Effective Makeup Packaging Design Tips with Acrylic Plastic

Ever picked up a lipstick just because the packaging whispered sweet nothings to your inner glam goddess? That’s no accident. Smart makeup packaging design doesn’t just hold product—it sells an experience. In a world where shelf appeal fights for survival like it’s Fashion Week backstage, acrylic plastic is becoming the go-to MVP: sleek, tough as nails, and ready to play dress-up in every shade of Pantone.

Here’s the kicker—according to Grand View Research, the global cosmetics packaging market is projected to hit $41.8 billion by 2030, with acrylic options climbing thanks to their luxe feel and customization perks. “Consumers want beauty that performs and looks good doing it,” says Maria Cheng, Senior Analyst at Euromonitor International.

So if you’re thinking about upgrading those tubes or jars from meh to magnetic—you’re in exactly the right spot.

Quick Points in Acrylic Elegance: A Guide to Smart Makeup Packaging Design

➔ Durability That Dazzles: Acrylic plastic stands strong against impact and daily use, making it a reliable alternative to fragile glass or flimsy paperboard.

➔ Color with Character: From Pantone precision to pearlescent flair, acrylic packaging brings your brand palette to life with vivid accuracy.

➔ Sustainability Matters: Incorporate recycled materials and refillable systems into acrylic designs for eco-aware beauty consumers.

➔ Design Made Simple: Streamline your workflow by starting with 50ml–100ml acrylic options tailored for compacts, tubes, and jars.

➔ Speed Meets Style: Use rapid prototyping for fast feedback on oval tubes or round compacts before scaling full production.

➔ Decoration Done Right: Elevate design appeal using hot stamping foils and screen printing inks that pop on transparent surfaces.

➔ Seal It Securely: Prevent leaks with gasket inserts, tight-fit caps, and label adhesives built specifically for shaped containers like 15g jars or oval tubes.

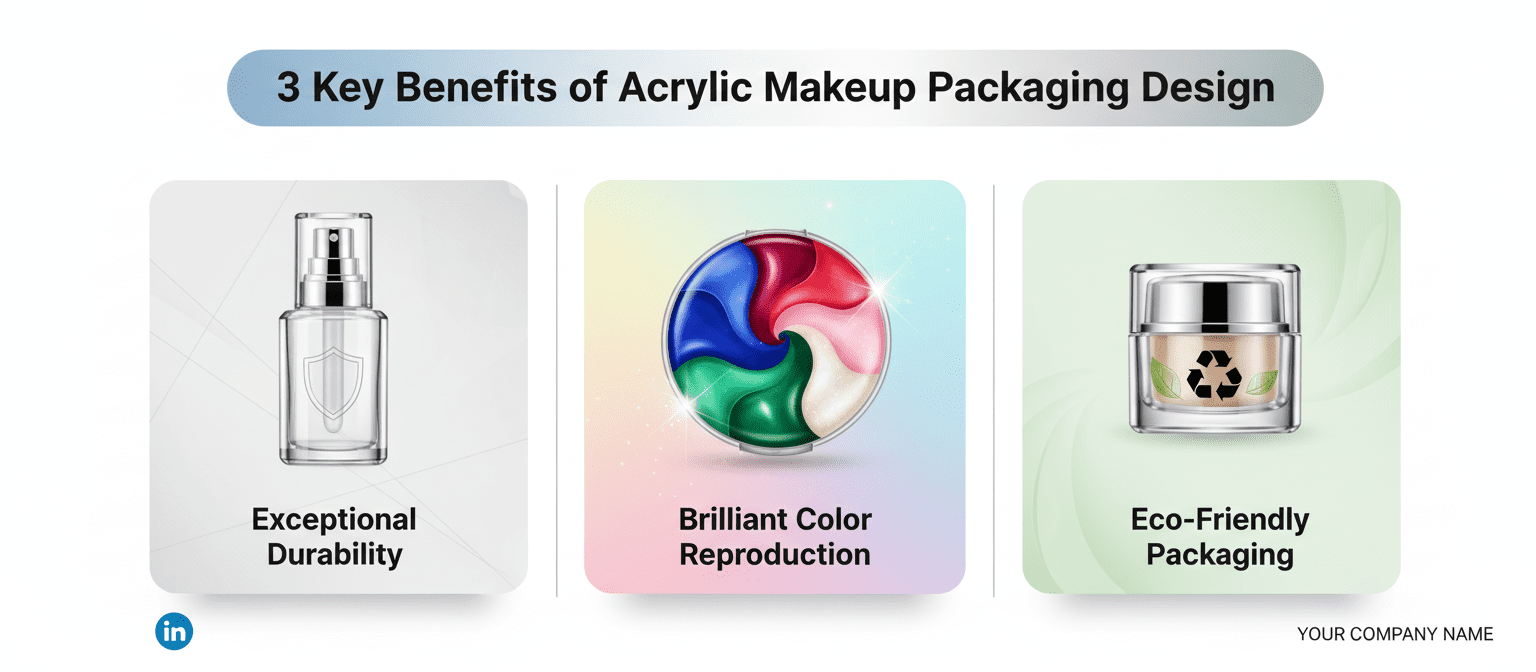

3 Key Benefits of Acrylic Makeup Packaging Design

Acrylic-based cosmetic packaging brings together strength, shine, and sustainability—three things beauty brands can’t afford to ignore.

Exceptional Durability with Acrylic Plastic

Acrylic isn’t just tough—it’s nearly unbreakable, making it a solid choice for cosmetic products that get tossed into bags or dropped on countertops.

• The material’s high-impact resistance shields against cracks and dents better than glass or other plastics.

• It holds up under pressure—literally—making it ideal for pumps, compacts, and jars that need to keep their shape.

And it doesn’t just survive rough handling; it still looks good doing it. That kind of durability means fewer customer complaints and longer shelf life.

Brilliant Color Reproduction Using Pantone Colors and Pearlescent Additives

When brands want their packaging to pop off the shelves—and Instagram feeds—they turn to acrylic.

✓ Pantone-matched colors stay true under bright lights or natural sun.

✓ Pearlescent finishes add shimmer without compromising clarity or strength.

✓ High transparency lets inner contents shine through if desired—or hides them completely with opaque additives.

The ability to layer color effects while maintaining clean lines gives acrylic unmatched flexibility in packaging design, especially when paired with bold brand aesthetics.

Eco-Friendly Packaging: Recycled Materials & Refillable Systems

Sustainability is no longer optional—it’s expected. Fortunately, acrylic can play nice with the planet too.

Recycled acrylic blends are now widely available, cutting down on virgin plastic use without sacrificing performance. Some designs even allow refillable inserts—a win-win for both users and the environment.

Topfeel has crafted solutions that combine sleek aesthetics with smart eco-features like modular components and reduced-waste refills. This approach supports both branding goals and environmental responsibility without compromise.

By integrating sustainable systems into makeup packaging design, brands stay ahead of shifting consumer demands while still delivering standout shelf appeal.

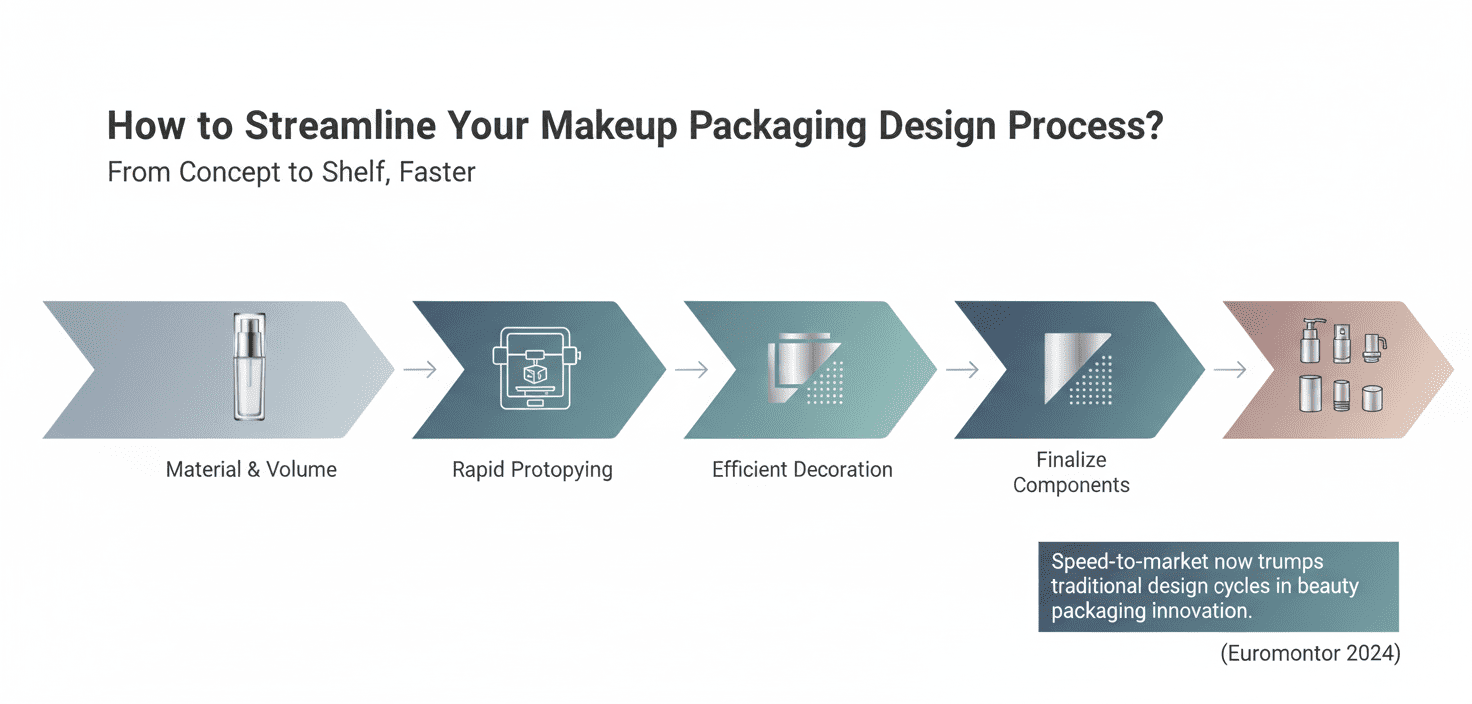

How to Streamline Your Makeup Packaging Design Process?

Quick wins, fewer headaches—that’s the goal when you’re trying to speed up your whole makeup packaging setup without sacrificing quality.

Select Material & Volume — Acrylic Plastic (50ml to 100ml)

- Acrylic plastic is a solid pick—tough enough for travel, clear enough for shelf appeal.

- Go with 50ml if you’re targeting trial-size or lightweight formulas; it’s compact and budget-friendly.

- Bump up to 100ml when your product lineup includes moisturizers or setting sprays—it balances volume and portability.

- Consider cost optimization early by aligning material choice with your fill weight and shipping strategy.

- Acrylic also plays nice with decoration techniques, which saves time during production runs.

Rapid Prototyping for Oval Tubes and Round Compacts

Oval tubes = sleek. Round compacts = classic. Both need testing fast.

• Start by sketching out ergonomic forms that match your target user’s grip comfort—yes, ergonomics matter more than you think.

• Then move into CAD modeling—don’t over-engineer it; just enough detail to test feel and function.

• Use rapid prototyping tools like SLA printers that mimic final textures so you can test closures and hinges too.

Once you’ve got those first few mockups in hand, get feedback from real users—not just your internal team—and revise based on how they interact with it.

As Euromonitor noted in its 2024 report, “Speed-to-market now trumps traditional design cycles in beauty packaging innovation.”

Efficient Decoration with Hot Stamping Foils and Screen Printing Inks

Hot stamping? Flashy but efficient. Screen printing? Durable and sharp.

Short bursts below explain how both play their part:

• Hot stamping foils bring metallic accents without slowing down the line—just heat + pressure = instant glam.

• Screen printing inks hold up against oil-based products, perfect for long-lasting labels on foundation bottles or balms.

• Combine both when branding is front-and-center; screen the logo, foil the trim—done right, it’s a vibe.

Each technique supports distinct visual goals while keeping timelines tight—a win-win for brands chasing faster launches without skimping on shelf impact.

Finalize Components from Sifter Inserts to Pump Dispensers

Choosing components isn’t just about function—it’s about user experience meeting smart manufacturing.

Grouped by purpose:

Dispensing Systems

- Airless pumps: Ideal for serums needing controlled dosage

- Fine mist sprayers: Best for setting sprays or toners

- Push-button droppers: Adds precision for oils or treatments

Powder Control

- Sifter inserts: Keeps loose powders mess-free

- Rotating sifters: Offers open/close control without extra parts

Caps & Closures

- Flip tops: Fast access, great for casual use

- Screw caps: More secure; better suited for travel kits

Every piece should align with your audience’s lifestyle while also satisfying manufacturing, compliance needs, and ease-of-use expectations—which is why Topfeel always recommends testing combinations under real-world conditions before mass production kicks off.

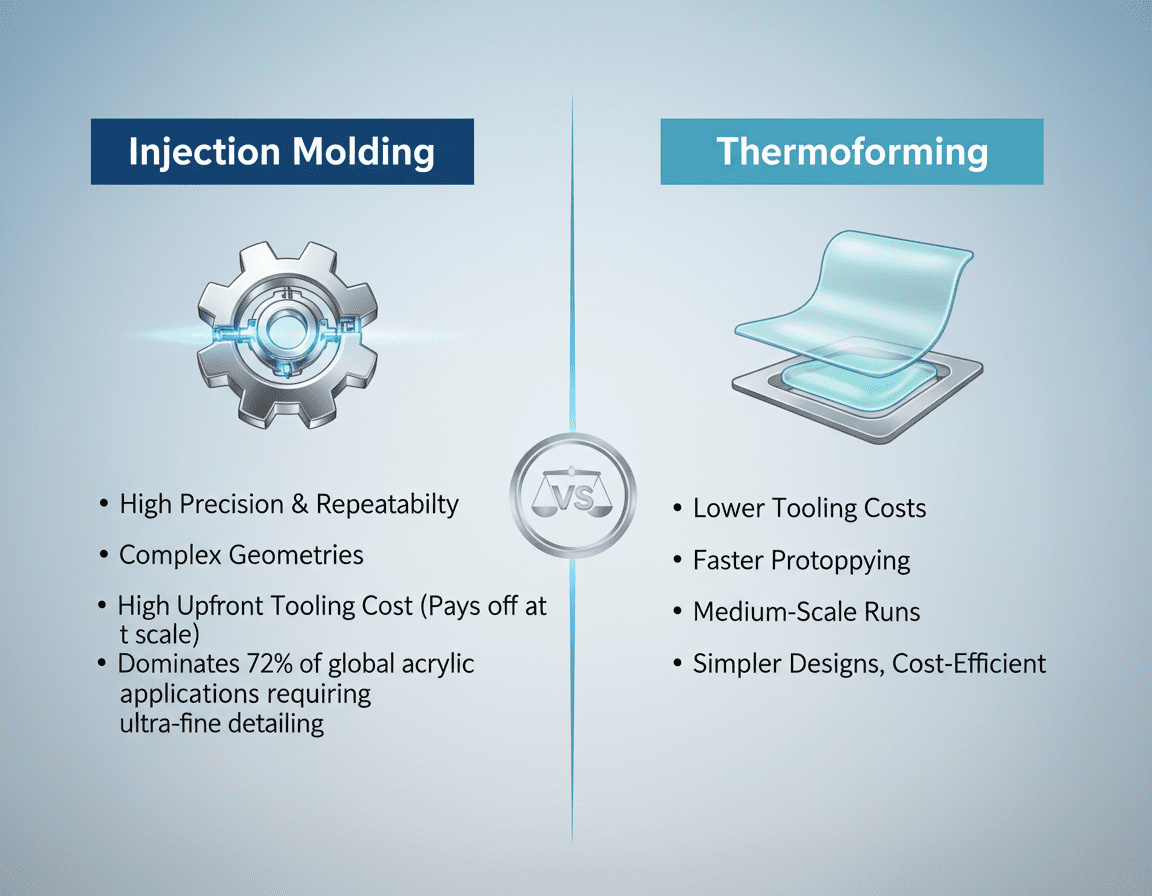

Injection Molding vs. Thermoforming for Acrylic

Choosing between these two methods boils down to production needs, design complexity, and budget flexibility.

Injection Molding

Precision is the name of the game here. This method nails tight tolerance levels and replicates intricate details with ease—perfect if you’re producing hundreds of thousands of acrylic compacts or display cases.

- You get high repeatability—each piece looks just like the last.

- It supports complex geometries that thermoforming simply can’t handle.

- The upfront cost is steep due to tooling, but it pays off at scale.

- According to a 2024 report by Plastics Market Watch, injection molding dominates 72% of global acrylic properties applications requiring ultra-fine detailing.

Despite its higher initial investment, it’s ideal when high-volume consistency and top-notch surface finish matter most.

Thermoforming

Thermoforming’s more chill—less cash upfront and great if your design isn’t rocket science.

• Lower tooling costs = faster prototyping

• Best suited for medium-scale runs or custom shapes

• Flexibility in material selection, especially when weight-saving matters

You won’t get the same precision as injection molding, but if your application suitability leans toward simplicity over intricacy, this process wins on cost-efficiency alone. For brands looking to test out new styles in their compact or palette lines without committing big bucks early on, thermoforming offers breathing room.

Topfeel taps into both processes depending on project scope—balancing production volume, design ambition, and budget realities with smart manufacturing choices that keep your makeup packaging fresh and functional without blowing up costs.

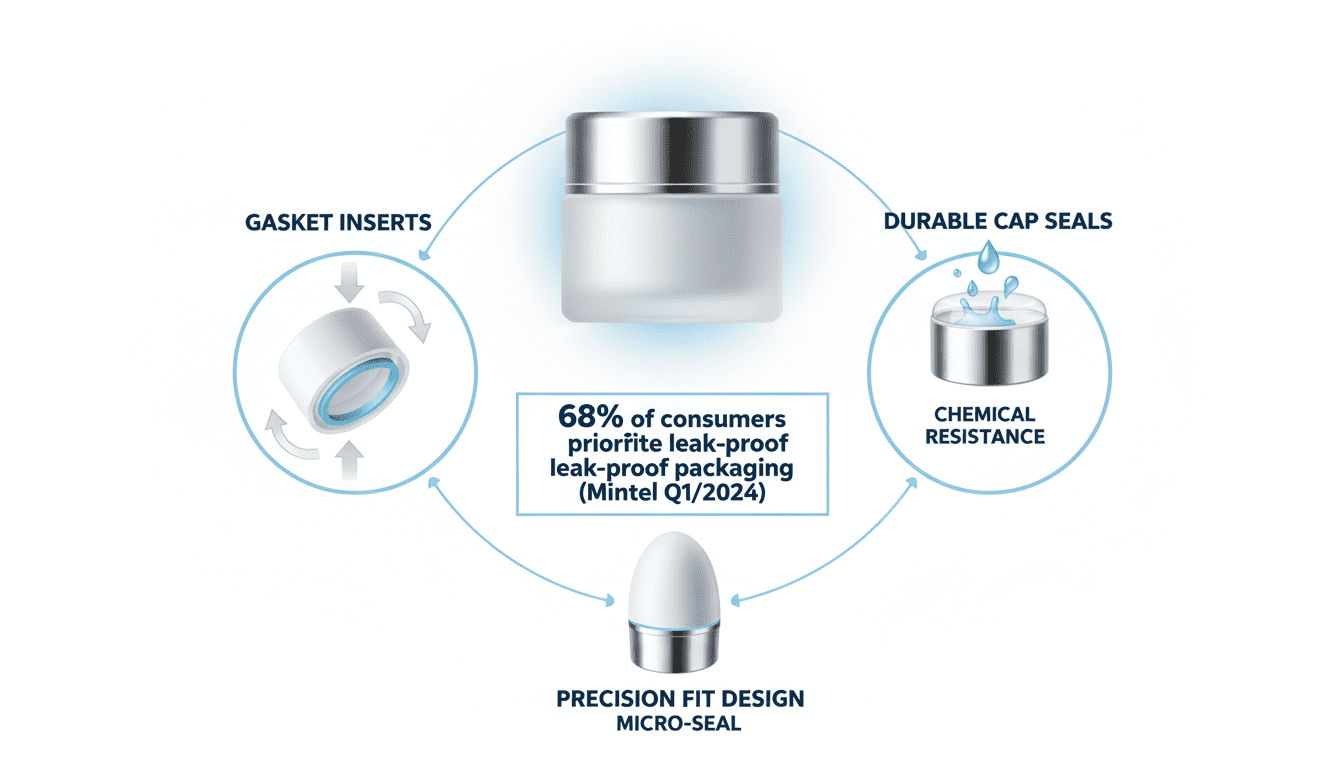

Packaging Leaks? Tight-Seal Acrylic Cap Tips.

When it comes to keeping formulas fresh and mess-free, nailing the seal is everything. Let’s talk real fixes for leak-prone packs.

Gasket Inserts: The Secret to Leak-Proof 15g Jars and 50ml Bottles

• Gasket inserts act as a pressure buffer between lid and jar, sealing off any potential escape routes for creams or serums.

• Designed specifically for smaller formats like 15g jars and compact bottles, they support high-viscosity contents without bulging or cracking.

• These inserts are especially handy when dealing with temperature-sensitive products that expand under heat—no more sticky surprises in your handbag!

• Compatibility across materials ensures these closures don’t warp over time, maintaining tightness even after multiple uses.

By integrating these into your makeup pack setup, you’re not just preventing leaks—you’re extending shelf life through smart sealing technology.

Durable Cap Seals with Protective Coatings

A good cap is only as strong as its protective layer—and that’s where coatings come into play.

- Start by choosing caps that are chemically resistant to oils, alcohols, or acids commonly found in skincare blends.

- Apply UV-cured coatings that offer scratch resistance and prevent surface degradation—this keeps the container looking sharp on shelves.

- Use inner linings made from food-grade silicone or PE foam; these liners adapt to subtle shifts in cap positioning while preserving a strong seal.

- “In recent testing conducted by Mintel Reports Q1/2024, over 68% of consumers cited ‘leak-proof packaging’ as a top priority when purchasing face creams.”

So yeah, it’s not just about making things look pretty—it’s about ensuring your container closure performs under pressure.

Topfeel gets this right by balancing aesthetic design with rugged functionality—no fluff, just results.

Precision Fit Design for Oval Tubes Using Label Adhesives

• Oval tubes often pose sealing challenges due to their asymmetrical shape—but label adhesives solve this smoothly.

• Pressure-sensitive adhesives bond seamlessly around curves without adding bulk or interfering with squeezability.

• These adhesives also create micro-seals along the edges of closures, reinforcing the tube’s resistance against leakage during transit or usage.

Pairing oval formats with smart adhesive applications means better grip at the seal line and less chance of product drying out mid-use—a win-win for both aesthetics and product preservation.

By fine-tuning fitment using adhesives instead of relying solely on mechanical force, you’re enhancing both user experience and closure performance, all while keeping things sleek on-shelf.

FAQs

Acrylic has this sleek, glass-like look but without the fragility. It holds up to drops and bumps—ideal for daily use. Designers love it because:

- Colors pop vividly, especially with Pantone shades or pearlescent finishes

- It plays well with recycled content and refillable designs

- You get that premium feel without sacrificing durability

Leaks ruin everything—from your product’s reputation to someone’s purse lining. The secret weapon? Gasket inserts. These tiny components form tight seals that lock in creams, serums, or powders. No spills, no mess—just peace of mind.

Absolutely—and you don’t have to settle for dull packaging either:

- Acrylic can be made from post-consumer recycled materials while still looking high-end

- Refillable systems are gaining traction; think pump dispensers designed to last through multiple refills

Sustainability doesn’t mean compromising on beauty—it just means designing smarter.

It depends on what kind of vibe you’re going for: bold branding or subtle elegance?

- Hot stamping adds metallic accents that shimmer under light—great for logos or borders on oval tubes and round compacts

- Screen printing offers crisp detail that’s perfect when you want text clarity across curves or flat surfaces

These techniques don’t just decorate—they define identity.

This is where function meets finesse. A beautiful container isn’t enough if it frustrates users:Pump dispensers must deliver smooth flow every time; sifter inserts should release powder evenly—not too much, not too little. Every component—the hinge on a compact mirror, the snap of a lid—shapes how people feel about your brand each day they use it.