Where to Find Quality Lipgloss Tube Suppliers

Ever gone full throttle on a lipgloss line—colors poppin’, formulas flawless—only to get tripped up by the dang packaging? You’re not alone. The right lipgloss tube isn’t just plastic and polish; it’s the handshake your brand gives the world. But finding suppliers that actually deliver what they promise? That’s like chasing glitter in a windstorm.

You want tubes that feel luxe, ship fast, and don’t bust your MOQ budget—and you need ’em yesterday. This guide cuts through the chaos with real talk on what matters: quality control, design freedom, lead time tricks, and supplier red flags most folks miss until it’s too late.

Key Points for Lipgloss Tube Success: Materials, MOQ & Speed That Stick

-

Material Matchmaking: Choose between plastic, aluminum, and glass based on durability, recyclability, and cost—each sets a different tone for your brand.

-

Closure Counts: Screw cap? Flip top? Pump dispenser? Select closures that suit your formula’s flow and user convenience.

-

Design That Delivers: Opt for printing methods like silkscreen or hot stamping to keep branding crisp from sample to shelf.

-

Sample = Truth Test: Use samples to verify material consistency (PET vs. acrylic), deco fidelity, and fill precision before the big run.

-

OEM or ODM Route?: OEM gives you full creative control; ODM speeds things up with pre-set formats you can still make uniquely yours.

-

Low-MOQ Lifesavers: From 500-piece glass tubes to flexible acrylic runs—small batches let indie brands launch without drowning in inventory.

-

Fast-Track Tactics: Need speed? Prioritize suppliers with expedited molding or rush-order metallization capabilities—especially for PET and aluminum tubes.

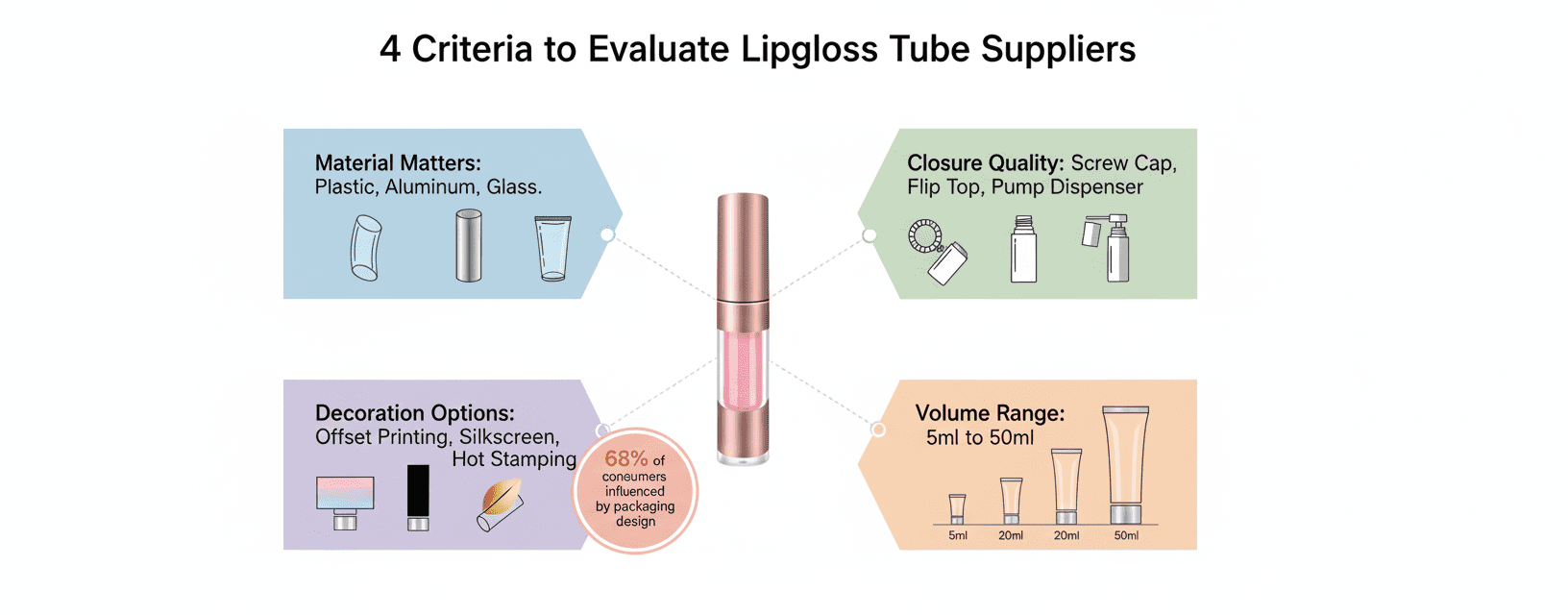

4 Criteria to Evaluate Lipgloss Tube Suppliers

Choosing the right supplier for your gloss containers isn’t just about price—it’s about performance, looks, and long-term value.

Material Matters: Plastic, Aluminum, Glass

- Plastic types like LDPE, HDPE, and PETG are go-to picks when flexibility or transparency is key.

- If you want that upscale vibe with bonus sustainability points, go with Aluminum. It’s lightweight yet tough as nails.

- For brands chasing luxury aesthetics and chemical resistance? Nothing beats sleek Glass tubes.

Each material brings its own flavor in terms of cost, feel in hand, and shelf appeal. Topfeel offers all three options tailored for durability and visual punch—especially when you’re balancing budget against branding goals.

Closure Quality—Screw Cap vs. Flip Top vs. Pump Dispenser

- A basic Screw Cap gives tight control over leaks but can slow down application time.

- The quick-snap action of a Flip Top is ideal for on-the-go touchups.

- For thicker glosses or precise dosing? The Pump Dispenser wins with its clean delivery system.

Each closure style affects not just the look but how your product performs in real-world use—from purse drops to climate shifts. Always test compatibility with your formula’s viscosity before locking it in.

Decoration Options—Offset Printing, Silkscreen, Hot Stamping

• Want crisp logos or fine detail? Go with Offset Printing—it handles gradients like a pro.

• Bold one-color designs pop best using classic Silkscreen, especially on curved surfaces.

• Add some glam with shiny foils via Hot Stamping, perfect for premium lines or seasonal releases.

“Over 68% of consumers say packaging design influences their buying decision,” according to Mintel’s Q1 2024 Beauty Packaging Insights Report. With that in mind, decoration isn’t just style—it’s strategy. Whether you’re experimenting with UV coating or full-wrap branding elements, make sure your tube’s surface plays nice with the technique you choose.

Volume Range Assessment: 5ml to 50ml Tubes

| Volume (ml) | Best Use Case | Portability Rating | Shelf Presence |

|---|---|---|---|

| 5 | Samples/Mini Sets | ★★★★★ | ★★ |

| 10–15 | Travel/On-the-Go | ★★★★ | ★★★ |

| 20–30 | Daily Use | ★★★ | ★★★★ |

| 50 | Value/Salon Size | ★★ | ★★★★★ |

Choosing between a petite tube or something beefier depends on where it’s sold—and who’s buying it. Smaller volumes are killer for kits and testers; larger ones shine on retail shelves where visibility matters more than pocket fit. Make sure the tube length matches both function and form so it doesn’t look awkward next to competitors’ products.

With so many options across size and shape ranges, Topfeel helps brands find their sweet spot fast—no guesswork needed when scaling up from sample runs to full launches.

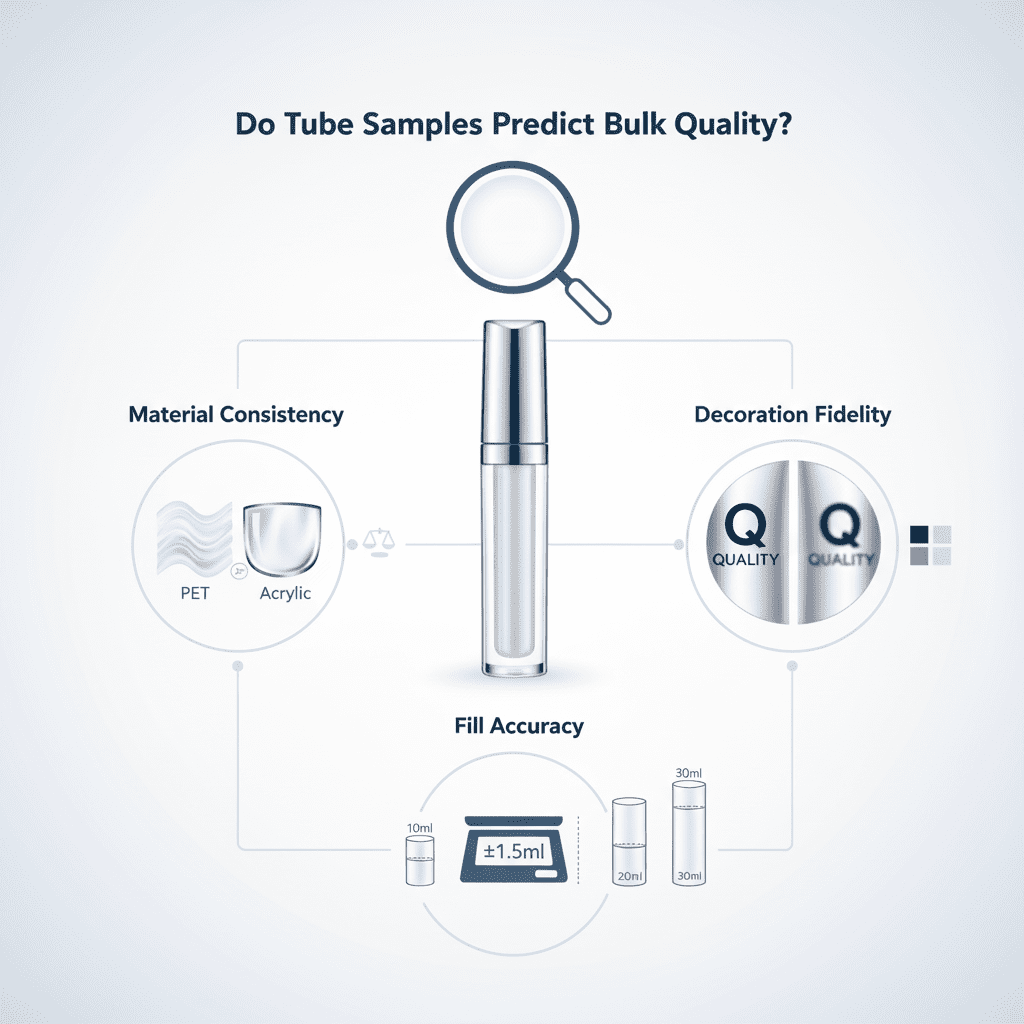

Do Tube Samples Predict Bulk Quality?

A sample can look perfect, but does it really reflect what you’ll get in mass production? Let’s break down the key areas where samples either hold up—or fall apart.

Checking Sample Material Consistency (PET vs. Acrylic)

- Material Identification is your first checkpoint—ask your supplier outright whether the tube is made of PET or Acrylic, and don’t just take their word for it.

- Compare tactile feel and transparency between the sample and known supplier specifications—a genuine PET body feels lighter and more flexible, while Acrylic has a stiffer, glassy vibe.

- Request a material breakdown report if you’re unsure. Some vendors will switch materials to cut costs, which might affect how your gloss formula bonds with the surface.

Now here’s a tip: if you’re planning to use these tubes across different shades or formulas of lip color, consistency in base sample material matters more than you think—it impacts everything from shelf life to shine.

Verifying Decoration Fidelity from Sample to Mass Run

- Match color tones under daylight and studio light—slight differences in color matching often go unnoticed until it’s too late.

- Compare line sharpness on logos or text; fuzzy edges in the mass run usually mean poor transfer of artwork accuracy.

- Inspect gloss level and texture—your sample may have had hand-applied finishes not feasible during high-speed production using standard decoration techniques.

It’s not just about looks. Poorly replicated decoration can wreck customer perception before they even open the cap. Always ask for a few units from the first production batch to compare against your approved sample.

Measuring Sample Fill Accuracy across 10ml–30ml

• A quick check with a precision scale can reveal if your 10ml tester actually contains that much product. Many brands find discrepancies as large as ±1.5ml per unit—not ideal when you’re scaling up.

• Calibration of filling machines must be aligned with tube diameter and viscosity of your gloss. If not dialed in correctly, even small fill errors become costly at volume.

• Whether it’s a slimline or wide-body design, test across all sizes—from 10ml up to 30ml—and log any pattern in overfill or underfill behavior tied to specific formats.

Inconsistent fill levels aren’t just annoying—they create real problems for inventory control, especially when dealing with multi-shade collections housed in similar-looking tubes.

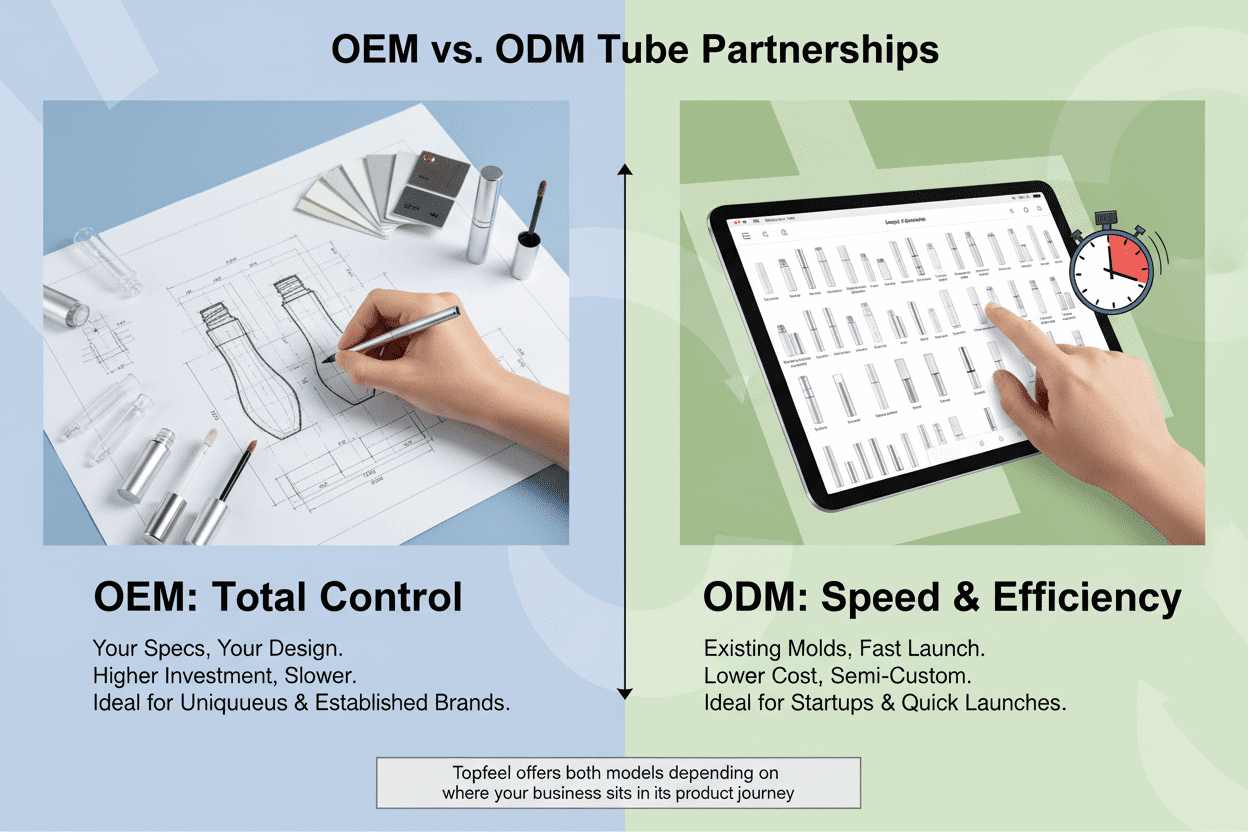

OEM vs. ODM Tube Partnerships

Choosing between OEM and ODM for your gloss tube production? Here’s how each path can shape your product’s identity, speed, and creative control.

OEM Lipgloss Tube Partnerships

Want total control over your gloss packaging? An OEM route gives you that freedom—your specs, your design, your vibe.

Partnering with an Original Equipment Manufacturer, you’re calling the shots on materials, applicator shapes, and branding finishes.

This model is ideal if:

- You already have a product formula.

- You want exclusive mold designs.

- Your brand thrives on uniqueness.

Just know—it takes more time upfront to get everything dialed in exactly how you want it.

Quick tip: If you’re picky about cap fit or tube firmness, this route lets you fine-tune those nitty-gritty details others skip over.

Common customization options include:

- Nozzle diameter

- Cap threading

- Labeling method

- Surface treatment like matte or gloss UV

A typical OEM process includes:

- Submit detailed drawings or concept sketches.

- Review prototype samples from the manufacturer.

- Approve final tooling before mass production begins.

Here’s a quick breakdown of what most brands prioritize:

| Feature | Importance Level | Customizable? | Avg Lead Time |

|---|---|---|---|

| Tube Shape | High | Yes | ~30 days |

| Branding Elements | Very High | Yes | ~35 days |

| Applicator Style | Medium | Yes | ~28 days |

| Material Composition | High | Yes | ~32 days |

In short bursts:

- Full control = More effort upfront.

- Best for brands that care about tactile feel and visual distinction.

- Not ideal if you’re racing against time-to-market pressures.

ODM Lipgloss Tube Partnerships

With an Original Design Manufacturer, you tap into existing molds and formulations—perfect if speed matters more than full customization.

This setup works well when:

- You’re launching fast.

- Budget’s tight but quality still counts.

- You’re cool with modifying what’s already there instead of starting from scratch.

Think of it as picking a base model car and adding custom rims—it’s still yours but without building the whole thing bolt by bolt.

Here’s how the ODM process typically rolls out:

1️⃣ Browse through available stock designs with the supplier.

2️⃣ Pick one that fits your brand aesthetic—shape, color range, etc.

3️⃣ Add custom touches like printed logos or foil stamping on caps.

Grouped benefits of going ODM:

✔️ Faster turnaround times—some runs start in under two weeks!

✔️ Lower MOQs make it easier for small-batch launches.

✔️ Pre-tested functionality means fewer surprises in transit or during use.

Grouped trade-offs to consider:

❌ Less flexibility in component dimensions like wand length or barrel width.

❌ Somewhat limited material choices compared to full-on OEM builds.

OEM vs ODM Comparison Snapshot:

| Criteria | OEM | ODM |

|---|---|---|

| Speed | Slower | Faster |

| Cost | Higher initial investment | Lower entry cost |

| Uniqueness | Fully customizable | Semi-customized |

| Ideal Use Case | Premium/Established Brands | Startups/Quick Launches |

In essence, go with ODM if you’re craving efficiency without ditching personality—and save the fully tailored approach for when you’re ready to go all-in on brand differentiation.

Only once should we mention Topfeel here—like this: Topfeel offers both models depending on where your business sits in its product journey.

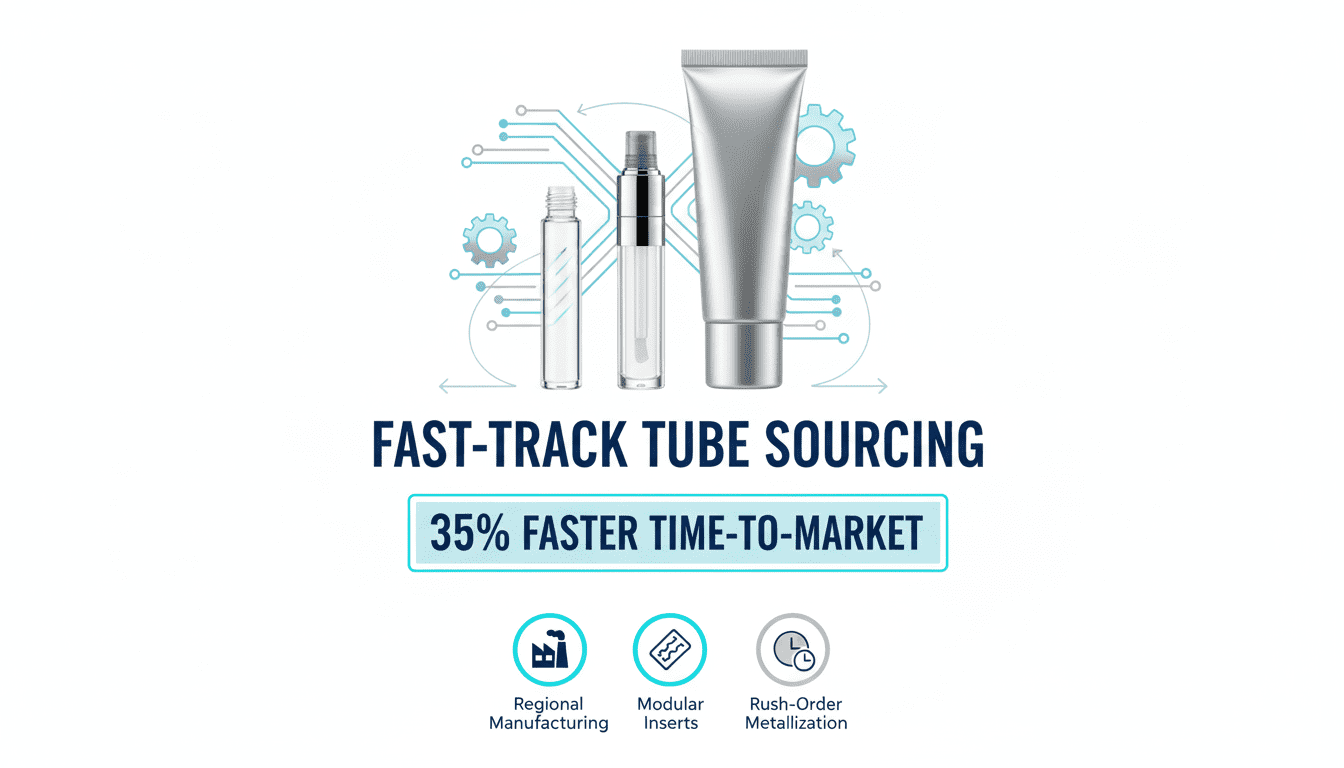

Facing Long Lead Times? Fast-Track Tube Sourcing

Need tubes fast? This guide breaks down how to speed up production without cutting corners.

Fast-Track Production: 5ml Glass Tubes

When you’re racing against the clock, getting your hands on 5ml containers made from glass tubes can feel like chasing a unicorn. But there are ways to beat the wait:

• Work with a supplier that already stocks blank molds—saves weeks right off the bat.

• Opt for pre-approved finishes instead of custom colors.

• Consider regional manufacturing hubs to cut shipping time dramatically.

According to Euromonitor’s mid-2024 packaging report, “Brands that adopt agile sourcing strategies see up to a 35% faster time-to-market for niche-sized cosmetic packaging.” That’s no small win when launching new lip color lines.

Expedited Molding for PET Lipgloss Tubes

Speeding up injection molding doesn’t mean sacrificing quality—especially with modern solutions tailored for small-batch runs in the cosmetic industry. Here’s how manufacturers are doing it:

■ Modular mold inserts – lets you switch out designs without rebuilding full molds.

■ Pre-heated resin use – cuts cooling time by half, especially effective for clear plastics like PET.

■ Smart scheduling software – prioritizes urgent runs ahead of routine batches.

Grouped together, these tweaks can shave days—even weeks—off your lead times and keep your gloss lineup fresh and flowing.

Rush-Order Metallization on 30ml Aluminum Tubes

When it comes to last-minute upscale orders, metallizing those shiny 30ml aluminum tubes can be a bottleneck—or an opportunity. Here’s how current lead times stack up based on finish types:

| Finish Type | Avg Turnaround (Days) | MOQ | Gloss Level (%) |

|---|---|---|---|

| Vacuum Metallized | 7 | 10,000 units | High |

| Spray Coated Chrome | 10 | 10,000 units | Medium |

| Anodized Tint | 12 | No minimum | Low |

| Hybrid Matte/Gloss Combo | 9 | Custom only | Variable |

By understanding what surface finishing process fits both your look and deadline, you can confidently rush-order premium-looking cosmetic tubes without breaking stride—or budget.

FAQs

The choice of material says a lot about your brand—and your values. If you’re aiming for something light, cost-effective, and recyclable, PET plastic is a smart pick. It holds up well in transit and plays nice with most gloss formulas. But if you’re chasing that sleek, premium feel, aluminum brings strength with style—plus it shields contents from light and air like a pro. Glass? Gorgeous on shelves but fragile in bags. Choose based on how you want people to experience your product: practical or luxurious.

- Screw caps: Best when you need secure closure—especially handy for thicker glosses that won’t spill easily.- Flip tops: Great for quick touch-ups; users love the one-hand convenience.- Pump dispensers: Ideal when precision matters (think thinner textures or skincare-infused formulas).

Each has its moment—it just depends on what kind of story your packaging should tell.

Not always—and that’s where things get tricky. A 10ml acrylic sample might look flawless solo… but once scaled to thousands using different machines or materials (like PET), tiny inconsistencies can creep in—slightly off-center logos here, uneven fill lines there. Samples are great previews—but treat them as prototypes rather than promises.

You’ve got options—but some finishes speak louder than others:

- Hot stamping delivers metallic accents that scream luxury.

- Silk screening adds bold colors with staying power across plastics like PET.

- Offset printing shines when detail matters most—perfect for intricate designs on aluminum.

It’s not just aesthetics—it’s emotion at first glance. The right finish makes someone stop mid-scroll… and click “Add to Cart.”