, share, and recommend.

- It’s not only about looking good but doing good. Beauty buyers now expect transparency around packaging origins.

- Smart design using plastic-free alternatives helps brands stand out via zróżnicowanie rynku, especially on crowded e-commerce shelves.

- Consistent use of compostable or recyclable materials builds long-term trust through authentic sustainability claims.

Cost Savings with Refillable Systems: A Win for Companies and Earth

Refillable systems don’t just feel good—they make economic sense. And when done right, they cut waste big time.

| Typ opakowania | Initial Investment | Avg. Refill Cost | Redukcja odpadów (%) |

|---|---|---|---|

| Airless Pump Bottles | Wysoki | Niski | 60% |

| Glass Jar Refills | Średni | Średni | 45% |

| Aluminum Cartridges | Wysoki | Niski | 70% |

| Compostable Pods | Niski | Niski | 30% |

- Start by switching high-volume products to refill-friendly formats like airless pumps or aluminum inserts.

- Reduce your carbon footprint by cutting down on single-use plastics—refillables require fewer raw resources over time.

- Customers love the convenience; they’re more likely to stay loyal if refills are easy to access.

Tip: Topfeel has successfully integrated refill systems across its skincare line—reducing both costs and landfill burden while keeping things sleek.

Meet Industry Standards: Importance of Certifications like Biodegradable Products Institute

You can’t fake credibility—especially when it comes to eco-labeling. Certifications from groups like the Biodegradable Products Institute act as your brand’s passport into trusted territory.

✔ Labels such as BPI, OK Compost, or ASTM D6400 prove compliance with strict biodegradability standards.

✔ These certifications help companies avoid greenwashing accusations while aligning with evolving global regulations around sustainable beauty packaging.

According to Mintel’s Global Beauty & Personal Care Trends report, “Consumers increasingly demand proof—not promises—when it comes to environmental claims”.

Getting certified shows you’re serious about meeting industry-wide expectations for zgodność z przepisami, not just chasing buzzwords. It also supports your R&D teams in creating future-ready solutions grounded in real science—not guesswork.

By aligning cosmetic biodegradable packaging strategies with recognized standards, you build consumer confidence while staying ahead of shifting regulatory tides.

How Biodegradable Packaging Cosmetics Reduce Environmental Impact

Biodegradable packaging cosmetics are flipping the script on waste and pollution by making beauty routines smarter, cleaner, and way more planet-friendly.

Mushroom Packaging: The Future of Sustainable Cosmetic Containers

cURL Too many subrequests.

cURL Too many subrequests. puderniczki na podkładcURL Too many subrequests.

cURL Too many subrequests. mikroplastikamicURL Too many subrequests. cURL Too many subrequests. lub cURL Too many subrequests..

cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests. cURL Too many subrequests.cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

- This shift reduces total factory emisji dwutlenku węgla, helping tackle long-term climate change mitigation cele.

- Ethical labor practices often follow suit since these systems require less human strain and hazardous exposure.

- According to clean beauty manufacturing data, factories with low-energy protocols saw operational efficiency increases without sacrificing quality.

- All this plays into better transparency for buyers who want skincare that doesn’t cost the Earth—literally.

Compostable Inks: Water-Based Options That Are Kind to Earth

- Traditional inks used in cosmetic printing often contain petroleum-based solvents—bad news for both air quality and recyclability.

- Water-based compostable inks ditch those chemicals entirely and instead use plant-derived pigments that safely degrade with packaging.

- They’re ideal for printing on cardboard lipstick sleeves or refillable eyeshadow trays made from bamboo or sugarcane pulp.

- These inks don’t interfere with industrial or home composting, meaning no extra sorting is needed before disposal.

- Plus, they support the use of other eco-materials like recycled kraft paper without compromising aesthetics or brand identity.

- The result? A cleaner finish that aligns perfectly with zero-waste goals while keeping everything looking sharp and professional.

- And yes—they’re safe enough that even smudging them won’t release harmful VOCs into your bathroom airspace.

A Closed Loop System: Reducing Waste Through Efficient Processes

Closed-loop production isn’t just smart—it’s essential if we’re serious about reducing beauty industry waste long-term.

| Reusable Inputs | Recyclable Outputs | Waste Reduction Rate (%) | Average Time-to-Reuse Cycle (days) |

|---|---|---|---|

| Aluminum casing | Recycled aluminum sheets | 85% | 30 |

| Słoiki szklane | Crushed cullet glass | 92% | 45 |

| Paperboard boxes | FSC-certified recycled pulp | 78% | 20 |

| Bioplastics scraps | Re-extruded pellets | 66% | 25 |

Short reuse cycles keep materials circulating longer without degrading performance—a win-win for both brands and buyers trying to live sustainably. More companies now design packaging under cradle-to-cradle principles where nothing gets tossed—everything loops back into production again. This not only curbs landfill overflow but makes real strides toward true circularity in beauty supply chains using eco-friendly sourcing methods tied closely with ethical manufacturing values linked directly to reducing overall environmental impact through smarter production models built around zero-waste ideals like this one championed by Topfeel’s latest refill pod system rollout earlier this year.

Challenges in Adopting Biodegradable Packaging for Cosmetics

The road to eco-friendly packaging isn’t as smooth as it looks. Let’s unpack what’s really holding things back behind the scenes.

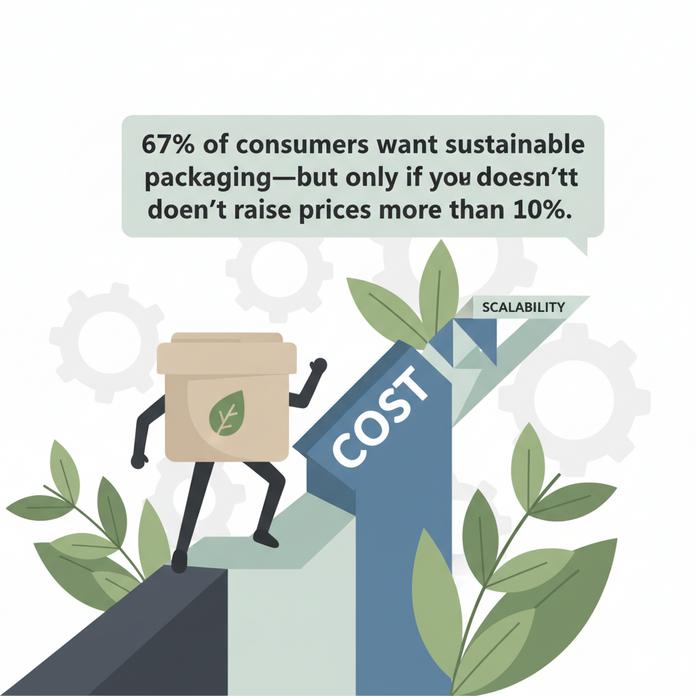

Cost Perspectives: Balancing Sustainability and Affordable Pricing

Eco goals are great, but when your budget’s tight, things get tricky. Here’s how pricing plays tug-of-war with green intentions:

- Production costs of biodegradable packaging cosmetics materials like sugarcane pulp or mushroom leather are still higher than conventional plastic.

- Brands face pressure to maintain slim profit margins while investing in greener solutions—especially indie vegan brands.

- cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests.cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests. cURL Too many subrequests. cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

cURL Too many subrequests.

- cURL Too many subrequests.

- cURL Too many subrequests.

cURL Too many subrequests.

- Poor barrier properties vs. traditional plastics

- Risk of early degradation impacting shelf life

📈 Investment Requirements:

- Need for specialized machinery upgrades

- Training workforce on new handling protocols

Until we see broader innovation across material science and manufacturing infrastructure, scaling biodegradable cosmetics packaging beyond boutique batches remains a serious hurdle.

Najczęściej zadawane pytania

How do biodegradable packaging cosmetics benefit bulk cosmetic buyers?

Sustainable beauty brands and ethical retail outlets gain value beyond sales numbers.

- Appeal strongly to eco-conscious consumers who notice every material choice.

- Bamboo fiber, mushroom packaging, or tektura z recyklingu naturally return to earth with grace.

- Bulk shipments can pair with carbon neutral shipping for a complete green image.

Result: cleaner branding, lighter footprints, happier audiences.

Why does mushroom packaging stand out in sustainable makeup designs?

Mushroom-based blush cases and puderniczki na podkład quietly transform waste into soil again—without leaving toxins behind. Its texture feels organic yet durable; its origin story impresses vegan cosmetic companies seeking tactile elegance that still protects product quality.

What makes refillable systems efficient for large-scale cosmetic packaging?

Refillable palette cases, twist-up applicators, or airless pump bottles save materials through repeated use cycles while maintaining convenience:

| Cecha | Wpływ na koszty | Korzyści dla środowiska |

|---|---|---|

| Refillable Palette Cases | Lower long-term cost | Zmniejszenie odpadów jednorazowych |

| Airless Pump Bottles | Stable dosage control | Supports Plastic-Free Options |

This approach becomes both budget-friendly and brand-aligned for sustainable beauty lines.

Can compostable inks suit lipstick tubes or eyeshadow palettes effectively?

Yes—seaweed-based or plant-fiber surfaces embrace water-based coatings perfectly. The result is vivid color on tubki szminek oraz palety cieni do powiek that leaves behind no harmful trace when the package meets composting soil.

Which certifications prove trustworthiness in wholesale biodegradable packaging cosmetics?

Suppliers aiming higher pursue these marks of integrity:

1️⃣ Forest Stewardship Council – ensures bamboo fiber sourcing respects forests.

2️⃣ Biodegradable Products Institute – verifies real-world breakdown times meet expectations.

3️⃣ Compost Manufacturing Alliance & Zero Waste International Alliance – validate closed loop system commitments and recycling alignment.

How does a closed loop system influence production ethics in sustainable cosmetic supply chains?

A circular rhythm arises here: excess from pojemniki na tusz do rzęs lub dropper style bottles reenters manufacturing streams instead of languishing as landfill relics. Combined with low energy production methods and ethical labor practices under a steady waste reduction program—it’s sustainability made intimate, not industrial.

Odniesienia

- [1] Przyszłość opakowań do urody: Co marki muszą wiedzieć – Mintel

- [2] Globalne trendy w opakowaniach kosmetycznych – Mintel

- [3] Environmental Sustainability – P&G

- [4] The 2024 Beauty Trend Report – Prime Matter Labs

- [5] The changing story of sustainability – NielsenIQ

- [6] Is Refillable Packaging a Competitive Advantage for Beauty Brands? – Hangar12

- [7 Is Sustainable Beauty Packaging Worth It? – Colorich

- [8] Recyclable vs. Reusable Packaging: Which is Better for Skincare Products? – APC Packaging

- [9] cURL Too many subrequests.

- [10] cURL Too many subrequests.

- [11] cURL Too many subrequests.

- [12] cURL Too many subrequests.

- [13] cURL Too many subrequests.