Unlock Your Brand’s Potential with Premium Custom Lip Gloss Tubes

Blink and you’ll miss it—that split-second when someone picks up a lip gloss off the shelf. That moment? It’s make-or-break. In an aisle bursting with sparkle, shimmer, and shine, custom lip gloss tubes are your brand’s red carpet dress—either unforgettable or forgettable.

Here’s the kicker: 72% of consumers say product packaging influences their buying decisions (according to Ipsos). Not just what’s inside—but how it looks in their hand, on their feed, in that makeup bag they carry everywhere. Looks aren’t everything… unless you’re talking about cosmetics.

You don’t want your product whispering on a crowded shelf—you want it singing lead vocals under a spotlight. Drab tubes feel like last year’s leftovers; design-forward ones scream deluxe from swipe one.

And if you’re scaling up? You need consistency tighter than winged eyeliner at 8am.

Essentials of Custom Lip Gloss Tubes

→ Enhanced Protection: Premium materials like PETG and Acrylic prevent leaks and maintain product integrity.

→ Elevated User Experience: Ergonomic designs and applicators, such as doe-foot wands, enhance product application ease and precision.

→ Distinctive Branding: Custom decorations like UV coating and silk screen printing transform tubes into eye-catching marketing assets.

→ Sustainability Matters: Sustainable cosmetic packaging options and compliance with regulations cater to environmentally-conscious consumers.

→ Choosing the Right Materials: Assessing PETG, AS Plastic, and Glass helps determine the best fit for your brand’s needs.

→ Innovative Aesthetics: Unique shapes and finishes can captivate consumer attention on retail shelves.

→ Quality Assurance: Implementing leak testing, defect inspection, and regulatory approvals ensures high-quality packaging and customer satisfaction.

→ Marketing Logistics: Efficient supply chain strategies, from warehousing to delivery, boost brand visibility and product accessibility.

4 Key Benefits Of Premium Custom Lip Gloss Tubes

Premium lip gloss tube containers aren’t just packaging—they’re a smart play for beauty brands aiming to win on shelves and socials alike.

Enhanced Protection: Quality Materials that Ensure Product Integrity

- PETG and Acrylic are top-tier choices, offering excellent protection against leaks and oxidation.

- These materials create a strong barrier, shielding delicate formulas from air exposure.

- Tough enough to handle bumps during shipping, they maintain long-term product integrity.

According to industry insights, packaging durability directly influences consumer trust in a cosmetic product’s quality.

Elevated User Experience: Ergonomic Designs and Applicator Options

Comfy grip? Check. Smooth swipe? Double check.

• Thoughtfully designed curves improve hand feel—no more awkward twists or slips during use. • Swappable applicators like angled silicone tips, mini brushes, or classic doe-foot wands boost functionality without sacrificing style.

Each applicator style plays into different needs—from precise contouring to quick touch-ups—making your lip gloss feel custom-built every time you use it.

Distinctive Branding: Custom Decorations and Finishing Techniques

A tube isn’t just a container—it’s your brand’s first impression on the shelf.

- Hot stamping adds metallic flair that screams premium.

- UV coating boosts shine while enhancing scratch resistance.

- Matte finishes lend sophistication; glossy ones pop under store lights.

- With endless options like gradient sprays or embossed logos, every detail reinforces your unique brand identity.

Topfeel takes these techniques further by offering personalization down to cap shape and color gradients—because even small touches speak volumes about your brand story.

Sustainability Matters: Eco-Friendly Packaging Materials and Compliance

Consumers want glam without guilt—and brands are listening.

Short segments:

• PCR plastic options reduce virgin plastic usage while maintaining strength and clarity in your tube design. • ISO-certified production ensures adherence to global environmental standards—no greenwashing here! • Biodegradable components are now viable alternatives thanks to material innovation in sugarcane-based resins.

Eco-conscious buyers don’t just love sustainable packaging—they expect it now as part of any serious beauty brand’s DNA when choosing their next favorite lip gloss tube set-up.

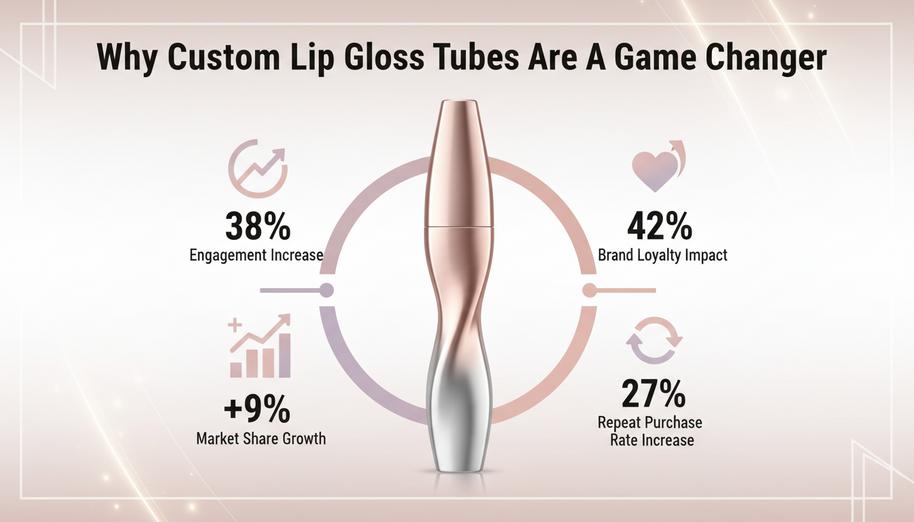

Why Custom Lip Gloss Tubes Are A Game Changer

Personalized, functional packaging for cosmetics isn’t just cool—it’s changing the game for beauty brands everywhere.

Market Trends Shifting: The Rise of Personalized Packaging

- Personalized packaging is no longer just a trend—it’s the new standard. Beauty buyers expect brands to reflect their identity.

- Social media has made customization trends explode, with users flaunting unique lip gloss tubes like status symbols.

- Brands that lean into packaging innovation are seeing better engagement and stronger consumer behavior patterns.

In fact, recent data from Mintel highlights that “Sophisticated Simplicity” and personalization are driving forces in 2024.

| Packaging Type | Engagement Increase (%) | Brand Loyalty Impact (%) | Market Share Growth (%) |

|---|---|---|---|

| Personalized | 38 | 42 | +9 |

| Standard | 12 | 15 | +2 |

| Eco-friendly | 29 | 33 | +5 |

This shift in market demand is about more than looks—it’s about emotional connection and standing out through smart brand differentiation.

Competitive Edge: How Design and Functionality Attract Customers

• Sleek curves or edgy geometric shapes? The right product design can make your gloss stand out on even the busiest shelf. • Flip-top lids, leak-proof seals, or soft applicators—clever functionality makes people come back for more. • Add metallic finishes or frosted textures to boost your product’s aesthetic value, making it feel high-end without the markup.

Grouped benefits of custom lip gloss packaging:

- Visual Appeal

- Matte vs glossy finishes

- Transparent or tinted tubes

- Practical Features

- Ergonomic grip designs

- Refillable cartridges

- Brand Messaging

- Embossed logos for instant recognition

- QR codes linking to tutorials

With these upgrades, your brand doesn’t just look better—it feels smarter and more personal. That’s how you build real customer attraction and keep a strong competitive advantage in today’s saturated beauty space.

Customer Preferences: Aligning with User Experience and Aesthetics

You know what people hate? Sticky lids, awkward shapes, and bland designs. When it comes to lip products, every detail matters—from how it looks to how it feels in hand.

Here’s what today’s consumers want:

- Smooth-glide applicators that don’t waste product.

- Compact tubes that fit easily into small bags or pockets.

- Eye-catching colors that reflect their vibe—or mood of the day.

These preferences tie directly into overall user experience, boosting both satisfaction and repeat purchases. And when you align with evolving tastes in color schemes and tactile design elements, you’re also tapping into deeper levels of subconscious brand memory—what some call sensory branding or even emotional UX.

As reported by Euromonitor International, lip products continue to be a dynamic category where packaging innovation drives value growth. That kind of insight should be driving every decision around your next batch of custom lip gloss containers—even if you’re not Topfeel yet.

By nailing both form and function through thoughtful tube design, you’re not just selling gloss—you’re creating an experience worth remembering.

Choosing The Right Custom Lip Gloss Tubes For Your Brand

Finding the perfect custom lip gloss tube isn’t just about looks—it’s about function, feel, and fitting your brand vibe.

Material Options: Comparing PETG, AS Plastic, and Glass

Choosing the right material sets the tone for your product experience. Each has a vibe:

- PETG is tough as nails—lightweight but super strong. (See our lip gloss tube clear petg bottle)

- AS Plastic keeps costs low while still offering slick clarity.

- Glass screams luxury but adds weight and fragility.

| Material | Durability | Cost Efficiency | Sustainability | Visual Appeal |

|---|---|---|---|---|

| PETG | High | Medium | Moderate | Clear |

| AS Plastic | Medium | High | Low | Semi-clear |

| Glass | Low | Low | High | Crystal-clear |

For brands like Topfeel that balance eco-awareness with high-end design, mixing materials in different SKUs might be the magic formula.

Selecting Applicators: Doe-foot Wands vs. Brush Applicators

What touches the lips matters just as much as what’s in the tube:

- Doe-foot wands offer controlled swipes—great for pigmented glosses.

- Brush applicators spread smoothly—ideal for sheer or shimmer formulas.

If your gloss is thick or creamy, go with a doe-foot wand for better precision. Thinner textures? A soft brush feels more natural on application.

Importance of Closure: Cap and Neck Finish Considerations

A busted gloss tube? Total buzzkill. That’s why proper closure, including cap fit and neck compatibility, is non-negotiable:

• A tight-sealing cap prevents leaks during shipping or daily use. • Matching the neck finish ensures consistent product flow. • Sleek closure designs also boost shelf appeal.

Don’t overlook this tiny detail—it can make or break consumer trust in your product line.

Design Factors: Custom Shapes and Fill Capacities

Shape up your packaging game with smart design moves:

Short & chubby? Feels luxe in hand. Tall & slim? Slides into pockets easily. The shape you choose reflects brand character—edgy, playful, elegant?

Then there’s volume to consider:

- Small fill capacity = travel-friendly + premium feel

- Large fill capacity = value-driven + mass-market friendly

Tailoring these design elements helps align with your target market while reinforcing branding through tactile memory.

Quality Standards: Ensuring Compliance and Material Safety

Before that gloss hits shelves, it better pass every quality check out there:

Step 1 – Confirm all materials meet FDA or EU cosmetic-grade standards. Step 2 – Run leak tests under heat and pressure to test durability. Step 3 – Certify packaging free of BPA or other harmful additives.

Brands cutting corners here risk recalls—or worse—bad reviews spreading fast online. Stick to certified suppliers who take safety seriously from start to finish.

Additional Tips on Balancing Functionality & Style

Smooth meets stylish when you hit these sweet spots:

- Ergonomic shapes enhance grip without sacrificing aesthetics.

- Transparent barrels show off color payoff while hinting at formula quality.

- Matte finishes add a modern edge; glossy ones read clean and classic.

Balancing form with function turns ordinary lip products into memorable brand moments—and keeps customers coming back for more custom lip gloss tubes they trust.

Final Thoughts on Packaging Strategy Alignment

Packaging isn’t just eye candy—it’s part of your marketing DNA:

• Want to look eco-conscious? Go glass or recycled PETG. • Targeting Gen Z? Neon caps + quirky shapes grab attention fast. • Building a prestige line? Weighty components signal quality before they even open it.

Topfeel understands how critical these details are when building standout collections of custom lip gloss tubes tailored to real-world users—and real-world shelves too.

Maximizing Brand Visibility With Custom Lip Gloss Tubes

If your lip gloss packaging doesn’t turn heads, it’s time to rethink the tube. Let’s break down how to make your brand pop—on shelves and in transit.

Eye-Catching Finishes: UV Coating and Metallization Techniques

According to market trend reports, beauty shoppers say glossy or metallic finishes make products feel more premium. That’s where finishes like UV coating and metallization come into play.

- A high-gloss UV coating doesn’t just catch light—it grabs attention. It also adds a protective layer that resists smudges.

- For brands aiming at a luxury vibe, full or partial metallization brings that mirror-like shine that screams high-end.

- Want something bolder? Combine matte textures with shiny accents for contrast that stops scrolls online and feet in-store.

When you’re customizing lip gloss tubes, these finishes aren’t just decoration—they’re part of your product’s personality. And when done right, they match the vibe of your formula inside. Topfeel nails this balance by offering sleek finish combos that elevate both shelf presence and unboxing moments.

Labeling Strategies: Effective Silk Screen Printing and Application

When it comes to branding on custom lip gloss tubes, your label isn’t just there to inform—it needs to impress too. Here’s how smart design meets durability:

• Silk screen printing ensures vibrant colors stay crisp even after weeks in a purse or makeup bag. No peeling here. • Use contrasting ink tones to boost visibility on clear or tinted tubes—like white print on smoky mauve plastic. • Opt for multi-pass printing if your logo has gradients or fine detail; it keeps things sharp without bleeding edges. • Add tactile elements like raised ink or soft-touch coatings—these little touches amplify perceived value instantly. • Keep label placement consistent across SKUs so customers recognize the brand at a glance—even when shades vary wildly.

Combining smart layout with resilient materials means every swipe of gloss reinforces your identity.

Shipping Considerations: Logistics That Promote Visibility

Getting those pretty tubes from warehouse to vanity table isn’t just about speed—it’s about keeping them flawless while boosting visibility along the way.

Step 1: Choose shipping cartons designed specifically for cosmetic packaging dimensions—this minimizes jostling during transit.

Step 2: Use protective inserts tailored for fragile components like caps with metallic details or embossed logos.

Step 3: Partner with fulfillment centers experienced in beauty logistics; they understand how vital pristine presentation is upon delivery.

Step 4: Incorporate branded outer packaging—not just inside retail boxes but even during bulk freight—to keep up brand exposure during distribution touchpoints.

Step 5: Track delivery performance metrics regularly and tweak routes as needed for faster arrival times without compromising condition quality.

From factory floor to customer doorstep, every step counts when you’re building recognition through custom gloss tubes—and Topfeel gets that better than most brands out there.

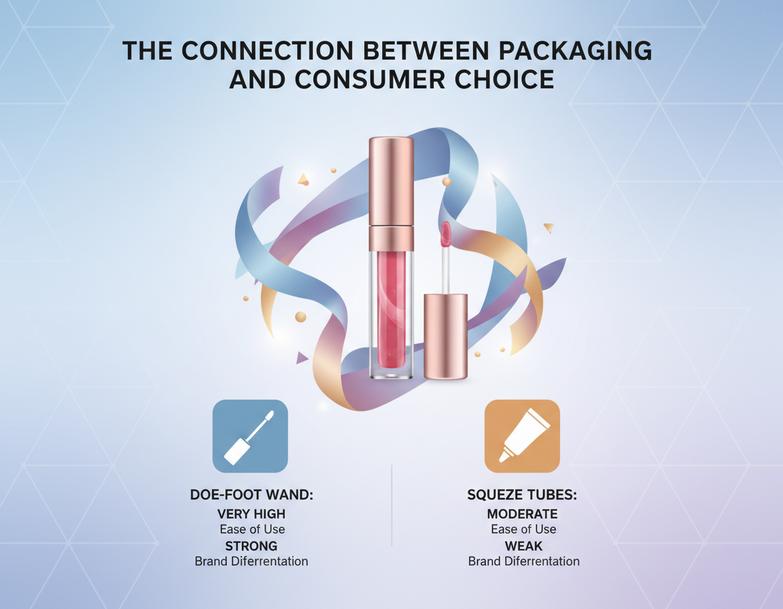

The Connection Between Packaging And Consumer Choice

How stuff looks—and works—on the shelf can make or break a sale. Let’s unpack how packaging sways consumer choices, especially for custom lip gloss tubes.

Impact of Design: Visual Appeal and User Experience

When it comes to snagging attention, visual appeal, smart layout, and intuitive design do more than just look pretty—they drive decisions fast. Here’s what matters most:

- Shelf presence: Bold colors, clean typography, and unique forms help lip gloss tubes pop in crowded beauty aisles.

- Brand perception: Sleek or minimalistic designs boost perceived value; flashy graphics can suggest fun or youthfulness.

- Ergonomics: Easy-to-hold shapes and well-balanced weight improve grip and usage comfort.

- Aesthetic design: Harmonizing color palettes with brand identity builds instant recognition.

- User experience: Flip-top caps or twist dispensers add tactile satisfaction while enhancing usability.

- Packaging design: Transparent windows show off product shades—especially popular for tinted glosses—and reduce guesswork.

- Bonus tip? Add tactile finishes like matte coating or soft-touch plastic for that luxe feel without the luxury price tag.

In short, killer packaging isn’t just skin-deep—it’s your silent salesperson doing all the heavy lifting on the shelf.

Functionality in Aesthetics: How Packaging Drives Purchase Decisions

Looks matter—but so does how well it works. When form meets function in cosmetics packaging, shoppers take notice…and action.

• Many buyers weigh both style and utility when choosing their next favorite gloss tube. If a package feels awkward or leaks? It’s game over—even if it looks amazing.

• For example:

- A wide applicator may look cool but frustrate users needing precision.

- Squeeze tube lip gloss options offer convenience but lack control compared to wand applicators.

- Magnetic closures scream premium but might be overkill for casual buyers.

• Here’s how key factors stack up across different types of custom lip gloss tube designs:

| Tube Type | Material Quality | Ease of Use | Brand Differentiation |

|---|---|---|---|

| Twist Pens | Medium | High | Moderate |

| Doe-Foot Wand | High | Very High | Strong |

| Squeeze Tubes | Low | Moderate | Weak |

| Click Dispensers | High | High | Unique |

• Shoppers often associate better usability with higher product value—even before trying it out. That’s why good design means more than just looking nice; it must function flawlessly too.

• Smart brands treat every detail—from cap type to squeeze resistance—as part of their storytelling strategy using their custom lip gloss tube as the medium.

So yeah—don’t sleep on functionality when designing something beautiful. Your customers won’t forgive a leaky lid no matter how cute the label is.

Custom Lip Gloss Tubes That Capture Attention And Sales

Creating custom lip gloss tubes is more than packaging—it’s about making a product that pops on shelves and wins hearts. Here’s how to do it right.

Innovative Applicator Designs: Exploring Rollerball and Sponge Tip Options

• Rollerball applicators offer a cooling glide perfect for sheer glosses. • Sponge tip designs provide smooth, even coverage ideal for pigmented formulas.

- Brands aiming at Gen Z often pick oversized sponge wands—they’re trendy, fun, and selfie-ready.

- Precision lovers? Slim applicator tips are your go-to—they’re clean, controlled, and classy.

- Want something different? Mix both! Some tubes feature dual-ended designs, combining a rollerball on one end with a soft sponge on the other.

When picking an applicator, think about your formula’s texture, your audience’s habits, and the vibe you want to give off. That’s how innovation meets functionality—and sells.

Quality Control Measures: Defect Inspection and Leak Testing

• Every batch goes through strict defect inspection—no cracks, no misalignments allowed. • High-pressure air is used in leak testing to spot weak seals before they hit shelves. • Visual checks ensure consistent color matching across batches—nothing ruins brand trust like mismatched hues.

Grouped into three checkpoints:

- Pre-fill inspection: Checks molds for flaws before production starts.

- Mid-line monitoring: Real-time cameras catch any surface imperfections.

- Final QA review: Manual testers squeeze each tube to test seal integrity.

These steps protect your product’s reputation by ensuring every piece meets the highest standard of quality assurance.

Manufacturing Excellence: Tooling Development and Prototyping

- It all kicks off with CAD files—digital blueprints that shape your vision into real-world molds.

- Then comes precision tooling—custom metal forms that define every curve of your future tube.

• Early-stage prototypes let you test ergonomics—is the grip comfy? Does it snap shut right?

Multi-step manufacturing flow: Step 1 → Concept sketch & CAD modeling Step 2 → Prototype printing & mold refinement Step 3 → Small-batch trial run using final materials

Each step focuses on aligning form with function while staying true to your brand identity in the crowded world of lip makeup packaging.

Customization Options: Tailoring Aesthetics for Target Markets

Grouped by customization type:

Design Elements: • Unique shapes—from heart-shaped barrels to sleek cylinders—create visual impact instantly. • Transparent bodies or frosted finishes allow customers to peek at shades inside.

Brand Identity: • Hot stamping logos or embossed icons make each tube unmistakably yours. • Color palettes aligned with seasonal drops keep things fresh without overhauling everything.

Market Adaptation: • For luxury markets, metallic caps scream premium appeal. • For eco-conscious buyers? Recycled plastic or refillable formats win big points.

According to Global Market Insights, consumers increasingly expect personalization in cosmetic packaging—not just what’s inside. So investing in tailored designs isn’t extra—it’s essential when crafting standout custom lip gloss tubes that resonate deeply with your audience.

FAQs

What makes premium custom lip gloss tubes appealing for high-volume cosmetic orders?

A blend of durability and beauty draws attention—PETG or Acrylic barrels keep formulas fresh, while Glass adds a touch of luxury. Caps with secure closures guard against spills during freight forwarding. Hot stamping or UV coating transforms each tube into a miniature billboard on the shelf.

How do different materials influence packaging performance?

- PETG: Tough enough for busy shipping logistics.

- AS Plastic: Cost-friendly yet precise in dimensional accuracy.

- PP Plastic: Lightweight, easy to mold via injection molding.

- PCR Material & Aluminum: Eco-conscious choices that still protect contents with stability testing approval.

Which applicators work best for diverse formulas?

- Doe-foot wand – smooth control for creamy textures.

- Rollerball – cooling glide perfect in warmer climates.

- Brush applicator – even sweep ideal for glossy finishes in promotional kits.

- Sponge tip or spatula tip – playful options that enhance user experience through tactile appeal.

Can design elements truly sway consumer decisions at retail?

Yes—ergonomic shapes feel natural in hand, matte finishes invite touch, and frosting teases the eye under store lighting; silk screen printing keeps brand alignment intact long after purchase.

| Finish Type | Effect on Appeal |

|---|---|

| Matte finish | Soft elegance |

| Glossy finish | High-shine glamour |

| Metallization | Metallic drama |

Each choice tells its own story before the cap is even twisted open.

Are sustainable solutions practical when ordering thousands of units?

Short description + bullet point structure:

- PCR Material reduces environmental strain without sacrificing quality standards under ISO certification.

- Aluminum parts fit neatly into closed-loop recycling programs.

These moves speak directly to eco-conscious buyers while keeping production schedules steady.

How is product integrity safeguarded from factory to storefront?

Short bullet point structure + summary description:

- Leak testing ensures zero mess upon arrival.

- Compatibility testing prevents formula breakdown inside barrels or wipers.

From tooling development to customs documentation, every step is tuned so each wholesale lip gloss tube arrives as flawless as it left the assembly line—ready to charm its first customer’s hand and heart alike.

References

- Most Americans Say That the Design of a Product’s Packaging Often Influences Their Purchase Decisions – Ipsos

- Mintel announces Global Beauty and Personal Care Trends for 2024 – Mintel

- Beauty and Personal Care in the US | Market Research Report – Euromonitor International

- Personalized/Customized Skin Care Market Size Report – 2034 – Global Market Insights