Why Cushion Packaging is Essential for Your Cosmetic Products

Your cosmetics might be flawless—but if your cushion packaging doesn’t hold up, neither will your reputation. Fragile compacts crack in transit. Leaky lids ruin unboxings. And don’t get us started on dull plastic shells that make even the most radiant blush look like a gas station freebie.

Customers today? They shop with their eyes, values, and sometimes one hand while juggling a toddler. If your product isn’t protected, pretty, and planet-friendly—you’re out of the cart before checkout.

According to Mintel’s 2023 Global Packaging Trends Report, over 65% of beauty consumers say sustainable packaging directly influences their purchasing decisions. That’s not niche anymore—that’s mainstream behavior knocking on your warehouse door.

So here’s the question: is your current packaging doing justice to what’s inside? Or are you handing over high-end formulas in low-rent outfits?

Key Points to Elevate Your Cushion Packaging Strategy

➔ Product Protection: Cushion packaging features like magnetic closures and airless pumps safeguard against spills and contamination.

➔ Eco-Friendly Materials: Sustainable options like biodegradable polymers and recycled aluminum align with eco-conscious consumer demands.

➔ Aesthetic Appeal: Custom color finishes and finishes like Pantone matching or pearlized effects help make your products stand out on the shelf.

➔ Supplier Quality: Partnering with ISO-certified and GMP-compliant suppliers ensures reliability and adherence to global standards.

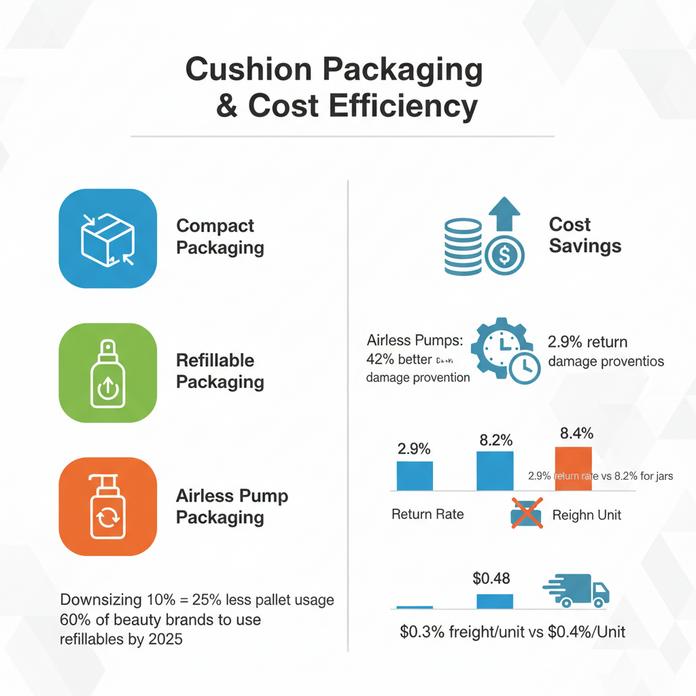

➔ Cost Efficiency: Compact designs and refillable features minimize shipping costs, while airless pumps reduce breakage and shipping damages.

➔ Customization for Differentiation: Unique shapes, custom molding, and luxury decoration techniques enhance both functionality and market appeal.

Why Invest in High-Quality Cushion Packaging?

Smart brands know that cushion packaging does more than just look good—it protects, impresses, and saves money long-term.

Enhancing Product Protection with Cushion Packaging Features

• Magnetic clasps keep lids tightly sealed during transit, blocking leaks and preserving formulas.

• Airless pump designs prevent oxygen exposure—protecting sensitive ingredients from degrading too early.

• Layered sponge inserts absorb shocks from drops or rough handling, especially in global shipping routes.

A premium experience starts with safety—no one wants cracked compacts or messy spills on delivery. These features aren’t fluff—they’re your frontline defense for damage prevention, reducing returns and boosting customer satisfaction in one smart move.

Eco-Friendly Cushion Options: Sustainable Materials for Modern Brands

♻️ Plant-based polymers made from corn or sugarcane offer biodegradability without compromising strength.

♻️ Recycled aluminum shells reduce waste while maintaining a sleek look and sturdy feel.

♻️ FSC-certified paperboard inserts support forest sustainability and lower carbon footprints.

According to Euromonitor’s 2024 Beauty Packaging Insights, over 60% of Gen Z shoppers prefer brands using sustainable materials—even if it costs more. Choosing green options for your cushion packaging isn’t just ethical; it’s a brand loyalty magnet for the eco-aware crowd who care deeply about their impact on the planet—and yours too.

Aesthetic Appeal: Custom Color Finishes for Distinctive Branding

Pearlized coatings reflect light beautifully under retail lighting conditions.

Pantone-matched hues ensure consistency across product lines and marketing visuals.

Matte textures create a soft-touch feel that screams elegance without saying a word.

When shelf space is tight, standing out isn’t optional—it’s survival. Bold design choices on your cushion packaging boost visual appeal and reinforce brand identity at every glance. It’s not just makeup; it’s an extension of your vibe—and trust us, consumers notice when you’ve nailed the details that elevate their unboxing moment into something memorable.

The Role of Quality Suppliers: ISO Certified and GMP Compliant Standards

Certified suppliers bring more than credibility—they deliver peace of mind:

- ISO Certification: Guarantees consistent quality control across all production batches.

- GMP Compliance: Ensures hygienic manufacturing practices to avoid contamination risks.

- On-time delivery rates above 95%, as tracked by audited supplier performance reports.

- In-house testing labs reduce dependency on third-party checks—cutting lead times significantly.

Teaming up with reliable producers means fewer headaches down the road—from avoiding costly recalls to ensuring every unit meets international safety standards before it ever hits shelves. That kind of reliability safeguards your brand reputation, supports smoother logistics, and keeps the whole operation airtight from start to finish—even if you’re scaling fast like Topfeel did last fiscal year with its new refillable line rollout.

Cushion Packaging & Cost Efficiency in Shipping

Shipping costs can spiral fast. Smart cushion packaging choices cut waste, trim damage, and keep your bottom line healthier.

Standard Size vs. Compact Design: Finding the Right Fit

Choosing between standard and compact designs isn’t just about aesthetics—it’s about smarter freight optimization and reducing overhead.

-

Standard-size containers are:

• Easier to stack

• Often compatible with existing logistics systems

• Slightly more costly per unit due to unused space

-

Compact designs offer:

• Tighter packing density

• Lower volume = lower shipping costs

• Better for brands shipping high volumes

For example, downsizing by even 10% can slash pallet usage by up to 25%. That’s not small change—it’s strategic savings baked into your packaging decisions.

The Cost-Benefit of Refillable Designs in Cushion Packaging

Refillable formats are gaining traction—and not just because they’re trendy. They directly impact material usage and long-term cost reduction.

- Reduced raw material input per refill cycle lowers material costs.

- Encourages customer loyalty through sustainable incentives.

- Cuts down on landfill waste, supporting ESG goals.

- Lowers recurring production expenses—fewer pumps, fewer parts.

“By 2025, over 60% of beauty brands plan to implement refillable packaging systems,” according to the Global Packaging Innovation Monitor Q2/2024 report.

Refillables also open the door for bulk shipping models that reduce per-unit freight rates—a win-win for both brand and planet.

Shipping Savings: How Airless Pumps Minimize Breakage

Airless pump technology isn’t just slick—it’s tough where it counts. These units help minimize returns by keeping product integrity intact during transit.

• No air exposure = less chance of leakage under pressure changes

• Durable outer shells absorb shocks better than traditional glass jars

• Built-in seals reduce mess if dropped or mishandled

Cushion Packaging: Balancing Functionality and Aesthetics

A killer cushion compact isn’t just about what’s inside—it’s how it looks, feels, and works in your hand.

Magnetic Closures: The Perfect Blend of Security and Style

• Keeps the lid tightly shut—no surprise spills in your bag.

• Adds a sleek, high-end vibe that screams quality.

• Works smoothly every time without wear and tear.

- Looks matter—aesthetic design plays a huge role in how people perceive product value.

- Function matters too—magnetic closures protect product integrity, especially during travel or handling.

★ Magnetic clasps give off that satisfying “click” that makes users feel confident their product is secure.

This tiny detail elevates the entire consumer experience by merging tactile satisfaction with visual elegance. It’s not just closure—it’s part of the brand story.

Decoration Techniques: Hot Stamping and Embossing for Luxury Appeal

- Hot stamping = shiny metallic logos that catch light like jewelry on packaging.

- Embossing = raised textures that feel expensive to touch.

- Together? They create visual drama with tactile richness.

Think velvet boxes with gold foil logos—that’s the vibe hot stamping and embossing bring to cushion packaging. These techniques boost visual appeal, turning everyday compacts into collector-worthy pieces. When done right, they make your brand unforgettable at first glance—and first touch.

The Importance of Including a Mirror in High-End Cushion Packages

Short takes:

• Mirrors mean no need to carry extras—huge win for makeup lovers on the go.

• Built-in mirrors reflect more than faces—they reflect thoughtful product protection through usability.

• High-end cushion compacts without mirrors? That’s a miss in today’s luxury beauty space.

It all comes down to convenience meeting premium design expectations—and elevating the daily routine into something special.

Exploring Custom Molding: Unique Shapes for Market Differentiation

Grouped features:

Visual Identity Boosters: – Curved edges, asymmetrical lids, geometric bases—all help grab attention instantly on crowded shelves.

Brand Storytelling Tools: – Custom shapes can reflect brand ethos (eco-friendly lines use leaf motifs; tech-inspired brands opt for minimalism).

Material Innovation Enablers: – New molds often demand fresh materials—lightweight resins or blended plastics—to keep things functional yet beautiful.

Custom molding gives you freedom to play with form while maintaining core values like product protection, portability, and style cohesion across collections.

Travel Size Solutions: Convenience Meets Design Elegance

- Compact doesn’t mean compromise anymore—mini formats now deliver full-size performance with clever designs.

- Lightweight but sturdy cases ensure product integrity, even when tossed into overstuffed bags.

- Integrated features like refillable pans or snap-lock lids enhance both eco-friendliness and ease-of-use.

- Below is a comparison table showing consumer preference trends across standard vs travel-size formats:

| Feature | Standard Size (%) | Travel Size (%) | Preference Shift |

|---|---|---|---|

| Portability | 42 | 91 | +49 |

| Reusability | 55 | 78 | +23 |

| Aesthetic Design Appeal | 68 | 83 | +15 |

| On-the-go Convenience | 39 | 94 | +55 |

Travel sizes aren’t just shrunken versions—they’re smart redesigns tailored for modern life while preserving key elements of great cushion packaging like durability and style appeal.

FAQs

What makes cushion packaging stand out for luxury cosmetics?

In hand, the feel matters—magnetic closures click softly shut on foundation compacts and blush containers, mirror-included lids invite quick touch‑ups, and custom molding ensures powder cases or concealer palettes fit beautifully in one’s palm.

How can eco-friendly materials fit into large-scale production without losing charm?

- Sustainable bamboo brings warm tactility

- Biodegradable polymer shapes stay sleek yet compostable

- Recycled aluminum frames shimmer while cutting waste

Even at travel size or standard size, beauty meets conscience in every compact design.

Why do decoration techniques change how customers connect with a product?

Hot stamping dances light across acrylic plastic covers; embossing detail lets fingertips feel the logo rise; UV coating guards pearlized effect finishes like armor against wear from countless purse rides.

Why invest in refillable designs instead of single-use options?

Refillable powder cases and foundation compacts carry stories—less eco-friendly paperboard used over their life spans means each sifter component or airless pump becomes part of a longer companionship between brand and buyer.

Which supplier certifications signal dependable packaging quality?

ISO certified makers hold precision steady through each batch; GMP compliant factories ensure hygiene that matters when powders kiss skin; global shipping keeps miniature versions and oversized options arriving right on time during rush season.

Can custom color finishes truly shift shelf appeal for high-end lines?

Pantone matched hues echo across blush containers to highlighter kits; metallic finish stirs curiosity under boutique lights; pearlized effects give even compact designs a subtle glow shoppers love to reach for again and again.

References

[1] Global Packaging Predictions: 2026 & Beyond – Mintel

[2] Why do some blush compacts have a magnetic closure? – APG Packaging

[3] Sustainability to Remain Key in the Agenda for Beauty Players – Euromonitor

[4] Refillable Packaging Market Size | Industry Report, 2030 – Grand View Research