Ultimate Guide to Yellow Tube of Mascara Materials

It’s wild how much drama can live in something as small as a yellow tube of mascara—but trust me, there’s more happening behind that sunny shell than meets the eye. In beauty aisles packed to bursting with glitter and gloss, one hue screams confidence from across the room. But if that punchy yellow leaks, cracks, or feels cheap in hand? Game over. Packaging isn’t just packaging anymore—it’s your brand’s handshake.

Now here comes the headache: balancing style with function while keeping costs from chewing through your budget. Do you go glossy plastic for pop? Glass for luxe vibes? Aluminum for durability on-the-go? It’s like picking an outfit for prom when you’ve got three dates and one limo.

Cosmetic engineers at Topfeel say up to 63% of product returns are tied directly to packaging flaws (May 2024 R&D Report). So yeah—choosing materials isn’t just a box to tick. It’s the difference between “Wow!” and “Why is this leaking in my purse?”

Quick Answers for Choosing the Right Yellow Tube of Mascara

➔ Material Makes the Mood: Plastic is cost-effective and light, aluminum is durable and luxe, while glass adds elegance but risks breakage.

➔ Seal It or Spill It: Screw caps with silicone linings or snap lids with inserts drastically reduce leaks—don’t overlook closure quality.

➔ Decor That Pops: Use hot stamping for shine, embossing for texture, and printing for bold branding that stands out on shelves.

➔ Strength in Structure: Reinforce thin-walled tubes using ribbing patterns, layered acrylics, or metallized coatings to prevent cracking.

➔ Sizing Smarts: Pick between 5 ml to 20 ml based on usage occasions—travel size? Touch-up tube? Full-day glam? You decide.

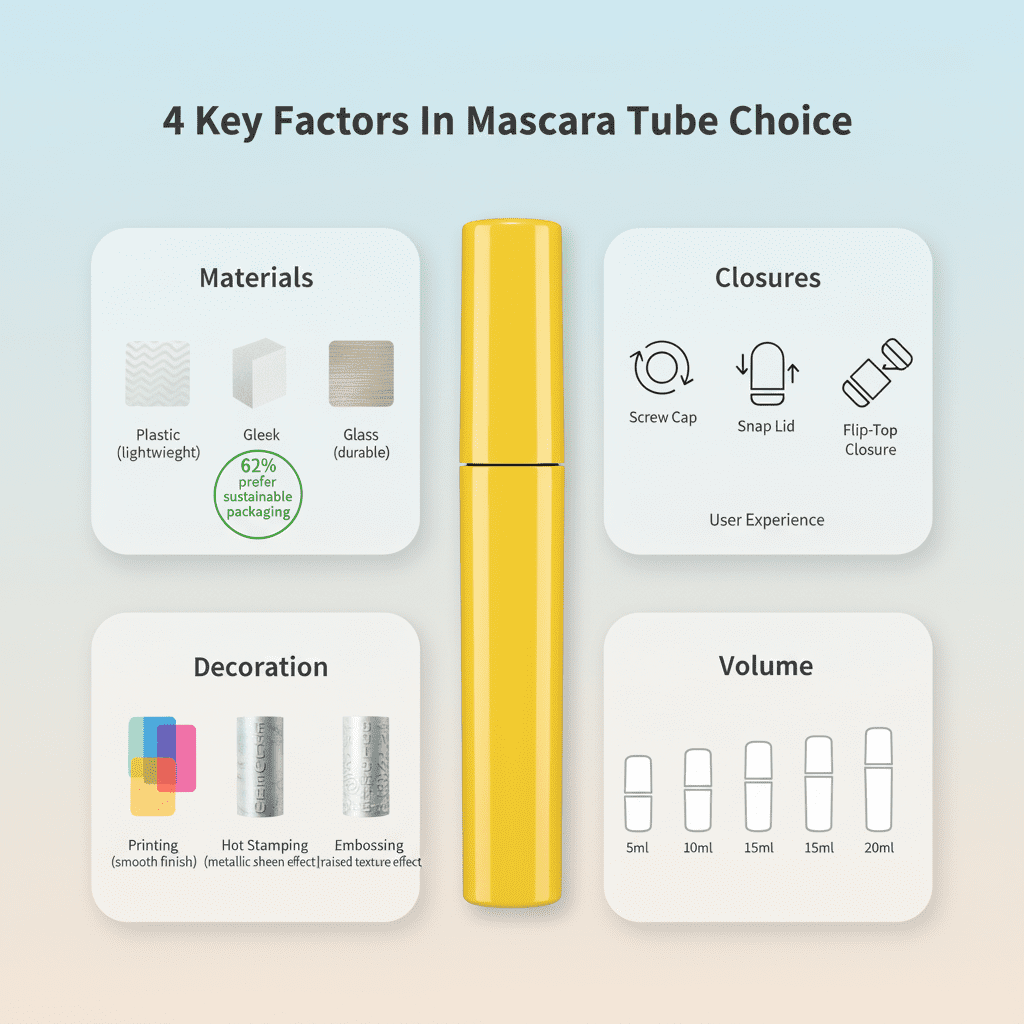

4 Key Factors In Yellow Tube Of Mascara Choice

From materials to volume sizes, every detail in mascara packaging tells a story. Let’s break down what really makes a tube stand out.

Material Matters: Plastic, Glass & Aluminum Yellow Tubes

When picking the right vibe for your mascara packaging game, don’t sleep on the materials—they’re doing more than just holding product.

- Plastic: Lightweight and cost-effective; great for on-the-go users who toss their makeup into bags without thinking twice.

- Glass: Sleek and luxe but heavier; often chosen by brands aiming for that premium feel.

- Aluminum: Durable and eco-friendlier than plastic; gives off a cool industrial aesthetic while protecting formulas from light exposure.

- All three materials can be color-matched to achieve that iconic bright yellow tube, but each brings its own texture and finish to the table.

- Consider recyclability too—consumers are watching. According to Topfeel’s latest client data survey, over 62% of buyers prefer sustainable packaging options.

Choosing Screw Cap & Flip-Top Closures

Closures might seem like small potatoes—but they’re actually clutch when it comes to user experience and product safety.

• A classic screw cap keeps things tight—literally. It minimizes air exposure and extends shelf life.

• If you’re all about quick access during morning rush hour? The snap lid wins for speed but may compromise on sealing strength.

Mixing aesthetics with practicality is key here. Want your yellow mascara tube to be remembered? Make sure opening it feels just as good as applying what’s inside.

Printing, Hot Stamping & Embossing Decoration Options

Design isn’t just surface-level—it’s how people remember your brand at first glance. Here’s how different decoration methods stack up:

| Decoration Method | Finish Type | Cost Impact | Visual Impact |

|---|---|---|---|

| Printing | Matte or Glossy | Low | Moderate |

| Hot Stamping | Metallic Foil Effect | Medium | High |

| Embossing | Raised Texture | High | Very High |

Hot stamping adds that premium metallic shine—great for logos or accents on a bold yellow container. Meanwhile, embossing creates tactile engagement that screams luxury without saying a word.

5 ml, 10 ml, 15 ml & 20 ml Volume Options

Size matters—but only when it fits the lifestyle of your target crowd.

5 ml – Perfect for travel kits or sample giveaways; tiny but mighty in impact.

10 ml – The sweet spot for daily use with minimal bulk in makeup bags.

15 ml – For those who go hard on eye makeup daily; offers more bang without being bulky.

20 ml – Ideal for pro kits or long-term users who hate frequent repurchasing.

Depending on whether you’re targeting casual users or seasoned beauty junkies, matching volume with intent is crucial when designing any yellow-hued mascara tube offering from Topfeel or beyond.

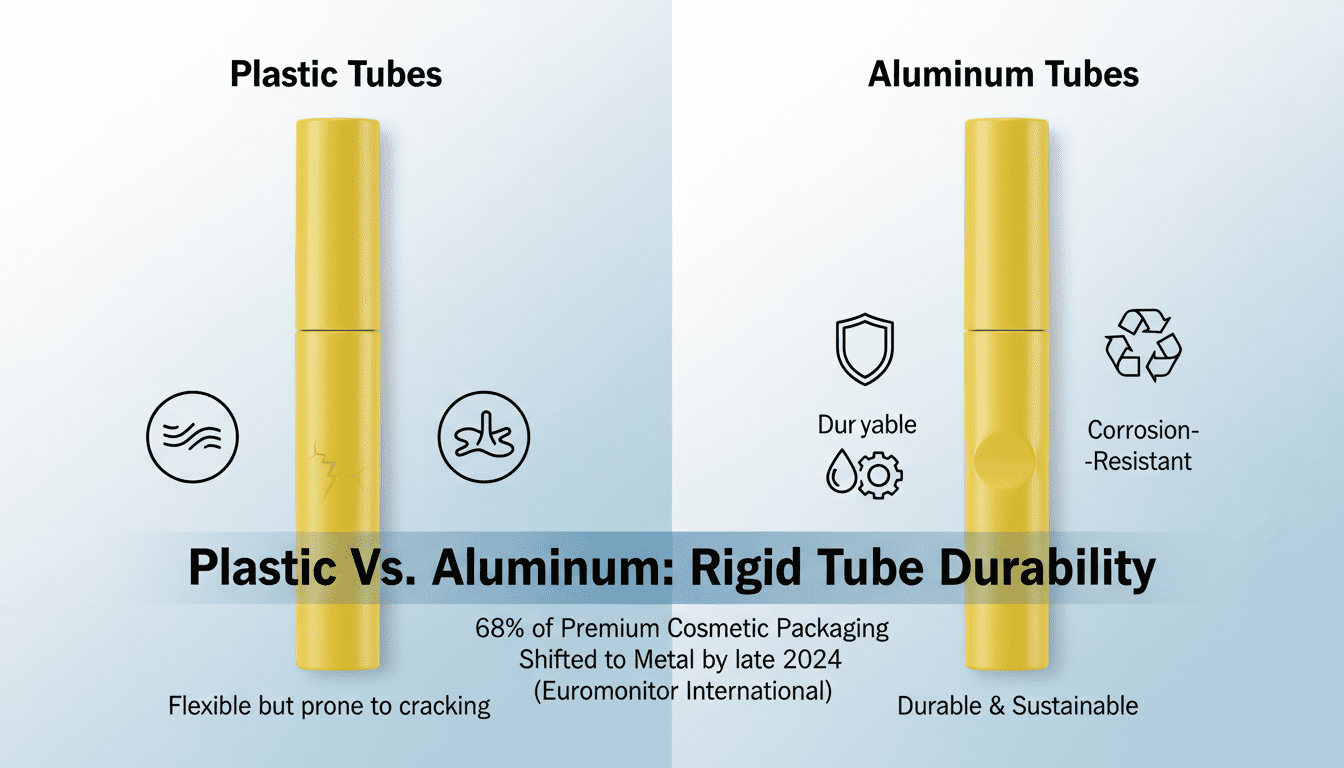

Plastic Vs. Aluminum Yellow Tube Durability

A quick look at how different materials hold up when used for those yellow tubes found in your favorite mascara picks.

Plastic

When it comes to the classic lightweight yellow tube of mascara, plastic is still a go-to. Here’s why:

- Flexible enough to survive daily drops and handbag chaos.

- Easy to shape through molding, offering creative design freedom.

- Typically made from polyethylene, polypropylene, or sometimes PVC, depending on texture and finish needs.

- More prone to cracking under pressure or over time, especially in dry climates.

- Doesn’t always scream “premium,” but it gets the job done affordably.

Plastic tubes are common because they balance cost and function. But if you’re after something that feels luxe? Keep reading.

Aluminum

Aluminum tubes give that yellow mascara casing a whole different vibe—sleek, solid, and built to last.

• You get serious protection from outside elements thanks to its corrosion-resistant nature.

• The material is naturally more durable than plastic; it’s less likely to suffer wear during long-term use.

• It’s also fully recyclable, which aligns with today’s eco-conscious consumer mindset.

“By late 2024, over 68% of premium cosmetic packaging shifted toward metal-based materials due to perceived luxury and sustainability,” according to Euromonitor International.

Still, aluminum isn’t flawless—it can show signs of wear like denting or subtle surface oxidation if not treated properly. But overall? It gives your mascara tube that upscale edge without sacrificing function.

Leaky Tubes? Improve Seal With Silicone Lining

Tired of messy makeup bags and sticky lids? Here’s how silicone features can totally change the sealing game in mascara packaging.

Screw Cap Tube: Adding Silicone Lining for Leak-Proof Performance

Adding a silicone lining to a screw cap tube isn’t just smart—it’s essential if you want your product staying put, not leaking out. These features make all the difference:

- Precision fit: The silicone hugs the threads inside the cap, creating a tighter grip that resists loosening over time.

- Pressure resistance: Whether tossed into a purse or squished at the bottom of a drawer, this kind of seal holds up under pressure.

- No product waste: Keeps every drop of formula inside where it belongs—especially helpful for premium mascara blends.

- Temperature resilience: From freezing temps to heatwaves, silicone stays flexible and effective without warping.

- Sustainability boost: Reusable and long-lasting materials mean less waste overall—good news if you’re eco-conscious.

This is especially useful for thick formulas like those found in bold black or even yellow-tinted mascaras that tend to clog or crust around traditional seals.

Snap-Lid Tubes with Silicone Inserts for Drip Prevention

You know those annoying blobs that sneak out after snapping shut your mascara? That’s what these clever little silicone inserts were made to fight.

• They act like cushions between lid and rim, catching excess formula before it spills.

• A snug fit means air stays out—so less drying, more glide when you swipe on.

• Even after hundreds of opens and closes, they don’t lose shape or grip.

The combo of a solid snap-lid with inner flexibility makes these tubes ideal for travel-sized options or funky colored mascaras like green or yellow ones that typically have thinner consistency.

According to data from Mintel’s Global Packaging Trends Report 2024, “Consumers increasingly expect beauty products to be mess-free and portable without compromising on style.” These inserts check both boxes—and then some.

Pump Applicators and Silicone Seals for Zero Leakage

Let’s talk about mess-free dispensing. Pairing pump-style applicators with tight-sealing silicone seals gives you total control without any goop drama.

| Feature | Benefit | Impact on Product | Ideal For |

|---|---|---|---|

| Airtight barrier | Blocks air entry | Longer shelf life | All-day wear mascaras |

| Flexible compression | Adapts as pressure changes | No leaks | Travel-friendly formats |

| Precision channel design | Directs flow cleanly | Less smudging | Liquid-based pigments |

| Easy-clean surface | Wipes off fast | Better hygiene | Daily-use cosmetics |

These are especially handy when dealing with lighter-hued products like pastel pinks or soft yellows—the kind that show every leak stain instantly. With this setup, not only does your bag stay clean, but your look stays sharp too.

Thin Walls Causing Breakage? Reinforce Tube Structure

When tubes snap or crack too easily, the wall design is usually the culprit. Here’s how to toughen up those fragile shells.

Layered Acrylic Tube: Wall Reinforcement Strategies

• Acrylic tube designs with multiple layers boost durability without bulking up the product. A thin outer shell, a reinforced middle, and a clear inner layer work together for strength and transparency.

• The layered construction acts like armor—each layer absorbs different types of stress from pressure or drops. This means fewer cracks during shipping or use.

• In cosmetic packaging, especially for things like a yellow-themed mascara case, this build offers both aesthetic clarity and improved wall reinforcement.

• Bonus benefit? It helps maintain structural integrity even when using thinner materials to save on cost or weight.

Internal Ribbing Patterns Strengthen Plastic Mascara Tubes

Short vertical ridges running along the inside of a plastic mascara barrel aren’t just for show:

- They create internal tension lines that make the tube stiffer.

- These internal ribbing patterns resist flexing under pressure.

- During injection molding, ribs can be formed without extra material costs.

- For lightweight items like a yellow-branded lash applicator tube, this keeps things light but strong.

The key is balancing rib height and spacing so they don’t interfere with product dispensing but still offer solid tube strength.

Metallized Tube Coating Adds Structural Support

A recent study from Mintel’s Q1 2024 Beauty Packaging Report noted that “metallized coatings not only improve barrier properties but also significantly enhance overall rigidity.”

That’s why metallizing isn’t just about glam shine—it adds serious backbone. A fine metal layer, typically aluminum-based, is applied via vacuum deposition onto the outer surface of plastic tubes. This coating reinforces the form while boosting shelf appeal.

Especially effective for slim formats like certain yellow-tinted mascara containers where structural support needs to come from more than just thick walls.

Material Science Meets Cosmetic Packaging Durability

Here’s how smart material choices keep your tubes intact:

▪️ Use hybrid polymers with high tensile strength for base materials.

▪️ Combine thermoplastics with UV-resistant additives to prevent brittleness over time.

▪️ Select finishes that protect against scratches while enhancing grip—ideal for slippery bathroom counters.

In short, it’s not just what goes inside your makeup—it’s what holds it together too.

Design Patterns That Prevent Cracks Before They Start

Tiny tweaks make big differences:

- Rounded corners instead of sharp angles reduce stress points.

- Tapering wall thickness near openings prevents split seams.

- Strategic embossing can double as branding and reinforcement.

Even when working with bright-colored mascaras—like those housed in a vivid yellow casing—these details protect against breakage from repeated use.

Injection Molding Adjustments That Boost Tube Strength

To reinforce thin-walled tubes during production:

- Slow down cooling rates slightly to avoid internal stress fractures.

- Increase back pressure during fill stages to ensure denser material packing.

- Add venting channels at weak points so air doesn’t create voids inside walls.

These small changes help keep even brightly colored packaging—from neon pinks to golden yellows—in shape longer under daily wear-and-tear conditions.

Balancing Form & Function Through Smart Tube Engineering

Grouped by purpose, here are ways engineers tackle fragility:

🟡 Material Enhancements:

– Blend ABS into acrylic bases for added shock absorption.

– Use multi-layer coextrusion techniques for seamless reinforcement layers inside acrylic tube bodies.

🟡 Structural Features:

– Integrate micro-ribs at high-stress areas using precision molds.

– Apply localized thickening only where needed—not across entire walls—to retain elegance without losing toughness.

🟡 Surface Treatments:

– Add matte textures that resist scratches yet feel luxe in hand.

– Include anti-slip coatings helpful when applying products like mascara on-the-go.

This mix ensures that everything from minimalist black designs to playful yellow lash tubes stays stylish—and intact—even after months of tossing around in handbags or drawers.

Reinforced Tubes Without Compromising Style

You don’t have to sacrifice looks for strength anymore:

- Transparent acrylic blends let you showcase vibrant formulas while hiding inner structural supports.

- Metallic sheens mask thicker walls or ribs beneath while giving off premium vibes.

- Even ribbed interiors won’t show through opaque colors like deep navy or sunshine-yellow exteriors—making them perfect companions for bold beauty brands aiming high on design without risking breakage complaints later down the road.

FAQs

Aluminum doesn’t just look sleek—it feels it. Holding an aluminum tube gives the impression of care, intention, and quality. It resists dents and scratches far better than plastic, keeping your product looking sharp long after purchase. Plus, its cool metallic finish instantly signals premium to customers scanning crowded shelves.

- Add a silicone liner inside the cap—this tiny detail creates a tight seal that keeps formulas from seeping out during shipping or daily use.

- Make sure threads on both tube and cap are smoothly molded; rough edges lead to weak closure points.

- Test with real-world handling: toss it in a purse or makeup bag before finalizing production.

Absolutely—and you should! A bright yellow base already catches attention, but what happens next depends on you:

- Use hot stamping for gold foil logos that shimmer under light.

- Emboss patterns into the surface so users feel texture as they hold it.

- Match typography styles with your brand voice—sleek sans-serif fonts say modern; hand-drawn scripts whisper artisanal charm.

Every design decision turns this simple object into something emotionally resonant.