How to Pick the Right Lip Gloss Tube Containers

Picking the right lip gloss tube containers might not sound like a big deal—until a batch leaks, caps crack, or your product fades under the spotlight. For brands buying in bulk, packaging isn’t just plastic—it’s profit, perception, and peace of mind.

You’ve probably had one of those moments: your supplier swears the tubes are airtight, but your customers end up with gloss in their purse lining. Yeah, not a good look. And when you’re selling online, blurry prints and dull finishes won’t cut it either.

“It’s not just about holding the formula—it’s about holding up your brand,” says a senior designer at Topfeel.

This guide breaks it all down. No fluff. Just smart choices that save you headaches and help your gloss stand out—right where it counts.

How can lip gloss tube containers cut your costs?

Looking to squeeze more profit from your packaging spend? These tips will help you keep costs low without skimping on quality.

Bulk plastic tube sourcing for lower per-unit pricing

| Supplier Region | Avg. MOQ (Units) | Avg. Unit Price (USD) | Volume Discount (%) |

|---|---|---|---|

| Southeast Asia | 10,000 | 0.13 | 15% |

| Eastern Europe | 8,000 | 0.16 | 10% |

| China Mainland | 20,000 | 0.09 | 20% |

Bulk purchasing plastic tubes for lip gloss isn’t just smart — it’s essential. When you hit high MOQs, suppliers start throwing in volume discounts and bonus freight perks like reduced pallet space or free storage for 30 days. That’s how you bring down your unit cost.

Quick wins for cost-cutting:

-

Choose standardized packaging materials instead of fully custom molds.

-

Negotiate yearly contracts to lock in low rates.

-

Work with suppliers that offer logistics partnerships — fewer hands, lower margins.

It’s not about being cheap — it’s about being clever.

Refillable PP designs to maximize wholesale value

Refillable PP designs don’t just look sustainable — they actually are. Polypropylene is tough, lightweight, and ultra-cost-effective in the long run. These refillable packaging options allow brands to position themselves as eco-friendly while reducing the cost of repeat sales.

-

Why brands love PP: It resists wear, stands up to greasy formulas like lip oils, and doesn’t crack easily.

-

Wholesale win: Fewer full-package reorders when refills become part of your lineup.

-

Sustainability sells: Buyers are more likely to restock when they know they’re backing a product that minimizes waste.

Slim PETG containers reducing shipping and storage fees

Shipping adds up fast — and PETG containers with slim designs are a hidden weapon against bloated logistics costs.

-

Slim = space saving. You can pack more units per pallet and per box.

-

Lightweight = less freight. PETG is tough, transparent, but lighter than acrylic.

-

Durable = no losses. Fewer breakages in transit mean fewer replacements or customer complaints.

Pair that with smart stacking shapes — like round and oval slim tubes — and you’re looking at major freight reduction over time.

Recycled ABS materials and volume-discount opportunities

Recycled ABS is not just eco-marketing fluff. It’s a smart material move for brands hunting sustainable value without stretching budgets.

♻️ Recycled = lower costs: Some suppliers offer pre-sourced recycled ABS plastic at a lower rate than virgin material. It’s a win-win: green points + cost savings.

📦 Volume discounts: ABS blends often qualify for bulk manufacturing promos, especially when you standardize mold specs across multiple SKUs.

🧠 Smart sourcing: Brands opting for recycled ABS often benefit from government incentives or subsidies, depending on region — and that means lower effective costs overall.

You save the planet. You save money. You stay ahead of the curve.

Messy applicators? Try spill-proof lip gloss tube containers

Leak-proof neck and stopper designs for clean dispensing

Leak-proof necks and stopper tech can stop leaks cold and keep things looking sharp — no sticky mess, no wasted gloss.

-

Improved sealing matters: A smartly designed container neck helps the stopper sit tight, giving you a secure, spill-proof fit — even in transit.

-

Clean dispensing builds trust: Users notice when tubes stay clean after use. Better closure systems mean fewer wipe-downs and more satisfaction.

-

Wholesale benefits: Fewer defective returns, better reviews, and cleaner branding — that’s the leak-proof power combo for mass orders.

-

The Topfeel touch: According to a packaging engineer at Topfeel, “Reinforced neck angles and widened stoppers reduce leak incidents by up to 38% during shipment.”

Silicone tip applicators ensuring controlled, drip-free application

Getting gloss in the right place — not all over the place — is what today’s silicone tip applicators do best.

-

Soft tip = comfy swipes for the user

-

Smooth dispensing = no gunky build-up

-

Hygienic shape = keeps things clean inside and out

-

Precise shape = perfect for lip gloss, lip serum, and even tints

Controlled application isn’t just about function; it’s a feeling. Brands that care about the experience choose soft applicator materials and clean-flow design for both hygiene and satisfaction. Bonus: drip-free tubes reduce complaints and returns in wholesale sales.

Squeeze-tube mechanism that prevents product backflow

No one wants sticky gloss tubes, wasted product, or clumpy air-filled messes. Smart squeeze-tube packaging is the fix — and wholesale buyers know it’s a game changer when it comes to product integrity and user experience.

Here’s how the right squeeze-tube mechanism saves your bottom line:

-

One-way valve design: Keeps air from flowing backward into the tube after dispensing, extending shelf life and preventing oxidation — a big deal for sensitive formulas like lip oil or lip plumper.

-

Controlled flow outlet: Reduces sudden gushes or inconsistent application. This means less mess, more control, and less product wasted.

-

Airless squeeze-tube construction: Prevents contamination while maintaining internal pressure balance. These are ideal for maintaining consistency from the first use to the very last.

💡 Why it matters for wholesale:

-

You minimize leakage complaints during shipping

-

You reduce spoilage and return rates

-

You impress end users with silky-smooth dispensing every time

Quick Tip: Pair squeeze tubes with slim, recycled plastic builds to shrink both your costs and carbon footprint.

Color fading? Opaque lip gloss tube containers keep hues true

UV-blocking PP tubes preserving lip gloss pigment

UV rays are sneaky enemies when it comes to fading lip gloss color. That’s where UV-blocking PP tubes come in strong.

-

UV protection built-in – Polypropylene (PP) naturally offers solid UV resistance. When enhanced for packaging, it adds another layer of pigment stability.

-

Better gloss retention – Your lip gloss stays vibrant longer, resisting that annoying light degradation.

-

Budget-friendly material – PP is one of the most affordable options in bulk, making it perfect for wholesale needs.

-

Lighter weight for shipping – PP tubes are light and tough, cutting down your logistic headaches.

Frosted SAN finish for enhanced color stability

Want that sleek, high-end look without compromising the formula? A frosted SAN finish gives you both: color integrity and that cool, muted surface.

-

Why SAN? Styrene-acrylonitrile (SAN) balances toughness with transparency. When frosted, it reduces direct light exposure, helping preserve product hue.

-

Color integrity matters – Bright lights can kill color vibes. SAN’s light diffusion protects lip tints and balms from fading.

-

Bonus: Aesthetic appeal – The frosted look screams premium. It’s ideal for clean beauty brands or luxury lip oils that want to stand out on shelves.

-

Hue protection FTW – Paired with leak-proof closures, SAN-frosted tubes are reliable and chic.

This combo? Total win for both product performance and packaging aesthetic.

Cylindrical acrylic containers with built-in light filter

These containers blend visibility and protection like champs. Acrylic’s natural clarity lets shoppers peep the lip gloss inside, while built-in UV filtration ensures it won’t fade under the spotlight.

· Clarity meets color protection.

· Toughness meets shelf appeal.

· Premium meets practical.

Cylindrical shapes are no accident either — they roll well into production lines, stack neatly in boxes, and make your gloss pop in photos. Acrylic (PMMA) is seriously durable too, so you’re getting a tube that won’t crack under pressure — literally.

If your product sits in bright lighting (hello, storefronts), this is a wholesale no-brainer.

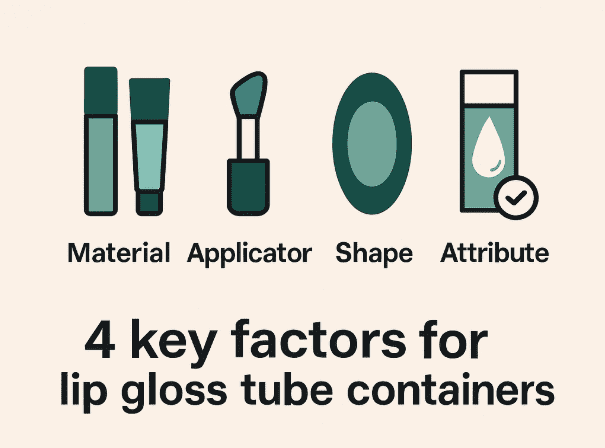

4 key factors for lip gloss tube containers

Choosing the right lip gloss tube isn’t just about looks — these four key factors shape quality, performance, and the wholesale buying decision.

Material selection: comparing plastic, PETG, and PCTA

When sourcing in bulk, the material isn’t a small detail — it’s everything. From durability to clarity, here’s how plastic, PETG, and PCTA stack up:

-

Plastic: Basic, budget-friendly, and great for short-term products. However, it may fall short in clarity and long-term durability.

-

PETG: Clear like glass but tougher. It resists cracks and can withstand a few tumbles during shipping.

-

PCTA: The premium pick. High transparency, solid chemical resistance, and feels luxe in-hand. It’s a favorite among brands aiming for upscale appeal.

Applicator choice: doe-foot, brush applicator, or flocked tip

Getting the right wand for your gloss isn’t just cosmetic — it’s about how the product performs in the customer’s hand.

-

Doe-foot: Soft and angled, these are a fan favorite for lip glosses and lip oils. They give a smooth glide and absorb just the right amount.

-

Brush applicator: Think of this as your go-to for thinner formulas like lip serums. Offers flexible, full coverage but may fray over time.

-

Flocked tip: Precision lovers adore this one. The texture grabs product better, and it delivers sharp, clean lines — perfect for lip tints or lip plumper formulas.

-

Hygiene tip: Sealed applicators help maintain cleanliness, which matters more for products like lip treatments.

👉 Match the applicator to the product content and usage vibe — wholesale buyers can’t afford mismatched functionality.

Shape considerations: round, oval, flat, or slim designs

Not all shapes are just for show. Each one has real-world benefits:

-

Round: Classic and versatile, often the most cost-effective to produce in bulk.

-

Oval: Comfortable to grip and has a slightly more premium feel — a hit for lip serums.

-

Flat: These are space-savers. Great for travel-size lip treatments and organized retail displays.

-

Slim: Chic and minimal, these scream “luxury” and are a growing trend in lip balm packaging.

✱ Pro tip: Aesthetic meets ergonomics. Choose a shape that fits both your product’s purpose and your brand’s story.

Attribute priorities: transparent vs. opaque vs. leak-proof

Let’s break it down by feature — because when it comes to packaging, your gloss deserves more than “just cute.”

-

Transparent:

-

Great for showing off lip tint or glittery lip gloss.

-

Boosts product visibility — especially in online listings.

-

-

Opaque:

-

Best for lip treatments with sensitive ingredients.

-

Protects content from UV and light degradation.

-

-

Leak-proof:

-

A must-have attribute for wholesale.

-

Prevents mess during shipping, reduces return rates, and builds trust.

-

🧠 Each attribute contributes to the container’s integrity filter — where clarity, protection, and durability align with your formula’s needs.

Standard vs. Custom lip gloss tube containers

Sometimes, deciding between standard containers and custom containers feels like choosing between a ready-made suit and a tailor-made outfit. One saves you time and money, the other turns heads with unique design. For buyers in the wholesale makeup packaging space, this choice can affect everything—from budget to brand perception—so let’s talk real pros, cons, and what the folks at Topfeel think when helping clients make the right call.

💬 “If you want speed and low MOQs, standard’s your friend,” says Lily Zhao, Senior Project Manager at Topfeel. “But if you’re after next-level branding and don’t mind a longer lead time, custom all the way.”

Here’s how the two stack up:

| Feature | Standard Containers | Custom Containers | Key Consideration |

|---|---|---|---|

| Design Flexibility | Basic shapes, colors, and finishes only | Any shape, color, finish—endless design options | Do you want to stand out visually? |

| Production Time | 10–15 days (in-stock models) | 30–60 days, depending on complexity | How fast do you need them? |

| MOQ | As low as 1,000 pcs | Typically 5,000 pcs or more | Can your budget meet custom MOQs? |

| Branding | Limited space for customization | Full surface customization, embossing, logo print | Is branding central to your sales pitch? |

🔢 Top 3 things to ask yourself before picking one:

-

Are you just starting out or scaling up? Newer brands often start with standard containers to test the market without burning cash. You’ll find PETG, PP, and acrylic options readily available with basic applicator types like doe-foot or squeeze tubes.

-

Is your brand all about aesthetics and differentiation? For bold packaging statements—like a square lip oil tube with a metallic wand and frosted finish—custom containers deliver that edge. Plus, you can go wild with applicator types and finishes that scream high-end.

-

Do you need flexibility or control? With standard models, you’re working with preset shapes and materials. Custom lets you control everything—down to orifice size and applicator softness.

📌 Pro tip from Topfeel’s design lead Jason Liu: “We often see clients underestimate how long it takes to develop a mold. If you’re heading the custom route, start that process early, especially if your launch is seasonal.”

E-commerce photos: Elevate lip gloss tube containers on white backdrops

Get your gloss tubes popping online with simple styling tips that drive clicks.

Round clear tubes for consistent light reflection

Crystal-clear design shows off product clarity and consistent glow.

-

Light reflection perks:

-

Highlights glossy finish for eyeball-grabbing shots

-

Creates a soft halo that amps up photography lighting

-

Lets the lip gloss color shine through without glare

-

Mini cylindrical containers highlighting product contents

-

Lean, compact design keeps focus on ingredient focus.

-

Sample-size vibe makes viewers feel “gotta try it”.

-

Close-up shots reveal texture and pigment pop.

Flat oval shapes enabling dynamic product layouts These unique flat oval tubes let you craft creative arrangements that stop scrollers in their tracks. Modern aesthetics blend with versatile display options—lay them side by side or stack at angles to underscore your brand’s personality.

Conclusion

Picking the right lip gloss tube containers isn’t just a box to check—it’s a make-or-break detail. I’ve heard from plenty of folks in the biz who’ve dealt with leaky tubes, faded colors, or stock that just didn’t sell because the packaging looked cheap. It’s like wrapping a designer dress in a grocery bag. Doesn’t matter how great the product is—if the packaging flops, so does the sale.

Here’s what I always tell friends sourcing in bulk:

-

Pick the right material. PETG’s got that high-end shine, but PP’s the workhorse.

-

Watch the applicators. A bad one will have customers tossing your gloss in the trash.

-

Shipping matters. Flat or slim tubes cut costs—and fit more on the pallet.

-

Want bold color that lasts? Go frosted or opaque. Simple fix, big difference.

As packaging consultant Carla James once said, “The tube isn’t just the vessel—it’s the handshake before the sale.”

Bottom line? Don’t guess—get samples, ask questions, and choose packaging that works as hard as your product does.