MA-50 Wholesale Flat Lip Gloss Tube PETG

Model Number: MA-50

Capacity: 5ml

Material: PETG, PE

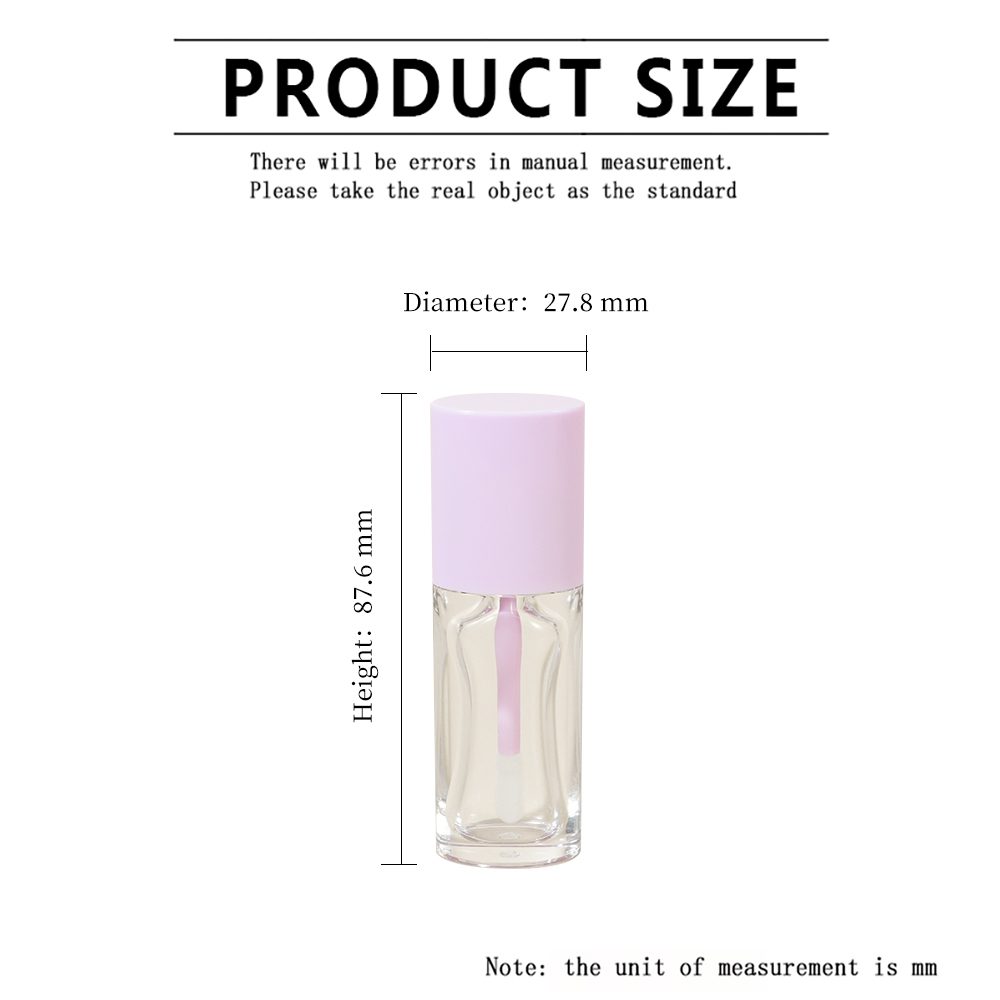

Size: L84.2mm x W22.3mm x H17.5mm

MOQ: 10,000 pcs

Application: Lip Gloss, Lip Oil, Serum

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom Color, Custom Printing (Hot Stamping, UV Coating, Silk Screen)

Sample:

Advantages

-

Flat oval shape and PETG material offer a modern look with high compatibility and structural integrity.

-

Flocked applicator and stopper ensure smooth, controlled application with minimal waste and high hygiene.

-

Supports wand, stopper, and mold customization to meet diverse formula and branding requirements.

-

Slim silhouette enhances visual presence and optimizes display space in retail and online settings.

You May Also Like

View Product Details

Compact Form, Premium Build

-

Flat Oval Bottle Shape

The flat profile supports high-density packing during shipping and shelf stocking. It’s engineered for compact displays and storage efficiency—a plus for minimalist packaging needs.

-

In terms of footprint, the oval bottle offers a reduced width-to-height ratio, making it suitable for vertical shelving and e-commerce flat lays.

-

The oval neck supports secure placement of the PE inner plug, which provides seal reinforcement and helps reduce leakage risk during transit.

-

-

Unified PETG Material System

All exterior components—cap, bottle, and stick—are manufactured using PETG.

-

PETG is known for its balance of toughness and flexibility, making it less prone to stress whitening or breakage in drop or vibration tests.

-

-

Clean and Precise Use

Built with everyday usage in mind, the MA-50 tube includes a functional flocked applicator and plug system that helps brands deliver consistency in product usage and cleanliness for end consumers.

A pre-inserted inner PE plug controls the amount of formula dispensed per use. The applicator tip—standard in cosmetic use—is flocked for precise application and smooth glide, without overwhelming the lips with excess product.

This structure enhances consumer satisfaction while reducing formula waste, especially useful in high-viscosity or high-pigment lip gloss applications.

According to a 2024 industry report by Beauty Packaging Magazine, over 70% of cosmetic brands prioritize applicator functionality in primary packaging to reduce return rates and increase product usability.

Custom Options, Seamless Fit

-

Applicator & Stopper Variants

Different applicator heads (e.g., slanted, flat, or pointed) can be substituted depending on viscosity and intended application zone.

-

Stopper designs can be tailored to manage tighter product flow for thinner serums or more open diameters for thicker lip oils.

-

These options can be supplied pre-installed during production or separately for downstream assembly workflows.

-

-

Mold Customization Support

For brands looking to launch exclusive collections or enter new regional markets, Topfeel offers custom mold design services.

-

All custom molds are built using high-precision tooling with ±0.3mm tolerance range, ensuring structural consistency across large volume orders.

-

-

Stands Out in Flat Display

The tube’s flat vertical silhouette makes it easier to align in grid-based shelf displays, and it maximizes visibility in point-of-sale (POS) and planogram arrangements.

-

In markets with crowded lip product SKUs, such as North America and Southeast Asia, shelf optimization can translate to increased velocity.

Based on a 2023 study by Mintel, packaging structure affects purchase decisions more than color when viewed online—making this structure an asset in digital marketplaces.

FAQs

-

Flat profile enables high-density shipping and shelf stocking

-

Vertical silhouette aligns well with POS and planogram displays

-

Reduced width-to-height ratio suits e-commerce flat lays

-

All exterior parts of the MA-50 are made from PETG, offering strength, compatibility, and recycling benefits.

-

Unified PETG system: cap, bottle, and stick

-

Recyclable and environmentally conscious

-

Crack-resistant and thermally stable for decoration methods

-

Avoids stress whitening during handling or drops

-

Applicator types: slanted, flat, or pointed

-

Stopper variants for different formula viscosities

-

Custom mold support with ±0.3mm tolerance

-

Yes, its PETG construction ensures stable dimensional behavior under thermal stress, making it highly compatible with heat-based decoration and automated filling equipment.

Absolutely. Stopper designs can be tailored to adjust product flow for different viscosities, ensuring a smooth and controlled consumer experience across various formula types.

Unlike round cosmetic tubes, the MA-50 offers a space-saving flat design, precision applicator system, and full PETG body that supports custom molding and premium presentation.