What Is UV Coated in Makeup Packaging

Ever ripped open a fresh box of makeup packaging only to find the colors dulled, scuffed, or faded like last season’s Instagram filter? That’s exactly where the magic—and muscle—of UV coating steps in. So what is UV coated? It’s a slick (literally) polymer finish cured under ultraviolet light that keeps your packaging looking sharp from factory floor to vanity drawer.

Think of it as sunscreen for your beauty brand. Without it, your high-end lipstick tubes or luxe foundation bottles might look like they’ve been through a sandstorm before they even hit shelves.

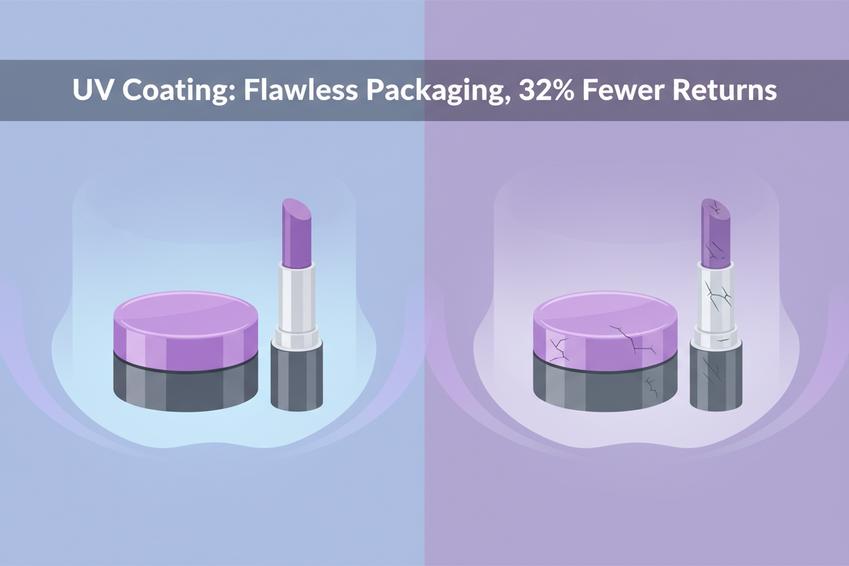

According to Smithers’ 2023 Global Packaging Report, brands investing in protective coatings like UV saw up to 32% fewer returns due to damaged appearance alone. That’s not just pretty—it’s profitable.

Because when you’re shipping out tens of thousands of units across coasts and continents, every scratch costs more than just product—it chips away at your brand story.

Essentials of What Is UV Coated Packaging

- Understanding UV Coating: UV coating is a polymer finish that hardens under ultraviolet light, providing durability and enhanced aesthetics.

- Types of Coating: Various finishes, including glossy and matte, offer different looks and tactile experiences for makeup packaging.

- Durability Benefits: UV coatings protect against scratches and UV damage, keeping packaging looking new longer.

- Sustainable Choices: Eco-friendly coatings are available to support environmentally responsible packaging practices.

- Regulatory Compliance: Ensure packaging adheres to regulations like FDA standards and Proposition 65 for safety and legality.

- Comparison with Non-Coated Options: UV coated packaging provides superior visual appeal and scratch resistance compared to standard coatings.

What Is UV Coated in Makeup Packaging?

UV coating is a slick upgrade for packaging—it’s not just about shine but also protection, style, and compliance.

Understanding UV Coating: Definition and Process

Let’s break down what happens when you apply a UV coating to makeup packaging:

- A liquid polymer gets brushed or sprayed onto the surface.

- This layer sits on the substrate, whether that’s plastic, paperboard, or glass.

- Once exposed to intense ultraviolet light, the curing kicks in fast—think seconds.

- That hardening process? It’s called polymerization, locking everything into place for durability.

- Depending on the application method, results can vary slightly—spray vs. roller coat makes a difference.

So when someone asks “what is uv coated,” it’s all about using light to zap liquid into armor for your product. And yes, this stuff matters—it keeps packaging looking fresh even after months on a store shelf.

Types of Coating: Glossy, Matte, and More

There’s more than one way to dress up packaging with a UV finish:

🟢 Glossy Finish – Think mirror-like shine; reflects light beautifully and screams premium.

🟢 Matte Finish – Smooth but non-reflective; gives off that modern minimalist vibe.

🟢 Satin Coating – Somewhere between matte and gloss; subtle sheen without being flashy.

🟢 Soft-Touch – Adds a velvety feel; great for high-end lines where texture speaks volumes.

🟢 Textured Coating – Offers grip and visual interest; often used for limited editions or bold branding moves.

Each type brings its own flavor—and when consumers pick up that lipstick tube or compact case—they’re feeling more than just color. They’re experiencing brand identity through touch and sight.

Impact of Coating on Acrylic and Glass Packaging

Here’s how UV finishes interact with two common materials:

1️⃣ Start with prepping the surface—both acrylic packaging and glass need proper cleaning so the coating sticks well.

2️⃣ Apply the coating evenly across curves or flat planes. Uneven layers = future peeling issues.

3️⃣ Cure it under strong UV lamps. This step is crucial since both materials reflect light differently—glass especially needs longer exposure due to its transparency.

4️⃣ Once cured:

- On acrylic: boosts scratch resistance big time.

- On glass: enhances chemical resistance while keeping clarity intact.

- For both: adds serious durability against daily wear-and-tear from bags, hands, shelves—you name it.

5️⃣ Final result? Sleek looks + long life = win-win combo for any makeup line trying to stand out without falling apart over time.

And yep—when folks search what is uv coated, they’re often wondering exactly how their fancy serum bottle stays so pristine. Now they know!

Essential Regulatory Compliance for Coated Makeup Packaging

Navigating regulations isn’t optional—it’s survival mode in cosmetics manufacturing. When applying any kind of coating—including glossy or matte—to makeup containers, brands must follow strict rules tied to material safety:

In the U.S., coatings must align with existing FDA regulations, especially if there’s potential contact with product contents through migration. Over in Europe? The bar’s set by REACH guidelines—which require full disclosure of every chemical involved in your formula stack-up including what’s inside that shiny topcoat layer. And don’t forget California’s infamous Proposition 65 list—you’ll need proof your coatings won’t leach harmful substances over time under heat or pressure conditions typical during transport or storage cycles.

According to Mintel’s Q1 2024 Global Cosmetic Packaging Report, “Consumer trust hinges increasingly on visible compliance cues—even among younger demographics.” So yeah—compliance isn’t just legalese anymore; it’s part of your brand story too when people ask what is uv coated on their favorite lip balm tube cap.

Benefits of UV Coated Makeup Containers

UV-coated containers aren’t just about the shine—they’re built to last, protect, and keep your products safe and stylish.

Enhanced Durability: Scratch Resistance Explained

• Daily handling of cosmetic containers often leads to scuffs and surface wear. A UV coating adds a hardened layer that boosts scratch resistance, keeping packaging sleek longer.

• It helps maintain visual appeal on store shelves and inside makeup bags—where keys, brushes, and other items can cause damage.

• This added abrasion resistance means fewer returns due to damaged packaging and longer shelf presence without visible wear.

• Whether tossed into handbags or stacked in drawers, UV-coated surfaces shrug off the rough stuff with ease.

Protection from UV Damage: Why It Matters

- UV rays don’t just mess with skin—they wreck packaging too. Without protection, colors fade fast under light exposure.

- A strong UV barrier helps maintain both the look and integrity of the container over time.

- More importantly, it protects formulas inside by limiting exposure to damaging light that could break down active ingredients—especially critical for SPF products or serums.

- With proper cosmetic preservation, you get better product performance over time—and fewer customer complaints about spoiled formulas.

- So if you’re wondering “what is uv coated” really doing? It’s guarding against invisible enemies like sunlight damage that quietly ruin good makeup.

The Role of Coating in Child Resistant Closures

Short Snapshots:

– A good child resistant closure needs more than clever design—it requires durability through repeated use.

– The right CRC coating reinforces locking mechanisms by preventing material wear at stress points like twist caps or push-and-turn tops.

– Over time, uncoated plastics can degrade or become slippery—compromising child safety standards set by global packaging regulations.

– By integrating a toughened surface via UV treatment, manufacturers ensure closures stay tight, intact, and effective even after months of use at home.

– It’s not just about safety; it’s also about maintaining functionality where it matters most—in homes with curious little hands exploring everything within reach.

So next time someone asks “what is uv coated” meant for in makeup packaging? Tell them—it’s all about smart protection where appearance meets performance every day.

Choosing UV Coated Packaging: Key Considerations

When figuring out what makes UV coated packaging tick, these two angles—function and sustainability—are where the magic happens.

Top Features: Airless Pump Bottles vs. Standard Options

Picking between airless pump bottles and standard pump bottles isn’t just about looks—it’s about performance, too. Here’s what you should weigh:

- Product preservation: Airless pumps limit air exposure, helping extend shelf life by preventing oxidation.

- Contamination control: These bottles reduce bacteria contact since nothing flows back into the container.

- Precise dosing: They dispense consistent amounts every time—no waste or mess.

- Extended shelf life: Less oxygen means your formulas stay potent longer.

- Oxidation prevention: Especially key for natural or organic products that spoil fast.

- No product left behind: The vacuum mechanism ensures nearly all contents are used up.

- Better for sensitive formulations: Think serums, retinol creams, or anything prone to degradation.

So if you’re asking yourself “what is UV coated” packaging really doing here? It complements these high-performance formats by shielding labels and surface designs from fading while keeping things looking premium.

Sustainable Choices: Eco-Friendly Materials in Coatings

With climate talk everywhere, it’s no surprise that even your packaging’s finish matters. Let’s break down how switching to sustainable cosmetic packaging options changes the game:

• Start with the coating itself—eco-friendly coatings like water-based UV options emit fewer volatile compounds than traditional ones. That means less harm to air quality during production.

• Look for materials made with PCR (Post-Consumer Recycled) content. These repurposed plastics give new life to old stuff without sacrificing durability.

• Choose substrates that pair well with biodegradable finishes. Some brands now combine paperboard with compostable layers under a UV coat for a fully green solution.

• Prefer packaging labeled as using recyclable packaging, especially when paired with low-energy curing processes found in modern UV systems.

• Many suppliers now offer hybrid solutions—mixing traditional gloss with matte areas using only plant-based resins or non-toxic inks under a protective coat.

And here’s a quick look at how different eco-coating types stack up:

| Coating Type | VOC Emissions | Compostable | Compatible With PCR? |

|---|---|---|---|

| Water-Based UV | Low | No | Yes |

| Solvent-Based Gloss | High | No | Sometimes |

| Bio-Based Resin Coat | Very Low | Yes | Yes |

| Traditional Acrylic UV | Moderate | No | Rarely |

So next time someone asks “what is uv coated” material doing on an eco-product—you’ll know it’s not just aesthetic; it’s part of a cleaner process from start to finish.

The Science Behind What Is UV Coated Makeup Packaging

Understanding what is UV coated packaging starts with the science behind it. These layers do more than just shine—they protect, preserve, and perfect.

Chemical Properties: How UV Coating Works

So, what’s really going on when a makeup box gets that sleek, glossy finish? Here’s how UV curable resins and photoinitiators come into play:

- When exposed to ultraviolet light, monomers and oligomers react rapidly through a process called polymerization, forming a solid film.

- This reaction is kicked off by specialized photoinitiators, which absorb the UV energy and trigger the curing process.

- As the coating hardens, it creates a network of cross-linked molecules—this cross-linking boosts its toughness big time.

The entire curing mechanism takes just seconds under high-intensity lamps. No heat ovens. No long waits. That’s why brands love using it to protect their packaging while keeping production fast.

Plus, this slick layer isn’t just for looks—it’s part of the chemical armor that keeps everything beneath it safe from wear or environmental damage. So next time you ask what is UV coated packaging, remember—it’s chemistry doing overtime.

Effects on Performance: Packaging Material Preservation

A good coating does more than seal—it shields. Here’s how this invisible layer helps makeup packaging stay fresh-looking longer:

• Abrasion resistance & Scratch resistance: Prevents scuffs from handbags or rough handling during transport. • Chemical resistance: Shields against oils or solvents often found in cosmetics bags or retail environments. • Moisture barrier: Keeps humidity out so paperboard doesn’t warp or peel. • Product protection: Acts as an outer shell against external contaminants like dust or fingerprints. • Shelf life extension: Maintains print clarity and structural strength over extended periods—especially important for limited-edition collections. • Durability & Material integrity: Preserves shape and rigidity even after months on store shelves.

According to Mintel’s Global Packaging Trends Report 2024, “More than 68% of beauty consumers expect premium packaging not only to look good but also to last longer without visible wear.” That expectation makes understanding what is UV coated protection all the more essential for modern cosmetic brands.

UV Coating and Its Influence on Color Accuracy

Color matters—a lot—in makeup branding. And here’s how this coating keeps things visually locked in:

Short bursts of intense light can fade pigments over time—but not when there’s strong UV light absorption built into your packaging’s shield.

It also helps maintain: – Brightness through controlled light reflection, making colors pop without distortion; – Smooth surfaces that enhance gloss but don’t cause unwanted glare; – True-to-design hues thanks to stable pigment stability, resisting yellowing over time; – Consistent finishes across batches due to minimized risk of unexpected color shift.

With such high standards for appearance in cosmetics, knowing what is UV coated means knowing your palette stays exactly as planned—from factory floor to vanity drawer.

Comparing UV Coated and Non-Coated Makeup Packaging

Quick intro: Looks matter, but so does durability—here’s how UV coated makeup packaging stacks up against the rest.

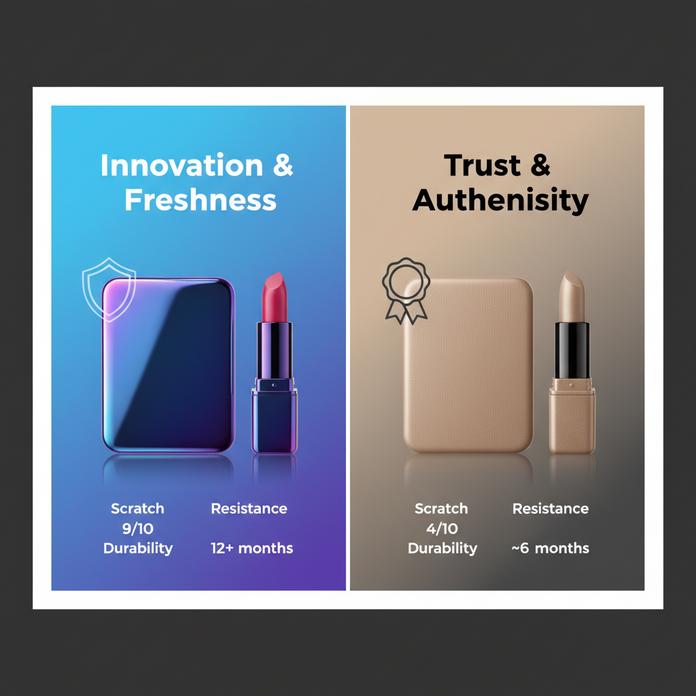

UV Coated vs. Matte Finish: A Visual Appeal Showdown

- Glossy pop or understated charm? That’s the real question.

- If you’re asking what is UV coated, think high-shine, eye-catching brilliance that makes colors leap off the shelf.

- Meanwhile, matte finishes whisper elegance—they don’t scream for attention, but they sure hold it.

-

Reflectivity:

- UV coating creates a mirror-like shine that amplifies color saturation.

- Matte absorbs light, giving packaging a soft-touch feel with minimal glare.

-

Visual appeal for luxury brands:

- High-end cosmetics often lean toward matte for an exclusive look.

- Drugstore and trend-driven brands love the gloss of UV coated designs.

-

According to Mintel’s Packaging Trends Report 2024:

“Consumers associate glossy finishes with innovation and freshness, while matte textures evoke trust and authenticity.”

☑️ Bottom line? The choice between matte and glossy isn’t just about looks—it’s about brand vibe. And understanding what is UV coating helps clarify why some products dazzle while others keep it cool.

Scratch Resistant vs. Standard Coatings: Stability Under Stress

• Ever tossed a lipstick into your purse only to find the label scratched off later? Yeah, we’ve all been there.

• That’s where scratch resistance, especially through UV coatings, really shines—literally and figuratively.

• Here’s how things stack up:

| Feature | UV Coated Packaging | Standard Coating | Result |

|---|---|---|---|

| Scratch Resistance Level | 9/10 | 4/10 | Winner: UV |

| Surface Durability (Months) | 12+ | ~6 | Longer life |

| Abrasion Tolerance | High | Low | Less wear |

-

The science behind it:

- A thin layer of cured resin forms a hard shell over printed surfaces.

- This not only boosts aesthetics but also fortifies against daily damage like keys, zippers, or rough handling during transit.

-

While exploring what is uv coated, it’s clear it’s more than just shine—it’s armor for your product’s face.

-

For long-term shelf presence or e-commerce shipping resilience, this kind of coating might be non-negotiable.

So next time you’re weighing options between standard packaging versus something tougher, remember this protective edge could mean fewer returns and happier customers—especially when appearances count as much as performance.

FAQs about What Is UV Coated

1. What is UV coated packaging in makeup manufacturing?

A sleek polymer layer, cured by ultraviolet light, binds onto acrylic plastic or aluminum containers—giving every lipstick tube and foundation compact a glossy shield that resists scuffs.

- Adds strength to delicate glass bottles and paperboard cartons.

- Allows clear decorative contrast for silk screen printing or hot stamping foil techniques used by certified manufacturers worldwide.

2. Why choose scratch resistant UV coating for bulk orders?

It keeps makeup surfaces as pristine as their first production run even after travel through global sourcing options.

- Reduces friction marks on refillable packaging designs and sustainable cartons.

- Preserves the brand’s image with fewer product losses during shipping handled by experienced exporters.

3. How do matte, glossy, and soft touch finishes change appearance?

Each finish tells its own story: a visual rhythm between shine and restraint.

| Finish Type | Typical Use | Emotional Tone |

|---|---|---|

| Glossy Coating | Eyeshadow palettes & mascara containers | Vivid luxury |

| Matte Finish | Eco-friendly materials & paperboard cartons | Calm sophistication |

| Soft Touch Layer | Lip gloss applicators or compact lids | Velvet-like comfort |

4. Does UV coating help maintain color vibrancy over time?

Yes—the barrier stabilizes inks under store lighting so printed shades stay faithful across lip gloss applicators or tamper evident seals.

• Works beautifully with pad printing services and label application process when brands demand long-term clarity.

5. Which packaging features gain most from what is uv coated treatment?

UV layers support modern convenience systems:

- Airless pump bottles: extend cream life while blocking oxidation; perfect for foundation lines requiring FDA compliance standards.

- Child resistant closures: retain precise locking ability under constant use; reliable distributors often pair these with customized engraving options for safety plus style.

6. Are eco-friendly coatings certified for large cosmetic projects?

Sustainable formulas are rising fast among custom cosmetic packaging solutions seeking international safety standards.

- Eco polymers suit recyclable paperboard cartons without dulling print colors.

- REACH regulation adherence and Proposition 65 warning labels ensure market entry ease within both U.S.A. and E.U territories alike—proof that beauty can protect the planet too.

References

- [Smithers’ 2023 Global Packaging Report – https://www.smithers.com/resources/2023/november/packaging-market-set-for-further-growth]

- [FDA Regulations for Cosmetics – https://www.fda.gov/cosmetics/cosmetics-labeling-regulations/cosmetics-labeling-guide]

- [REACH Guidelines – https://echa.europa.eu/regulations/reach/understanding-reach]

- [Proposition 65 List – https://oehha.ca.gov/proposition-65/proposition-65-list]

- [Mintel Global Packaging Trends 2024 – https://www.mintel.com/insights/packaging/global-packaging-trends/]