MA-56 Transparent Lip Stain Packaging Supplier PETG

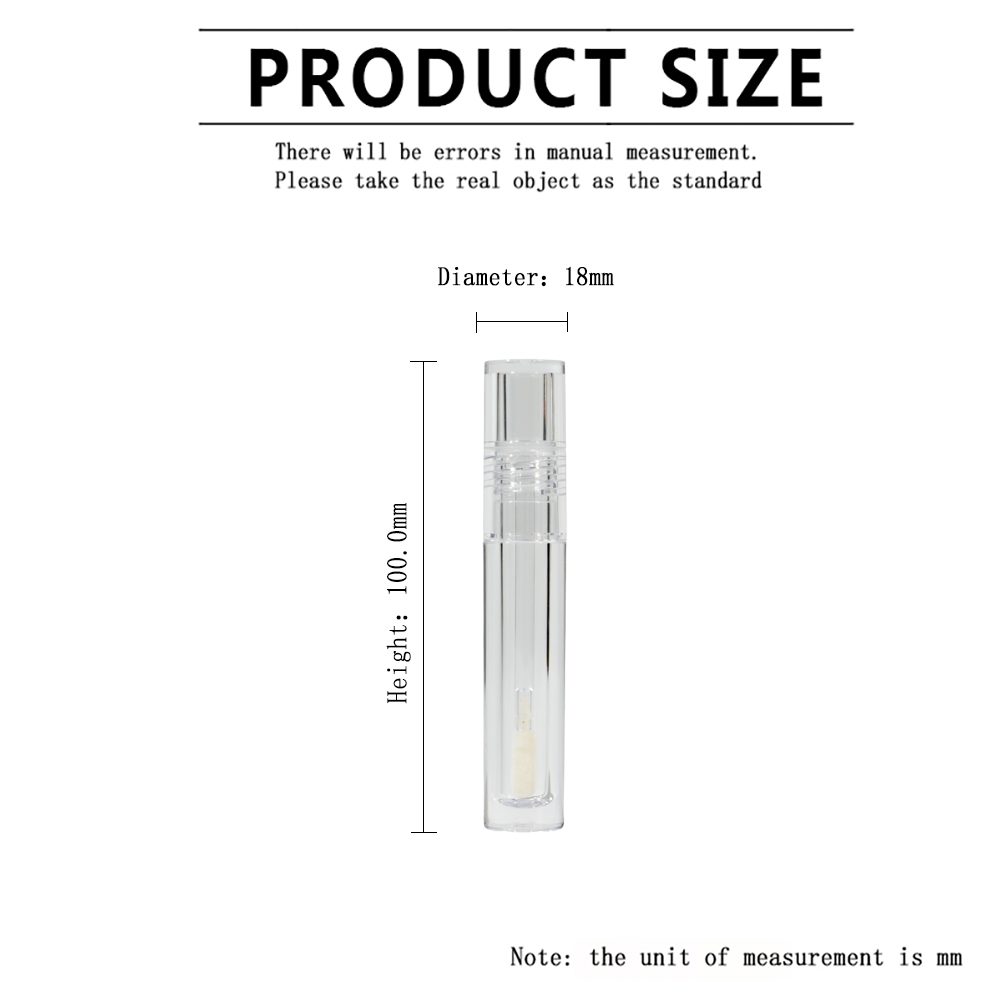

Model Number: MA-56

Capacity: 3.6ml

Material: PETG

Size: L100.2mm × W18mm

MOQ: 12,000 pcs

Application: Lip Gloss, Lip Serum

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom color and printing

Sample:

Benefits

-

Transparent PETG and a precise applicator structure ensure product visibility, leak protection, and smooth application.

-

Minimalist and fully clear design enhances the visual appeal of pigmented or shimmer-based lip gloss formulas.

-

Supports multiple logo and finish customizations, enabling brand differentiation without altering the base structure.

You May Also Like

View Product Details

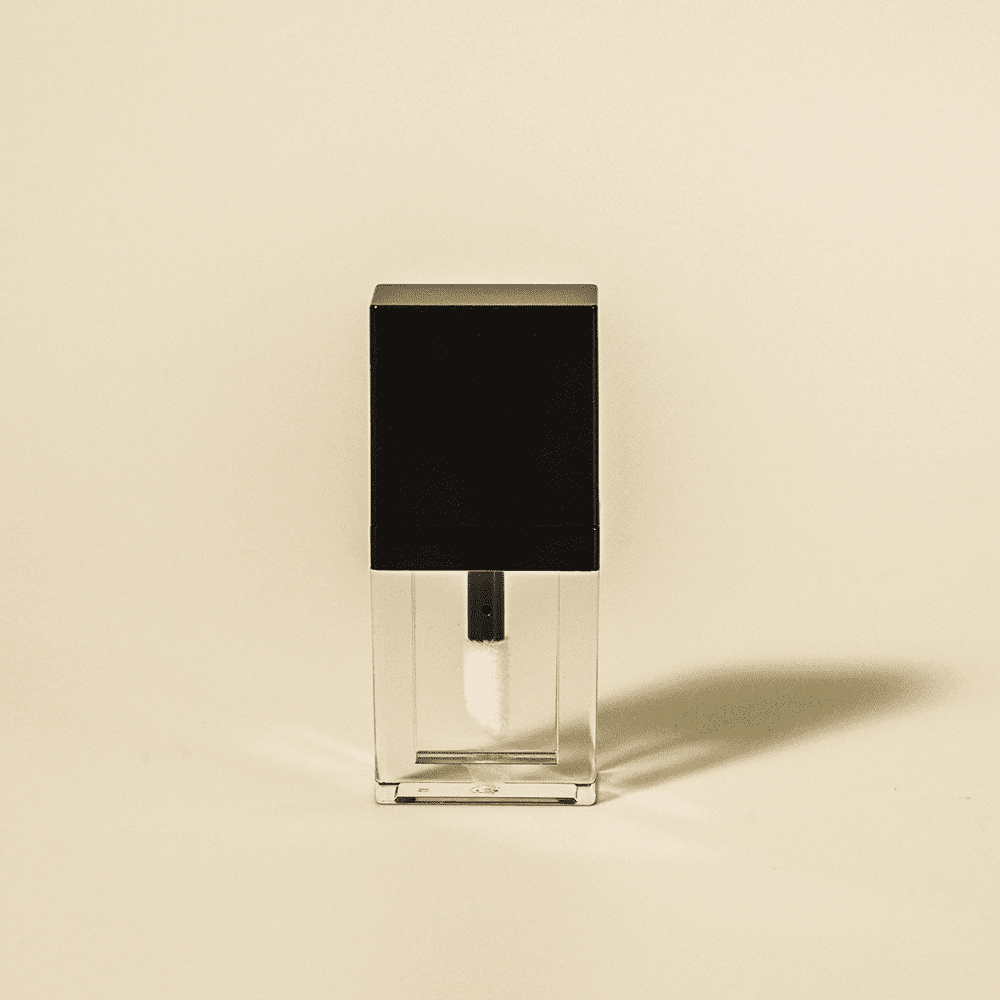

Clear & Functional Design

Transparent PETG Body

The MA-56 tube is manufactured using high-clarity PETG (Polyethylene Terephthalate Glycol), a widely recognized material in the cosmetics packaging industry due to its chemical resistance, impact strength, and optical transparency. This clarity allows manufacturers and consumers to clearly observe the product’s fill level and texture.

PETG is preferred in over 70% of new lip gloss packaging designs launched in the North American market since 2023, according to Packaging Insights Report Q1 2024 by BeautyStat Research.

-

PETG ensures full recyclability under existing PET sorting streams, which supports brand sustainability targets.

-

Showcase-Ready Aesthetics

Amplifies Formula Visuals

The minimalist, cylindrical design is purpose-built to emphasize the product inside. Whether displaying tinted glosses, shimmer-based formulas, or oil-based lip serums, the tube acts as a visual frame that complements rather than competes with the content.

According to NPD Group Beauty Industry Outlook 2024, 67% of lip gloss buyers consider product visibility a major purchase factor in-store and online.

Flexible Branding Options

Logo & Finish Customization

Topfeel provides multiple customization options that align with the MA-56 tube’s design and material properties:

-

Silk-Screen Printing: Ideal for permanent brand markings, offering high opacity and abrasion resistance.

-

Hot Stamping: Metallic or colored foils applied under pressure to add branding flair without adding bulk.

-

Spray Coating or UV Finish: Enables matte or glossy finishes based on brand identity requirements.

These services are executed in-house through Topfeel’s GMPc-compliant decoration lines, ensuring full process control and fast lead times. Logos, color matching, and finish preferences can be applied to the cap, shoulder, or body surface based on the client’s design map.

“This model is one of our most mold-stable designs, meaning clients can adjust the visual branding freely without retooling the main structure. It’s one of our most requested lip packaging formats globally.” —

FAQs

Clients have access to comprehensive customization services aligned with the tube’s structure:

-

Logo printing via silkscreen

-

Color-matched cap and components

-

Hot foil stamping for decorative accents

-

Finish options: glossy, matte, frosted

-

PETG is resistant to breakage and distortion

-

Leakproof sealing passes standard torque and break testing

-

3.6ml capacity keeps weight low for bulk freight

-

-

High-transparency PETG material

-

Simple cylindrical design that directs focus to the formula

-

Applicator alignment that doesn’t obstruct the inner view

-

Yes. While PETG is a virgin material, it’s recyclable under PET stream standards. Topfeel also offers PCR and biodegradable alternatives in its portfolio for clients prioritizing sustainability in lip product packaging.

Topfeel applies rigorous QA processes:

-

Torque test to validate cap sealing strength

-

Break & drop testing to ensure structure integrity

-

Optical image inspection for cosmetic defects

-

Humidity and temperature resistance trials