Best 2025 Mascara Tubes Options for Custom Packaging

Mascara tubes in 2025 aren’t just about holding product—they’re your brand’s first handshake. When buyers pick up a tube, they’re already judging what’s inside. For wholesalers, this means packaging isn’t fluff—it’s strategy. You’ve got to nail the look and the function.

Think of it like dating: you wouldn’t show up in wrinkled clothes to impress someone new. Same goes for beauty packaging—it needs to be clean, consistent, and say exactly what your brand stands for. But here’s the kicker: not all mascara tubes are built for scale, storage, or staying leak-free on the move.

One of our engineers at Topfeel put it best: “If it doesn’t survive shipping, it doesn’t belong in production.” That’s why build quality and material choices matter—especially when you’re ordering thousands at a time.

This guide walks through what really counts: materials that don’t crack under pressure, finishes that elevate your shelf presence, and smart designs that make bulk orders easier to manage.

If you’re tired of cheap-looking tubes, messy leaks, or endless back-and-forth with suppliers, you’re in the right place. Let’s find packaging that works as hard as your product.

Why Mascara Tubes Material Matters in 2025 ?

Choosing the right tube material is about more than looks—it’s the backbone of performance, durability, and bulk shipment savings in the mascara packaging game.

Barrel Polymer Choices for Waterproof, Smudge-Proof Sealing

-

The barrel needs to keep water out and formula in—period.

-

Choose HDPE or PP polymers for stronger barrier properties.

-

Waterproof and smudge-proof mascaras need packaging that won’t sweat or crack.

-

A poorly chosen barrel can turn your shelf-ready product into a leaky nightmare.

-

Here’s what counts:

| Barrel Material | Barrier Rating | Cost per Unit (Est.) | Ideal Use Case |

|---|---|---|---|

| HDPE | High | $0.08 | Waterproof mascaras |

| PP | Medium | $0.06 | Smudge-proof formulations |

| LDPE | Low | $0.05 | Conditioning-only formulas |

“Waterproof formulas are tough, but our HDPE barrel designs are tougher,” says Karen Li, Packaging Engineer at Topfeel.

Aluminum vs. PET Impact on Bulk Packaging Costs

-

Aluminum: Looks sleek, feels luxe—but packs a price punch.

-

PET: Lightweight, reliable, and cuts shipping bills.

-

Cost Comparison: PET saves 12–18% on long-haul shipments.

-

Supply Chain: PET is more available post-pandemic, meaning faster fulfillment.

-

Bottom Line: For mass-market mascara lines, PET is the smart move.

Let’s be real—aluminum feels elite, but PET keeps you lean when you’re ordering 50,000 units at a time.

Cap and Stopper Compatibility with Conditioning Formulas

Conditioning mascaras are rich—think oils, waxes, and sometimes even serum-style ingredients. When those meet incompatible caps or stoppers, things get messy fast.

-

The wrong cap material may warp or allow formula to seep.

-

Stopper friction needs to balance grip with smooth release.

-

Over time, poor sealing can cause ingredients to break down.

-

For nourishing lashes, applicator compatibility = formula stability.

-

Always test silicone vs. elastomer interactions with conditioning formulas before bulk ordering.

Wiper Material Effects on Coating and Layering Consistency

A good wiper can make or break how well the mascara coats your lashes. Here’s the scoop:

-

Silicone wipers dose better for volume and coating thick waxes.

-

Soft elastomers help with smoother layering—great for tubing mascaras.

-

Hard wipers? Avoid ’em. They pull too much off, killing drama.

And the brush? It’s only as good as the wiper that preps it. Clean coating + consistent layering = smooth sweeping every time.

Recyclability and Sustainability of Mascara Tube Components

The beauty biz is going green, and your packaging better keep up.

-

PCR materials: Popular for barrels and caps—lower carbon footprint, lower guilt.

-

Bio-based plastics: More stable now and ready for scale.

-

Recyclable designs: Avoid mixed materials (like aluminum + plastic blends) that clog the recycling stream.

-

Eco wins: Lifecycle assessments show up to 30% environmental impact reduction with circular designs.

Using eco-friendly materials isn’t just a nice touch—it’s becoming non-negotiable for retailers and bulk buyers alike.

5 Key Features of Mascara Tubes You Need

Looking to lock in the best custom mascara packaging for your 2025 line? These 5 key features aren’t optional anymore—they’re essential.

1. Leak-Proof Cap Threads for Spill-Free Shipping

-

Precise cap threads matter:

-

Create an airtight seal for mess-free shipping

-

Prevent product oxidation

-

Maintain shipping integrity across long hauls

-

Reduce returns from leaks

-

Leak-proof packaging equals peace of mind, especially in bulk shipping. A secure thread design means buyers don’t worry about half-empty tubes arriving damaged. It’s about product security from factory floor to storefront.

2. Precision Wiper Blades for Clump-Free Separation

-

Precision wiper design manages formula flow

-

Controls how much mascara gets on the brush

-

Clump-free lashes every time

-

Maintains performance across formulas (waterproof, volumizing, etc.)

Wiper blade tech isn’t just a detail—it’s the heartbeat of applicator performance. Poorly designed wipers = clumpy chaos. Buyers want dosing control, especially with pricier pigment-loaded formulas.

3. Ergonomic Barrel Shape for Easy Sweeping and Lifting

Comfort matters when it comes to lash drama. A smart ergonomic design does more than look cute:

-

The barrel shape helps users master the sweeping motion

-

Good handle design allows better grip for lifting effect

-

A smoother experience keeps loyal customers coming back

Topfeel Packaging’s Product Director, Li Yun, once said:

“If the grip feels wrong, the entire application fails—packaging design is user experience.”

4. Soft-Touch Finish to Enhance Brand Perceived Value

Here’s how a soft-touch finish boosts your brand game:

Table: Finish Types & Consumer Reactions

| Finish Type | Perceived Value | Grippability | Preferred Market Segment |

|---|---|---|---|

| Glossy Plastic | Medium | Medium | Drugstore |

| Matte Laminate | High | Medium | Premium Mid-Range |

| Soft-Touch Film | Very High | High | Luxury / Prestige |

That tactile experience? It communicates quality before the product’s even opened. Add surface treatment with soft-touch coating and instantly raise brand value in the customer’s eyes—no pun intended.

5. Fiber-Friendly Inner Stopper for Tubing and Lengthening Formulas

Quick hits on why the inner stopper matters:

-

Prevents fiber fallout in tubing mascaras

-

Ensures clog-free flow in thick lengthening formulas

-

Maintains perfect wiper orifice pressure

-

Helps with formula consistency from first coat to last

Mascara with fibers needs a fiber-friendly stopper or you’re dealing with clogged tubes and angry emails. Smart formula compatibility leads to smoother runs, fewer defects, and happier buyers.

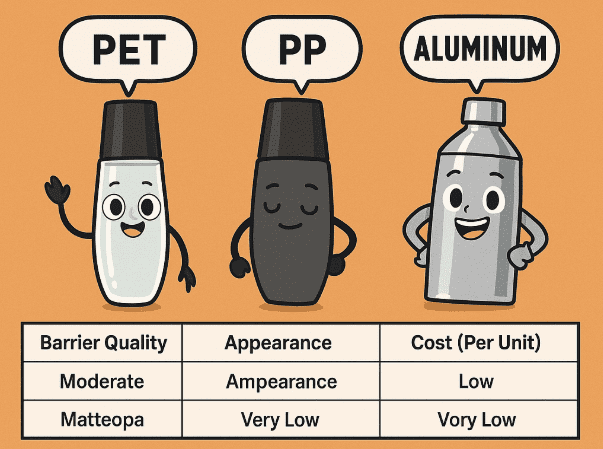

PET vs. PP vs. Aluminum Mascara Tubes: Which Wins?

Looking to pick the perfect tube for your mascara packaging line? Let’s break down the strengths of PET, PP, and aluminum tubes so you can find what works best for your business goals.

PET Tubes

-

PET plastic is:

-

Transparent, letting you show off bold pigment colors

-

Lightweight, which helps slash shipping costs

-

Super recyclable, keeping eco-conscious buyers happy

-

A solid barrier against water-heavy and oil-based formulas

-

Designers love PET for custom packaging because it’s flexible on shapes and finishes, while still keeping everything neat and tight inside. If you’re chasing affordable options with shelf appeal, PET tubes are a go-to.

PP Tubes

-

PP plastic offers durability and resilience, which makes it ideal for hectic production lines.

-

It brings solid chemical stability to the table—no weird reactions with polymer-rich formulations.

-

The matte finish gives a clean, modern vibe perfect for minimalistic branding.

-

Bonus: it’s affordable and can handle heat, making it great for hot fill lines.

“When speed meets volume, PP is our best bet for mass-market runs. It holds up under pressure, literally.” — Lina Z., Packaging Engineer at Topfeel

Aluminum Tubes

Barrier protection? Check.

Luxury vibe? Absolutely.

High-end feel? You bet.

Recyclable? Yes, and easy to market.

Aluminum metal tubes are perfect when you want a premium feel—they scream upscale. Thanks to their corrosion resistance and airtight barrier properties, they pair well with high-pigment, long-lasting, and conditioning mascaras.

Here’s a quick side-by-side for buyers weighing options:

| Material | Barrier Quality | Appearance | Cost (Per Unit) | Recyclability |

|---|---|---|---|---|

| PET Plastic | Moderate | Transparent/Glossy | Low | High |

| PP Plastic | Moderate | Matte/Opaque | Very Low | Moderate |

| Aluminum Metal | High | Metallic/Luxury | High | High |

If your brand’s all about luxury and you’re serving boutique or prestige clients, aluminum tubes might be your hero product.

Leak-Proof Mascara Tubes: Solve Packaging Spills

Stop product damage in bulk packaging by eliminating tube leaks at the source. These solutions target stopper engineering, smudge-free applicators, cap gasket systems, and validation testing.

High-Precision Stopper Seals to Prevent Drips

-

Precision-fit stopper and orifice pairs ensure the right squeeze on the wand—no more gloopy messes.

-

Tight closure interaction with the barrel neck forms a reliable drip prevention barrier.

-

Stopper materials like silicone and TPE provide stretch-flex to handle thick pigment or wax-based formulas.

-

Consistency matters: every stopper needs to align with the wiper geometry and closure torque.

-

Brands focusing on waterproof mascaras benefit the most—these formulas love to leak if seals are off.

Advanced Wiper Designs for Smudge-Proof Application

-

Geometry matters. The angle of the wiper blades controls how much formula hits the brush.

-

Material counts. Soft elastomers help with dosage control, especially for thick, smudge-proof mascaras.

-

The wand-wiper connection has to be tight—otherwise, you’ll get overloaded brushes and raccoon eyes.

-

Good application consistency builds customer trust and makes refills easier for clients doing bulk orders.

“Smudge-proof mascara starts at the wiper. If that design isn’t locked in, everything else falls apart.” — Lina Guo, Senior Product Engineer, Topfeel

Cap Gasket Innovations for True Leak Resistance

Smart cap designs are your final defense against costly shipment leaks. Here’s how different cap gasket materials and designs perform:

| Gasket Type | Material Used | Seal Integrity Score | Packaging Compatibility |

|---|---|---|---|

| Flat Elastomer | Silicone | 8.5/10 | Excellent |

| Dual-Lip Insert | TPE | 9.2/10 | Moderate |

| Dome Seal | EPDM | 7.9/10 | High |

💡 Material innovation like dual-lip gaskets not only improves barrier protection, but also cuts down rejects during bulk shipping. If you’re dealing with high-output production, don’t skimp here.

Quality Control Tests: Pressure, Drop, and Torque Checks

Keeping packaging integrity tight means pushing each tube through rough real-world conditions. Here’s how:

-

Pressure Test: Simulates cabin pressure changes during air freight. No leaks allowed.

-

Drop Test: Tubes get dropped from waist height onto hard surfaces—caps and closures must survive.

-

Torque Check: Ensures consistent closure force to avoid over-tightening or loose seals in the field.

✅ Real QC isn’t optional—it’s your insurance policy for large-volume buyers. Skip this, and you’re rolling the dice on customer complaints.

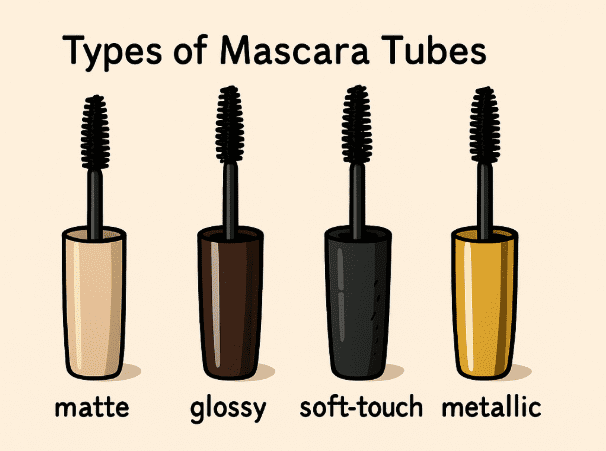

Types of Mascara Tubes Finishes

A good finish isn’t just skin-deep—it sells the feel, look, and story of your mascara. Here’s how tube coatings deliver real value in wholesale packaging.

Matte Coating for Elegant Brand Storytelling

-

Non-reflective, modern, and straight-up classy

-

Ideal for brands selling understated luxury or a “clean girl” aesthetic

-

Helps highlight brand narrative with minimalist labels

-

Softens visual glare under retail lighting for a sophisticated design tone

-

Pairs well with soft-bristle brushes for gentle, conditioning mascaras

A matte finish gives off that smooth, luxe vibe that whispers quality without shouting. If your buyer loves subtle elegance, matte coating screams (quietly) “premium.”

Glossy Lacquer to Highlight Pigment-Rich Formulas

-

High-shine lacquer grabs attention on crowded shelves

-

Reflective surfaces amplify vibrant colors and pigment intensity

-

Perfect for rich blacks, bold browns, or dramatic volumizing mascaras

-

Works well with formulas loaded with wax and polymer for staying power

-

Adds an instant luxurious sheen that signals value

Want a tube that matches the drama of the lashes it delivers? A glossy finish turns heads and adds that deluxe energy shoppers can’t resist.

Soft-Touch Film to Convey Premium Handling

| Feature | Benefit to Brands | User Perception | Ideal Mascara Type |

|---|---|---|---|

| Velvet texture | Adds tactile uniqueness | Soft, refined | Lengthening or tubing |

| Comfortable grip | Prevents slippage in use | Secure and premium feel | Conditioning or daily wear |

| Luxury perception | Enhances unboxing moment | High-end branding cue | Smudge-proof, multi-coat |

Soft-touch coating isn’t just looks—it’s the feel that seals the deal. It delivers a tactile experience buyers love, especially on premium, user-focused SKUs. Your fingers know it’s fancy before your eyes do.

Metallic Finish for Dramatic Retail Impact

-

A metallic finish throws serious light—think high-impact, reflective, and bold

-

Works like a magnet under retail lighting, giving you real shelf presence

-

Great for lash formulas promising drama and enhancement

-

It’s an instant luxury statement, making even mid-tier mascaras feel top-shelf

-

Adds that eye-catching shimmer that says: “Yeah, I’m extra.”

A metallic finish makes your packaging work double-time. It turns mascara tubes into glam showpieces—perfect for brands that want their lashes (and sales) to pop.

Sleek Design, Maximum Impact

A good mascara tube doesn’t just hold the product—it sells it. Sleek design can change how your brand is seen, remembered, and shared.

Design that Talks Before the Product Does

When you’re selling cosmetics in a crowded aisle or across a glossy website page, visual impact is everything. Your packaging needs to say “quality” before the customer even picks it up. Here’s how the smartest brands are nailing it with sleek, eye-catching mascara tube designs that go beyond function:

Topfeel Senior Designer: Kayla Ren, Packaging Design Lead “Minimalist packaging makes your brand louder, not quieter. Clean lines, custom finishes, and distinctive silhouettes are like instant street cred for a mascara line. Shoppers see it and instantly know: this product means business.”

Why Sleek = Smart

-

Minimalist packaging creates shelf power – Fewer distractions mean more focus on your brand name and your message.

-

Sleek contours = better ergonomics – It’s not just about looks. A mascara tube that fits the hand comfortably boosts user satisfaction and application control.

-

Custom finishes elevate brand identity – From matte soft-touch to high-gloss metallics, a finish is more than pretty—it tells a story.

-

Premium materials change perception – A heavier cap or solid-feel barrel made from recyclable aluminum can instantly make a brand feel more luxurious.

-

Color blocking plays with visual cues – Clean color divisions or subtle contrast helps reinforce brand language and makes SKUs easier to distinguish.

Q&A with Michelle Zhang, Product Manager at Topfeel

Q: What’s the most requested design feature from bulk buyers in 2025? A: “Honestly? Custom silhouette requests. Brands want tubes that don’t look like anyone else’s—something that’s unique but still ergonomic and easy to fill on the line.”

Q: How much does visual design influence repeat orders? A: “Massively. If the customer loves how it looks on their vanity or in their purse, they’re way more likely to repurchase—especially with social sharing in play.”

Quick Wins for Brand Builders

-

Keep it slim – Tubes with slimmer profiles feel more modern and easier to carry.

-

Avoid clutter – One clear font, one bold logo, one strong visual concept—done.

-

Make it photogenic – Instagram-ready packaging isn’t a luxury—it’s a sales tool.

-

Color tells a story – Use black for drama, nude for elegance, white for purity—each shade can reinforce your product’s purpose.

-

Weight it right – Just enough heft in the cap or barrel makes it feel luxe without jacking up freight costs.

Wrap-up: Sleek design isn’t about being flashy. It’s about being intentional. Whether it’s the click of the cap, the curve of the barrel, or the velvet feel of the finish—every design choice shapes how customers feel. And in the mascara game, feel sells.

Conclusion

Picking the right mascara tubes for your business isn’t just about looks—it’s about solving real problems that show up in your production line and customer feedback. Smudging, leaking, brushes that miss the mark… it adds up. This guide walked you through the key stuff—materials, finishes, features—that’ll help you skip the headaches and order smarter.

For bulk buyers, smart packaging is half the battle. You need options that check all the boxes: easy to fill, tough enough to ship, and custom enough to match your branding. That’s where the right partner comes in—someone who gets what matters when you’re buying by the thousands.

We’ve helped brands get from test runs to shelves without breaking a sweat. Want in? Let’s talk.

FAQs

1. What are the most durable materials for mascara tubes in bulk packaging?

-

High-impact PP barrels resist cracking under pressure and transport stress.

-

PET polymer offers chemical resistance against oil-rich, waterproof formulas.

-

Aluminum tubes provide superior barrier performance for pigment-filled, smudge-proof mascaras.

-

Bio-polymer blends meet sustainability mandates without sacrificing structural integrity.

2. How do wiper designs affect mascara application? Precision-engineered wipers control coating thickness on bristles, enabling even layering and clump-free separation. A well-matched wiper polymer prevents overloading of volumizing or tubing mascaras, improving fringe definition and user satisfaction.

3. How can I ensure leak-proof mascara tubes for waterproof formulas?

-

TPU or silicone stopper seals to lock viscous, film-forming formulas

-

Integrated cap gaskets for extra leak resistance under torque tests

-

QC protocols: drop, pressure, and torque checks on each batch

-

Tight cap threading to prevent spills during pallet stacking

4. What role does cap threading play in packaging quality? Accurate cap threads ensure a tight seal between cap and barrel, preventing formula exposure to air and water. Proper torque tolerances reduce leaks in oil-based conditioning mascaras and maintain wiper alignment for consistent coating.

5. Which finishes enhance mascara tubes’ visual appeal?

-

Matte film-former coating for a luxury, soft-touch feel

-

Glossy lacquer to accentuate deep-color pigment richness

-

Metallic finish for high-drama, reflective retail impact

-

Transparent or frosted PET options to showcase fiber-laden formulas

6. How should I choose barrel polymers for smudge-proof mascara? Opt for PP or PET blends with high moisture-barrier properties to protect smudge-proof formulations containing wax and polymer film-formers. These materials balance cost and performance, reduce returns, and support large-scale filling operations.