Simple Steps to Customize Your Empty Lip Gloss Tube Design

If your brand’s story starts with a wand and some shimmer, then the empty lip gloss tube is your stage. Think of it less like packaging and more like the opening act—because what’s outside draws them in before they ever swipe the applicator. Now, here’s where most folks hit a wall: too many choices, not enough clarity. Shapes, sizes, wipers? It’s like picking toppings at an all-you-can-eat sundae bar—sweet but overwhelming.

“Packaging isn’t just form—it’s function dressed in drag,” says Ava Lin, Senior Designer at Topfeel (2024 Q1 Packaging Trends Report). “We see brands spend months on formula development… only to wrap it in generic tubes that say nothing.”

Here’s the kicker: flashy doesn’t always mean functional. And simple shouldn’t mean basic either. You want something that feels good in hand and pops on camera—without playing Russian roulette with material specs or MOQ nightmares.

This guide strips away the guesswork so you can skip straight to the good part: creating custom tubes that look made-to-measure without costing you sleep—or shelf appeal.

Key Points to Charm Every Shelf: A Quick-Styling Primer on the Empty Lip Gloss Tube

→ Material Matters: Choose from PET, acrylic, PCR, ABS, or glass depending on your formula’s needs and sustainability goals.

→ Shape Says It All: Cylindrical for classic appeal, oval for ergonomic handling, or go custom to stand out—shape influences both aesthetics and function.

→ Decoration Delivers Impact: Elevate your brand with silk screen printing on PET, hot stamping on acrylics, or full Pantone spray coating for color precision.

→ Volume Variety Wins: From 5ml travel-friendly tubes to 15ml long-wear formats—size selection should match consumer habits and retail positioning.

→ Component Compatibility Counts: Ensure seamless fit between wiper inserts, screw caps, sealing rings and tube body to avoid leaks and product waste.

→ Templates Save Time: Use ready-made design templates (like the 10ml square mockup with metallization) to streamline production without sacrificing visual flair.

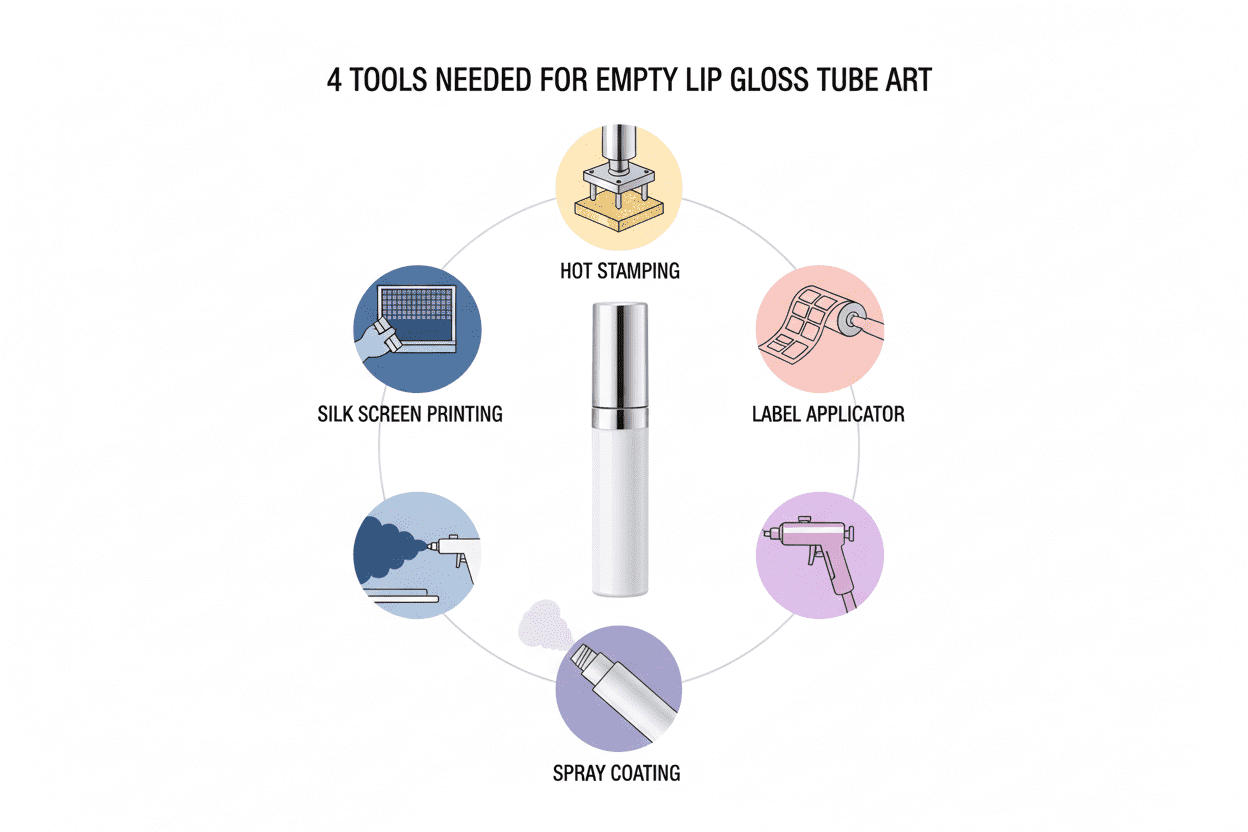

4 Tools Needed for Empty Lip Gloss Tube Art

From bold graphics to sleek finishes, these four tools bring life to every gloss tube makeover. Each tool plays its part in the creative magic.

Silk-Screen Printing Setup for PET Plastic Tubes

Creating eye-catching designs on PET tubes calls for a reliable silk-screen printing setup. This isn’t just about slapping on ink—it’s about precision and staying power.

• A solid frame holds the mesh tight, keeping your stencil crisp and clean.

• The right type of inks, especially UV-curable ones, bond well with smooth plastic surfaces like PET.

• A quality squeegee ensures even pressure across the tube, avoiding streaks or smudges.

• You’ll need custom-cut stencils, tailored to fit cylindrical shapes without distortion.

This setup is perfect when you want logos or patterns that pop and last through wear and tear—like, say, bouncing around in a purse all day.

Hot Stamping Station for Opaque White Acrylic

When you’re working with glossy white acrylic tubes that need a luxury upgrade, nothing beats a clean hit of metallic foil from a proper hot stamping station.

Grouped Essentials:

— A precise heating element that maintains consistent temp throughout the stamping cycle; no scorch marks allowed.

— Rolls of high-shine or matte finish stamping foil, available in everything from rose gold to holographic chrome.

— Pressure control mechanisms so each press applies evenly across curved acrylic surfaces without warping them.

With this gear dialed in, your opaque tubes go from “meh” to high-end boutique shelf-ready with just one press.

Label Application Tools for 8ml Eco-Friendly PCR Designs

Labeling smaller PCR-based tubes can get tricky fast—but not if you’ve got the right lineup of tools built specifically for tight curves and eco-conscious materials.

Grouped Toolkit:

• An ergonomic handheld or automated label applicator designed specifically for small-diameter containers like 8ml tubes.

• Pre-cut adhesive-backed labels made from recyclable stock that adheres securely to PCR material without bubbling up over time.

• Fine-tuned alignment guides help ensure each label lands perfectly straight—even when you’re cranking out dozens at once.

These tools make sure your sustainable packaging doesn’t look DIY—instead, it screams “professional” right off the shelf.

Precision Spray Coating System on Custom-Matched Pantone Finishes

Here’s where things really get personal: finishing each gloss case with an exact-match Pantone shade using a fine-tuned spray system gives it serious brand identity vibes—and yes, we’re talking legit color science here.

| Component | Function | Customization Level | Notes |

|---|---|---|---|

| Spray Gun Nozzle | Controls spray width & density | High | Adjustable tips needed |

| Color Mixing Chamber | Blends pigments accurately | Very High | Matches Pantone standards |

| Coating Material | Provides surface protection | Medium | UV-resistant options available |

| Rotating Fixture | Ensures even coverage on curves | Moderate | Essential for cylindrical tubes |

By syncing your coating system with exact Pantone references, you’re not just painting—you’re branding at the molecular level. That’s how standout packaging gets made today—even Topfeel only recently upgraded their own systems to match this level of detail.

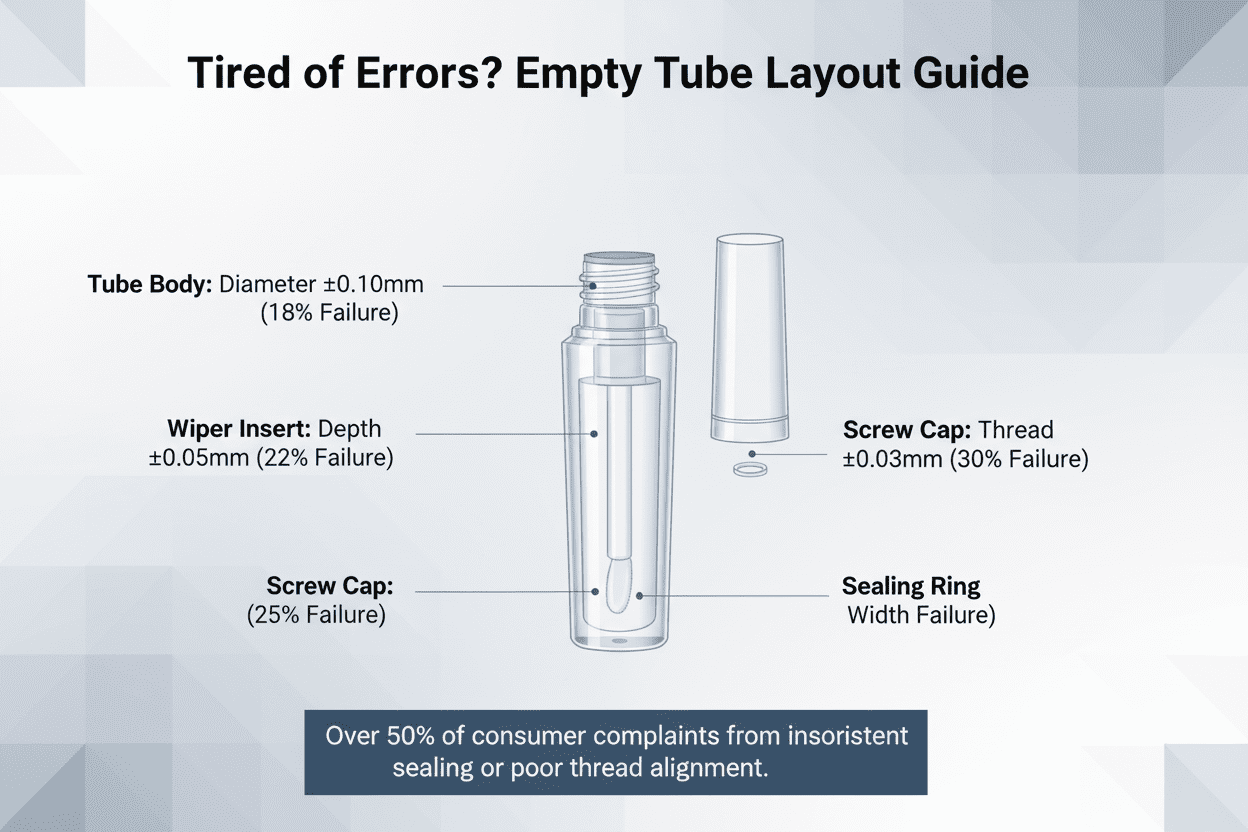

Tired of Errors? Empty Tube Layout Guide

Getting the design right on an empty lip gloss tube can feel like threading a needle blindfolded. This guide helps you avoid those common layout fails and nail precision.

Aligning Tube Body Dimensions for 12ml Cylindrical Shapes

• Always check that the total height of your tube body matches cap compatibility specs. Even a millimeter off can ruin the fit.

• Stick to standard wall thicknesses—going too thin warps under pressure, while too thick wastes material and adds weight.

• Maintain uniform diameter across the full length of the cylindrical shape for even filling and visual balance.

Designers often overlook internal volume loss caused by shoulder tapering, so always factor that into your final dimension checks when working with a compact format like 12ml tubes.

Perfect Wiper Insert Placement to Eliminate Product Buildup

- Measure neck inner diameter precisely before selecting your wiper insert.

- Ensure insertion depth is consistent across all units—this prevents uneven product flow.

- Test with actual formula viscosity; some inserts work better with thicker glosses than others.

- Avoid sharp ridges near the seating zone, which can cause clumping or tearing during use.

A poorly placed wiper means wasted product and messy application—both instant turn-offs for users trying out new gloss formats.

Ensuring Seamless Screw Cap Fit on Custom Oval Molds

★ Match thread pitch between tube neck and screw cap to prevent stripping over time.

★ Use digital calipers to verify oval mold tolerance levels are within ±0.05mm—caps won’t align otherwise.

★ Choose materials with similar thermal expansion rates; mismatched ones warp after hot-fill processes.

Even if your mold looks perfect, don’t trust it until you’ve tested cap twist resistance under real-world torque conditions using automated testers or manual stress testing kits.

Sealing Ring Margins: Preventing Leaks in 15ml Designs

Long gone are the days when sealing was just about snapping things shut tight enough. For modern-day tubes, especially around the 15ml range, it’s all about precise margin control on your sealing ring surface area.

When margins are too narrow, leaks happen under pressure or altitude changes during shipping; too wide, and you risk unsealable gaps due to uneven compression forces along curved edges—especially tricky with flexible plastics or hybrid barrier layers found commonly in mid-size gloss packaging formats.

Scientific Table – Tolerance Ranges for Common Lip Gloss Tube Components

| Component | Ideal Tolerance Range | Failure Rate if Exceeded (%) | Recommended Material |

|---|---|---|---|

| Tube Body Diameter | ±0.10 mm | 18% | PETG |

| Wiper Insert Depth | ±0.05 mm | 22% | LDPE |

| Screw Cap Thread | ±0.03 mm | 30% | PP |

| Sealing Ring Width | ±0.07 mm | 25% | HDPE |

This data comes from Q2–2024 packaging performance audits conducted across Southeast Asian cosmetic production lines by JISPA Research Group.

Market Insight Quote Integration

“Over half of consumer complaints tied to lip applicator products stem from inconsistent sealing margins or poor thread alignment,” according to Mintel’s Global Packaging Trends Report published April 2024.

That stat says it all—you can’t afford sloppy execution when designing an empty lip gloss tube, especially not when user expectations are sky-high thanks to ultra-smooth applicators becoming standard among big-name brands like Topfeel and their recent luxury line releases.

Short Descriptive Segments – Avoiding Overlooked Design Pitfalls

• Don’t forget airflow channels beneath wipers—they help equalize pressure during retraction.

• Keep oval molds symmetrical; even slight asymmetry causes rotation issues.

• Use rounded sealing ring edges rather than flat ones—they compress more evenly under heat-seal machines.

• Always test with formula-in-tube before going into mass production rounds!

Each tweak might seem small alone—but together they make or break how well your tube performs once it’s filled up and shipped out into the world.

Natural Combination – Practical Fixes Across All Stages

Start at CAD modeling: define every curve of that tube body, especially shoulder angles that affect fill volume accuracy later down the line.

Next up? Factor material shrinkage post-molding—it impacts thread alignment between custom oval caps and base tubes more than people expect, particularly when working with dual-layer designs involving both rigid plastic exteriors and soft interior linings typical of high-end gloss tubes around the 12ml–15ml mark.

Finally, run pilot tests using different viscosities through your preferred applicator tip + wiper combo—what works perfectly for one formulation might clog horribly for another unless you’ve got proper clearance built into those tiny contact zones inside your closure system!

No Design Skill? Try These Templates

From eco-friendly builds to luxe finishes, these design-ready mockups make creating your own gloss packaging feel like cheating—in a good way.

Oval 5ml PET Tube Template With Silk Screen Printing

- Oval shapes offer compact elegance, perfect for pocket-size appeal.

- The 5ml fill size suits trial kits and limited runs effortlessly.

- PET Tubes are lightweight yet durable, ideal for brands that ship globally.

- Pre-made Templates reduce design time and cut down on back-and-forth with suppliers.

- Silk Screen Printing delivers crisp lines and vivid color saturation—your logo won’t fade after a week in someone’s purse.

If you’re working with mini gloss formats, this setup nails it without breaking a sweat.

Round 8ml Eco-Friendly PCR Layout With Hot Stamping

• Start by choosing the right Round body that balances grip and aesthetics.

• Opt for an 8ml fill—big enough to last, small enough to carry everywhere.

• Go green with an Eco-Friendly PCR material; it’s recycled, strong, and brand-forward.

• Use the provided layout as your base—no need to reinvent the tube!

Then comes the fun part: add some flair with Hot Stamping, which adds metallic shine without extra bulk or plastic layers.

This combo turns your empty gloss container into something worth showing off on Instagram stories.

Square 10ml Acrylic Mockup Featuring Metallization Accents

Step 1: Pick your base—a sleek Square profile gives off modern vibes instantly.

Step 2: Go for a generous but manageable size like 10ml, ideal for daily use formulas.

Step 3: Choose sturdy yet transparent materials like high-grade Acrylic, letting product color pop through the walls.

Next up, apply those shiny details—subtle or bold—with precision-applied Metallization Accents, giving your branding that luxury edge.

Finally, review in mockup mode before production—it saves you from costly mistakes later.

Cylindrical 12ml Glass Design Blueprint for Label Application

Clean lines define the classic look of a tall, slim tube—and nothing says premium quite like real glass.

Use this detailed blueprint to align every label perfectly on your next batch of cylindrical tubes:

The slightly wider body holds up to 12ml, giving customers more bang per swipe.

Glass not only elevates perceived value but also works beautifully with clear or tinted formulas.

And when it comes time to apply labels? This layout ensures they sit flush every time—no bubbling or slanting here.

Custom Mold 15ml ABS Tube Layout With Integrated Wiper Inserts

- A unique shape starts at the mold level—this one’s fully customizable from cap to base.

- The roomy 15ml size lets you load up on bold pigment blends or plumping serums.

- Tough-as-nails construction thanks to molded-in-place ABS Tubes, built for long-term use.

- Built-in layout guides help you plan everything from embossing zones to applicator fit.

- What sets this one apart? The clever addition of an integrated wiper insert—it wipes excess gloss clean as you pull out the wand.

If you’re tired of off-the-shelf solutions and want something truly yours, this is where Topfeel brings its A-game in packaging innovation.

Which Empty Lip Gloss Tube Sizes Work Best?

Finding the sweet spot between size and practicality in a gloss tube can make or break your product experience.

5ml capacity

- Compact enough to slide into any pocket or mini clutch.

- Great for travel size kits, especially when you’re on-the-go.

- Often used in sample size promotions for new launches.

You’ll spot these tiny tubes in beginner makeup sets or trial packs. Their small footprint makes them perfect for quick touch-ups during commutes or short trips. While not ideal for heavy users, they’re a smart pick for testers and limited editions.

8ml capacity

- Daily use? This is your jam—just the right amount without overkill.

- A moderate size, making it easy to toss into your purse without thinking twice.

- Often found in eco-conscious lines using PCR materials.

According to Mintel’s 2024 Beauty Packaging Report, mid-sized gloss containers like this are gaining traction due to their balance between functionality and sustainability. For brands looking to hit that sweet middle ground, this volume just works.

10ml capacity

• Sits at the intersection of style and substance

• Offers an ample product load without feeling bulky

• Popular among consumers who want something more than basic

This is where most people land when choosing a standard gloss tube. It’s versatile enough for everyday wear but still has enough juice for weeks of use. Think of it as the “blue jeans” of gloss packaging—reliable, flattering, and always in demand.

12ml capacity

- Built for repeat users who don’t want to refill often

- Holds its own on vanities while still being portable

- A go-to choice when creating bold color collections

With its larger size, this option speaks directly to those who love layering their look throughout the day—or anyone who’s loyal to one favorite shade. It also supports designs that show off more dramatic branding styles due to its taller profile.

15ml capacity

→ Designed with pros and long-term storage in mind

→ The largest size, often used backstage or by MUAs

→ Perfect if you hate running out mid-week

This one’s less about convenience and more about commitment—it’s meant to last. Whether you’re stocking up or building kits for clients, these tubes keep you covered longer than most others on the shelf. Some commercial lines even pair them with applicator refills for extended usability.

FAQs

Each size tells a different story. Some brands lean into the 5ml—tiny, portable, perfect for slipping into a clutch on date night. Others go bold with 15ml: generous and long-lasting, built for daily rituals. In between?

- 8ml is popular among eco-conscious labels using PCR plastic

- 10ml adds elegance without bulk—think sleek design meets function

- 12ml strikes balance: compact but satisfying

Color inconsistency kills brand identity fast. A precision spray coating system calibrated to Pantone shades keeps your vision intact across thousands of units. No surprises when that first shipment lands.

It’s not just about looking pretty; it’s about staying power too:

- Silk screen printing pops beautifully on PET and resists wear from handling.

- Hot stamping works wonders on opaque white acrylics, adding metallic flair without peeling over time.

No worries—you don’t need to be an artist to get this right. Choose from ready-made templates shaped around real-world designs like square acrylics with chrome accents or classic cylindrical glass forms. These mockups take the guesswork out so you can focus on what matters: your product.

That tiny rubber ring inside—the sealing margin—is more important than it looks. If it’s off by even half a millimeter during production, pressure builds up and boom… leakage during shipping or use becomes inevitable, especially in high-volume formats where there’s more formula trying to escape.

Crooked labels scream amateur hour—but fixing that isn’t hard if you prep smart:

- Use label applicators designed specifically for curved surfaces (like round PCR bottles)

- Always test dimensions against physical blueprints before any full run begins

Even one misaligned batch can throw off your entire launch vibe—don’t let it happen!