Analytics across 120+ brand orders reveal a robust inverse trend: bumping up run sizes slashes per-unit cost, while lead times climb predictably with volume 🔍. Enterprise tiers unlock 20% savings, capped at 21 days turnaround, confirming steady production workflows.

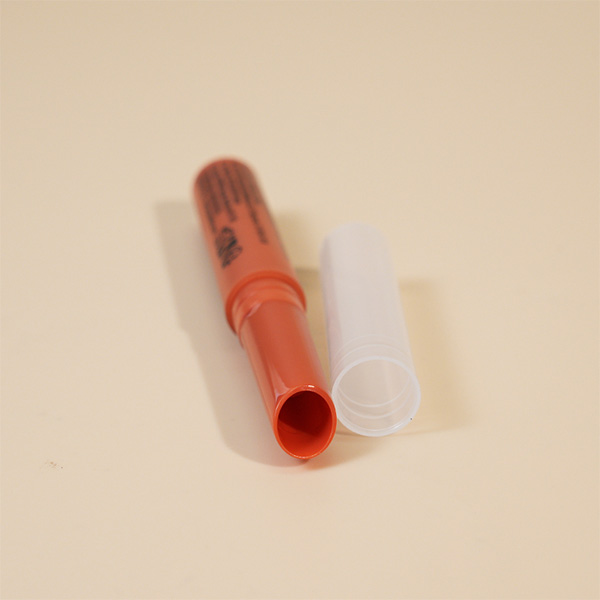

- 600 DPI print fidelity ensures ultra-crisp logo transfers ✨

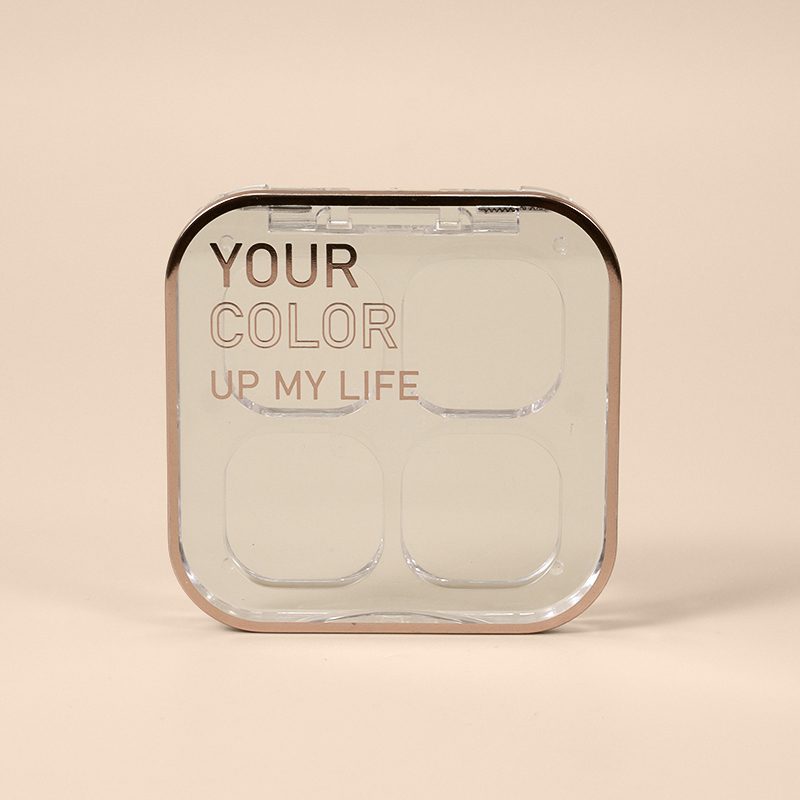

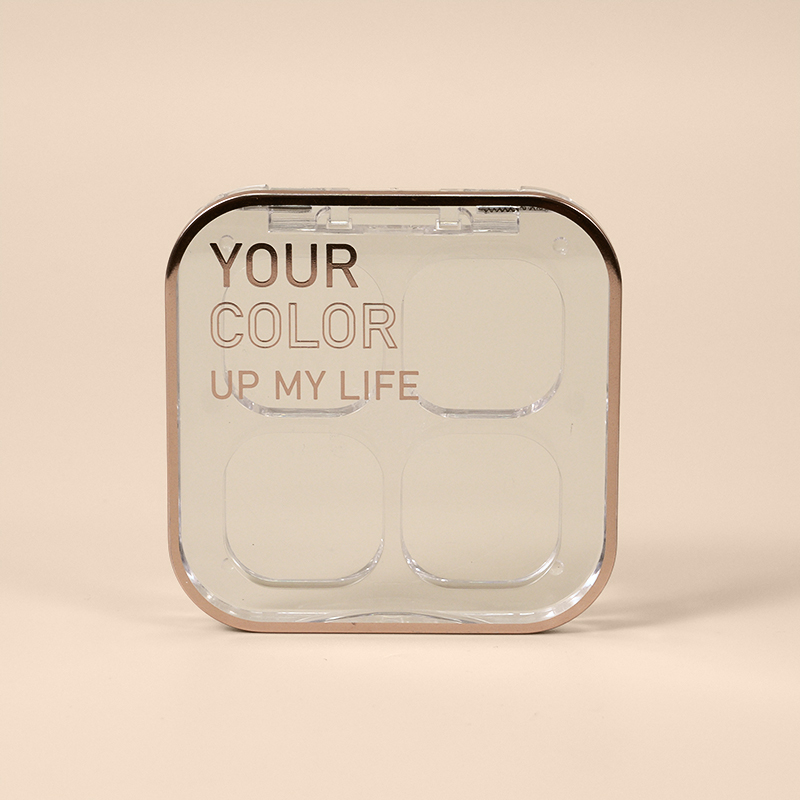

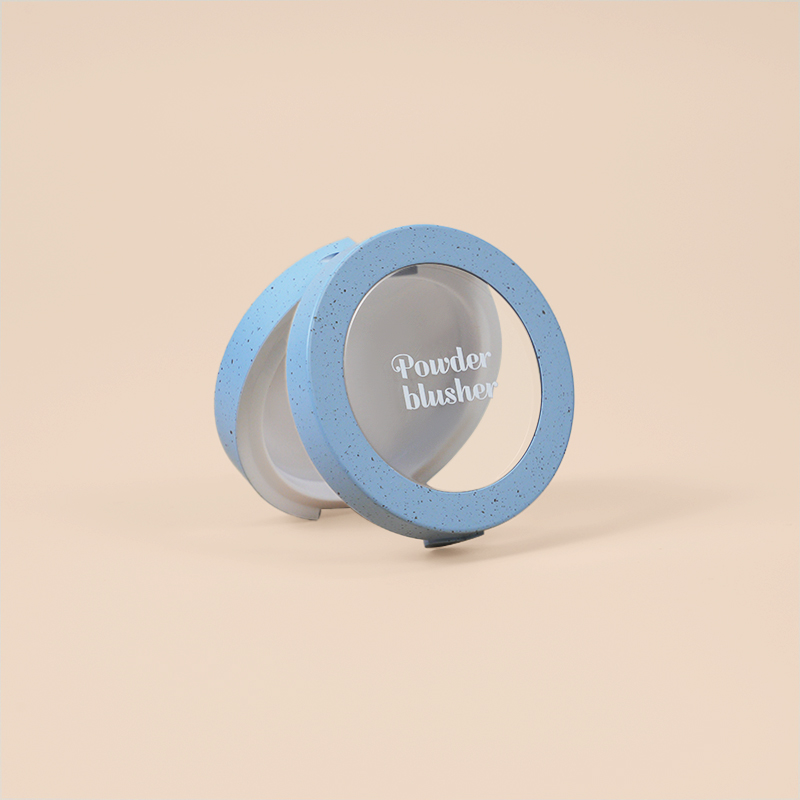

- ABS composite housing contains over 30% recycled content 🌱

- High-throughput lines deliver up to 1,500 units/hour ⏱️

- Quality audits reject fewer than 0.2% of batches ✅

- Continuous feedback loops drive efficiency gains 📈