Want Your Brand to Shine? How to Get Your Lipgloss Tube Imprinted Logo!

Your lipgloss tube imprinted logo isn’t just a pretty face—it’s the loudest whisper your brand will ever send across a crowded shelf. In an industry where packaging decides fate faster than product performance, that little logo might be your biggest power move. Think of it like a handshake before someone even opens the box.

According to NielsenIQ, 64% of consumers say packaging influences their purchase decisions in-store. That’s not fluff—that’s dollars walking out the door if your branding doesn’t pop with precision and polish.

So why do so many beauty brands mess this up? Sloppy materials, clashing color codes, or printing that fades faster than last year’s TikTok trend. But don’t sweat—we’re about to untangle the whole mess and get you shining in all the right places.

4 Key Benefits of an Imprinted Logo on Lipgloss Tubes

Adding a lipgloss tube imprinted logo isn’t just about looks—it’s a smart branding move that packs visual punch and builds trust with your buyers.

Establishing Brand Recognition through Lipgloss Tube Imprinting

- Boosts brand identity: A crisp, visible imprint helps people instantly recognize your product on shelves or in purses. It’s like a mini billboard.

- Increases customer recall: When folks see your gloss again, they remember the vibe it gave them. That’s how repeat buys happen.

- Strengthens market presence: The more consistent and clear your logo is across products, the louder your brand voice becomes in a crowded beauty space.

The logo visibility on each lip gloss tube acts like a signature—subtle but powerful. It tells customers who you are without saying a word, building long-term brand awareness and solidifying your spot in their daily routine.

Enhancing Aesthetic Appeal with Custom Color Matching

🟢 Custom color matching ensures every lipgloss tube not only looks high-end but also feels aligned with the rest of your branding.

🟢 It’s not just about pretty hues—it’s about precision. Matching tones to align with existing palettes gives off major visual appeal, making displays cohesive and eye-catching.

🟢 Want that sleek Instagram-worthy packaging? Pairing exact brand colors with an imprinted logo creates that scroll-stopping effect people love to share.

When everything matches down to the last detail, it elevates the entire presentation. That kind of polish screams quality—and yes, customers notice.

Increased Perceived Value and Customer Trust

Grouped Benefits:

- Perceived value: A well-designed lipgloss tube featuring an engraved or printed logo immediately feels more luxe.

- Customer trust: People associate thoughtful packaging with reliable products—it’s psychological.

- Brand credibility: Consistency in visuals signals professionalism; no one trusts sloppy branding.

- Consumer confidence: When buyers feel good about how something looks, they’re more likely to believe in its performance too.

According to NielsenIQ, 41% of consumers will continue to purchase a product because they prefer its packaging cite. So yeah—your glossy little tube matters big time.

Eco-Friendly Practices: Aligning Your Brand with Sustainable Values

♻️ More than ever, shoppers want brands that reflect their values—and sustainable cosmetic packaging is top-tier important now.

♻️ Using biodegradable materials for lipgloss tubes while still rocking an imprinted logo shows you’re serious about both style and substance.

♻️ That combo hits hard for today’s eco-conscious crowd—they’re looking for brands practicing real-deal green moves like compostable plastics or refillable formats.

By aligning visual branding with strong environmental responsibility, you’re not just selling gloss—you’re selling a message rooted in modern ethical consumerism and solidifying long-term loyalty through shared values.

Choosing the Right Material for Your Lipgloss Tube Logo

Picking the right tube material isn’t just about looks—it affects your lipgloss tube imprinted logo quality, sustainability, and even how customers feel about your brand.

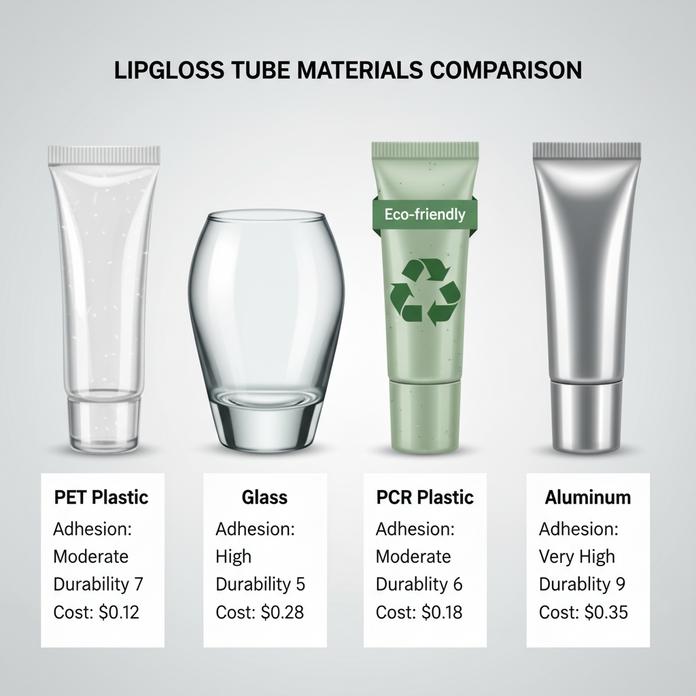

PET Plastic vs. Glass: Which is Better for Imprinting?

• PET plastic gives you flexibility. It’s light, durable, and cheaper to mass-produce—perfect if you’re printing thousands of tubes with consistent logo clarity.

• Glass packaging, though heavier and more fragile, delivers a sleek aesthetic that screams premium. Logos printed on glass tend to pop thanks to its smooth surface and high clarity.

• Cost-wise? PET wins hands down. But when it comes to tactile luxury and shelf appeal, glass edges ahead—especially when paired with metallic inks or UV imprinting methods.

• For brands chasing both affordability and decent imprinting quality, PET is often the go-to. But if you’re trying to wow with a bougie vibe? Glass might be your best bet.

Exploring Eco-friendly PCR Materials for Your Packaging

Sustainability isn’t just trendy—it’s expected now. More beauty brands are turning toward PCR materials, aka post-consumer resin, as their go-to eco-choice.

- These materials help reduce landfill waste by reusing plastics from consumer goods.

- They cut down on carbon emissions during production compared to virgin plastic.

- Using them can boost your brand image among green-conscious buyers—win-win!

♻️ Bonus perk? Most PCR options still work well with modern imprinting methods, although some finishes may slightly affect surface adhesion depending on recycled content levels cite.

If you’re aiming for an earth-friendly image without compromising too much on design flexibility or cost-efficiency, PCR could be your sweet spot in packaging strategy.

Aluminum: The Premium Choice for Luxury Lipgloss Tubes

Let’s talk prestige—aluminum packaging has it in spades. It’s not just about shine; it’s about perception.

▪ Group A – Visual Appeal:

- That sleek metallic finish instantly elevates your product.

- Reflective surfaces enhance visibility of an imprinted logo under store lights. ▪ Group B – Functionality:

- Super durable—no cracks or leaks here.

- Keeps formulas stable inside due to opaque barrier properties. ▪ Group C – Brand Impact:

- Feels luxe in hand—a tactile experience that aligns with upscale branding.

- Signals premium positioning even before someone opens the cap.

| Material Type | Surface Adhesion Quality | Durability Score (/10) | Avg Cost per Unit ($) |

|---|---|---|---|

| PET Plastic | Moderate | 7 | 0.12 |

| Glass | High | 5 | 0.28 |

| Aluminum | Very High | 9 | 0.35 |

That chart pretty much sums it up—if you’re gunning for a top-shelf look and don’t mind spending a bit more, aluminum might be exactly what your next lipgloss tube imprinted logo needs to shine like a diamond (literally).

5 Mistakes to Avoid When Designing a Lipgloss Tube Logo

Designing the perfect lipgloss tube imprinted logo isn’t just about looking good—it’s about doing it right. Avoid these five common pitfalls that could wreck your packaging game.

Overlooking Supplier Certifications: Why ISO 9001 Matters

• Relying on suppliers without proper certifications often leads to inconsistent quality. • ISO 9001 ensures that your packaging partner follows strict quality control protocols cite. • Skipping this step? You risk delays, defects, and even failed compliance audits.

✔ Always ask for proof of manufacturing standards, especially when sourcing custom cosmetic packaging for your brand’s next launch.

💡 Topfeelpack works only with vetted partners who meet international compliance benchmarks—because shortcuts never pay off long-term.

Ignoring Color Accuracy: The Role of Pantone Colors

- Your logo looks fire on screen—but prints dull? That’s a color mismatch issue.

- Using Pantone colors ensures exact shade replication across batches.

- This is vital when matching brand colors with other elements like boxes or labels.

Research indicates that color consistency can boost brand recognition by up to 80% cite. With so many lip glosses out there, nailing your shades using accurate color matching tools like CMYK and RGB systems is non-negotiable.

Skipping the Right Cap Type: Screw Cap vs. Flip Top Cap

▸ Choosing between a screw cap and a flip top cap isn’t just aesthetic—it changes how users interact with your product daily. ▸ A tight-sealing screw cap might be ideal for travel kits, while flip tops offer one-hand convenience for on-the-go touchups.

Think about it this way—your closure isn’t just functional; it defines the product experience from shelf to purse to pocket.

| Cap Type | Functionality | User Preference | Leakage Risk |

|---|---|---|---|

| Screw Cap | Secure & tight | High | Low |

| Flip Top Cap | Fast access | Moderate | Medium |

| Magnetic Closure | Premium feel | Niche | Very Low |

| Twist-Up | Built-in applicator | Trendy | Medium |

Choosing wisely can make or break repeat purchases—especially in saturated beauty aisles where details matter most.

Neglecting Decoration Techniques that Enhance Brand Identity

You’ve got an amazing logo—but how you print it matters just as much as what it says. Here’s why:

• Basic ink printing fades fast under friction or sunlight exposure. • Premium options like hot stamping, UV coating, or even subtle touches like embossing/debossing instantly elevate shelf appeal.

According to Mintel’s Global Packaging Trends, packaging changes are driving 20% of new product introductions, proving that unique decoration is a key differentiator. So don’t cheap out here—your brand identity rides on these little extras.

Topfeel Makeup offers full-service customization for any type of decoration technique, helping you turn every single tube into an eye-catching piece of branded art.

And remember—the right finish doesn’t just protect; it speaks volumes before anyone even opens the cap.

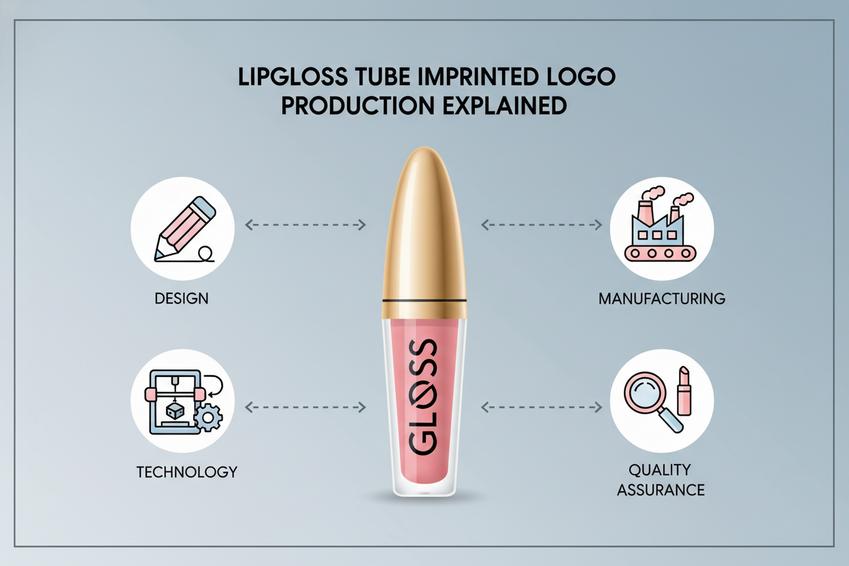

The Process: Lipgloss Tube Imprinted Logo Production Explained

From concept sketch to shelf-ready packaging, here’s how your custom-branded lipgloss tube becomes reality—without cutting corners or style.

Step-by-Step Journey from Design to Production

Every lipgloss brand wants that perfect balance between aesthetics and function—and it starts right here:

- Logo design begins with high-resolution vector files tailored for cylindrical surfaces.

- After artwork submission, digital mockups are generated, showing how the logo wraps around the tube.

- The internal proofing process includes color matching and finish selection—matte, glossy, or metallic.

- Once approved, advanced printing technology like silk screen or hot stamping brings your brand alive on plastic.

- Then comes full-scale manufacturing, where thousands of tubes are molded and decorated per your spec.

- A final check ensures every piece in the initial production run meets visual and tactile standards.

This is how a simple idea turns into a sleek, branded lipgloss tube with an eye-catching imprint that sticks.

Quality Assurance: Ensuring GMP Compliance Throughout

Keeping things tight on quality isn’t just about being picky—it’s about protecting your brand and customers at every turn.

• Routine checks ensure each batch follows strict GMP standards, especially during filling and sealing stages. • Randomized inspections test for leakage resistance, label adhesion, and cap torque under simulated transport conditions. • Every production line has embedded sensors to support real-time alerts when deviations from set parameters occur—this reinforces consistent output across batches. • Final products undergo layered verification protocols including visual review, weight calibration, and barcode validation—ensuring full traceability as per global safety guidelines.

By integrating sharp-eyed oversight throughout the process, Topfeelpack guarantees every single printed lip gloss container meets international compliance expectations while looking fresh off the runway.

Throughout this journey—from sketching a standout logo to verifying batch consistency—you can be sure that each element of your custom-designed lip gloss packaging hits both aesthetic goals and quality benchmarks.

Maximizing Visibility with Effective Lipgloss Tube Imprinted Logo Strategies

Want your lip gloss packaging to turn heads? These tactics help your lipgloss tube imprinted logo shine bright and stick in buyers’ minds.

Utilizing Offset Printing for Standout Brand Messaging

Offset printing isn’t just about slapping ink on a surface—it’s how you make your brand messaging pop off the shelf and into someone’s cart.

- Offset printing allows for ultra-crisp detail, ideal for small fonts or intricate logo icons.

- It supports full CMYK color, ensuring vibrant hues and precise color accuracy.

- Works well with large-volume orders due to its speed and cost-efficiency in mass production.

- Offers consistent output across thousands of units—your logo looks the same on every single tube.

- Great for custom finishes like matte or gloss effects that elevate perceived quality.

- Compatible with various materials used in lip gloss tubes, including plastic and aluminum.

- Ideal when you’re aiming for sharp contrast between background color and the logo imprint.

- Helps maintain long-lasting durability; logos won’t smudge or fade during shipping or use.

No matter how bold or minimalistic your design is, offset printing ensures it lands exactly as envisioned—clean, professional, and unmistakably yours.

Shipping Terms Explained: Which One Suits Your Needs?

Choosing the right shipping setup can save you time, cash, and serious stress when moving branded lip gloss packaging across borders.

• FOB (Free On Board) puts responsibility on the buyer once goods leave the port—cheaper upfront but riskier if delays hit. • CIF (Cost Insurance Freight) means sellers handle freight + insurance; it’s pricier but more secure.

- Understand what you’re paying for—some shipping terms include customs clearance while others don’t.

- Ask suppliers about Incoterms updates—they change periodically based on global trade laws.

★ Want flexibility? DDP (Delivered Duty Paid) gives you door-to-door service but usually comes at a premium rate.

If you’re scaling up fast or testing new markets, aligning your logistics with smart shipping terms, optimized freight, and clear delivery timelines is non-negotiable. That’s where Topfeelpack helps simplify things—you focus on branding while they smooth out the supply chain kinks.

Innovative Marketing Techniques for Enhanced Brand Exposure

More than flashy colors or influencer shoutouts, true visibility starts with strategy baked into every move from product design to launch day buzz.

Step 1: Use user-generated content from real customers rocking their favorite shades—authenticity sells better than any ad campaign ever could.

Step 2: Launch limited-edition drops tied to trending moments—a seasonal twist keeps people coming back just to see what’s new.

Step 3: Partner with micro-influencers who align with your niche audience—they convert better than mega-celebs when it comes to building actual trust.

Step 4: Optimize your packaging for cosmetics aesthetics so that even unboxing becomes share-worthy; remember that your brand exposure begins at first glance of that lipgloss tube label.

Step 5: Mix traditional ads with modern storytelling via reels, TikToks, swipe-ups—it’s not just about being seen but being remembered through creative digital footprints.

By embedding these strategies into every layer—from product design to post-purchase engagement—you’re not just selling lip gloss; you’re creating a brand experience worth talking about.

FAQs about Lipgloss Tube Imprinted Logo

1. How does an imprinted logo influence lipgloss tube branding?

- Builds a memory link between the product and its visual mark on every use.

- PET Plastic, Aluminum, or Glass materials can carry Screen Printing or Hot Stamping details that stand out under retail lighting.

- A consistent logo across mascara tubes, eyeliner packaging, and powder compact cases creates emotional familiarity for buyers—brand loyalty in tangible form.

2. What decoration techniques enhance the appeal of custom lip gloss tubes?

Short description + bullet structure: It’s all about surface storytelling—the art meeting chemistry.

• Screen Printing: Classic method with crisp edges for daily-use tubes.

• Hot Stamping & Metallization: Adds depth through metallic finishes with instant luxury perception.

• Offset Printing & Labeling: Allows detailed designs while keeping Pantone color authenticity intact.

3. Which materials work best for durable yet elegant lip gloss packaging?

Natural combination style—each material speaks differently but shares one purpose: beauty protection.

1️⃣ PET Plastic: Flexible, cost-effective; suits high-volume lines with Screw Cap sealing options.

2️⃣ Glass or Acrylic: Define premium personality; perfect with Dropper Caps for foundation bottles or Pump Caps for skincare assortments.

3️⃣ Aluminum & PCR blends: Sustainable stars carrying eco-friendly charm under REACH Compliance and ISO 9001 certification.

4. Why is Pantone accuracy crucial during logo imprint production?

Symbol-style + artistic branch line → it’s not just color—it’s recognition essence ✳️ consistency builds trust ✳️ deviation erodes prestige ✳️

Each hue affects how consumers perceive quality; precise color matching across opaque to transparent finishes ensures every item from Eyeliner Packaging to compact cases sings in harmony under GMP rules.

5. What are the shipping preferences when ordering customized cosmetic packaging internationally?

Short description + summary table element: logistics shape brand reach—from factory heart to beauty shelf glow!

| Term Type | Best Usage Situation | Common Material Flow |

|---|---|---|

| FOB Shanghai | Ideal for bulk export control | PET Plastic / Eco-friendly PCR |

| CIF Destination Port | Balanced risk sharing on sea shipments | Aluminum / Glass |

| EXW Factory Pickup | Direct sourcing by global distributors | Mixed-material lots |

| DDP Delivery / Express Shipping | For limited-edition releases needing speed | Acrylic / Metallic Finishes |

Every choice reflects rhythm between business scale and creative touch—a dance where your imprinted logo travels safely into new markets each time a tube arrives unopened yet full of promise.

References

Know Your Market: Leveraging Package Design to Influence Buyers – nielseniq.com

Cosmetic Packaging with PCR – containerandpackaging.com

Why Brands Should Work with an ISO 9001:2015 Certified Packaging Supplier – johnsbyrne.com

Color Psychology for Startup Branding Success – maccelerator.la

2025 Global Packaging Trends – mintel.com