MB-26 ODM Dual-End Blush Stick with Sponge Applicator

MB26 is a durable twist-up makeup container for blush or foundation. It offers a built-in sponge applicator and OEM-ready customization to fit your brand.

Capacity: 3.5g

Material: AS, ABS, PP, SBR

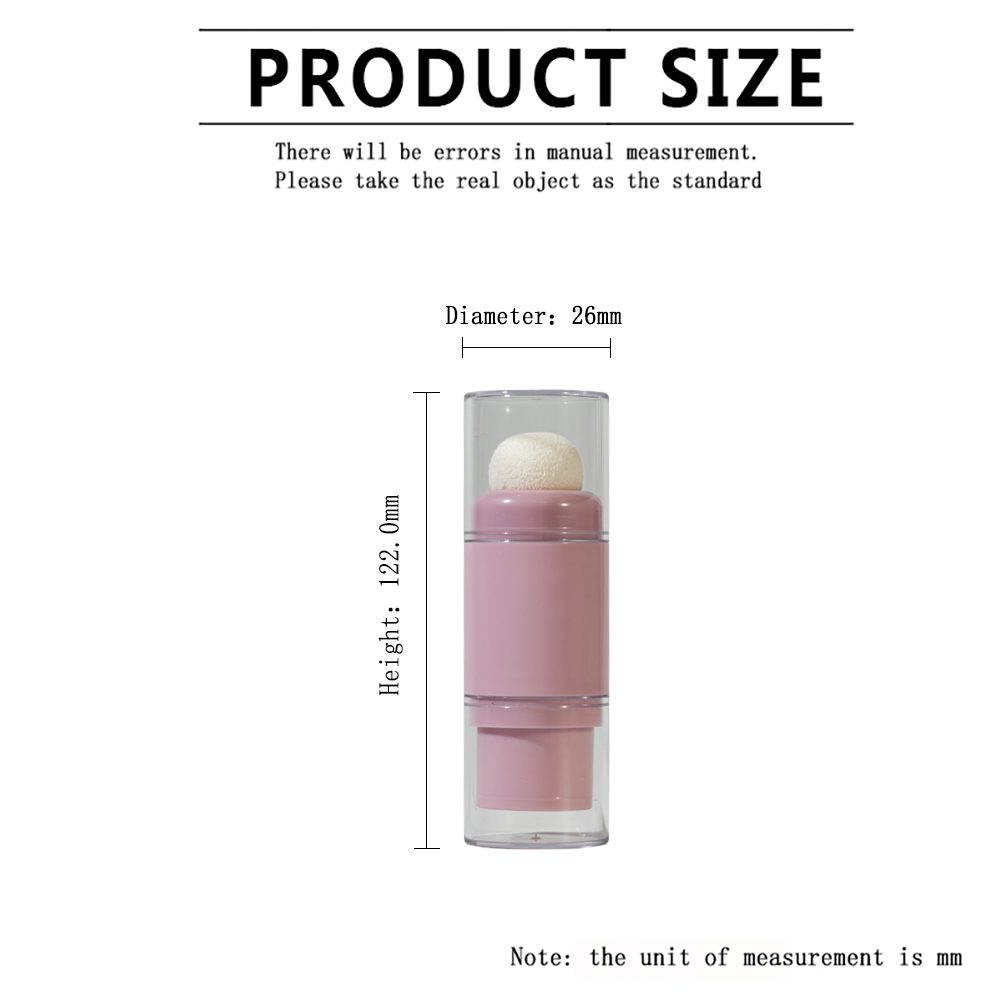

Size: H81mm x D26.5mm

MOQ: 12,000 pcs

Application: Blush Stick, Highlighter Stick, Foundation Stick

Service: Private Label, OEM, ODM

Logo: Custom Logo

Handling: Custom color and printing

Features and advantages

-

Features a clear, airtight twist-up design with precise dispensing and full product visibility for enhanced usability.

-

Integrated sponge applicator offers convenient, tool-free application and hygiene for mobile, everyday makeup routines.

-

Modular structure supports mold, finish, and applicator customization to meet diverse branding and packaging needs

You May Also Like

View Product Details

Dual-End Precision Design

-

Twist-Up Control System

This mechanism enables consumers to dispense product smoothly and in controlled increments.

-

The PP inner tray and tail form a reliable spiral structure designed for low-resistance turning.

-

Supports accurate dosage delivery and minimizes internal friction, extending component life during repeated use.

-

-

Visible and Airtight Construction

Product visibility is a key packaging demand for today’s beauty brands. MB26 achieves this without sacrificing hygiene.

-

A transparent AS cap and base let consumers clearly view the product level, reducing overuse or premature disposal.

-

The tight-sealing mechanism minimizes air exposure, which is critical for preserving formula stability—especially for sensitive pigments or skincare-infused formulas.

-

-

Built-In Sponge Applicator

This SBR sponge head is soft enough for facial use yet firm enough to maintain application precision.

-

It eliminates the need for external brushes, allowing for direct and even distribution of cream or stick-based formulas.

-

The material selection (SBR) ensures compatibility with oil- and emulsion-based products, reducing absorption loss.

-

Mounted securely on the top end, it complements the twist-up system for a fully contained unit that supports fast, hygienic usage.

Flexible Brand Customization

Topfeel offers OEM and ODM services that align with the product’s modular design:

-

Moldable components (cap, spiral body, tail, applicator) can be produced in custom materials, finishes, or surface treatments including silkscreen printing, hot stamping, and spray coating.

-

Applicator types and sponge densities may be modified to meet specific formula or performance requirements.

-

Full color matching and branding integration can be applied without altering structural dimensions, maintaining production efficiency.

FAQs

-

A twist-up mechanism for precise dosage control

-

Airtight sealing to maintain formula integrity

-

SBR sponge applicator for even product distribution

-

-

Customizable mold designs that reduce packaging waste

-

Compatibility with PCR or recyclable PP materials upon request

-

-

Transparent AS caps provide airtight seals

-

The applicator is integrated into the twist-up structure

-

No external tools are required, reducing exposure risk during use

-

You can modify colors, finishes, logos, and surface treatments like silkscreen printing or hot stamping, all without altering the internal mechanism or affecting filling compatibility.

-

Private mold design and rapid prototyping (as fast as 3 days)

-

Surface decoration (spray coating, printing, hot stamping)

-

Formulation compatibility consulting via the Topfeel Beauty sub-brand

-