The Complete Guide: Unraveling Every Aspect of What is ABS Used for

What is ABS used for? Picture this: You’re holding a lipstick tube so sleek it could moonlight as modern art, but tough enough to survive the bottom of a purse warzone. That, my friend, is ABS—Acrylonitrile Butadiene Styrene—a name only chemists love but packaging pros swear by.

In the fast-paced world of cosmetics, brands don’t just need cute—they need containers that won’t crack under pressure (literally). ABS struts in like the unbothered cool kid: customizable shades, fancy finishes, and strong enough to take a tumble off retail shelves without breaking your heart—or your budget.

“By 2025, global cosmetic packaging is projected to reach significant heights,” reports Market Research Future. “Durable plastics like ABS are leading that charge due to their high-impact resistance and design flexibility.”

So if you’ve ever stared at twenty identical compacts wondering how yours can stand out and stand up—stick around. This guide’s got answers.

What Is ABS Used For in Packaging Solutions?

ABS plastic isn’t just tough—it’s the go-to for stylish, secure, and adaptable packaging. Let’s check out how it shapes today’s product experiences.

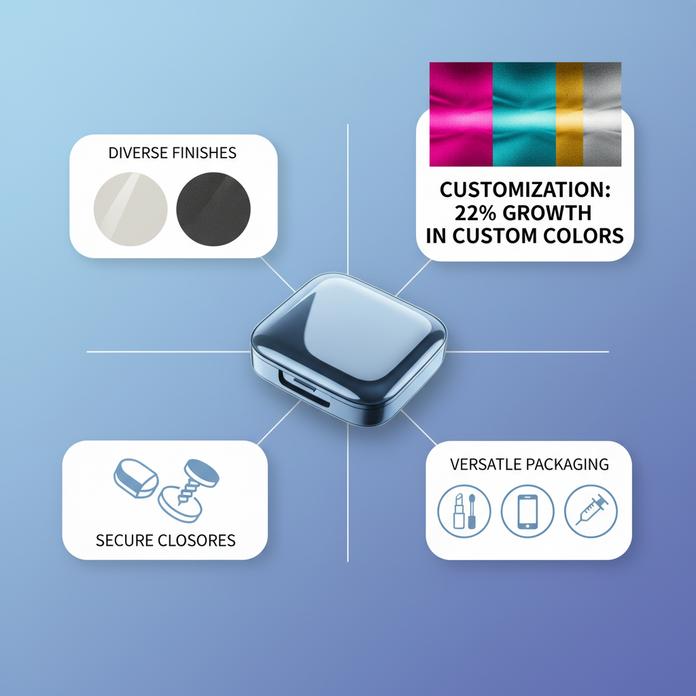

Versatile Packaging Type: Compact Cases for a Diverse Range of Products

- Cosmetics: Think lipstick tubes, mascara tubes, or powder compacts—ABS cases are lightweight yet sturdy enough to protect delicate formulas.

- Electronics: Small gadgets like earbuds or USB drives find their perfect match with durable containers made from ABS.

- Medical supplies: Single-use diagnostic kits or portable pill organizers use compact packaging that keeps contents safe and sterile.

→ From makeup bags to first-aid kits, this kind of protective enclosure is all about flexibility. That’s what makes it a staple when folks ask “what is ABS used for.”

Highlighting Customization: Custom Colors and Metallic Finishes for Standout Designs

There’s nothing cookie-cutter about today’s custom cosmetic packaging. Here’s how brands are getting creative:

➊ Pantone-matched shades let you align your product perfectly with your brand palette. Want neon green? No problem.

➋ Shimmering metallic finishes—gold, chrome, rose gold—instantly scream luxury on shelves.

➌ Injection molding allows intricate details and logos to be embedded right into the surface.

A recent report by Smithers noted that demand for distinct packaging has grown significantly in recent years. Why? Because consumers now expect their products to look as good as they work.

Closure Mechanisms: Exploring Snap-on Caps and Screw-on Caps

-

Easy-open designs meet tamper-proof security head-on:

- Snap-on caps click into place fast—ideal for quick-use items like lip balm tubes or testers.

- Screw-on closures offer extra-tight seals for liquids or creams.

- Some hybrid designs combine both styles for added protection.

These ABS caps aren’t just functional—they’re part of the experience. When thinking about “what is ABS used for,” these little closure heroes often go unnoticed but make a big difference.

Surface Finish Options: Glossy Finish vs. Matte Finish for Brand Aesthetics

| Finish Type | Texture Feel | Visual Appeal | Common Use Case |

|---|---|---|---|

| Glossy | Smooth & sleek | Reflective shine | Beauty & tech |

| Matte | Soft-touch | Subtle elegance | Skincare & wellness |

| Semi-gloss | Balanced feel | Low-glare polish | Premium tools |

Choosing between a glossy shine or matte vibe isn’t just aesthetic—it tells your story at first glance. These ABS surface finish options help define the emotional tone of your product before it even gets opened.

Compact Cases Across Industries

▸ In fashion accessories, compact ABS holders keep sunglasses scratch-free without adding bulk. ▸ In art supplies, paint palettes often use molded ABS trays that resist warping and cracking over time. ▸ Even automotive key fobs rely on small-scale electronic housing, where durability meets design.

So when someone asks “what is ABS used for,” it’s not just one thing—it spans across industries because it’s so dang adaptable.

How Customization Meets Functionality

Let’s break down how form meets function:

Step 1 — Choose your mold shape based on the product size/weight. Step 2 — Decide if you want custom colors via Pantone matching or metallic overlays. Step 3 — Select closure type depending on content fluidity—snap vs screw cap makes a big difference here! Step 4 — Pick between glossy/matte finishes based on audience preference or branding moodboard.

This process shows why folks love working with an adaptable material like ABS—it bends around your needs without compromising quality.

Design Aesthetics that Drive Sales

Short bursts of brilliance:

✔️ Glossy black = sleek + modern = high-end electronics appeal ✔️ Matte pastel = soft + natural = ideal for skincare brands targeting minimalists ✔️ Chrome silver = futuristic + bold = perfect fit for men’s grooming lines

Each finish adds personality—and more importantly—helps products stand out where it matters most: on crowded shelves and social feeds alike.

Closure Types Tailored by Industry Needs

Grouped by usage:

🔹 Personal care – Snap-on works best when speed matters; think deodorants or trial-size lotions. 🔹 Pharmaceuticals – Screw tops ensure dose control and safety; think pill bottles or ointments. 🔹 Industrial – Dual-lock mechanisms handle pressure-sensitive materials safely during transit.

So yeah, if someone brings up “what is abs used for,” closures alone could be an entire conversation—and rightly so!

Only once does Topfeelpack enter this conversation—but its presence here proves how widespread this material truly is across packaging innovation today.

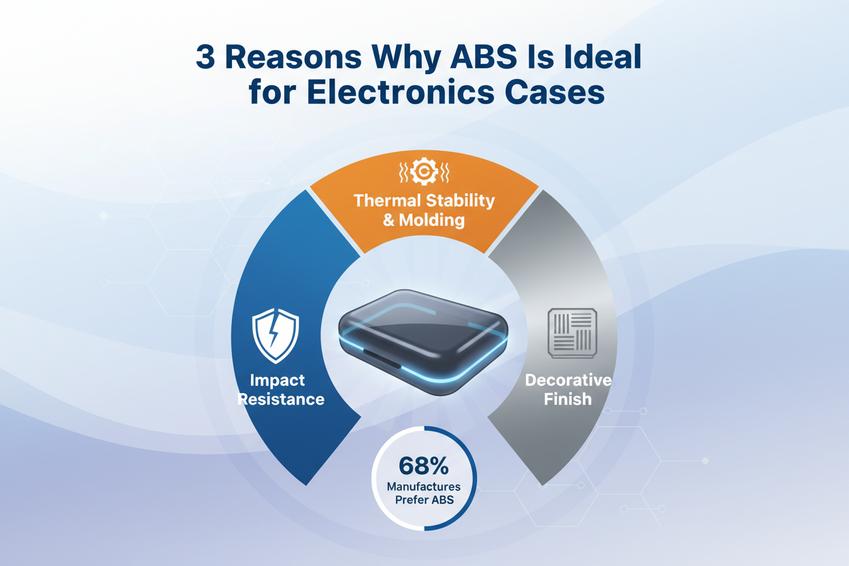

3 Reasons Why ABS Is Ideal for Electronics Cases

ABS plastic is a go-to material in electronics, and here’s why it’s always popping up in durable case designs.

ABS Plastic vs. PET Plastic: Which Is Best for Electronics?

When folks ask what is ABS used for, especially in gadgets, the answer usually involves toughness and reliability.

- ABS plastic brings solid impact resistance, making it great for devices that get tossed around.

- PET plastic might win on clarity and recyclability but falls short on heat resistance.

- Cost-wise, both are affordable, but ABS edges out with lower tooling costs in large-scale production.

According to a recent Reports and Data insight, the ABS resin market for consumer electronics is valued at billions, with manufacturers preferring ABS plastic due to its superior thermal stability and ease of molding.

In short bursts: • Want rugged gear? Go with ABS. • Need clear packaging? That’s where PET plastic shines. • For long-term durability in electronics? Again—ABS wins out.

It’s no wonder “what is abs used for” keeps showing up in design specs across electronics brands.

Key Decoration Methods: Hot Stamping Techniques for Electronics Packaging

Hot stamping isn’t just flashy—it’s practical too when sprucing up your tech cases made from ABS plastic.

• Surface Finish Options – Glossy metallics – Matte foil textures – Holographic patterns

• Material Compatibility – Works best with rigid plastics like ABS, less effective on flexible materials like PP or PE

• Branding Use Cases – Company logos that don’t rub off after months of use – Regulatory marks (like CE or FCC) embedded directly into the shell

| Foil Type | Durability Rating | Compatible Plastics | Avg. Cost Increase |

|---|---|---|---|

| Metallic Gold | High | ABS, PS | +8% |

| Matte Silver | Medium | PVC, PC | +5% |

| Color Foils | Low | PET, PP | +3% |

So next time someone asks “what is abs used for” beyond structural stuff—point them to the shiny branding details too.

Structural Integrity: The Manufacturing Process of Injection Molding in Electronics Cases

Making strong gadget cases starts with how they’re built—and injection molding nails it every time.

Step-by-step:

- Mold Design Phase — Engineers shape molds based on device dimensions and stress points using CAD software.

- Material Feeding — Granulated ABS plastic gets heated until molten and injected into the mold cavity under high pressure.

- Cooling & Ejection — Once cooled into shape, the new casing gets popped out cleanly without warping.

- Post-Mold Finishing — Burrs are trimmed; sometimes hot stamping or painting comes next.

Throughout this process, injection molding ensures tight tolerances—meaning your phone case won’t rattle or misalign even after months of use.

And yes, if you’re still wondering “what is abs used for,” this process shows exactly why it dominates electronics housing production today.

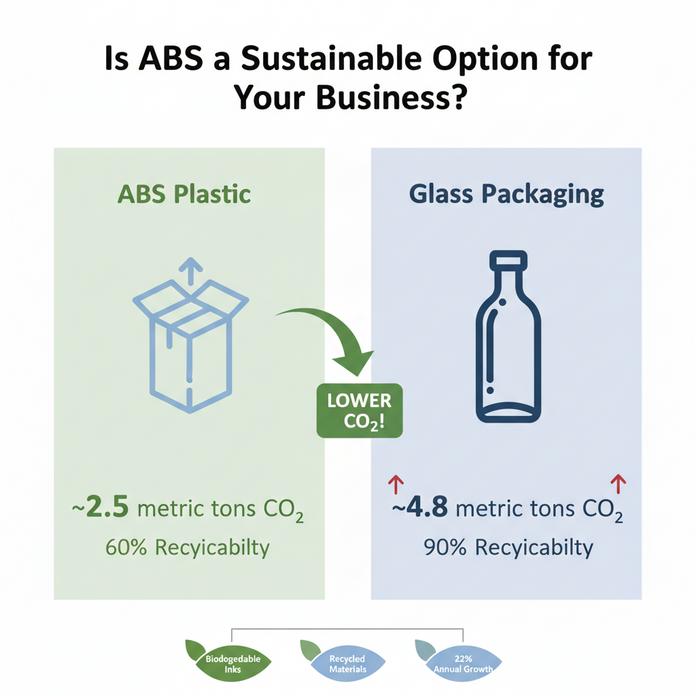

Is ABS a Sustainable Option for Your Business?

Wondering if ABS plastic is the eco-smart move for your packaging? Let’s break it down with facts and real-world comparisons.

Assessing Material Sustainability: ABS Plastic vs. Glass Packaging

- ABS plastic has lower melting points than glass packaging, making it more energy-efficient during manufacturing.

- While glass boasts infinite recyclability, its heavy weight increases transportation emissions—especially when compared to lightweight ABS plastic.

- A recent lifecycle assessment highlights that the transportation impact of heavy glass packaging can result in significantly higher overall CO₂ emissions compared to lightweight ABS plastic.

| Material Type | Avg. CO₂ Emissions per Ton | Recyclability Rate | Weight per Liter Capacity |

|---|---|---|---|

| ABS Plastic | ~2.5 metric tons | Moderate (~60%) | Light |

| Glass Packaging | ~4.8 metric tons | High (~90%+) | Heavy |

- In terms of what is abs used for in Sustainable Cosmetic Packaging, it’s often selected over glass where durability and lower shipping costs matter more than infinite recyclability.

- Topfeelpack uses smart design strategies with material sustainability in mind, helping brands reduce their carbon footprint without compromising on aesthetics or function.

Eco-Friendly Printing: Labeling Solutions That Minimize Environmental Impact

Let’s talk about how your labels can be just as green as your containers:

• Use biodegradable inks derived from soy or algae-based sources—they’re less toxic and break down naturally after disposal. • Choose labels made from recycled materials, reducing dependency on virgin pulp and synthetic polymers.

According to Smithers, the market for sustainable solutions and eco-friendly printing technologies is expected to grow significantly in the coming years.

• Reduce waste by avoiding oversized branding stickers; opt for minimalistic designs that still pop on shelves. • Many brands asking “what is abs used for” don’t realize that even their labeling choices can impact overall sustainability metrics.

Short answer? Go all-in with low-impact printing tech—it’s not just about looking good; it’s about doing good too.

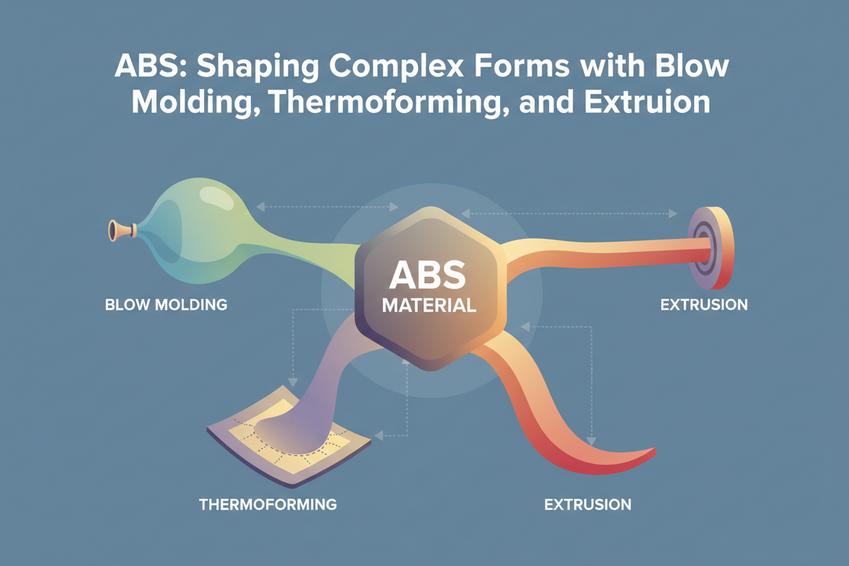

What Makes ABS Suitable for Complex Shapes?

ABS is a go-to material when you need parts with character—literally. Here’s how it gets molded into just about anything.

Advanced Techniques: Exploring Blow Molding and Thermoforming Capabilities

ABS plastic doesn’t flinch when it comes to complicated curves or fine details. Its adaptability in blow molding and thermoforming makes it a top pick across industries.

- Blow molding stretches heated ABS into hollow forms—ideal for items like tool housings or automotive ducts.

- In thermoforming, heated sheets are vacuum-shaped over molds, capturing sharp lines and detailed textures.

- Both techniques allow designers to push boundaries without sacrificing strength or finish.

That’s why when folks ask “what is abs used for,” these forming methods often come up as the answer—they allow wild creativity without losing durability.

Tailored Designs: The Role of Extrusion in Creating Custom Shapes

ABS extrusion is a beast when it comes to shaping things your way. It’s all about feeding melted plastic through a custom die, letting you churn out endless profiles with precision.

Short-form highlights: • Need a unique trim piece? Extrude it. • Want repeatable shapes with consistent specs? You got it. • Looking for flexibility in design changes? Easy updates on the fly.

This process gives manufacturers control over everything—from wall thickness to color blends—making ABS extrusion perfect for product customization. So next time someone asks “what is abs used for,” just point them toward anything that needs a slick, repeatable shape with flair.

FAQs about What Is ABS Used For

What is ABS used for in cosmetic packaging solutions?

ABS Plastic brings a sturdy yet smooth touch to makeup essentials:

- Compact Cases becoming sleek homes for powders.

- Lipstick Tubes that click shut with satisfying precision.

- Mascara Bottles shaped to fit both the hand and eye appeal.

It holds custom colors from Pantone Matching to Metallic Finishes, each surface—Glossy or Matte—echoing a brand’s voice.

Why choose ABS over PET plastic for beauty electronics?

When designing heated eyelash curlers or similar tools, durability speaks loud:

- ABS withstands bumps better than PET Plastic.

- Retains its shape under minor heat stress without warping casing edges.

- Gives protective shells a refined feel perfect for premium devices.

How does hot stamping play into enhancing ABS packaging?

Hot Stamping glides foil accents onto Smooth Surfaces of foundation bottles; paired with Silk Screening, designs sparkle under store lights while resisting wear across countless hands—a silent promise of quality.

Which closure styles match best with ABS containers?

Snap-on Caps suit quick moments like lip gloss refreshes; Screw-on Caps guard liquid foundations against spills; Magnetic Closures make powder compacts open and close as if by magic—each chosen for comfort and practical elegance.

What unique shapes can be made from ABS in cosmetic tools?

Through Injection Molding or Thermoforming, eyeliner pens curve gracefully, mascara bottles take intriguing contours; such crafted lines catch attention before the product even touches skin—a meeting point between function and art.

Would you like me to help you design a custom ABS packaging solution for your next product launch?

References

- Market Research Future – Cosmetic Packaging Market Size, Share & Industry Report 2035 – marketresearchfuture.com

- Smithers – The Future of Global Packaging to 2028 – smithers.com

- Reports and Data – ABS Resin for Consumer Electronics Market – reportsanddata.com

- Ecochain – What has the lowest impact: glass vs. plastic packaging – ecochain.com