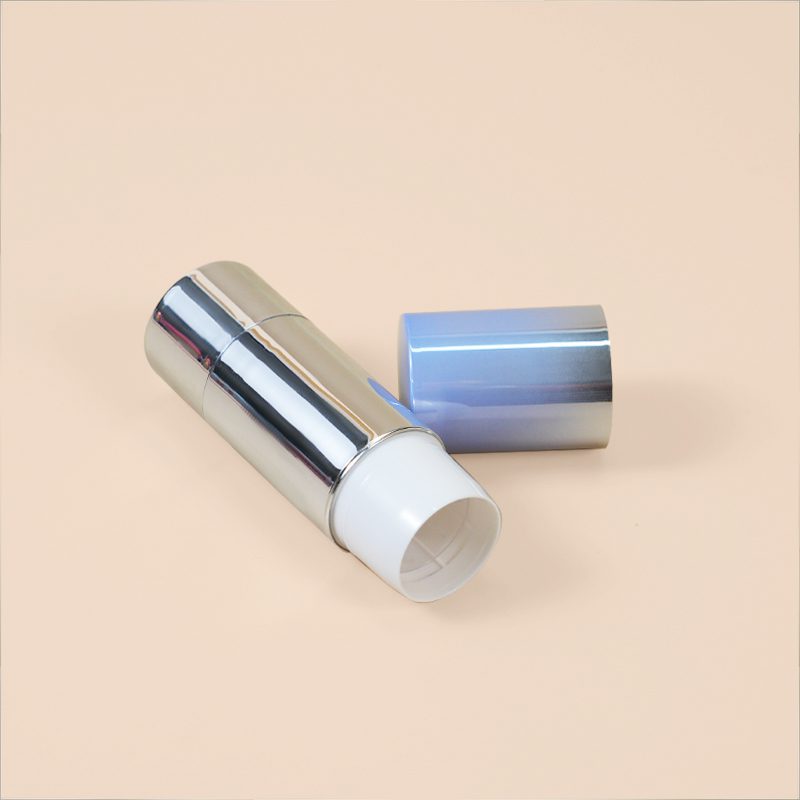

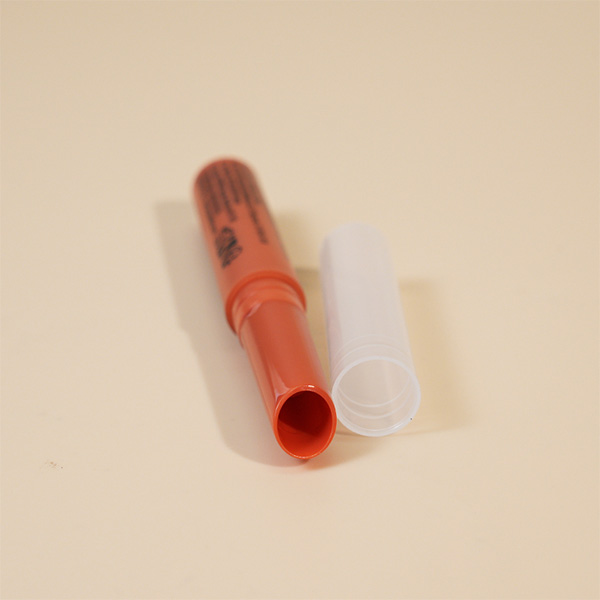

Our custom lash tube models deliver quantifiable precision and robustness 🧪📊. Each variant undergoes volumetric accuracy checks and shelf-stability trials to ensure batch integrity under stress. Elevate your line with verifiable metrics and premium-grade materials! 🚀

- Volume consistency within ±0.05 mL across batches

- Stability up to 36 months under accelerated ageing

- Material blends tested for thermal and UV resilience

- Custom-print fidelity validated via spectrophotometry

- ISO 22716–certified production processes