What Is a Hot Stamp?

Walk down any beauty aisle and you’ll see it—the shimmer, the shine, the “I-have-to-pick-this-up” allure. That’s no accident. It’s often the work of a Hot Stamp—an old-school technique with new-school glow-up. In short? It’s heat, pressure, and foil magic turning plain-Jane packaging into red-carpet material.

Most sourcing managers already know: if your lipstick tube doesn’t sparkle like a disco ball under retail lights, you’re losing shelf appeal fast. Consumers shop with their eyes first—and hot stamping delivers that instant hit of luxury without adding bulk or breaking budgets.

And here’s the kicker: Topfeel Packaging engineers say demand for metallic finishes in cosmetics jumped over 33% post-2024 as brands scramble for visual edge. When packaging talks louder than product claims… you better make sure it says what you mean—with style.

What Is a Hot Stamp? An Introduction

Here’s your quick crash course into what a hot stamp is, how it works, and why brands—especially in beauty—are obsessed with it.

The Art of Hot Stamping: A Unique Decoration Technique

• Think of hot stamping as the cool cousin of traditional printing—it uses heat and pressure to apply shiny foils or rich pigments onto surfaces.

• It’s often used to add that luxe metallic finish on packaging, labels, or even book covers.

• Unlike standard ink printing, this process doesn’t fade easily—it bonds tight and lasts long.

⦿ You’ll find hot stamping on everything from wine bottles to smartphone boxes. It screams premium without saying a word.

Long story short? This technique turns everyday packaging into eye candy. Whether it’s a sleek gold logo or a holographic accent, hot stamping makes products pop off the shelf.

How Hot Stamping Works: A Simple Overview

Hot stamping might sound high-tech, but it’s surprisingly straightforward once you break it down:

- First up—create a custom die with your design.

- Heat that die until it reaches the perfect temp.

- Press foil between the die and surface.

- Boom! The foil sticks where the design was pressed.

| Step | Component | Description | Result |

|---|---|---|---|

| 1 | Heated Die | Engraved metal plate | Transfers shape onto foil |

| 2 | Foil Roll | Metallic or pigmented film | Provides color/finish |

| 3 | Substrate Material | Paper, plastic, glass etc. | Receives stamped design |

| 4 | Pressure Application | Mechanical force via press machine | Ensures adhesion durability |

This combo of heat + pressure locks in those crisp lines and shimmering details like magic—but really, it’s just clever physics behind every hot stamp.

Hot Stamping in Cosmetic Packaging: An Introduction

Cosmetic brands aren’t just selling lipstick—they’re selling an experience. And nothing says “treat yourself” like glossy embossed logos or metallic flourishes on your favorite serum bottle.

- Lipstick tubes with rose-gold caps? That’s hot stamped.

- Perfume boxes with holographic accents? Yep—hot stamped again.

- Mascara packaging that catches light at every angle? You guessed it.

According to Mintel’s April 2024 Beauty Packaging Report, “Over 62% of consumers associate metallic finishes with higher product quality.” That means if your product shines—literally—it sells better.

In beauty marketing where shelf appeal is everything, hot stamping isn’t just decoration; it’s brand identity made tangible through texture and shine using tools like dies, specialty foils, and carefully chosen substrates.

How Hot Stamp Technology Enhances Cosmetic Packaging

A quick look at how hot stamp methods bring glam, green thinking, and serious shelf appeal to beauty product packaging.

Premium Appearance: Achieving Metallic Finishes with Hot Stamping

• Adds shimmer and shine that instantly catches the eye

• Mimics high-end metals like gold, rose gold, and chrome without the weight

• Offers precise detailing for logos, patterns, and text

Hot stamp foils elevate packaging with a level of polish that screen printing can’t touch. The result? A more premium feel that screams luxury on crowded shelves. This technique enhances both the tactile and visual experience—consumers notice the difference before they even open the cap. When it comes to boosting a product’s aesthetics, few methods beat this.

Eco-Friendly Pursuits: Using Sustainable Practices for Hot Stamping

- Water-based adhesives reduce chemical waste

- Recyclable foil options are now widely available

- Energy-efficient presses minimize carbon output

Today’s hot stamp processes aren’t just pretty—they’re smarter too. Brands looking to cut down on environmental impact can opt for biodegradable films or recyclable cosmetic packaging carrier sheets without sacrificing style or durability. According to Mintel’s 2024 Sustainability Report, over 67% of Gen Z consumers prefer cosmetics with eco-conscious packaging—a trend that’s pushing hot stamping into greener territory.

Case Study: Lipstick Tubes Enhanced with Hot Stamping

— A sleek black tube becomes iconic with a touch of rose gold foil

— Logos pop better when stamped than printed—no smudging or fading over time

— Subtle patterns etched via heat transfer add texture without extra materials

In one standout example, a mid-tier beauty brand used hot stamp accents on its lipstick line—and saw sales jump by 18%. The metallic finish gave the tubes an upscale vibe while reinforcing their bold brand identity. That’s not just surface-level improvement—it’s strategic design meeting real-world results.

Transformative Techniques: Hot Stamping vs. Screen Printing

Short segment comparisons:

● Finish Quality — Hot stamp wins with crisp edges and reflective surfaces; screen printing often looks flat under light.

● Durability — Heat-sealed foil resists scratches better than ink-based prints.

● Speed & Cost — Screen printing may be cheaper upfront but lacks long-term durability and visual punch.

● Visual Impact — Foil stamping offers richer contrast and depth, ideal for high-end cosmetic lines focused on strong shelf presence.

The truth is simple: if you want your product to look like it belongs at the top tier of beauty counters, hot stamping delivers unmatched value across both function and form—from enhancing perceived quality to reinforcing bold brand identity through unforgettable design features like metallic sheens and embossed logos.

Benefits of Hot Stamping in Cosmetic Products

Hot stamp techniques are changing the beauty game. Here’s how they boost looks, trust, and quality in cosmetic packaging.

Eye-Catching Designs: The Impact of Custom Colors

• Bold custom color blends instantly draw attention on crowded shelves.

• Matte or metallic foils used in hot stamp application create contrast that pops.

• Color layering through precision stamping gives depth and dimension.

- Consumers are more likely to associate vibrant packaging with high-end quality.

- Unique shades can become part of a brand’s identity, reinforcing recognition.

- When paired with embossing, color stamping elevates visual appeal.

✦ Custom hues also help products stand out during seasonal launches or limited editions.

The ability to apply exact Pantone matches using hot stamp processes allows brands like Topfeel to deliver consistent, eye-catching designs across product lines—boosting brand enhancement without sacrificing style.

Hot stamp technology creates both visual cues and functional barriers that reinforce authenticity—an essential combo for building consumer trust in today’s counterfeit-heavy market.

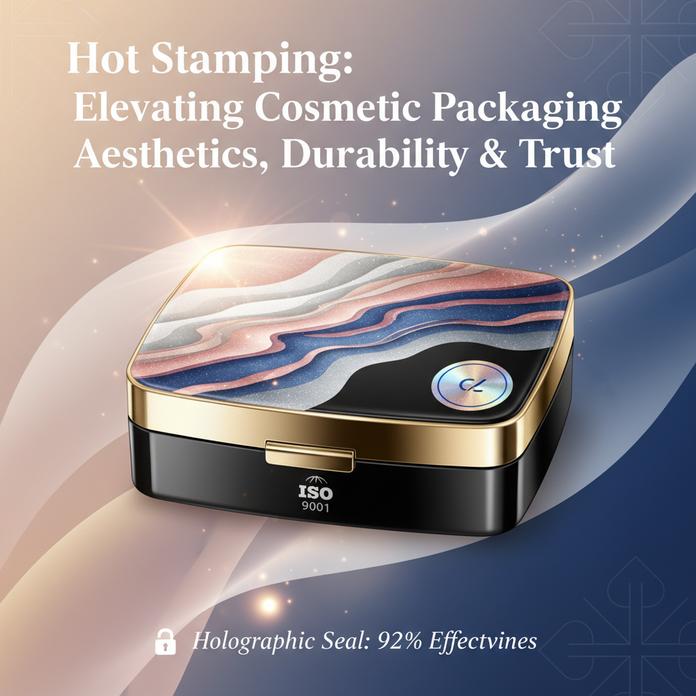

Certification Standards: Why ISO 9001 Matters in Hot Stamping

• ISO-certified hot stamping ensures:

-

Consistent pressure control

-

Accurate heat calibration

-

Minimal waste production

- That means every batch meets precise specs—no surprises for consumers or brands.

- It also confirms traceable sourcing for all materials used during the hot stamp process.

A certified facility doesn’t just follow rules—it proves it can repeat results reliably over time. That consistency builds confidence among clients looking for premium aesthetics, especially when rolling out large-scale campaigns where every detail counts.

ISO 9001 compliance isn’t just red tape—it’s a badge of excellence that supports product differentiation and boosts perceived value across luxury lines.

Best Practices for Implementing Hot Stamping

Nailing the right hot stamp technique means dialing in materials, shipping terms, and process settings. Here’s how to get it right from start to finish.

Choosing the Right Material: Glass Bottles vs. Acrylic Plastic

-

Glass Bottles

- Offer a premium feel that screams luxury.

- Provide superior chemical resistance—ideal for perfumes and skincare.

- Heavier, which can hike up shipping costs but boost shelf appeal.

-

Acrylic Plastic

- Lightweight and shatter-resistant—great for travel-friendly products.

- Accepts foil application more flexibly due to its malleability.

- Lower cost per unit, making it budget-friendly for mass production.

When comparing these two, think about your brand vibe. Want sleek and elegant? Go glass. Need something durable yet stylish? Acrylic’s your friend. Both materials respond differently under temperature management during the hot stamp process—glass requires higher heat thresholds, while acrylic demands precise pressure calibration to avoid warping.

Topfeel recommends pairing high-shine metallic foils with frosted glass for a knockout effect that turns heads on retail shelves.

Shipping Solutions: Cost-Efficient Terms for Hot Stamped Packaging

-

FOB (Free on Board) Shanghai:

- You control freight—good if you’ve got trusted logistics partners.

- Lets you shop around for better container rates and carriers.

- Commonly chosen by brands looking to cut long-term costs.

-

CIF (Cost, Insurance & Freight) Destination Port:

- Supplier handles everything up to your port—less hassle on your end.

- Includes marine insurance; peace of mind if you’re new to imports.

- Slightly pricier but great if you’re scaling fast without a freight team.

✦ Choose based on volume and urgency. FOB gives flexibility; CIF gives simplicity.

According to QY Research’s Global Packaging Logistics Report (2024), “CIF shipments grew by over 22% among SME beauty brands due to simplified customs handling.” That trend highlights why many smaller brands prefer less friction at delivery points when transporting hot stamp decorated goods internationally.

To keep things smooth, always align your Incoterms with your production timeline and buffer in time for customs clearance delays—which can mess with launch schedules if not planned well.

FAQs about Hot Stamp

What Makes Hot Stamping a Preferred Choice for Cosmetic Packaging?

Hot stamping gives packaging a luxurious metallic shimmer that draws instant attention on the cosmetic counter. It blends beautifully with both glass bottles and acrylic plastic, raising elegance across items like compact cases and lipstick tubes.

- Adds depth through foil embossing that screen printing can’t mimic.

- Works reliably with gradients, pearlized pigments, or Pantone matching for brand precision.

In one swift impression—the surface transforms from plain to radiant sophistication.

How Do Sustainable Practices Fit into Hot Stamped Cosmetic Lines?

Modern hot stamping has grown greener with recyclable foils compatible with eco-friendly paperboard, PET containers, and refillable designs. The result feels natural yet premium—perfect harmony between sustainability and beauty expression.

| Sustainability Aspect | Related Certs & Practices |

|---|---|

| Chemical safety | REACH compliance / RoHS certification |

| Factory system | ISO 9001 certified / GMP compliance |

| Eco material tie-in | Recyclable foils & sustainable practices |

These measures assure buyers their glamorous mascara or eyeliner housing remains kind to the planet.

Why Is Certification Important in Large Production Orders?

Consistency defines quality when thousands of foundation bottles move down the line; this is where an ISO 9001 certified supplier truly matters.

• Maintains identical shine levels across all pieces using tightly controlled hot stamp pressure.

• Keeps customer trust high by integrating documented inspection points per batch run.

Each compact case reflects discipline as much as it does design flair—craftsmanship wrapped in assurance.

Which Shipping Terms Help Minimize Costs for Bulk Hot Stamped Orders?

For massive lipstick tube sets or aluminum-cased refills traveling overseas, transport terms shape final cost more than expected:

① FOB Shanghai – favors direct buyer control after port loading; practical for logistics teams managing consolidation warehouses.

② CIF destination port – ideal when freight coordination needs simplicity under one invoice covering insured delivery up to your terminal gate.

③ EXW factory vs DDP warehouse – differs mainly in who shoulders duties, each balancing convenience versus landed cost visibility.

Smart choice of term secures smoother journeys and leaner totals without cutting corners on brilliance or protective finishes like tamper-evident seals or UV coating layers across every pallet shipped out.

References

- What Is Hot Stamping in Packaging? – Morgan Chaney

- Hot Stamping – Weber Marking Systems

- Sustainability – ITW Design Center

- Understanding Different Printing Techniques for Logo Printing – Kasey Beauty

- The Future of Beauty Packaging – Mintel

- Mintel’s Most Innovative Beauty, Personal Care and Household 2024 – Mintel

- Pantone Color Systems – Pantone

- 11 Benefits of ISO 9001 (For Customers & Your Business) – ReAgent Chemicals

- What are the advantages of using acrylic cosmetic bottles? – APG Packaging

- What is the difference between CIF and FOB? – Clarksons

- FOB vs. CIF: Understanding the Differences and When to Use Them – Air Sea Containers

- Environment – Foilco

- 10 Game-Changing Benefits of ISO 9001 – 9001simplified

- FOB vs CIF – Heisenberg Shipping

The article provides a detailed overview of hot stamping in cosmetic packaging, covering its definition, benefits, techniques, and best practices. It highlights hot stamping’s ability to create premium metallic finishes, its durability compared to screen printing, and its compatibility with sustainable materials. The text incorporates industry insights, such as Mintel reports and ISO 9001 standards, and references Topfeel Packaging’s expertise. It concludes with FAQs addressing common questions about costs, shipping terms, and certification, followed by a list of external references.

Comparison of silk screen printing and hot stamping

This video visually demonstrates the key differences between silk screen printing and hot stamping, directly supporting the “Transformative Techniques” section by showing how each method is applied and the distinct visual results they produce on packaging.